RMC

Members-

Posts

933 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RMC

-

Hi Jdieck Thank you for the link and for taking the time to reply. However I don't quite follow your point regarding the walnut. It is 3mm thick sheet on which are various laser cut parts, and is not really suitable for planking.

-

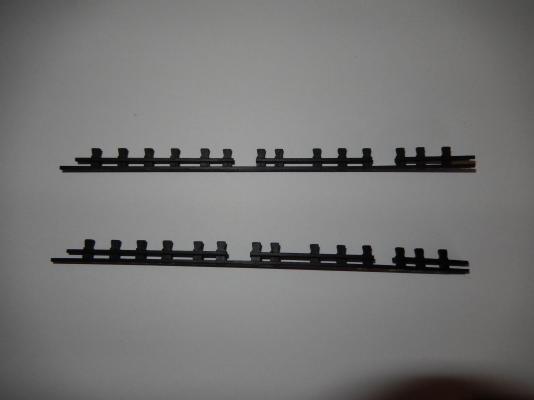

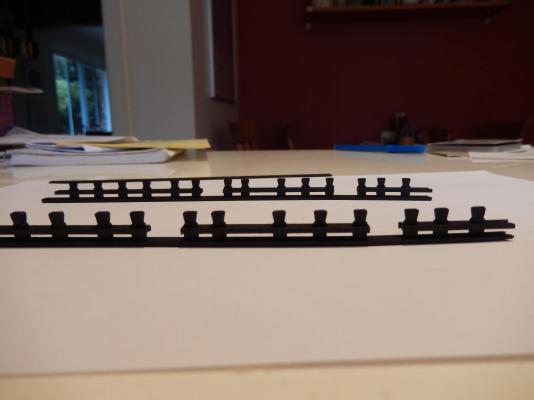

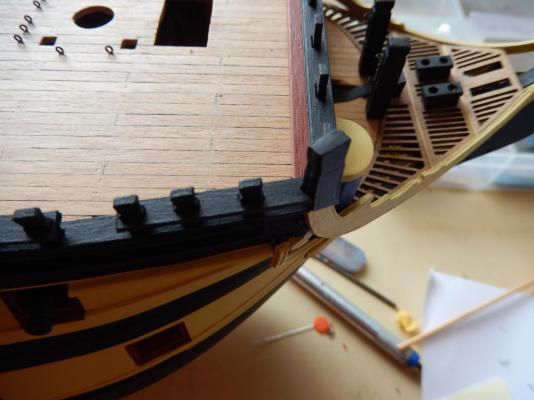

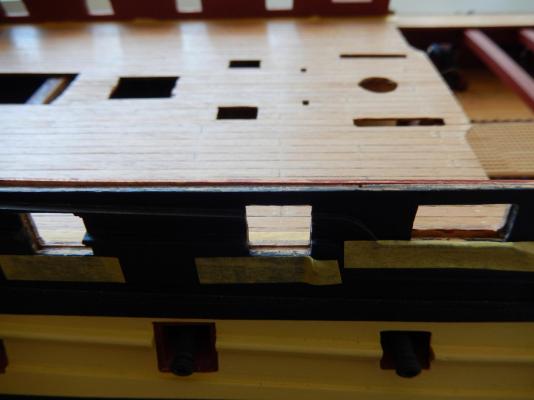

While trying to avoid doing any more rigging of guns, I have come upon a rather perplexing mystery. In the kit parts list there are specified 16 part 189 Deck Timberheads. There are in the kit, a total of 33 part 189 on two pieces of 3mm walnut. Looking at the plans I cannot for the life of me, find the need for more than the 6 required on the poop deck, and perhaps another 4 in the first opening on upper deck near the gunports. Thirty-three certainly seems to be rather excessive - at that rate they should be popping up all over the place. Can anyone help?

