-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

Julian I recently started a scratch build of Bluenose in large 1/24 scale. I am not totally sure how far i will get toward sailing her, but I am building her so she could sail. I have really enjoyed finding and learned much from reading you log. There are many folks like me that have so much to learn we really appreciate it. It's a wonderful build and thank you for sharing. I may be coming back to you with questions as I get into detail cheers jon

-

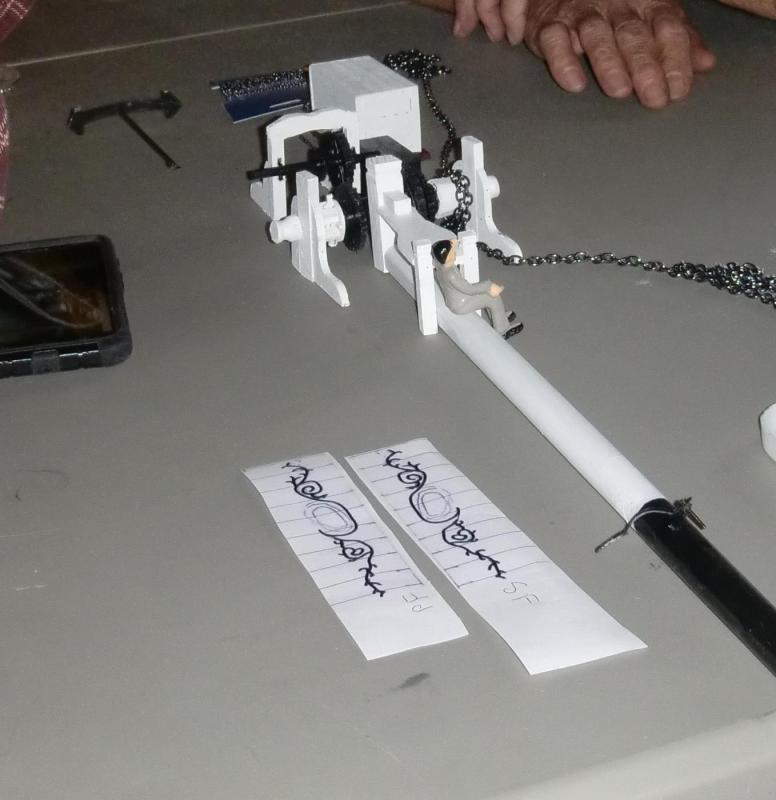

I had a chance to get in front of some good builders at the Monthly Guild meeting we hold at Maine Maritime Museum every month. Of course lunch is part of the deal. I took several parts and components and described what I was doing and asked a few questions. Here I l have assembled the main equipment and my tracings of the scroll work at the bow, a few chains a toy anchor etc. here we are looking aft and I asked more about the difference in the two sides of the windless and the fact the photos show the chain on the smooth barrel. Most discussion was all about chain. We talked about sizes and treatment of the typical jewelry chain we all start with. How to make it look real. Also how to make large realistic anchors without casting anything. This is still going to be a challenge. As this phot shows the chain is on the smooth barrel. most we OK with that but uI still need to look firther to find an explanation of the two different side barrels .Back home in the shop I continued working making more pieces. Here is a fun piece. I nested brass square sections, so the ends would be open squares ready to receive the handles. As per photos these handles should be stored loose and not left in place. here the two break "shoes" are lying on,the plywood. They will hang from the brass bracket now in place. here I have progressed and aligned the first three pieces. I noticed the rope winch is sitting backwards in this photo. Here I have set the forward winch on thickened deck beams painted to match. The exception is the black steel drive assemble on white as clearly show in the archive. here I have the chain box and the mast boom supports. At this larger scale I need to add in the edge trim, so I soaked some 1/32" plywood and then clamped it in place to dry to shape. The Laun box is the typical approach I take to size out the ID of deck houses hatched etc and then use that to build the planking sides. In this case i have to remove it because the chain box is empty More to make and progress. The main rope winch legs are clearly black in the survey photos ...and mistake one or really mistake 659. I wanted the thickened deck planks to line up with the deck and the spacing was off, so the top white cross member was shortened about 1/8" remember this goof for a future posting So let's take a look of how it's coming You can see here I am building up the forward hatch, all for now cheers

-

Dave I love the lettering. I will be struggling with that pretty soon. the rudder looks great. hope it fits next time. My rudders have to work, so the whole thing is different. it is while before I will do that on Bluenose. I will have a brass rod passing up through the hull with a arm attached for the steering cables. My hardware is only for show and does not actually connect rudder to hull. cheers

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Hamilton I have yet to build many boats but I can assure you I make many parts over again. They don't all make the log though.... Today I took of the forward hatch roof off because it was just wrong. good luck with making your fix cheers

-

Patrick and Bob You are both as always too kind. I have learned so much from yours and other logs. I agree that this boat is just too big. I have no idea where I will store or show it. I asked for the living room since like many folks we never sit in there any more, but was shot down. Today I completed the main boom.....wow it is like making a table leg.....40 inches long. I shall post it next week time to close up for now cheers

