-

Posts

876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

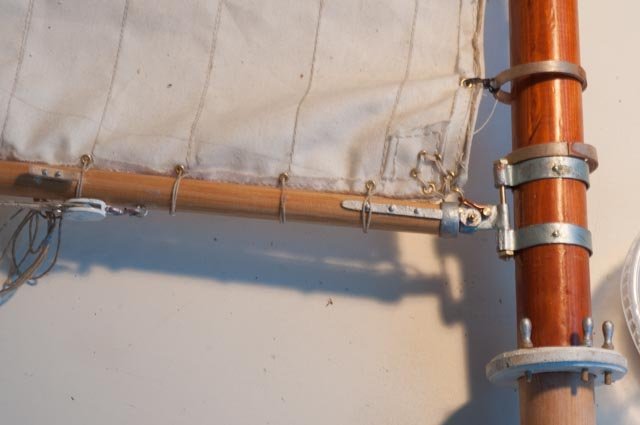

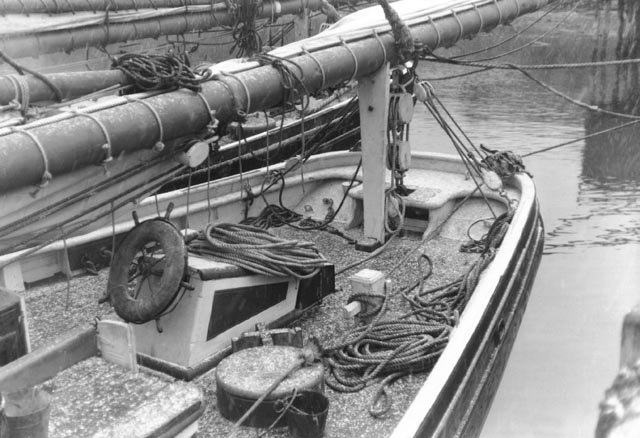

Re rig sails to fore and main gaffs I have gone around a few times trying to figure out what to model for the two gaffs. This post is my decision making before I do something and move on. The work is focused on the fore gaff that I have rebuilt along with a new sail. Due to such few archive photos though, I would like to better understand both main and fore sails at the same time. I find that Jensen drawings = BN ll, but the archive photos do not always agree. I also believe the racing rig of say 1930 could have been slightly different from the 1940 long time fishing rig that I am favoring and finding documented. In my last post I showed the four corners of the BN ll foresail and some progress. I liked the details and basically used the reinforcing, grommets, strapped rings, reefing points and new roping to remake the sail. Clearly the boom [ foot] is lashed tied and tails pulled through the lines. The three holes bored through the end of the two gaffs seems to have been carried over [ with my loose interpretation of the old photos.] · Here is Nova Scotia BN archive’s best photo of the boom and gaff. This shot and another one clearly shows some key items that I believe reflect ultimate rigging of the fishing Bluenose. I make some cropped views below to rationalize some detail decisions BN II used a bale in the gaff to hold the foresail peak [ recent posting] · Here BN ll lashed the peak to the gaff on the main sail and have bored four holes. First let’s look at a little progress · Here is my new foresail clew and iron mongery. see the attempted moused hook for the boom tackle. · Here is the new tack. note the use of black lines for the hoop ties. I cleaned up the boom cleat and that shall hold the down haul. · Here is the new throat. The shackle is not yet there. I need to figure out lashing connection and holes through the jaws first. · In this photo of the peak you can see I did the BN ll bale just to look at it, but I plan to change it to lashing. You can also see the topsail sheet block attached to the side of the gaff and the white peak halyard blocks with galvanized rings directly on the gaff…there was apparently no bridle on the 1940 version. Second let’s study old photos of the Nova Scotia BN archive · Here in a BN archive cropped shot, one sees two light colored lines running aft of the fore sail peak grommet [ ring]. I suspect they go through the holes in the gaff and thus sort of lash the sail less neatly than on BN ll . There is no bale. Also, there seems to be a fore and aft top ring that must be holding the down haul at the end of the gaff among the coiled line. [ likely the stored down haul in the photo]. You also see the white peak halyard block attached directly to the gaff · In this photo I cropped the best view of the end of the main gaff. It looks quite like the fore and confirms the top sail sheet blocks were not on top as they have been rigged on BN ll. · In this cropped archive photo there is a white block suspended on a leather cap like other fishing schooners. It rides on the starboard side. I believe but do not yet know how but I read somewhere that these leather gloves held the block and could ride over and around when tacking. Anyway, my other schooners have the topsail sheet blocks rigged like this, so I am using this photo to set mine on the starboard side. · Looking forward on the fore gaff and boom we see they are clean, no lazy jacks like BN ll Lashing details on BN ll · Here we already spoke about the boom lashing. This is this BN ll detail with tails tucked that I have copied. On the archive photo above the tails are left loose on the main, and I may do that if I rebuild that sail. One can also see the spiral lashing has a figure 8 knot holding it on top of the starboard jaw. That works for me. · Here in the end of the main gaff we see the knot and seizing detail of the lashing on port side. On the starboard side [ photo above] the lashing goes through a sail grommet before being tied off to port. We also see very nice lashing of the peak from all three holes. · In this cropped photo of the end of the fore gaff we see a similar detail of the end of the line tied off on the starboard side. The last line draped over the end is temporary line while sails are furled holding down the gaff. It came off when sailing. · Here is the main peak under sail. Note the flag is added to the down haul that was slice through the end hole and dropped on both side rails while sailing. · Here is the end of the fore gaff under sail. The down haul is single here. So I may not be right but at least I have had fun trying to figure our how all this stuff works. Now I just need to have the time to complete this step. cheers jon

