-

Posts

1,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

And a long one at that. BlueJacket alone has over 80 current kits, and 100's more from the past.

-

I think you've said that before....... Nic

- 23 replies

-

- Yankee Hero

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Painted the inside of the cabins flat red, per the instructions. Next step is to paint the outside dark brown.

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

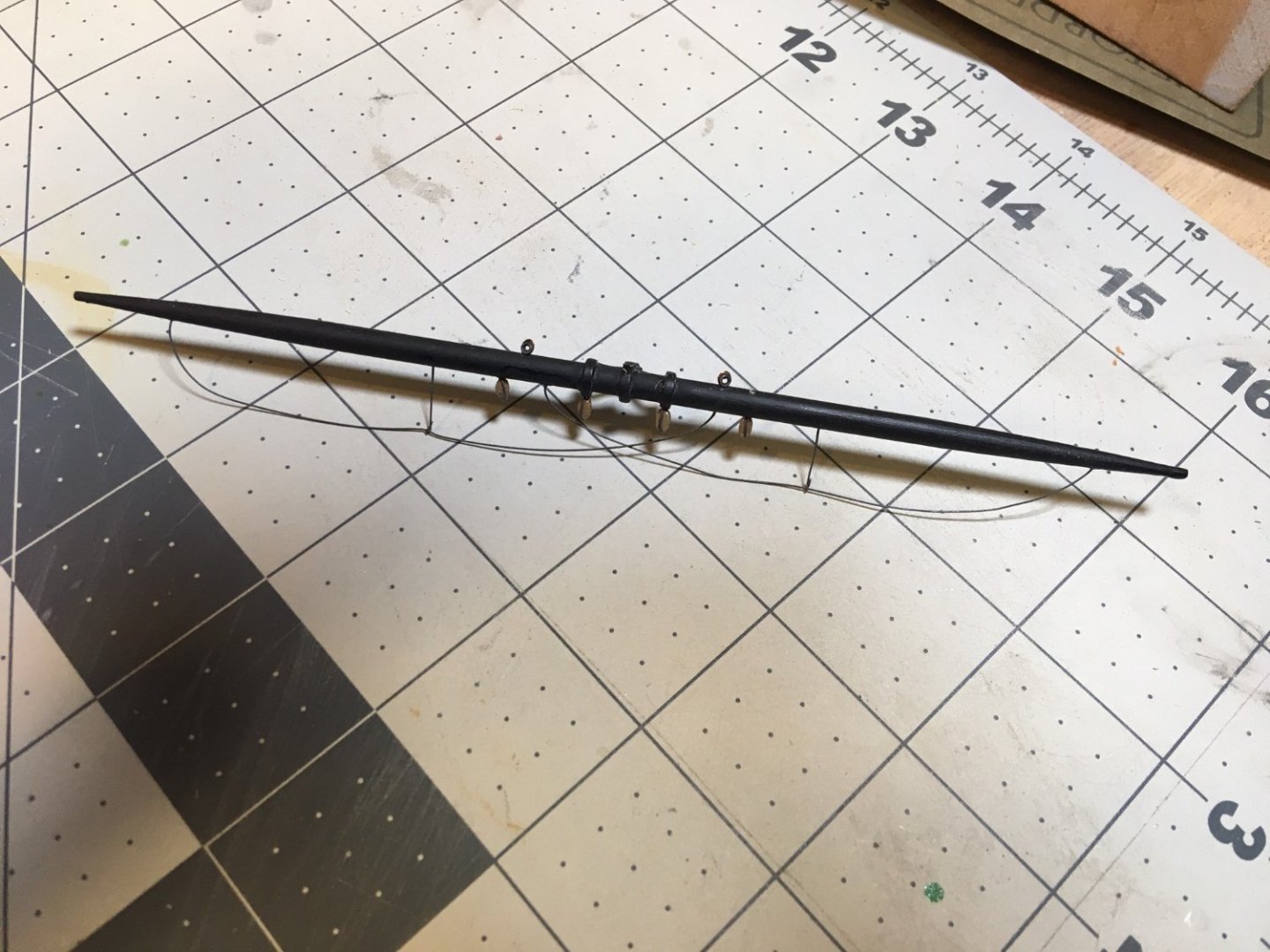

Yes, I make them out of .010 annealed wire. Nic

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

The pintle has a pin, the gudgeon has a hole.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Over the weekend, painted and installed the grating. I like the way it looks, I painted under it with black.