-

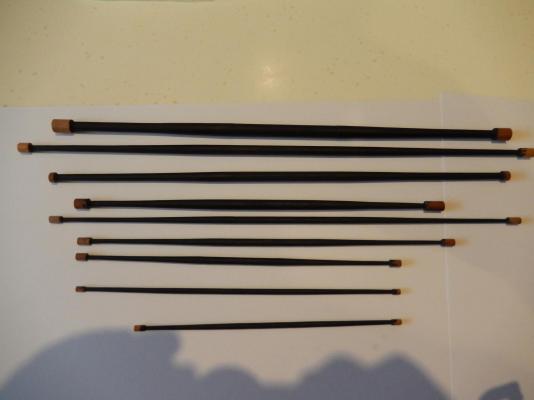

Here are some photos of the foredeck with guns rigged. I opted for partial rigging - though a bit more than the basic provided by the kit, rather than going the whole hog. At scale 1:72 I thought fully rigging them would have looked a little out of scale. Now I know what a fiddly job it is I'm not sorry. Getting the rope to be perfectly coiled proved just too difficult. The thread provided went everywhere, but where I wanted it to go. (If anyone can show me how to do it I'd be grateful (for future reference). I see from the pictures on the kit box it's obviously possible.) I ended up settling for something 'neatish'. Given my wars with the kit's thread, I have now ordered complete replacement from Syren model ropes. I shall report on my experience. These are the various rasps/files/emery boards I used to taper the yards. The fine ones are especially needed to taper down to 1mm.

-

Hi Arthur I'm not really ahead at all. I now spend a few days each fortnight away from home and am loathe to take small bits and pieces to work on while I am away. The hull is no longer easily transportable, so while away work on the things that are difficult to lose - the masts and yards. I still have a lot to do on the poop deck, the gun doors ..... I am now rigging the guns on the upper deck which is driving me crazy. I will try to post photos of progress such as it is tomorrow if I get the chance. Putting the garden back to some semblance of respectability may take precedence however. Doing the very small yards I found quite demanding. Rather than chisels, I used a fairly fine rasp and some nail emory (sp?) boards 'borrowed' from my wife) to file the yards down. It took quite a long time. There are two problems with the dowel supplied: it isn't round (as I earlier noted) and it isn't straight (which I forgot to note). My solution to those problems (described in my most recent post) worked quite well.

-

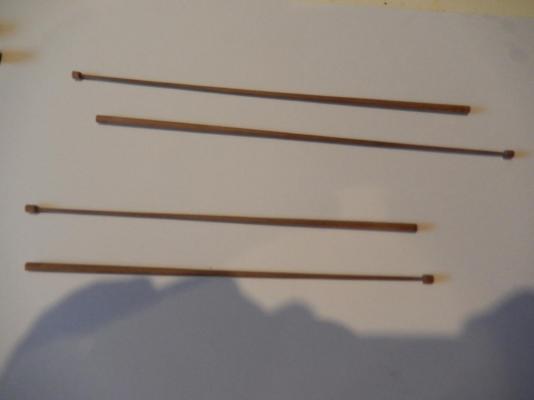

Hi Alan - this is a belated thank you for your kind thoughts. In the usual chaos before going away, I didn't get around to it. Well I did get the opportunity to work on the yards between eating and drinking far too much The little Proxxon lathe was invaluable in tapering them. Even so the job was very time consuming and the smaller yards I found to be quite difficult and in one case, easier to break. I found it best to taper in stages (see an earlier photo - I think on the previous page of this log). For example the fore topsail yard stunsail boom is 134mm. long tapering from 3mm to 1mm. From the plan, 57mm along the boom its diameter is 2mm. I then tapered that part of the boom from 3mm to very slightly more than 2mm (in fact 2.2mm). Next, a further 38mm along the boom the diameter is 1.5mm. I then tapered this part of the boom (again to a diameter very slightly greater than 1.5mm). I then blended the two lengths of taper. Then finally the taper from 1.5mm to 1mm was done. The reason for the slightly larger diameters and the 'blending' is that the dowel supplied is not perfectly round and it was impossible to accurately centre the spindle of the lathe, so that the 'joins' of the tapers are slightly offset. The extra diameter of the tapers allows a bit of judicious sanding for a suitable adjustment to be made. Here are the tapered yards (except the fore and main yards) And with a coat of paint. Thes are the stunsail booms for the upper yards. Those for the fore and main yard are yet to be done. For those who may be interested, this is sunset on the summer soltice - the sun is as far south as it will go. The interesting part of the photo is the mountain to the right of the setting sun. It is called Pigeon House Mountain, named by Captain Cook on his voyage up the New South Wales coast in 1770 before he got to Botany Bay. How he could see a pigeon house in this is a bit of a mystery to me, though perhaps there is another resemblance.