-

I am close to the end of sewing the new bolt rope and my crew just showed up outside the shop. In case some of you worry that we eat all of the turkeys for Thanksgiving, let me assure you there are plenty here in Maine

-

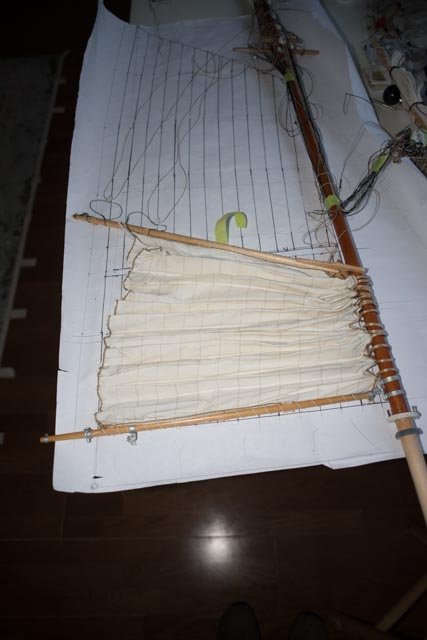

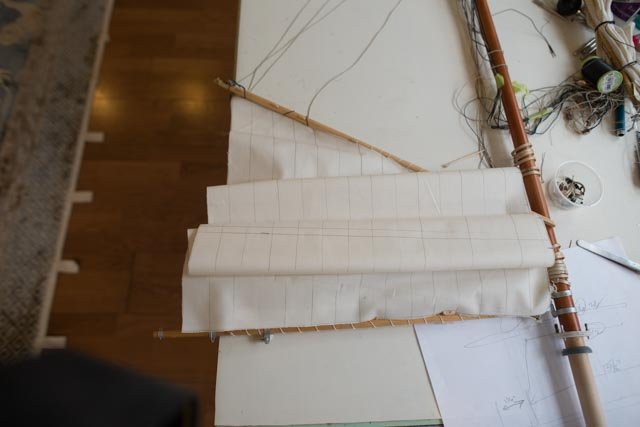

Making replacement foresail mid-point I am part way through the tedious sewing on the bolt rope and looking to a few new steps. This also rests those sore thumb joints a bit, gets more coffee, and brings me back to the hoops. I include here this wonderful image under sail in full size Here is the cropped view showing two hoops. Just like the lazy jacks they used twisted wire. Perhaps the original was line but maybe tarred. Not sure but i think this means we go to black thread; but how to tie it? if line tied is wire twisted. There are no good photos of this detail of the old one. Keith was nice enough above to send the text book. It looks sensible in real size but gives me two knots to finish off. I plan to practice a few since I need to make another batch of rings for my planned sailing mast. The next pictures show the slippery slope I have entered. My rear admiral came along and said she wanted to try to do a better job sewing the seem lines to reduce if not eliminate the puckering. While she was away working, I foolishly raised the other two sails After she came back I was playing around and here is the new foresail if I show it raised……. what to do?.. do I remake everything? Here we are coming at you how can I not do these sails raised????? Here is the sail peak detail. I do not agree with the block being on top, but I like the three holes and bale holding the sail and spliced down haul … here is the temporarily installed foresail peak....The sail is fine, but look at that gaff!!!! The ugly side sheave that works, the end band and eye, the Bluenose ll black bridles [ I just realized Bluenose did not have bridles on the fore gaff, the blocks were strapped…. another oops as I just added them based on jensen drawings and BNll. I decided to remake my fore gaff to bring up the details and to demote this first spar to sailing status. I think now it is inevitable that I must also change the main sail and that means a new main gaff too. Some day I will take steps only forward Cheers