-

Thanks guys for the comments... Here is another batch as we are still catching up with the posts. I am not too far ahead any more and soon will be posting in real time. Today we will see progress on the hull decoration. From time to time we need to clean up and touch up the hull. This presents a problem that I have because I need a painting process that I can do in the shop or in the field so to speak. That means water based acrylics from the local hardware store. You can see in details [ and it frustrates me] that the application of bondo putty and sanded to 600 grit finish actually gets worse with added coats of paint. Case in point to follow here below. for the outside decorations, first we must decide what we are trying to replicate and then find a way. lets talk first about the cove. Here again an image from the Nova Scotia archive. The cove looks like an applied piece with two Ogee curves ....raised "lips ...all painted light [i assume yellow. Another NS Archive photo...here on the stern, if you zoom way on there is no such detail. the lower edge of the thicker plank is obviously black. I came to the conclusion that the two "lips or one lip and plank would have been black and only the inside would have yellow. all the practicums etc describe the piece as a cove so unlike Charles Notman larger schooner I can't simply paint a piece and glue it on. My scale is large and it is very difficult to paint. Just to continue the research, here is one shot from Bluenose ll that agrees with my conclusion of the aft detail on the bluenose. This photo is the justification I am using for my current solution. this detail however disagrees and shows the two lips to be yellow...what to do. I could take a 3/16" by 1/16" strip and pull it or file it to try to put and extrude mill work. I suspect the small size and soft grain would be a problem. Styrene my work but I have yet to ever use it. here I tried process of placing a yellow racing stripe and then putting black tape over it. I did not like this at all. Plus as alluded to above I hated the paint that comes through in the photo more clearly than to the eye. I took both sides after this photo and sanded, re puttied, sanded and painted again. here after refinishing the outside hull again I chose to follow the Bodbar practicum. I have installed the yellow racing strip and it is crisp and looks ok. If I every find a material to make the millwork cove however I may try to redo this. The "filigree" or whatever it's called is another interesting thing. The Eisnor plan was traced scanned and scaled and that is what I have taped to the hull. Interestingly, the pattern on Bluenose ll is smaller. In the first photo of this posting above when one zooms way in , it is clear this was carved and not applied. I plan to first try to pin prick the pattern and use sharpie yellow pen to create. If this does not work I was told to go to Joann and find ear ring filigree that matched as closely as possible, spray it yellow and glue it on. I prefer not to apply something here because it will literally stick out like yellow filigree. here is a view that shows the side including the chain plates and the cove stripe. I used brass strips and pins. here is a shot across the deck to pick up the chain plates ready for stropped dead eyes I though I would show you now the pop out deck for the rudder access. This will be covered up some by the steering box. Here it is open.

-

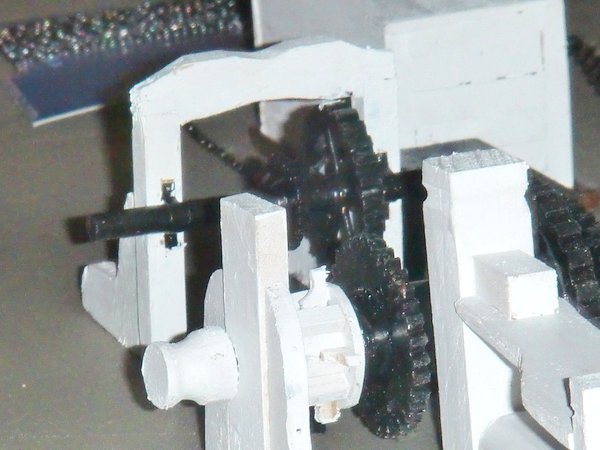

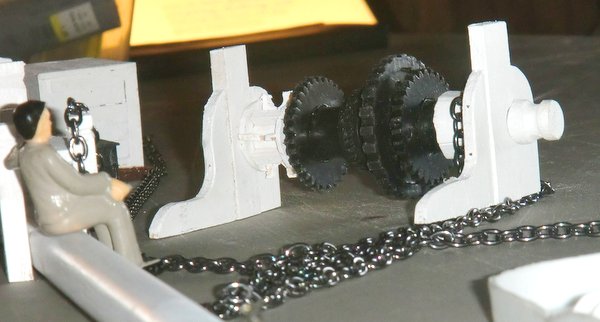

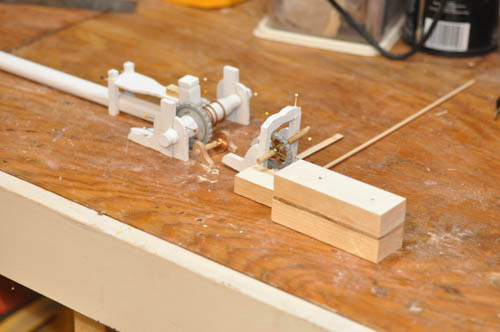

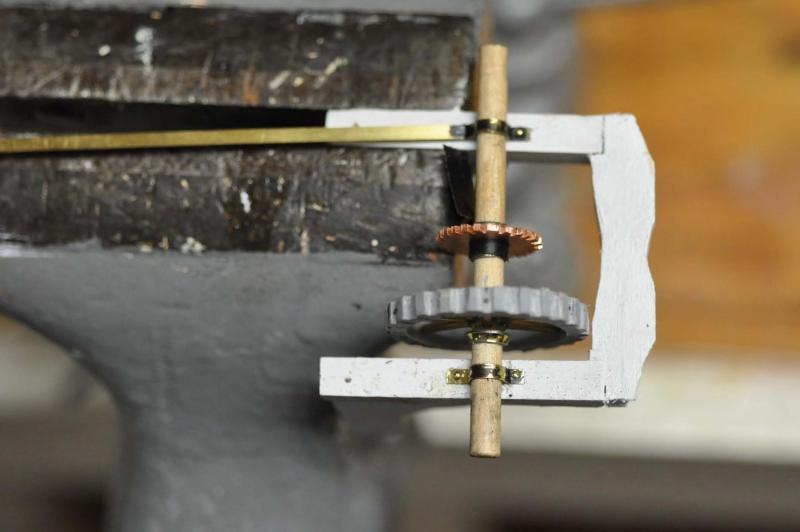

For this next installment of deck equipment, I want to divert to the issue I had with the deck color. Like most folks these are parallel efforts, so we shall continue the story that way. Sort of multitasking I think I have figured out my approach to the equipment, so lets start to put it together and see what we need to do. Here we see the block forms I made for the engine box and tool box and unpainted gears. here is my first attempt with the intermediate drive gear. I quickly learned I needed to replicate the steel frame and reduce the shaft size as it will attach to the tool box. this large 1/8" wood dowel shaft is convenient for the ID of the gears but wrong. here I am starting to build up cabin and hatches. [ too much deck shine} Lets put the windless on deck and think about sequencing.[ too much deck shine] I love this view. You can see I am playing with the fuel tanks aft of the main mast that showed up in the 1940 survey photos while working on the forward hatch, I realized I had made the skylight too big. I changed out the luan building block and needed new decking. here it is just basswood [ blond]. here you can see the cherry stain that gets the warm look we need. here you can see [ despite the flash] the affect of aging the walnut stain provides. Also note this is a matte stain only finish. I put on just the satin and it looked different. so to match it in I had to build up three coats of spar again then satin. It looked like the rest but TOO MUCH SHINE!!! Here I bit the bullet and really sanded everything. The risk and result is I hit high points exposing the light wood and needed to tone that down. here it is all sanded and ready to come back here I had added a satin old maple Minwax poly shade to grab the blond areas and bring all more together. My logic was I thought to use two step stain now with so much varnish still on the just sanded deck would be a waste of time. I need a thicker finish for outside use than a static model and to get on with things this coat should help. I thought it worked out ok. here we are with another 2 coats of satin poly. It still shines but is better than befgore and I need to move on back to the fittings and hull here you can see the combined copper rings and nylon cut gear getting painted out to be the main windless break. alright ...I did it ...two rings for the the aft hawse; hammered copper joined and soldered before installing. all for now cheers