-

To all, I hope you have a happy Christmas and a happy and healthy new year. My family and I are off to the beach on Sunday for the holidays where I may have a chance to do a little more work on the yards.

-

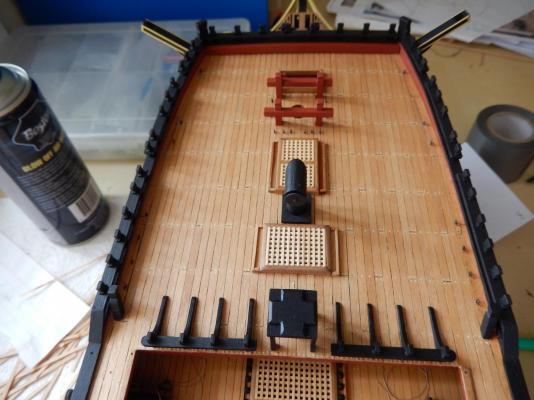

I have finally glued the fittings to the foredeck. The cannonballs have yet to be put in to their shot garlands, but that's about it. The middle rail has now been attached as well as the supports for the stanchions. I've assumed these to be 1x2mm strip. I can't see a measurement in the plans, so I've assumed it is the same thickness as the side railings. The quarter deck capping rails have also been glued. Finishing the curved part at the end of the capping was a bit of a problem. I eventually used some 5 x 0.5mm scrap, put it in a mug with some water and microwaved it for a couple of minutes. I then wrapped the softened strip around some old PVC pipe of about the right diameter and left it overnight. It turned out quite well. I also tidyed (sp?) up the vertical part under the front of the capping with the 5 x 0.5mm strip. The wheel etc. are only dry fitted.- just to see what they look like.

-

The forward and middle rails are now glued. Before doing so I have finally glued on the cat heads - something I have been delaying as long as possible. Sticking out as they do, is a sure invitation to disaster, to which I am quite prone. I found it is best to make the cuts in the forward railings (to provide for the guns) before they are glued to the model. Doing so makes them a bit more pliable, so that if you need to put a little more bend in the rail to fit, there is no great problem. Since the following photos were taken, some minor touching up has been done. . The bowsprrit is dry-fitted here - just to see what it will look like.

-

I have finally done something about the gap between the ship's railings on the fore and middle decks. It's not quite as I would like it. I think Arthur's nice rounded shape provided a better finish (the side decoration, not Arthur), but that's the way it worked out. This photo is a bit blurry but it shows how a piece of timber connects the top and bottom of the front railing. The plans here are rather sketchy. This shows the curved transition from the fore to the middle deck which has caused me some angst. The front railing dry-fitted The two railings both dry-fitted The railings are still to be finally painted, poly applied and a bit of touching up will need to be done before gluing everything together.

-

I seem to have lost some text. In the top photo the undyed material is on the bottom. In the second, the middle is the undyed piece. The lighter dyed piece had about 15 minutes in the tea; the darker, about 45 minutes. At this stage the slightly darker one is my choice. Comments welcome.

-

The last couple of weeks have been a bit hectic and not much progress on the model has been made. However I did finish turning the mizzen cross jack yard. It is derived from 8mm diamenter dowel, the cross-section of middle part is supposed to be a hexadecahedron (16 sided)(I hope my memory is accurate, even if my spelling is not). I thought (it turns out corrctly I think) to be rather a waste of effort. My method was to make an octagonal cross section and then to trim off the corners. It proved quite effective. However when viewed from a foot or two away, it wasn't reaaly possible to discern the difference between the 16 sided cross section and a circular cross section - and I'm quite short-sighted. Anyway it's done now. Some of the quite small diameter yards are also 16 sided cross-sections and I really don't think it's worth the effort. I may, however do the cross sections as octagons. Other than that I have experimented with tea-dying material for the hamock netting. The material I propose to use is blindingly white, and I would like to tone it down a bit. And just when you think you've seen some weather ....