-

OK I am back looking at this post of yours from last month. I will definitely set up a practice board. i was concerned with the diagram you put on my site because the tails are loose on both sides. I did it differently and had both tails on the same side allowing a simple square not. fun city I think as i figure out what to do here. cheers

-

I love the rats nest comment on temporary condition of lines. You can say that with a smile because you do a great job cleaning them up on their cleats. The binnacle detail is great too. Turning brass for lights wow ... can't wait to see the next step. Cheers

-

I just enjoyed another review of this incredible build. Each time I think about building schooners smaller than 1:96 or a split half showing the innards, I hesitate. Doing the interior is awesome and seeing your staging of the decks very instructive. Thanks for sharing Jon

-

Part one of remaking a new Foresail I am spinning out of control here. I thought it time to post what is happening, as I use this process to help think about what I am doing. It helps so I can decide if I keep going and adding more and more redo’s or to I cry uncle and move on. This scale leaves few excuses not to try to get things to show how they worked. So let’s see how much trouble I am in half way through remaking a sail. First let’s see what we learned about how the sails was rigged. · Here is a detail of both the ironmongery and clew attachment to the fore boom. I must redo everything · Example: …see how the boom tackle is attached to the boom. The block has a hook which is moused to the ring which is held by the bolt through the bands · Here is my attempt to replicate that. Yes another diversion · Here is the detail of peak connection to the gaff. There is much to talk about here… this post is only the sail, but the gaff is in trouble. · Here we see the tack connection and details of the gooseneck. · Four corners make these sails, so here is the throat. Wow much to do here · Finally let’s look and see the reef points. Yes they are diamond points and not the band that goes on the bigger schooners. How am I going to make them? First I made some samples and experimented with different size hollow mini rivets to use as grommets. · I made four corners, and the first one did not go so well. This is my second attempt. I am using thread to lash the grommets and two sizes of grommets. I would need a mini bicycle tire rim shaped ring to be the perfect lashed ring. I have no idea how to do that, so I drew the line, I soldered a small ring and moved on. · Here I am using a punch to rap the back and a small ball peen to hammer back the grommets. I suppose there is a tool to do this job. Maybe next time · Here is the completed clew and foot of the sail for lashing to the boom. OK if you are following you realize I do not have this much detail on the mainsail [ which is already relashed to the boom] or Jumbo. What to do? While thinking about that I decided to improve the bolt rope. You may recall I used the 20 # hemp twine for color but never really liked it because it was too big. · Here I bought more hemp craft line in softer color. This is the 20 # weight and I am not going to use it either · Here is the 10# line also softer color, and I think one can see that it is too small. · Finally..here is the 1mm tan line I have been using for halyards. It really is virtually 1 inch diameter in scale and what I plan to use. More to order... oh boy they love me cheers jon

-

Dave She is really looking good. Great idea to play with sails. I am now foolishly making my second set of sails. I tried the furling and am now thinking about fully rigged, the lower ones anyway. cheers jon

