-

Posts

907 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drtrap

-

Now, it's time for the foot ropes... Jason, finaly did you go with four or six stirrups per yard? Thank you. Merry Christmas to everybody!!

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Jim, it was a really great experience to have almost done the main yard. Go ahed for the parrals!!

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

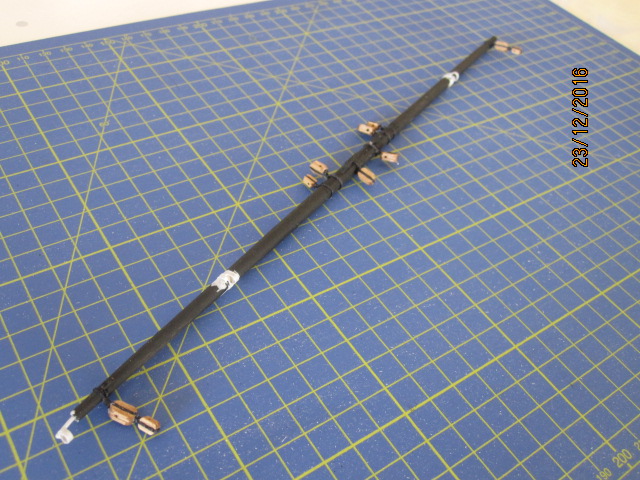

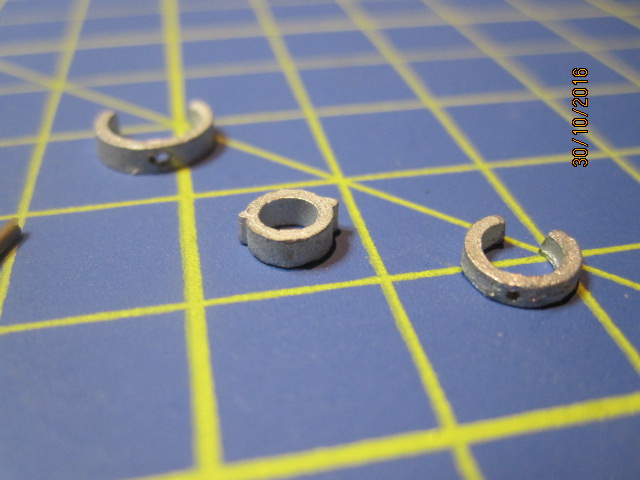

That's my 1st (main) yard with its boomsail irons in place. I'm quite satisfied witht the initial results. Thank you. PS: The 3mm dowel is just a guide for the right placement of all the irons. A 45 degrees inclination is required.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

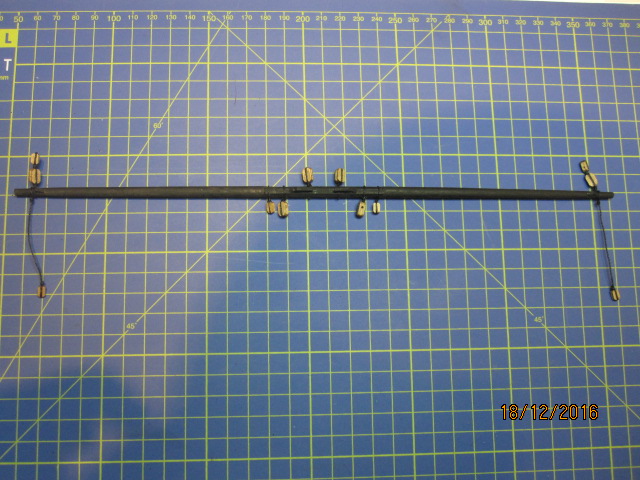

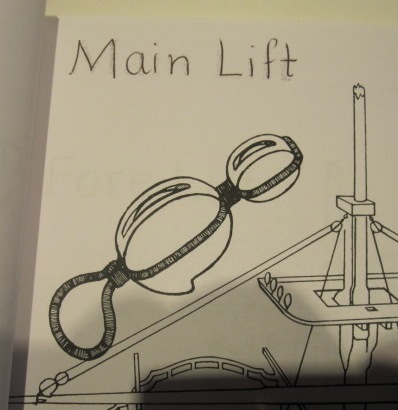

This is my personal point of view for the double blocks of 5 and 7 mm at each edge of the main yard...

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

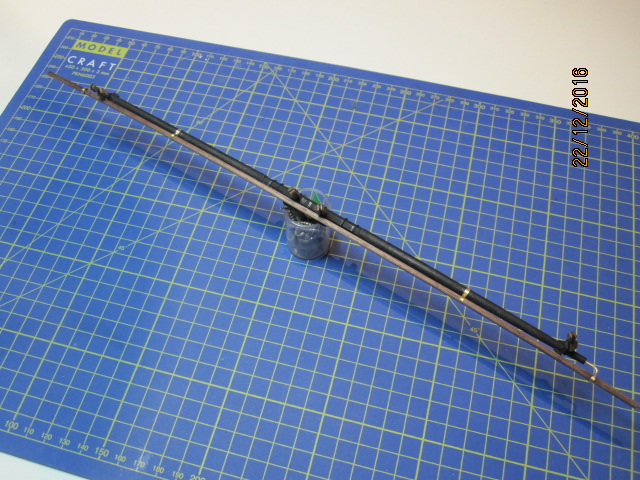

Jason, Mort Thank you my friends, I do appreciate so much your assistance. In the meantime, the yards-factory is running..