-

Here is round one of making deck equipment. Also the saga of the deck color continues. Let's see how far we get in this posting. I started off thinking that the main element of the windless is the large wooden center section. I figured if I got that going I could take each component one at a time and get going. So here we go. I grabbed a scrap dowel and started using files and things to make a practice winch. I took it to our guild meeting in mid September to ask the guys what they thought. One guy said I should be turning our gears on a metal lathe....oh I have no skill there. another said you can never get the teeth right if you cut them by hand.....oh I can cut soft things by hand. they then repeated a long time lecture about my needed to work more and learn to solder because without soldering I will never succeed making these parts.....oh well let's see...after i came home I figured the turning was OK so I am using it. the taper on the left side was going in the wrong direction so i had to cut it off and build up again...practice helps... I put the winch aboard just to get more of an idea what I was after. I was still struggling with the deck at this point because of its high gloss. Since I want to be able to sail this model I needed to build up 4-5 layers of spar varnish over the thin 1/32" deck. I had some good spar varnish that I used and I thought I could just lightly sand it and add a coat of satin finish to flatten it out.....It didn't work. more on that later. I had a Eureka moment while sifting through drawers at the hardware store. I am used to getting copper, brass or aluminum washers or other material when I made winches and things for the Boothbay Harbor One Design build last year. I picked up two gray conduit elbows that gave me the right diameter for the large gears and some copper washers that are easy to work with for the small chain drives. On another trip I found the nylon..... One of the guys had suggested I use the lathe to set radial measurements for the gears. I took the bowl chuck,put a small piece of plywood on it and then turned to the 24 points marking it all around. I then set the chuck on the work bench and started using it to mark the sliced conduit for the large gears. Here I simply cut with razor saw sliced with x-acto and filed to get the teeth. I ended up using conduit, copper and nylon washers and spacers. here I did the same process with smaller copper washersto get the chain drives....two sizes. you can see on the left side just cut lines and on the right side i had files to get the shape. here is the first attempt to put things together. Now I need the large break that sits aft of the Samson Post. I found nylon washers and spacers and they solved my missing problems and sizes. The copper rings are left over from Charles Notman [mast hoops where chose light copper for strength.] were perfect to make the side rails for the break here are some large gears in the mean time I was fooling around setting things aboard and playing with the color and shine. I have since added chain plates and repainted the hull as well. more coming cheers

-

Jeff and Hamilton Thanks for your comments. Jeff thanks also for getting me to Gene Bodnar work; I have his practicum pdf. I studied it a few years back and agree he is terrific and their model links are great too. They are available through their website....modelshipbuilderdotcom. FYI they say it is Philip Eisnor...and show him and his work as well as offer plans for sale. Someday I plan to start slowly and to learn how to do plank on frame. When I am able to do I, It hope to build some schooners like Bluenose and follow Genes guidance. I am not ready to do that yet. also it will not be a 1/2 " to a foot scale!!! I am doing some repairs today and getting ready to attach the first equipment...i will post it later and Jeff my approach is amateurish but the metal work is not difficult. cheers .