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Keith thanks for your post. I know there are some calculations to do. You can follow the link on my signature to my two former builds that sailed and I discussed what i did. not perfect but they sailed. Boothbay Harbor one design I had two boats. The image below of the Bittersweet shows the bolted on 10 pound keel and extension rudder. The 13inch moment is similar to the Marblehead 50 inch class sailboats that I have. I am sure I could raise bulbs up a few inches i just have too much invested to take that chance. I sail these at the Boothbay harbor Yacht Club......ocean! This image is the Charles Notman. She is roughly the same size and weight of Bluenose. Here a large sailing keel and extension rudder does the trick. Now that I am moving toward a possible sailing venture with Bluenose, I shall make the extension parts. Please note that the white stands I make are similar for each boat. That stand not only allows heeling over for display and working convenience, it allows setting on the dock, adding the temp keel etc. and sailing. Tthe two lead bricks are 5 pound each. FYI confirming the advise of a local schooner expert this model would not head up into the wind and tack. Just like the real ones, the center of influence is the center of the hull [ here it is forward end of the added keel]. The center of effort is somewhere in the foresail. If I took off the jibs she might sail. I have retired her and slowly work away at completing the detail. I know I am adding more and more scope to Bluenose making completing other projects go on and on. Oh well cheers jon

-

Make the bait barrels I thought it time to stop looking at the rough made barrel blanks rolling around the deck and turn them into racked bait barrels. · Here is the NS archive image of what I am trying to do. There is more detail in the picture in recent posting showing the top lids and some large storage boxes perhaps for loose fishing gear. There is also a steel barrel lashed up against the cabin, and a bucket on the roof. · Here are the blanks. I bought these in a craft shop maybe 10 years ago thinking a day would come where they would be handy. They are bored out on a lathe and if this works I will add to my list a need to make some blanks myself, because I need another barrel [ different use I believe] that goes up by the galley hatch. These blanks are the perfect size to try to copy the photo. · The jig in the photo is to allow gluing cut off dowel slugs with a matching recess this all 6. The cut dowels were about 1/16th smaller than the id of the barrel. They are screwed through the jig and then the barrel set down. I shimmed with 1/16 scrap and the after the first dry out filled the gap with more wood glue. · In this shot I have made up the second rack and precut all the pieces needed to make up the lids. I wanted a dirty, oiling, yucky look ….sort of what an old bait barrel might look like. For some reason I had an old can of ebony stain and it worked great as the under coat. I then did some random touch up with satin black so there is a mixed look. Nowhere near perfect but better I think than just paint. · Here they are on deck. The oil barrel needs trim and I ordered some styrene that might bend around to complete the drum details. i let the red putty show through the pain t a bit as i want a little rust to show. · Here we see the effect on deck. I need now to decide if I want to add the side boxes. I probably shall, but not yet. They are also loose as I am thinking more now about what comes off if we go sailing. Also they would not be on board if we are racing. PS my first attempt to make the small tub barrel was a disaster. I need to make the small tapered and bevels staves. I believe I will need to figure out a jig first, and set up a production line. on at a time is not good. Cheers jon

-

Prepare foremast to become removable and take it out Well here we go in finding the resolution of what one might do with this a model that is more than 6 feet tall and might also be able to sail. After the trial and error removal, upgrade and replacement of the main mast, let’s see how much better we can get working the foremast. · Let’s undo all the lines and use smaller pieces of masking tape to separate and hold them on proper side to prevent tangles. This include head stays, any future jibs all the lines made to the rail pins. · Here we are with loose lines more carefully taped. The jumbo boom and sail sits on top of the fore gaff and with a little tape is secure enough to move. I we had the jib and jib top sails they would be handled similarly. · being more careful this time, the mast easily comes up and out and then down onto the rigging table. See the small top mast extension did not break the toothpick this time…. Yippee! Now I need to have a large card board box [ tray really] to receive this and careful take to the car if we are going travelling of store while simpler mast and sail is rigged for sailing RC. · Here Bluenose sits with the foremast demasted. I hope we are on a roll now, but I fear it’s more like we're entering another rabbit hole, as I find more things to do. Now we have several items to fix. · First of all, the bridles for the peak halyards need to become black representing the cable material. To do that the sail lashing needed to be removed. · Here we find a big error and shifting resolution. The Jensen drawings and BN ll photos show the fore sail to be clearly 2 feet bigger running out further on the boom and gaff. It works out to be one extra panel. You can see the lighter line on the paper pattern. · Decision made…. I need to remake the sail. I will use the first sail for a possible sailing version on a simple mast and boom. Here the new sail is laid out. · Here the new cut sail is laid out and looks much better partially furled. More to think about as this new sail progresses. · The fragile top mast is easy to straighten out. Here in a detail it is easy to see the improved look of the draped shrouds and stays over the shoulder with only two blocks. Next decision is whether to paint the top ball gold. I am sure it was when new…….did it last? · I needed to put the boot on the mast. I found I needed to sand down the below deck mast to get the wood painted ring to slide up. The gray boot will slide down onto the deck after reinstalling. It seems each time I do something, I find two more things to redo…….oh well Cheers jon