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Here's my first attempt. Our gratings are rectangular, so I cut off the edging, squared it, and added new edges. Not happy with my joinery work, so I will re-do tonight. Like the noted modeler Steve Wheeler said, "The wastebasket is your best tool."

-

Shaped the wooden deck and traced the attachment points. Not sure if I will cut the grating off the plastic deck or use the laser cut gratings we sell. Opinions?

-

Next step is to insert wooden blocks because I will be using pedestals, not the plastic cradle tht came with the kit. First step is to rough up where the blocks will be with some 60 grit sandpaper. Then some 5-minute epoxy to hold the blocks, which were tapered to fit the curve of the bottom.

-

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Nice job! Your customer file now shows you will get a 10% discount on the next kit you buy from us. I can suggest the Smuggler, Charles P. Notman, Atlantic, Fannie Gorham, Bowdoin, or Alfred to name a few.....

- 50 replies

-

- Perry

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

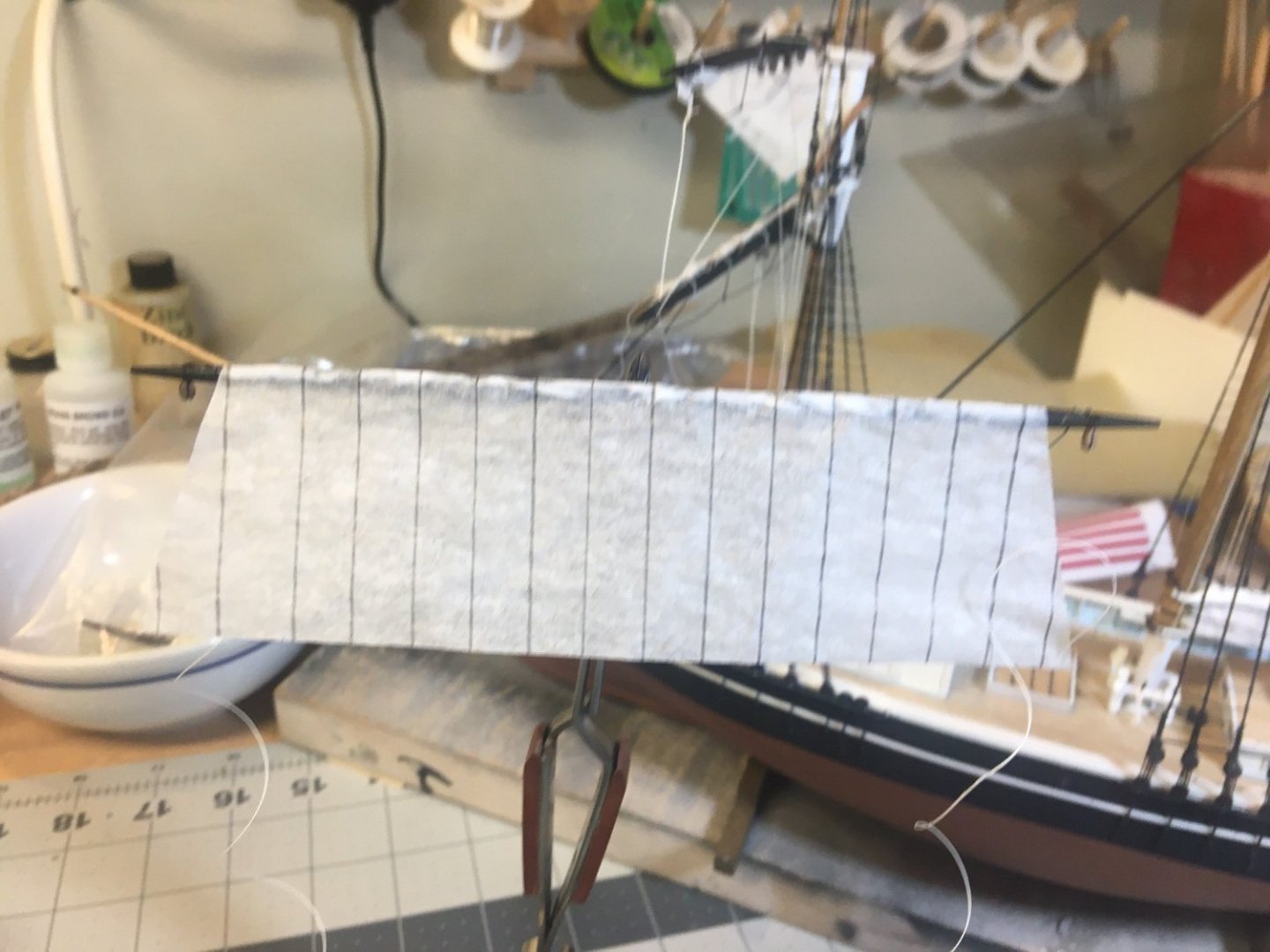

