-

Posts

1,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

A bit of a departure, but I was at an IPMS show in Sanford ME this spring, and decided to build a model to enter next year. Not anything too complex, like Cutty Sark of Constitution. This kit seemed perfect, and with just a little kit-bashing should produce a good model.

-

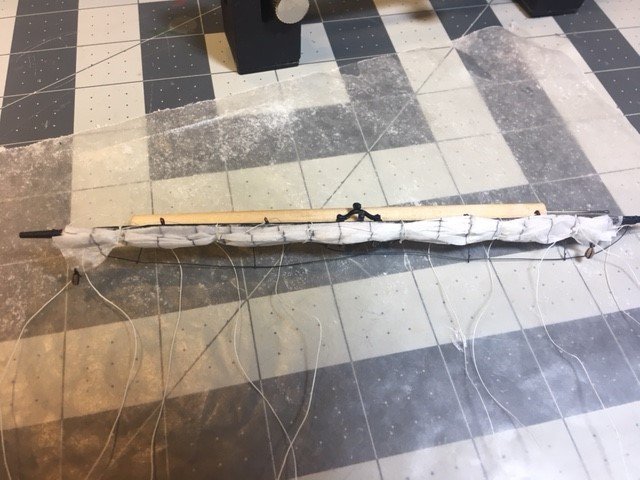

Mounted the yard this weekend. roughly placed all 10 sail lines and attached the chain sling, complete with leather chafing guard.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

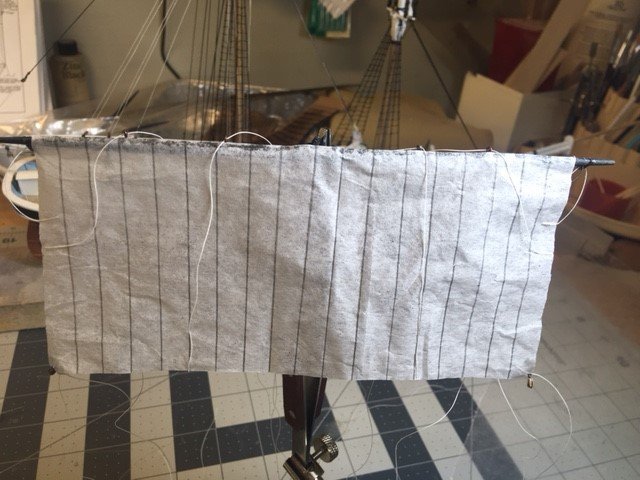

Furling the sail to my satisfaction took about 1/2 hour. I'm happy with the way it looks. Now to do 4 more, then the jibs.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