-

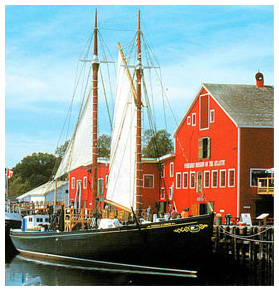

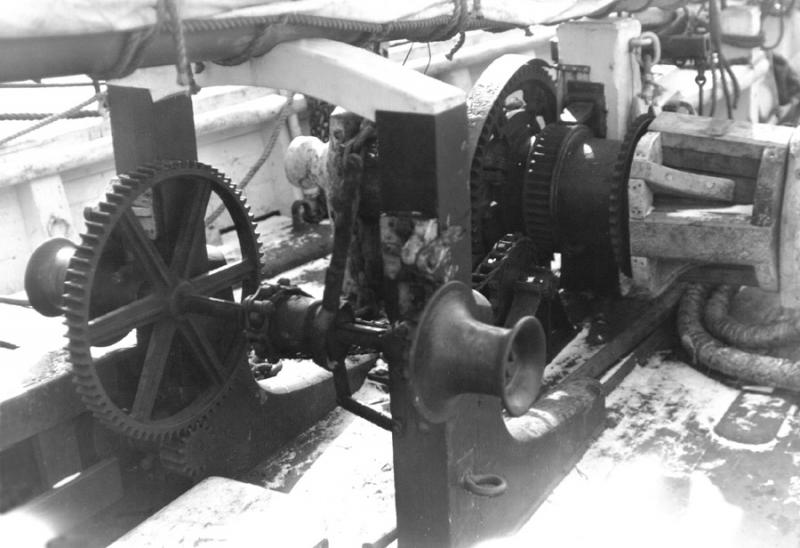

I thought it to be good to share some visuals from my research. They explain some of the decisions I have made as I move forward to build out the deck equipment. The research started with a trip to the Fisherman's Museum of the Atlantic in Lunenburg, Nova Scotia a few years ago. My vocabulary is probably off on several of the following items. It would be fun to learn of some sources where I could learn more about this equipment, its proper nomenclature and operations. One key feature is shown here in their website image and description of the schooner Theresa E Connor. She was built in the same ship yard as Bluenose in 1938. She is smaller, but I trust many features are very similar. The following 6 views I took while on board. They focus on the anchor and running line winches on the fore deck and I used these to figure out what I needed to build. here we are looking aft at the pivot style break levers for the anchors. here we walk a bit aft and see the running line winch and the chain drive that goes to the anchor winch. as we turn around we see a few things. First the engine box is just that...a box. The drive chain comes out the side inboard and runs forward with a guard board above and one on the side shown later on Bluenose. The drive wheel axle for the winch is housed on a bracket off the engine box. [ this is a smaller rig than Bluenose]. Also see the posts simply sit on the deck planking. The vertical clutch arm engages the chain drive going forward. I believe but did not see if the spools are un-engaged while transferring to the anchor winch. I fear not! Here the full anchor rig is visible including details of the "wild cat" [i have been told]. Dumb me thought that chain goes to the 'wild cat' [ starboard side with palls etc. to control the chain] and the rope [for deeper anchoring] goes on the smooth barrel to port. Hold that thought for a moment..I was obviously wrong. I show this hatch because it has doors. Doors are simple and much more practical for a fishing voyage. The Philip Eisnor plan show planks. I suggest planks are OK for occasional racing, but I think I vote for doors on Bluenose. I would love to hear other's comments. In this view we see the smooth barrel and notice no larger planks under the winch posts and rails. Small added planks are under the steel drive assembly. I am concerned about load transferred from the anchor into deck planking....see below Here I borrow cut and cropped images from photos on line with the Nova Scotia Archives. Their image number is in the link Here one can see a few things that I am using for my interpretation of the older fishing schooner... Through the snow you can see the waterways are dark...the same tone as the planking..but lighter than black. through the snow you see a thick plank under the anchor winch supports. I have added those to my boat and painted them white... I may change them to brown. Note the anchor chain goes directly from hawse to smooth barrel then lays on deck back toward the chain box. Chain box only on port side. I have something to learn here. Here are a few more items for consideration: In this cut image one can see the black tool box that sits forward of the engine box. It is backed up to the guard boards above and inboard the chain drive for the hoists. I used the photo of Theresa E Connor to complete this. Smaller scale models keep one out of this dialogue One can also see dead eyes are similar top and bottom...that is for later. here there are also a few points almost completing my study of this area: see the legs of the winch support are black...I think they are clad on top after much ware. They probably started out white. See the inboard guard rail on the drive chain off the engine box and tool box on the left. see the mystery box in the foreground. I think it is another vent hatch from below....not sure. that is what I am building oh no! just looking now I see I need to add a sheet metal guard on the large anchor drive wheel note the thick lines under what I thought was the wild cat head chain barrel....It looks like I have had it backwards for some time. Line on the starboard side chain to port...OK got it. OK next post we try to make this stuff.. fun trips to the hardware store cheers .

-

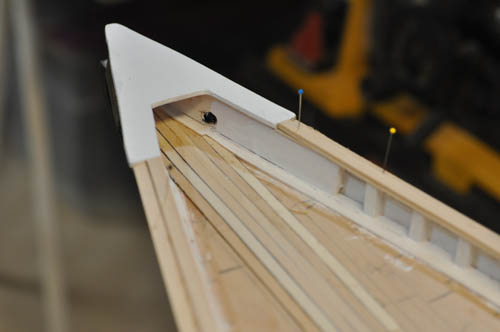

I wanted to add a few details that I left out involving getting the rails and deck on and getting the hull in shape. [ rescued ] I mentioned earlier that the "crude" pond yacht method gave us a 1-1/2 inch keel which made the bow stems ' awkward' and ugly. With no real keel meant for detail. first of all I built up the rails and rough fit the bow sprit . Here I have removed the spar and need to build out the bow exterior. I used small piece of scrap wood as a base. I then chose to add on a bow stem to make the full assembly work out. It is the stem that supports the bowsprit and gives that graceful look. In this picture it looks like I should have gone further with the added stem to perhaps have a thin keel. Because that would effectively enlarged the boat, I chose to compromise and add it here for the detailing and move on. Here all is in place and the 1st putty is in place. I used hammered copper #14 wire for the hawse ring. I can tell you know that paint, sand putty and paint was done twice up here. Next comes the monkey rail. I used the buildup method of damp wood and pins to dry and hold during glue up. I kept the pins in place , snipping and driving them home after glue set for strength. for the curved section at he forward end of the monkey rail, I use 1/32" plywood soaked and dry wrapped around pipe for the right diameter. I glued and screwed to hold shape then removed screws to finish. This is another example where this detail is easier at the large scale. for the transom, I made a pattern in 3/8" scrap plywood off the lower railand wrapped laminated and soaked 3 layers of 1/32" birch plywood. After drying I glued and re wrapped the layers tight on the form. The lower and top rails are 1/8 plywood at the transom and built up two layers, side by side 1/4" by 1/16" again for the rails. I mentioned before that the first coat of paint on the hull was indeed only that. Building up the rails made is necessary to smooth out the whole outside top edge with putty and get ready to paint. I will get the chain plates on next after painting out the rails and then repaint the hull. all for now cheers

-

Jeff and Michael thanks for your comments more coming as my build is currently still ahead of my posting. I am struggling making the break levers for the anchor winch and getting chain to stay on gears. The figures came from my brothers model train shop. I am told they are g scale I think. Not sure what is in the brief case of the commuter I have used so far. I will be adding some standing figures that are not painted.... a whole new area. cheers