-

Second part of main boom upgrades In this post, I need to record what I decided to do with the lazy jacks to get a view that replicates the 1940 ish boat photos, but also listens to the folks that tell me the Jensen drawings were accurate except for coast guard enhancements. I believe that there were no lazy jacks in the early races other than a single line that is seen in some of the distant photos. Regardless, I may have gone too far so I have installed the mid point system as it shows on jensen drawings. I have chosen for the moment not to add the inner most lazy jacks but did install the inner boom lift. · Here we have a view of the new lazy jacks and lifts. There are two lines [ lazy jacks] falling to the boom from the mid boom lift. You can see the port side back stay made to the aft position beyond, and the end boom lift line twisted in this photo. I need to figure out how to keep lines from twisting. · In this view the forward lift is clearer. Also you can see an issue for a future fix,the peak halyard bridles are made of rope[ they are tan with black seizing]. I made this in error based on my looking at the old photos months ago. After seeing the real thing I looked again at the old photos and yes, they are clearly cable. This is now a punch list and some how I need to come back on these. · This NS archive photo gives the simple look I need to get. There is center band over the deck house that looks like it is in the same location the forward lift. I chose this to justify installing the forward lift to the blocks under the cross trees. · This image is just to show where we are at this point as I move on. The lashing of the furled is also in the tan hemp colored material. The bait barrels need to come soon and yes the shall. Lazy jack details. · Here we see my first attempt, before going to Lunenburg of the wood fairleads. Reject.. · I looked around the shop for inspiration and found mini clothes pins. Some were broken so available. I cut them down and presto…not perfect at all but much better. I believe from reading more advanced builder's logs that if I had some pear or other good wood, I could file/ carve them down more and they would be even better. I am definitely not there yet. · Here we see the fairlead in place and the two eye spliced lines ready to be lashed through the fairleads · Now to install: the real ones are wire wrapped to hold the line eye splices to the cable boom lifts. So I sewed and tied hitches trying to respect the method. · Below the larger line is eye splices at the bottom about the height of the gaff, then a double smaller line is run through the fairleads under the boom and tied off. This hitching is the adjustment. Ok I am onward to the foremast Cheers jon

-

Thanks Keith I really liked your use of black construction paper for the photo in your build log. It was really clear. I am making a new foresail and will focus first on clew and head attachment up grades. I shall then relash new sail to spars and reset using your diagram to the hoops. Cheers. Jon

-

Keith I love the photo of the small triangular"fisherman staysail" instead of the top sail you posted. Looking at the images in your following post it is clear of what you are saying to be a challenge. It would be possible for a clewline to raise the topsail tack up above the Maine head stay, but unrealistic. I would guess it would be better with a continuous halyard (like a fisherman staysail) then drop a raise the topsail when tacking as they did a fisherman sail? I am not saying any of this with authority. I am only an interested student. We are off to eat too much turkey today Thanksgiving. Enjoy the season. Cheers Jon

-

Kieth Thanks for this diagram. As you will see up coming, I need to replace the foresail. My lacing of the hoops was a little different. I will definitely use this when I put on the new foresail. Regards Jon

-

what a fun build. The beautiful image in your first photo is one of the reasons I live here in Maine. I follow your process all the way until the magic shows up and you rebuilt is all inside the bottle....just amazes me how you do that. Thank you for sharing. jon

- 5 replies

-

- lobster boat

- bottle

-

(and 1 more)

Tagged with:

-

hi Keith the blocks come for the Bluejacket company site. They are a long time modelship company here in Maine and sponsor of NRG. I use them because in the large scale and need to able to sail they work well, as I can do things like relocate back stays, and the lines run through them reasonably. Also for the use of attachment both of strop or becket they have strength. cheers