-

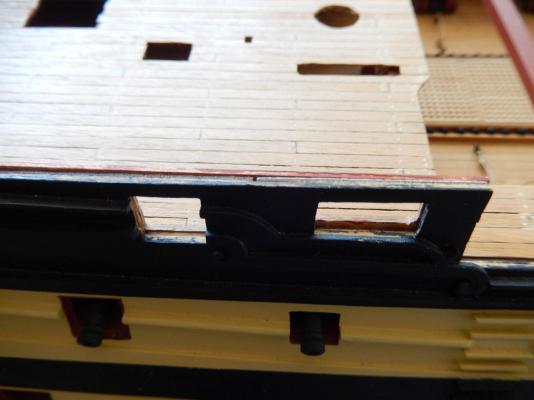

The side rails are causing a few self-inflicted problems. The head rail has been glued with far less drama than I expected. It is supposed to butt against the side rails. However I have fixed Part 96 in a way that makes that impossible. I have therefore shaped the forward part of the side rails to butt against part 96. As well I have cut the two gaps in the side rails to provide for the guns. Here are the notches cut to butt against part 96. The rails dry-fitted. The following photo shows a side rail butted against part 96. It is dry-fitted. I have cut a notch at the end of the mid-deck gunwale to enable fitting it in what appears to be in the correct position. I found the plan and instructions here far from clear. I am not sure at the moment how best to close the gap between the side rail and the gunwale.

-

Thanks for the info regarding part 88 Arthur. My problem with the corners stems from my positioning of part 96. I have sanded back the ends of the headrail 101 to receive 96. It gives better support to 96 but means I can't simply butt the side rails to the head rail as I have just now realised. I have found, I think, an acceptable solution, but have made things needlessly hard for myself. I will put up a couple of photos next week to illustrate the problem and my solution. I am just about to leave for a few days away and hope to make a bit more progress on the yards. Incidentally, thank to those for the 'likes' - they really do provide encouragement.

-

I have been working on the forward railings and the gunports on the upper deck. I have just realised that the rear end of the side railings require an angled piece of timber to join the upper and lower parts of the rails. As well there seems to be a curved bit of timber required that butts onto the end of the lower part of the railing that covers the curved decorative molding. I can't see a part like this listed, so I guess it needs to be fabricated. The forward railng is dry-fitted here and I'm not looking forward to gluing it over the curved timber to which it must be attached. It will be under a fair amount of stress. The side railings must then be fitted to the front railing and in doing this, the corners with the protruding decoration will be an intereresting exercise . The lower sills of the gunports required filling - I used Intergrain water-based woodfiller. (The Intergrain is far superior to others I have used.) The openings then need to be painted. As all the rest of the hull is already painted, each opening needs to be carefully masked. For this I used Humbrol Maskol again. It's effective but a bit fiddly to work with. So far I have only completed one side. Once both sides are painted, a couple of coats of polyurethane should finish the job. The next two photos show the gap between the exterior of the hull and the inside wall. Here, for the filling, the exterior was masked by Tamiya tape. The gaps filled. The gunport openings painted awaiting two coats of poly.

-

No Arthur, I haven't got as far as to spot the mistake. I'll have a look at it tomorrow. Thanks for the warning. I'll certainly try the varnish idea to finish off the yards before the final sanding. My plan is to do the yards while I'm away off and on over the next few weeks, and while at home, continue with the deck furniture, railings etc on the main deck. Most of it is now finished but not finally fitted. I hope to be working on the poop deck by Christmas. I have pretty well finished the masts. I have a couple of questions about the deck railings (there seems to be an omission in the plans), but I'll leave them for later if I haven't solved the problem beforehand.

-

Here is the beginning of the main yard. There was not as much progess over the weekend as I'd hoped. Doing the octagonal centre piece turned out to be not as difficult as I first thought and it turned out quite well. Having more suitable tools would have helped however in making the edges more defined. Once I had worked out the dimensions of each side of the octogon, I used Tamiya tape to delineate the edges, then used an Exacto knife to plane the surface flat. (The little plane I bought has proven to be the most useless tool in the box.) Once the octagonal section was done I used my Proxxon lathe to taper each end. The tapering was done in stages. For example I first measured 40 mm along the yard from the end of the octagonal section, referred to the plan to see the thickness of the yard at that point, and tapered the intervening distance appropriately. I then did to same for the next 40 mm ...... The following picture shows about 80mm tapered. Here is the (semi) finished yard tapered at both ends (the tapers turned out to be pretty well spot on to my pleasant surprise). The octagonal section does not show up well in the photo unfortunately