-

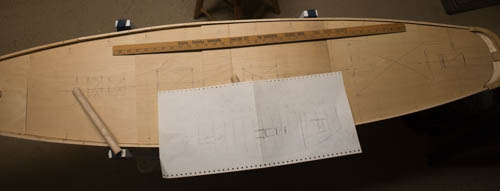

Now that we have the sailing components figured out, we can continue to build out the deck. It is possible due to the large size of this model, that I will only build a deck model including stub masts just tall enough to hold the booms. We'll see. There is one option then to have removable masts, more in a pond yacht style, with attachable rigging only for sailing. With the plywood sub deck in place, it is now time to figure our the water ways, stanchions, bulkheads and planking. To complete the study and decide on a color scheme I followed this thought process: I chose to rely on the Phillip Eisnor model and plans I bought viewable on the modelshipbuilder site I read and re read the wonderful practicum, written by Gene Bodner and edited by site manager Winston Scoville of Modelshipworld for many of my thoughts. In the Nova Scotia photo archive view 200330717 shows tones. under the light snow the water way is clearly darker than the white. It is very similar to the deck tone and obviously lighter than the black associated with the winch posts etc. This finding means for older boat...darker older decks and not black water way may be right. Bluenose II chose black water way and curbs and 6 inch dark shinny planking. The Eisnor model photos clearly used brown as the interpreted color for water ways and curbs. the Gene Bodnar practicum used a light brown stain for water ways. the model in the Lunenburg Fishermans Museum used green for both waterways and cabin roof I took these sources and decided I was going to try to achieve and older boat, A little beat up with oil tanks on deck and fish barrels more than racing colors. I am not sure how this will come out but that is where I am starting here we have a photo I took of Bluenose ll deck. They have a high gloss finish on dark stained plank that when counted supports 6 inch width. Comparing the 3/16 plans and the 1/4 scale plans counting planks we also get a 6 inch planking. So we decide on 1/4" planking and shall use 1/32" bass wood strips with black magic marker on one side edge. next we have to figure out the planking lay out. The practicum says we should figure out and install nibbing strakes first and plank to them. I agree and I hope a few years from now i get good enough to do that. I chose here to figure out the deck hatches and laying the planks based on that. I start in the center and cut nibs in the waterway plank when I get there. On the fore deck shown here, the hatch is 1-1/2" or 6 planks. Therefore a joint is dead center and then planks spread outward. before setting any decking we need to get the water way and stanchions all set. While doing this I also have to build up the bulkheads to get the grades all right. Here we are putting the first waterway that rides under the stanchions. Here you can see strips being added for shaping of the bulkhead. Wet strips are held by pins until the wood drys to shape. The glue and pin again. I snipped and kept the pins in many connections for strength. Here the outer waterway and stanchions are all in. I must say taking 1/4" square stock, cutting and canting and installing is so much easier than the tiny 3/32" square strips on the small scale boats. I can use push pins and even leave them in for strength where I feel it is needed. here we go forward and complete this phase. Now we have all the waterways and stanchions painted out in white. It's time for the rails. The after deck is a little different. It is 9 planks to cover the hatch and the after deck behind the cabin is all tapered to keep consistent planking. I chose here to follow my logic of whole planks for the hatch and openings. I needed a center plank unlike the forward deck as 9 planks spread the hatch opening and 23 planks at the cabin forward corners. here all the planks are in going aft. I covered the rudder opening and that is a knock out I will show later. Here we go starting to install the forward decking. You can see more clearly what I meant about my using the hatch dimensions as a control. I approached as I would planking a deck. I hope the difference in two decks gets lost. While installing deck planking we need to get rails on. I chose to build this realistically. to side bend 12 inch planks may have happened. I chose to bend 6 inch [ 1/4" in scale and to do inner and outer rail halves. With ammonia water only I would lay out inner rail with push pins down into the stanchions. After the glue set I snipped the pin and hammered it home to stay and strengthen the rails. As glue was drying on the inner plank I would set the wet outer plank and pin it to dry to shape before gluing it. The rails are two layers of 1/16" to get the right 1/8" thickness. to get an older deck my process has been a two step staining. Here I used a cherry stain to get the warm color as seen in the Bluenose ll. call it step 1. I will play with this color choice a lot. Here one can see the light color that could alternately take clear finish. I feel that would demonstrate a nice new deck and I want to replicate a boat of some age. looking at this overview I decided to go. forward with the second step which is an over wash of walnut stain on the cherry [ charles notman deck] all for now cheers

-

Dave I would like to follow up on a detail that comes through on Dave Borgens post 61 above. I hope he is still following. the water way in the embeded photo are brown...I think the B&W photos of Bluenose, in the Nova Scotia archive, and obviously in later life, show them similar tone to the decking but lighter than the black. Bluenose ll used black the main model inside Lunenberg Museum has them and the roof tops two tones of green do you have any more info that that? cheers Jon

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Moving forward I recall my first intent was to work through September and get a deck on. Funny how we get sucked in more and more. The first thing is to lay out the deck beams and then figure out openings that will be used for sailing. . I ripped stock to create a supply of deck beams. they are 3/4" by 5/16". My thought was as before they are deep enough that I can cut them to camber. I then chose a production method on a trial basis to see if it saves time. I used the cedar planks to double the shear line and set the deck line fore and aft. Then I laid out the deck beams on an common span same as frame stations of the 1/4 inch scale plans. Notice the beams have no camber cut and they are notched into the sides. I then added 1/16 "by 1/4" strips, edge to edge on top of the beams and a second to the mid point base on center . I then carved and sanded the cambers. It was actually quite fast, but I think not much time saving over cambering all the beams first. I had chosen this method because of the small camber on this boat compared to others I have done. If I ever do this way again I would delay this camber step until all the RC adjustments were made. That will be clear in the next sequence. My bottom line is not a great alternate.....camber first! The sub deck here is agian 1/16" birch plywood. The sections are laid out to allow working one at a time to coordinate revisions in frame needed for RC Here is the first lay out to use the two center hatches for access. beams had to be moved around. the two sticks could be screwed together through a mid hatch. The forward end will have a block attached to a shock [ bungee] cord and be pushed way up to the bow. This makes a loop that goes of a drum winch and controls the sail sheets. [ not flying, or working jib] here is the other second design for the servo location and sail sheet loop etc. This sheet has the worked out framing changes, and is what I meant about designing the deck. Here I have made the framing for the small hatch opening. This hatch gives access to the rudder servo. unfortunately the sharp angle of the rudder does not allow direct connection like most pond yachts where the rudder post is vertical. here is a lesson learned from my marbleheads. I took scrap 1/16 plywood and laid in a lower deck so the sticks holding sail loop block can slide on it as they are pushed forward from the aft hatch access. You can also see in this shot the first section of under deck including the small hatch is secured, so this forward section will be made to it. Here is the adjustments to the after deck house opening and the rudder access. The issue of using flat beams and then adding strips etc. just adds another nuisance step to get these right. One thing to notice here and the previous two photos is the darker color of the interior of the hull. It has a complete coat of resin to totally seal up the hull. Also in this photo you can see the internal carving of the 1.5 inch plywood keelson assembly and the block transom to fit the RC equipment and make the inside shape of the transom work. We are getting to the point where I originally planned to hang up the model for another year. but I find doing these steps my mind is on the three or four next steps and it gets harder to stop. It was at this time that I decided to use 1/32 decking [not a great decision by the way] and ordered it along with many strips to allow building up the bulkheads. I started looking at the deck equipment and at this scale knowing I needed to figure out gears and things.....but the masts? I can make them but where would I put this boat???? You can see the two short dowels sitting in place......??? Also for sailing, the two jibs have sheets that go on outer sides of the forestaysail rigging, so I cannot sail them like other boats with a single loop. I would need a 3rd Servo and all that logic. Alternately ones leaves them furled or worse choses to shrink them to self tack. I leave this stage with enough room in the after deck house opening to put a servo on each side and try to do that, That is the point of this build ....I am building it so it could sail, I am not committed yet to take it that far. I may not even put in real masts. all for now cheers . . .