-

Upgrade the main boom This step is a bit complicated and I will make at least two postings. I am finding my way through fog a bi,t but that is appropriate for grand bank fishing vessels. The first post is to share the research, show some options and share the first fix I completed. I keep wondering if the information regarding BN ll is really applicable? While there in Lunenburg, the captain confirmed a few changes in rigging from the original, I pointed out to him as coast guard requirements. I believe there are a few more involved with the main boom. So, I share my thought process below with photos: · Here we look up at the main sail and see three systems of boom lifts · Looking aft we see the forward lift then the midpoint lift is banded aft of the main sheet bale and the end lift is at the boom end. · Looking up at the dock side we see all three boom lifts and the lazy jacks as well as the peak halyards. Lots of lines, not seen on BN photos · Here is a detail of the forward lift. I beleive this is new but so far have added it to the model. · Here we see Bluenose sailing from a NS achieve file. There is a mid-point lift near the sheet bale. There is no forward lift and I don’t see the end boom lift. Most schooners had them, the captain told me the original had one. The Eisnor plans do not show any other but what is in this photo… That raises the hard question. I am still struggling with final solution for my model but have several other items we can do. · Here we see the boom tackle being made to a large wood cleat on the boom, not the jaw pin as on four masted schooners and other boats. · Here we see the attachment method that makes good sense for the lazy jacks. Simply sewing will do here. · Here we see a detail of the metal work for both the main sheet bale and mid boom lift. Note here the lift is clearly just aft of the sheet bale. It also highlights the choice made on BN ll to use all bright work on the blocks and blacken all the metal work. · He we see a conflict. This old NS archive photo shows the two lift bales. One next to the man’s hat just has two lines going straight up like a lazy jack. The other over the skipper’s head is clearly the large midpoint lift. · Here is a ns archive photo take in 1940 survey, post fishing. There is no evidence of lazy jacks and the boom lift is back just forward of the bale. Therefore, we see that this band was moved around by different skippers. · This blow up of the ns archive photo just confirms the lift band was not aft of the main sheet. So like my model, the foot ropes come to the sheet bale. My sheet bale needed to be rebuilt. It was too low and used ugly tabs for the foot ropes. I also need to use more real bolts at this scale when they are right. I found the 00-90 bolts perfect for the this. · To build the bale I use 14-gauge electrical wire. It is nicely annealed and takes a 1-72 die easily · Here we are in place with better connections to the foot rope. You can see I have currently placed the boom lift band forward of the main sheet. some more paint to get that galvanized look is next · And here is the cable becket looped blocks taking the mid boom lift as rigged on BN ll. Sure hope I am right but now I have committed to following Jensen drawings except where I clearly know there is a change. All for now Cheers jon

-

Thanks Keith We celebrated Beaujolais nouveau last night, so I am good for another day. For me it is rebuilding main sheet bale and lazy Jack's. Here is an area where bn and bn ll don't agree. Maybe the new wine will age as I try to solve this one. Cheers

-

Keith I continue to be inspired by the clean and crisp imagery of your build. Now watching you go through figuring out how the rigging works I love it even more. One of your comments was about tacking the topsail. I have read several different approaches. The 4 masted schooners used clew lines to gather up for top mast furling. It was thus a two step partial raising by clew line and the tack lines p&s transferred to allow tacking across the spring stays, lower gaffs and peak halyards etc. Bluenose has clew lines but the stories tell of a brave crew member staying aloft to pull the sail over and transfer the tack line while racing. If the topsail is raised from the deck . Perhaps having a double tack line would be enough to pull the sail up and let it flow over. Perhaps a lighter traveler line could have been rigged to pull up the tack ( opposite action of the jib down hauls) Anyway I love learning more about how these boats worked. And I love learning from logs like yours Thanks for sharing Jon