-

Thanks for the kind comment Arthur. No, the nails aren't glued. I was warned of the hammock crane problem from your log - I have appropriated much of your work I'm afraid. (The Cheque's in the mail). I still haven't decided how I will finally glue the top on the assembly (at the moment it's just dry-fitted). I would be grateful for your comments on the following. (Comments from others are welcome.) My wife bought some fine tulle which appears to be the same fabric as you have used for the hammock netting. Is that what you used? Fortunately, she has a wonderful machine for cutting material straight and cleanly. I will probably wash it (it is quite stiff) and dye some of it with a bit of tea to see how that goes. I hope to have the chance over the weekend to start on the yards. Some of the smaller yards have octagonal cross-sections; some even 16 facits (I don't know the word for a 16 sided cross-section). It seems to me that at 1:72 you would hardly notice. Did you bother? With some of the longer yards I am thinking of cutting them in half, turning the two ends and rejoining them. At 400mm+ and thin material to boot is at the extreme limit of my little Proxxon lathe. All the best.

-

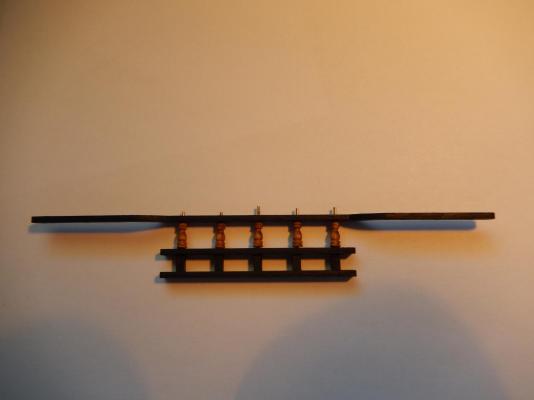

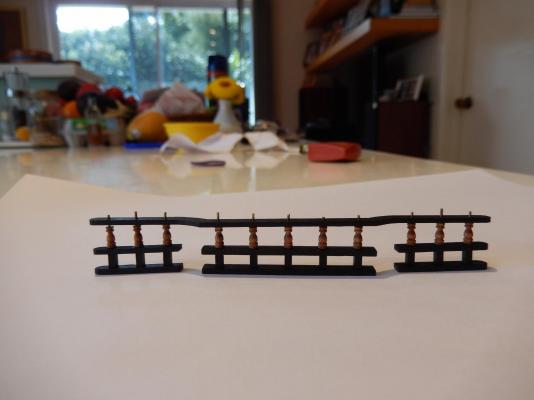

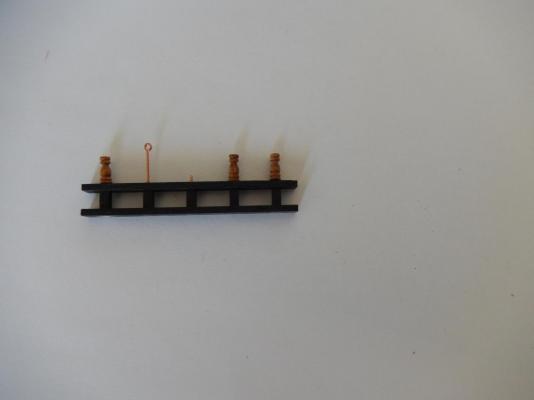

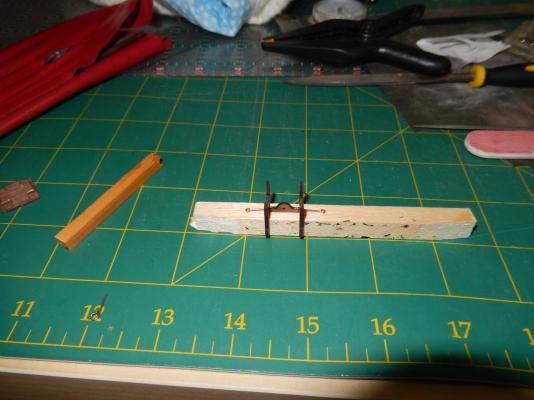

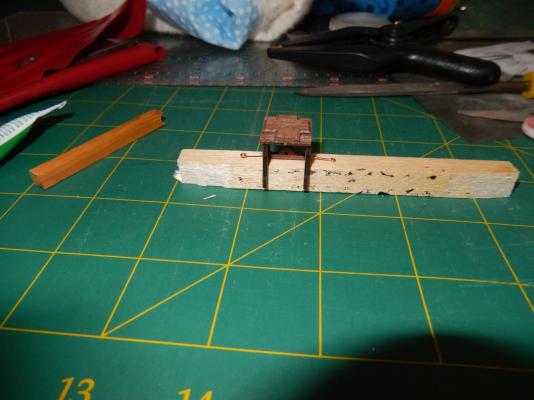

Thankfully the planking etc is finally finished. While taking a break from treenails I began the quarter deck barricade assembly. It proved, and is proving a very tricky little job. The columns are tiny - about 6mm high and about 1.5- 2mm in diameter. I used a pin vice to drill 0.6mm holes top and bottom of the columns and in the bottom part of the assemby to receive the columns. Brass 'rod' (from small eyelets) was inserted in the bottom assemby and the columns glued using 'slow' CA. Nails had been inserted in the tops of the columns to enable the columns to be properly aligned with the curved top-piece of the assembly. The screen has now been added and I have dry fitted the rear hatch, binacle and the mizzen mast, just to see how things look. The stairs and the hand ropes in the hatch have been done in the same way as earlier done. I gives a good result and is far less trouble than alternative methods.