-

Dave I wanted to say hello. I have been going through different logs to see how others interpreted this wonderful Schooner. Your build is great to watch and I look forward to following along. I am currently doing a scratch build in 1:24 scale. I am also favoring the look of an older version boat....more beat up so to speak, maybe a few fish on board. I too am painting and then repainting. I have latched onto the photos in the Nova Scotia archive to think about details. I share this thought because this boat and others likely had changes through the years. One example I just figured out this week is the 'buffalo rail". It is shown in a photo...obviously years later,... to have a cap piece on top painted white all around.and the lower section is black outboard. I am sure the cap piece was added to repair damage. Most photos show this rail all white and on most models and the real BN II it is a one large all white piece. anyway great to watch you and the others too cheers jon

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Starting again 2016 OK it is August this year and I am playing around in between projects. I decided first to give myself 6 weeks to get a deck on Gerturde and then hang her up again. Let's see what happens. the first thing to do is to cut off the building board and build her a stand. This style stand I now use regularly because the straps allow rotation to get gunnels up and free for work and way down the line to put a heel on the boat.[ very helpful while working on rigging] It is also good for carrying around, setting on the ground etc. Best of all it allows using up those many cut offs and scraps of lumber in the shop. next step....probably several days later... it is time to cut out the interior molds leaving the strip ribs. This removal starts rough and then ends with sanding to get ready to receive a coat of resin. let's see what we have. All the interior is clean and we are ready to go forward. Here we are visiting Charles Notman while I go sailing in the real Boothbay Harbor One design. Just FYI here we are sailing Bittersweet the real BHOD. You can see now why summer is not a productive modeling season. now we have the real test. I have set up with levels and squares to measure everything before we get into deck design.....and what does one find when this step is added.....the mysterious truth I stater scratching my head when the deck dimension was 71.5 inches. the beam maxed out around just under 14 inches lets see....gertrude is how long????? 135 feet on deck or....ah ah ah..67.5 iches let's see gertrude is how wide 23.5..................or ah ah ah 11.75 Ok I said I was over my head 15 years ago when I started this. I made a beginners mistake......I should have reduced the molds for the 1/32 strip ribs and 1/8 planking and say 1/32 fiberglass. I did not, so I should accept....and admit I am too wide by 2 times 3/16 or up to 3/8........ The truth so to speak...... if i had scanned an plotted the other set of plans that I bought at the same time 15 years ago it would have been Bluenose. let's see Bluenose is how long??? 143 on deck or ah .....71.5 inches let's see Bluenose is how wide 27 feet or ah...... 13.5 inches......add up to 3/8 for my begineer mistake ont he sizing of the forms= 13.78 inches Bingo... I am building....a 143 foot boat. I thought for a few seconds about switching to Columbia. The other American boat but decided against it. Let's face it... Nova Scotia and better Lunenburg created the best and fastest schooner. She beat the US boats in all matched races except one set. Therefore I am rescuing and building out Bluenose there you have it cheers

-

Jeff you are looking at a theodolite. they are for surveying. We used them in school 50 years ago and working both summers on property survey and for the first year or so in construction. They became antiques quickly as technology improved in the early 70's. You can check out pond yachts through AMYA.org the major site is focused on all classes and racing. Then go to the Vintage model yacht class to find the beautiful pond yachts that survive. In the early 20th century, central park NYC, and other similar ponds in Boston etc were filled with vane controlled models. the Marblehead class was one considered for the 1936 Olympics. Some of the old timers I met with while working there in say 2000 were founding members of what remains a very active group and club in Marblehead, MA.. easy to fine on the web cheers

-

Thanks Patrick and Hamilton I am working on building the winch and other gear. One good thing about this large scale is you can get you fingers onto the parts. I have taken the photos from the Nova Scotia archive and find the late timing , post racing,wonderful. With all the grit and oil tanks and other stuff on the deck. even light snow in one picture. Looking closely I now believe by example that under light snow, the waterways were dark......unfortunately mine are still white...oops. more later cheers

-

Hamilton I look forward to following along. I am scratch building Bluenose as well but at a large scale 1:24 for possible RC sailing. Cheers

-

CATCH UP POST 2...2013-2015 Progress in 2013/14 I retired in 2013 and started on many projects. I started the year building 3 kits in 1/4 scale to teach myself the skills needed before the big build of Charles Notman. I also spent a lion share of the year working on dancing feather making sails, and continuing the study of large Downeast schooners. In 2014, I not only began Charles Notman, but made a trip that I recommend to everyone who loves schooners. We took the fancy ferry from Portland, Me to Yarmouth, Nova Scotia and drove to Lunenburg. Wow three times over. Later in the build I will share some photos that help one study both schooners and all fishing vessels especially of the early vintage. One of the models of 2013 was a Gloucester Schooner, so I was up on detail and felt I knew what to look for in Lunenburg. You can learn much there from both the model collection and the schooners dockside to help understand deck level detail. Bluenose II was there and I photoed all I could and had fun talking with the crew. Let's build a skin 2015.. Well here we are in the late summer of last year. Charles Notman had sailed and was set in her new place of honor. I will continue to build her out and that story is in its own log. I was also gathering information and getting ready to build the Boothbay Harbor One Design racing sloops, so what to do during those warm days of September when I can take it outside....let's work on fiberglass skils needed to improve for the next builds and get 'gertude??' skinned up. Starting off we had to rescue the transom. Setting blocks with dowels and then carving with files and sanding has gotten easier for me. This build will be a possible sailing boat [ the hull at least] and it will have a fiber-glassed hull, so nice planking detail is not a focus.here. With the transom done we have also used water putty and wood fillers to prep for glass and resin. Putty has the risk of being tougher than the cedar, so I would not use it for a static model. It is the best though for filling gaps at this scale. Here again we are using 6 oz cloth for strength to the hull to sail. the first coat of resin is rough. I was told by a true artist who makes amazing hulls for RC to take coarse 40 and 120 grit sanding and don't be bashful in between coats of resin. . here is coat three done and sanded with120 to 240 grit. here is good old bondo full coat sanded with 400 and then solid coat of auto body putty at 600 grit. finally here is the auto body filler primer. Here I like to do the base with two coats of rattle can red. It will get over coats but is a good base. Here we are again with a double base coat of black. This will get painted again a few times as we build the deck, add chain plates etc. I love the shape overall . But here one can see 15 years ago when I started this build, the over simple lamination for the keelson assembly will make her sail well, but was not feathered out as it should have been. I love this view of the hull...it looks just like a graceful dolphin breaching..... Well here we are, it is fall 2015 and it was time to start Boothbay harbor one designs and put what I still thought to be Gertrude back up on the ceiling. The surprise is still coming cheers