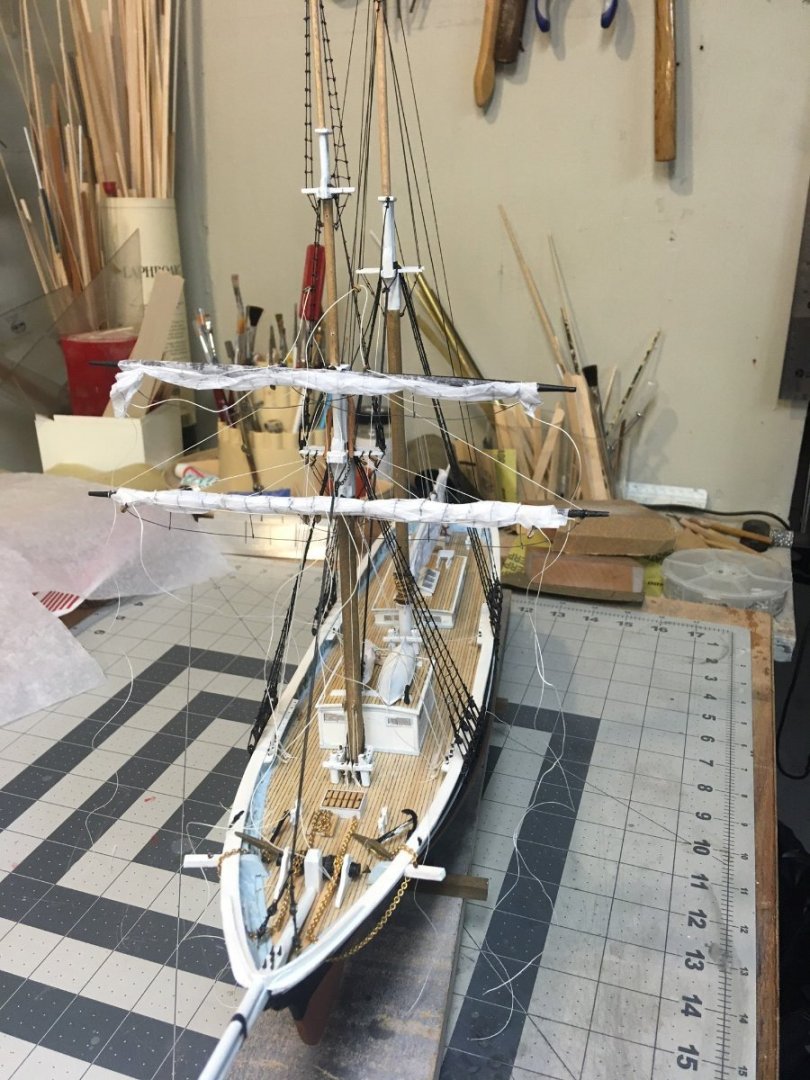

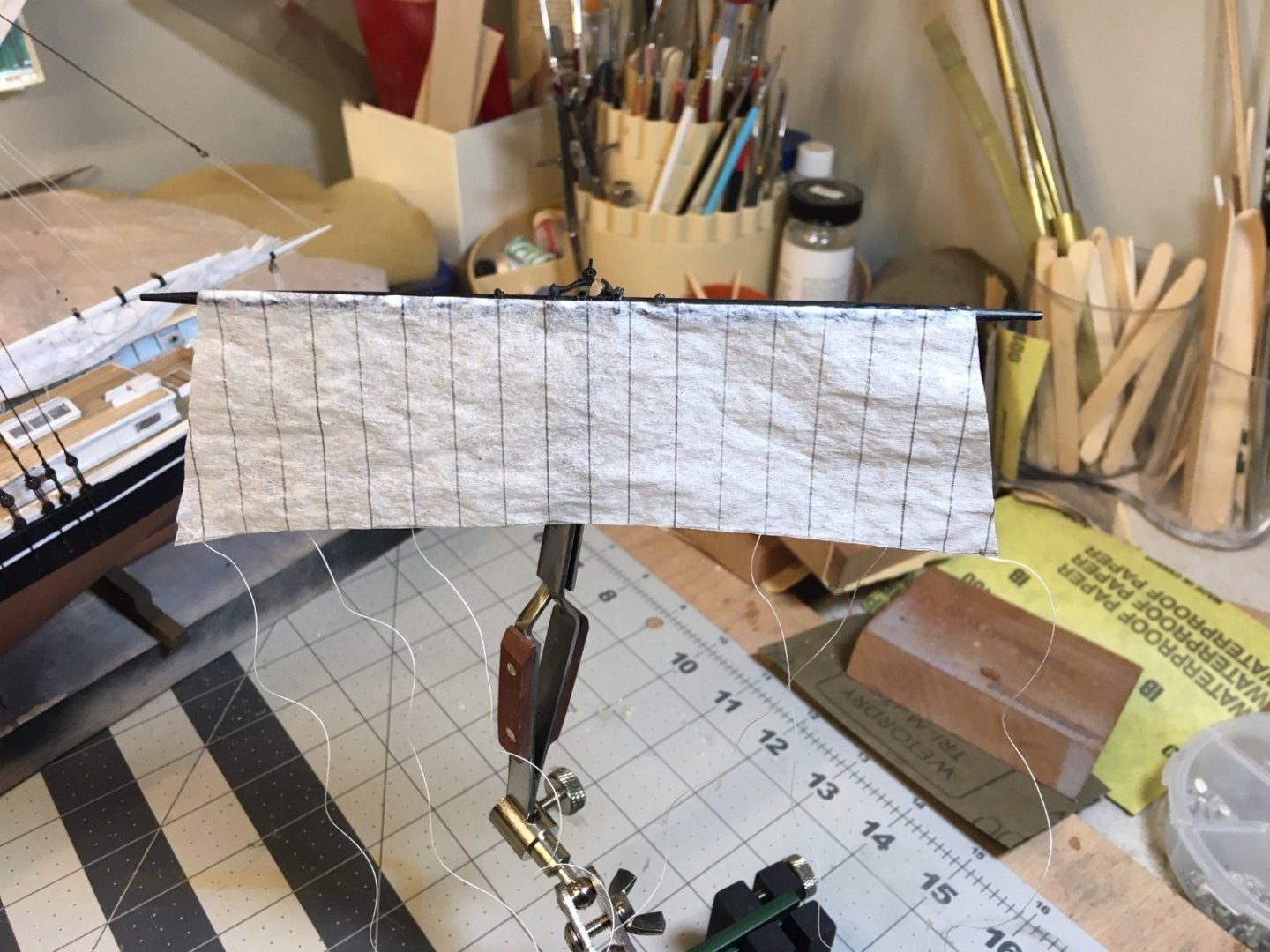

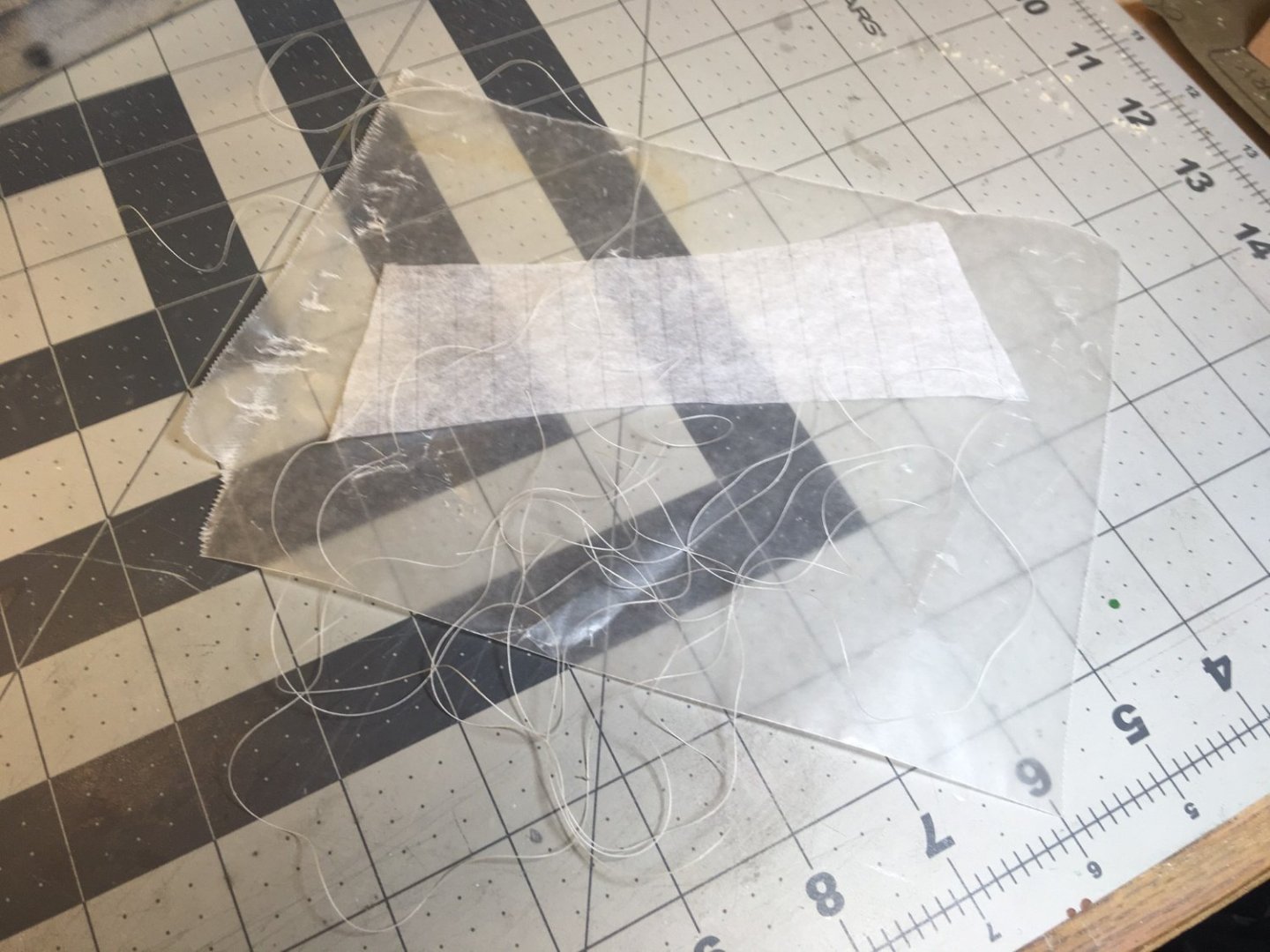

Then attach all the rest of the sail lines, except for the tack line, which would interfere with other stuff. The tack lines will get attached when doing the braces.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Next step is to attach the lifts. They start of course at the yardarm, go through a block in the cap, and terminate to a single becket block.There were two difficult steps which took about 2 hrs. One, getting a line through the little blocks under the fife rail. (see post#22) Second was to align the lifts so the yard would be perpendicular to the mast.

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

First, the vacuformed sails will be discarded. also, the plastic decking will be replace with wood. I took some glued-up decking, and painted it wood, then wiped it off with thinner. SInce the main deck was a little wider than the wood, I had to butt splice 2 sheets together. A scrap strip of 1/32 basswood added strength to the joint. When flipped over, you can't see the joinery.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.