-

I have just looked at my post and the last two photos seem to have come from nowhere and I haven't been able to get rid of them. Still, worse things can happen I guess ....

-

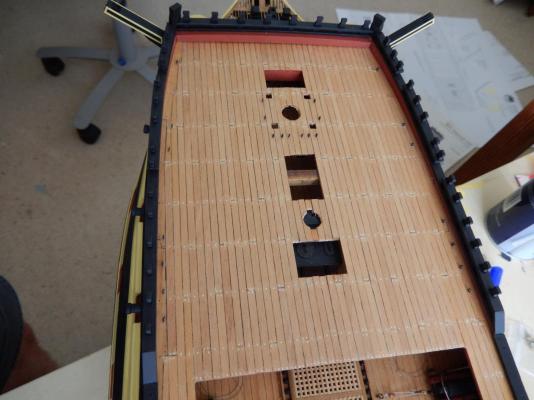

I couldn't find the post so I went ahead with pine water-based filler for the treenails. It is a bit too light and noticable unfortunately - but I'm certainly not doing it again. I hope that with all the other stuff that will eventually on the decks they won't really be all that obvious - which is a bit ironic. I have probably gotten a bit carried away with the number of photos here, but I am still experimenting with the new camera. The first two photos show the the holes for the treenails before filling. The following photo shows the holes filled before a coat of polyurethane. The deck with one coat of poly. Another coat has since been applied. I have not bothered too much about the deck planking that will be behind the screen towards the stern. It should hardly be noticed through the gun ports. While taking a break from drilling/filling holes I began making the belfry. It proved to be a bit tricky to get everything square. I eventually used a piece of scrap balsa to mount the sides and the cross-piece. Nails are supposed to provide support for the cross-piece, but they proved to be far too big for a very small piece of 1.5mm ply. I ended up using a couple of small brass eyelets. It has yet to be painted and coated with poly. In doing the treenails I found dust getting in to all sorts of comparatively inaccessible places. If anyone has some recommendations regarding small vacuum cleaners I'd be grateful.

-

Aaahh. Oddly enough I have just been experimenting with some Wattyl pine I have had lurking with intent. I have also mixed it with a bit of walnut filler which still produced too dark a result - as well it would have been difficult to make mixes of consistent colour. Then again I didn't realise that the treenails were supposed to be quite unobtrusive until I looked up 'treenails' in the planking forum (which I should have done in the first place) so I'll go with the straight pine which is just noticeable. It seems a pity to go to the effort of drilling all those wretched holes for them not be noticed at all.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.