-

This new building log is meant to tell a long and broken tale of model building. The serious work began a few months ago when I decided to try to rescue this model and take it further along. Perhaps to stop it with a deck only completion since it would be so big to include rigging, or to breeze through and design removable rigging to allow sailing. Before we get in to that dialogue I thought it best to tell the saga of the 15 years to get it here. Fortunately that will only take a few posts. so here we go again I started to learn the trade, and truly I still am really only learning, by setting up a small shop in the early 1990's, at a former summer home here in Maine and building a wooden kit of a Dark Harbor 17 at 1:12 scale sometime in the later 90's. Like many I was working away and had dreams to be relaxing in a shop but realty kept us away. I never worked closer than 3 hours from this summer home and usually further. During these years I thought about wanting to build models that would sail. I had roughly ten years to go before retirement and thought that was time to try a few things and figure it out. My first venture was to buy an Antique Marblehead Pond yacht, vintage 1936. I restored it partially and then copied it building a new replica. In august 2001 I went to the wooden boat school in Brooklin Maine with my son for a fun vacation and learned to build a 50 inch new Marblehead class pond yacht. They were called Naskeags. They are pretty but built purely for the challenge of sailing. Then looking at the half built dark harbor hull, at 17 inches, and the half built Marblehead Naskeag at 50 inches I decided on a goal. I would continue to build kits or scratch of classic boats to develop some skill. I would continue to read and read some more about the maritime history as well as model building, and thirdly i would continue to build sailable pond yachts to get some to sail. Ultimately I would learn to scratch build classic boats at a large enough scale that would respect the design but also try their luck in the sea....harbor or pond at least. Gloucester Schooners were also first on my mind for a challenge. When did we start this build??? Some of you have followed my earlier attempts with a four masted schooner the Charles Notman and the classic 1938 Boothbay Harbor One design racing sloops . Well here we have a boat construction that spans the whole period of 2001 until now. Here we see the 1992 to 2004 shop. I got to spend a few weeks a year there prior to 2000 and then weekends. You can see the two Marblehead pond yachts that filled much of my time . Hidden just out of the picture on the right is the partially built Dark harbor model. Most important on the back left is the building board and stations for a scratch build Gloucester fishing schooner that will become the basis of this build. This photo is dated 2002 At the time I built this frame, my memory tells me incorrectly as I recently figured out, that is built it up form Gertrude's lines. With the outgrowth of windows 98 and Auto CAD lt 97 it is not surprising that I no longer have any of the cad I did for this build. Here you can see the roughness of the build. I was clearly over my head at the time and fortunately stopped. The keelson assembly is made of three laminated 1/2 sheets of plywood so it is strong and true. [ It includes keel, stem, keelson and made up structure up to the the transom based on pond yacht construction methods... See my other log for detail] This method is Good for sailing but the forward stem is a problem [ you will see later]. Is she Gertrude Thebaud, Columbia or Bluenose??? I could write for pages but the short version is as follows. I read that Columbia was the same size as Bluenose and considered to be the fastest ever built. Unfortunately she died young. Here is the text from Ship Wiki ...remember length on deck 141 feet · Columbia is a Gloucester Fishing Schooner. It was built by Arthur Dana Story from the design of Starling Burgess, at Essex, MA, 1923. The Columbia represents the final development of the Gloucester fishing schooner, famous for speed and seaworthiness. It participated a number of international races, including the one against Bluenose in Halifax. In August 1927 when it was hit by the two Gales, the well-known "Graveyard of the Atlantic", Columbia was lost with all hands off Sable Island. · For years my memory was I had decided to build Gertrude. All my files said it etc. anyway part of the reason is in the following text from wikipedi....remember length on deck 135 feet · \Gertrude L. Thebaud was an American fishing and racing schooner built and launched in Essex, Massachusetts in 1930. A celebrated racing competitor of the Bluenose,[1] it was designed by Frank Paine and built by Arthur D. Story for Louis A. Thebaud, and named for his wife, Gertrude Thebaud.[2] In their first meeting at Gloucester, Massachusetts, in October 1930, the Gertrude L. Thebaud bested the Bluenose 2-0 to win the Sir Thomas Lipton International Fishing Challenge Cup.[3] However, in 1931, two races to none, and again in 1938, three races to two, the Bluenose defeated the Gertrude L. Thebaud to remain the undefeated holder of the International Fisherman's Trophy.[4] I further learned that she went to the arctic in 1934 with MacMillan one year as Bowdoin stayed home. I continued to think I was going to build her and I remembered incorrectly that I had taken measurements from her scanned set of prints when I built the frame.......you'll see Bluenose. Here is intro from wiki pedia ....and again please remember length on deck 143 feet · Bluenose was designed by William Roué and built by Smith and Rhuland in Lunenburg, Nova Scotia. She was launched on 26 March 1921, and christened by Audrey Marie Smith.[citation needed] She was built to be a racing ship and fishing vessel, in response to the defeat of the Nova Scotian fishing schooner Delawana by the Gloucester, Massachusetts fishing schooner Esperanto in 1920, in a race sponsored by the Halifax Herald newspaper.[citation needed] Bluenose vs. Gertrude L. Thebaud, International Fishermen's Trophy, 1938, final race ·After a season fishing on the Grand Banks of Newfoundland under the command of Angus Walters, Bluenose defeated Elsie (out of Gloucester), returning the International Fishermen's Trophy to Nova Scotia. In 1930, off Gloucester, Massachusetts, she was defeated 2–0 in the inaugural Sir Thomas Lipton International Fishing Challenge Cup by perhaps her most celebrated competitor, the Gertrude L. Thebaud.[2] However, over the next seven years of racing, no challenger, American or Canadian, could take the title from her.[3] The question again...which to build There are so many Bluenose models I thought for a long time about making an American boat. The designers Starling Burgess and Frank Paine come up again and again. The 1937 Ranger for us here in Maine is a big deal. The fact a new replica of Columbia sails and all who see her say she is a marvel. [ Images of the replica is easy to find on the net]. Well to be honest there is a funny story here on me how in the end the model became Bluenose. To make the original frame in 2001-2002 I obtained the 3/16 scale rough model plans from Piel Craftman in Newburyport, MA for both models BN and GT. While I was in his shop however I fell in love with another boat named Dancing feather. My rear admiral feels the feather is one of prettiest schooners she has seen so guess what took priority. On again off again working on vacations and moving houses to our current home [ means rebuild a shop] only it took from 2004 to 2012 to get this one far along and it was a real rough job much of which may be redone. Here she is a year ago moving away to live in the new sail loft and thus make room for Charles Notman to hold the shop entrance way display area. I had made her 3/4 scale to size at 50 inches on deck. I will never work in that odd scale again. In the mean time, I was assigned to work in Canada for 3 plus years and while I was there came across a set of really nice 1/4 scale drawings of Bluenose. These I now see are easy to get on line as are similar plans for Columbia. They are both drawing by Philip Eisnor and available though a sister site modleshipbuilder. Finally...we start again It is summer 2012. I am assigned to travel overseas but spend several weeks through the summer here in Maine. What to do...... Please look at my other two builds [ Charles Notman and Boothbay Harbor one design] for detailed discussions on the sailable hull build method. The plans were scanned, plumbed and inserted to CAD. The white paper inside on aft stations was printed off and attached to luan plywood. Blue tape separated a 1/32 birch plywood strip rib. The cedar is rough milled from 1"/6" stock to be 5/32 [ which only means 1/8 - 0 +1/16 tolerance] by 5/16 . We want to start faring the hull with no less than 1/8th wood thickness. Planks soaked in ammonia water then wood glue and toothpick pinning to the sstations through the ribs.. Here the laminations for the Keelson assembly are clear [see Notman build] . Notice there is no transom at this point. almost finished. See the roughness of the bow. As I said i was way over my head when I started this hull. Here we have all planking on and sanded. And here she goes back up to the ceiling for storage....it's 2012. and I am still thinking we are building Gertrude Thebaud. They sent me away for work again and it was another year before I could really focus on my modeling goals. This was the year I found forums like this one and started reading articles , sites like models of dummies, practicums and building logs. I was getting ready cheers