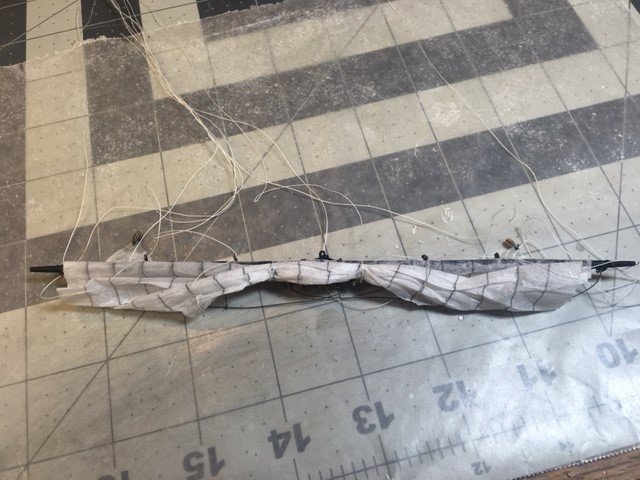

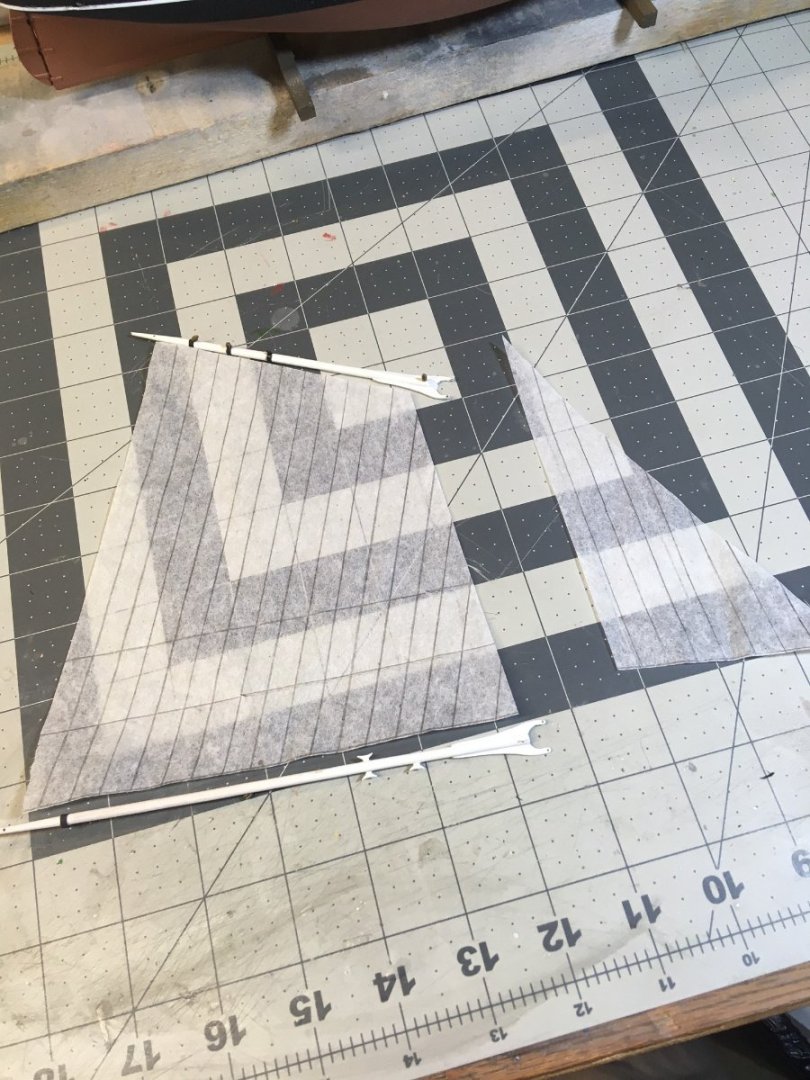

Getting ready to furl the sail. You can see the leech and bunt lines going up through the bullseyes on the top of the yard. Hard to see, but the reef line goes through a block at the end of the yard.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

All the lines and blocks attached. now it is time to glue the sail to the yard. I'm using Aleen's Tacky glue, which is like Elmer's on steroids. I lay a thin bead at the top of the sail. Next I place it on the yard, which is held up with an alligator clip stand (3rd hand) At this scale, jackstays would be parctically invisible.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Did some work on the main fore course this weekend. Attached the leech, bunt, and reef lines. Then I will need to turn it over to do the clew and tack lines. Then need to attach the sheet blocks to the corners (reinforced with a bit of CA)

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Next NRG Conference

MrBlueJacket replied to YankeeClipper's topic in NAUTICAL RESEARCH GUILD - News & Information

In the Northeast we hold an annual joint clubs meeting at the same place and time every year, and it draws 100 modelers. Always the last Saturday in April, at the Port & Starboard convention center in New London CT. Here is a video of this year's conference: So the idea of a rotating but repeat location is very attractive. -

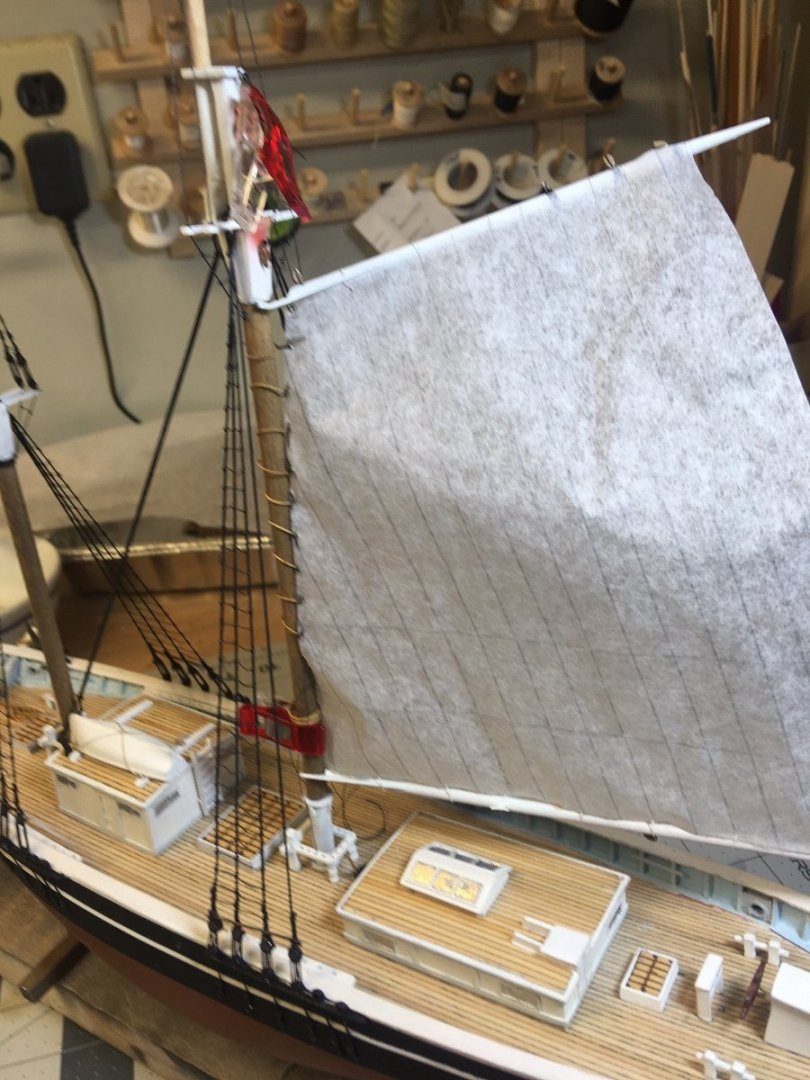

With that sail in place, I can now install all the main stays. The lower one, installed earlier, is .025" thread, doubled. The next one up is .020 and above that, .015 and the last two are .010 line.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Over the weekend, furled the sail, added the topping lift, throat and peak halyards, and a few other things.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Finished the mast hoops and strung the parrel beads to the boom and gaff. These tiny beads came from a craft store (many years ago - I don't remember which one)

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Nice to see you stepping up to the task!

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

If the parts are clean, no need to prime them. And for "considering not priming...." I call that inspired laziness, I do it all the time. Nic

- 48 replies

-

- Bowdoin

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Just a guess, but I've seen numerous examples of lines going to blocks on the deck, then up to a belaying point. I think it is because you can pull up with more force than you can pull down, being limited by your weight.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

We already have the USS Perry, similar in size and complexity. https://www.bluejacketinc.com/shop/model-ships/kits-model-ships/naval-vessels/uss-perry/

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.