-

Fix the main boom lashing Now that I have the main boom available for my thumbs, I needed to remove the spiral lashing. Let’s see how it went. · Here we see an image of Bluenose ll main boom under sail. This is the image that I am trying for. A few exceptions however, as I have figured out this rigging is not identical to the original Bluenose. The lashing looks right however, so that is step one. · Here is a detail and it shows the lashes wrap under to a square knot and the ends then tuck through a single strand of the line on either side. You can also see the outer topping lift line passing forward to the pin on the port side jaw. Please remember this image when we move to lazy jacks. · Here the boom tackle gets tied up to avoid sagging. · Here you see on the model I had fixed the first lashes aft of the main sheet bale. · Here is the needle tucking the end through. Most lay perfectly parallel but some are stubborn. Wax helped, though I fear more fabric glue will do the trick. · Here is a challenge. Like previous models I had staggered the jaw holes. That is wrong, and I shall plug them and align them as I go. · Here we are with the lashing done and the mast re-stepped. Oh for the breakage…..chuckle Remember the little top mast extension. I chose not to stress either dowel or mast by using a brass pin. I used a tooth pick to pin it so that the tooth pick would be the weak link. I was right; even the weight of the light strings and the waving around was enough to break the tooth pick. So far so good. when i was moving the whole boat for cleaning up and the camera hit the for stays, this tooth pick broke again. It might be too weak a link, and I need to think about it, perhaps plastic tooth pick. For now though it's easy to fix and it causes no mast damage.[ I do not glue this connection] cheers jon

-

thanks Patrick It is hard though on the great fall days to blow leaves , set up firewood and come inside and be careful. oh well it is all fun cheers

-

Thank you all for your concerns regarding going back together after demasting. Before I posted the demasting, I completed several upgrades on the boom , installed what I call the mast boot and put her back. It works; yes with some breakage and other issues I shall share. It definitely is not for once a week but may let me set the detailed lines and things aside and then add simple masts and sails just for sailing. More on that as I work it through. At least I can transport her to the Owls Head Museum show next march, and now have a scheme to let her sail if only once. i chuckle to see insanity listed above as a suggestion of my mixing scale with sail. I am using a new word...analidity to describe some of my plans. But that is what this is all about. Anyway, each time I move stuff, something breaks. Today the camera tripod fell on the bow sprit and broke a clip holding stays. Fortunately the 'sailable' bottle style turnbuckles are strong and the replacement was a simple brass founding. anyway I am struggling on a few things today [ remaking the main sheet bands to be correct] and hope to update in a day or so. I plan to remove the foremast next week. cheers jond

-

Take out masts I had an epiphany. If I improve the bolts on the chain plates and critical shackles, I could remove: · 20 bolts on shrouds · Three turn buckles on stays · Three sheets [ add bolts in shackles] · Cross stays above [ add bolts in shackles] · Jumbo boom gooseneck figure it out add bolt · Back stays two lines and deck blocks for each mast · Halyards, whips, boom lifts etc . say 20 lines now 30 lines later In maybe an hour or so I could remove the masts. I am not sure where this is going, but just to make some improvements on my current lists I need to get the masts out, so let’s try it. this could have been a big oops let's see how it went. I ordered more small bolts. i chose the 0-80 as they are a little more robust and if they are going to come out and go back that is important. I had snipped them to length. That crossed up the threads to help keep the nut in place, but that prohibits re-threading. In this photo you see I am trying new bolts at the right length. First on the left shroud is a new 1/4 in bolt...too short. The right shroud has a 3/8 bolt...too long Oh well I should have known no standard sizes would work here. Now i have two more bags of mini bolts. Here I have filed and chased the threads with a die so the right length bolt is ready to go Here i demonstrate the use of two mini bolt sockets that make this a reasonable option, especially if this is to be done and redone. You can see the black paint falls away from the brass, but that's no big deal as I am constantly going to be touching up if i choose to move this thing. here the first set is off and bolts saved in the plastic cup. yippee! I normally end up on the floor looking for that errant nut. Here I have untied and grabbed all the lines tight to the mast. simple masking tape to hold things from getting too messy. Now lets start working on upgrading those sheet blocks to see where a simple nut and bolt is all that is needed to disconnect. this is 0-90 bolt. Here is better view to the spaghetti taped to the mast. wish me luck on this one please. Now for all those cross braces. i like the idea of upgrading these shackles and ties through the bales to 0-90 bolts and nuts. I continue to use copper instead of brass for the bales because as here , I effectively chase threads into the copper as I install the bolt the first time. I suppose i could tab a bent loop if it were brass, but I find it too difficult to bend the brass as it is not fully annealed. Since I am painting it I currently stay with the copper. Well here we are finally ready.....Shall we lift the mast???? It came out...we'll discuss what happened when it's time to restep. not too serious, and if we made it, we should be able to fix it right?? cheers Jon

-

Nils i thank you for dropping in. You are just in time to here about my new idea of what to do with a model that is 7 feet long, six feet high etc. stand by jon

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.