-

Wow summer is ending quickly. Yesterday we had our final sail in real Bittersweet and it was great. I just wanted to share a final posting on the resolution of the sailing of the Bittersweet model that under performed previously in the log above. I first took the advice given and reset up the boat to check the rake, I found it was incorrect. i reset it at the 4 degrees. aft...thank you Cap 'n' Bob for suggesting it. You were right on! I then attached a line to hold the out haul snug to the boom. This is because shortening the main sail foot to keep in balance with the smaller jib allowed the out haul to ride up....thank You Mark for pointing it out. the light designed insert connection for the sailing keel failed and ripped out while in the car coming home from a previous sail. Here I copied old design of placing a #8 lag bolt [hanger] into the keel and then using a wing nut to add the sailing keel. This method works best for a boat that will be sailed a lot. For display we have the two bolts to look at if we remove the white sailing keel. Here we are on the working stand at the yacht club and I plan to display her mostly like this with the sailing keel in place. Here we have gone to our pond and found she sailed really well after re-raking the mast and yes she came about too. The line holding the out haul came off and she still performed, so I guess the rake was the real issue. I plan to have fun and sail these for the next few summers . Thanks to those who followed along and gave me encouragement and tips as I find my way in this great new challenge of building classics boats that can actually sail. I am playing with the 1:24 Bluenose listed on my signature right now, but am not sure if it is ready for a log yet. If I decide to keep going to complete it I shall post it. If I hang it back up to the ceiling for another year I will move on to other ventures. i want to try some smaller scale boats to to figure out how to do that because these big models are just that..BIG. cheers

-

wow In only a few more weeks summer is coming to a close, and it is time to figure out projects for next winter. I want to share a few photos of the work i did last spring getting Charlie to a fun place before resting this summer. There are tons to do however before we say done. I will continue from time to time to get back on this project and update. I have a few other of these bigger boats I want to get further along with, so when the snow comes, I can move into new territory. As spring was ending and summer beckoned, I had sorted out [ that means figured out mistakes and redid] ratlines on the port side...the intended display back side. I put on running lines that i thought were on the port side and then turned the model around. This was to be a milestone. Here we have all the ratlines on and various running lines intended for this side all in place. Here we are turned around, new LED lighting is in place and we are ready. she is not done but this is where she will live. wait for oops we are not done turning here I sent the crew up because it was time to figure out how to bend the top stay sails. Alright three cheers all CN sails are now on The next thing I carefully did was to install the clew lines just like I did on the top sails. If you look at the top sail behind you can see the small block and the clew line that lives on the starboard side and goes down to be made off. I then , thinking I wanted all the lines on the exposed side, installed the similar clew lines for the top stay sails. oops they are supposed to be on the port side, so here in the photo they are removed. a job for next winter. Finally after a bit of study I figured out the top stay sail trip lines and show one off in this photo. I finally interpreted the detailed Cora Cressy sail plan to have the block tied off to the top mast stay, so that point of purchase is higher than the jack stays and can thus pull the sheets over when tacking. So this is how she sits and I hope as summer activities run down through the next month or so we can get back to this fun build. cheers

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.