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

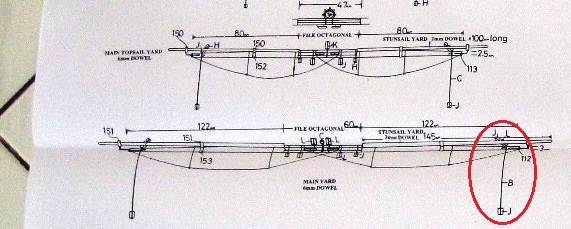

...any help for the J-L-B-J block-complex guys? I can't find any tip... Thanks again.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Snake-partners May I ask you about those J-L-B-J fittings..... those are two seperate sets of fittings/ropes or a single one with all the blocks included? Any idea or tutorial on how to deal with them? Thank you in advance!! Stergios

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi everybody the yards factory has started. Thinking to go with the blocks first and to continue with the foot ropes. I'll leave the section of the irons for the final stage. I hope to have your agreement on those steps. Thanks PS: The main yard with its marked blocks-ropes and irons attachments. I'm thinking to fix three foot ropes at each half yard at a distance of 2,5 cm.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Frank and thanks for the comment. Those are just two dowels dummies just to stimulate in practice yard's and stunsail's assembly. The real dowels are in a safe place!...

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

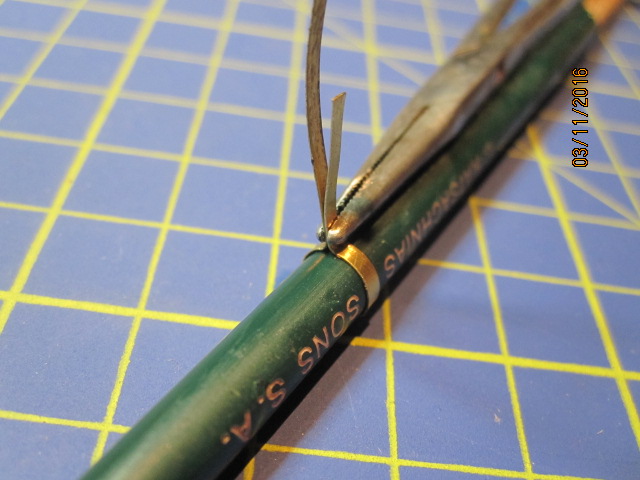

That;s my final approach for the yards stunsail boom irons. Of course the fittings of these pics are unpainted and in need of touch up... Thanks.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you Jason. I know that you follow the whole literature regarding the rigging and the other procedures. have you any idea about the distance "x" between the yards and stunsail boom? I think to go with the second method (no space between them) to fit the irons. Cheers.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

My main concern is about the strength of those 0,3mm strips against possible tension and other forces from the rest of rigging etc...?? Of course I'll stabilize the yards to the masts using 1,5mm brass wire.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

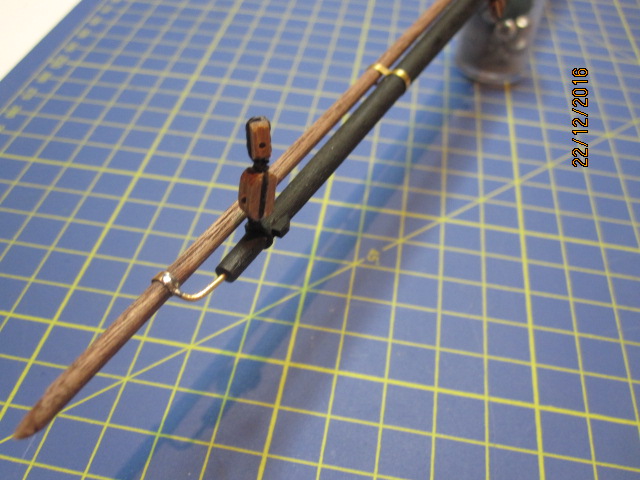

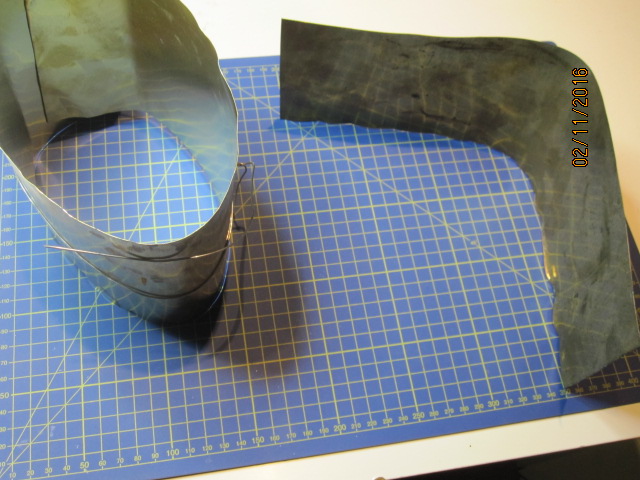

The second method is by calculating the distance of every circle for the iron using the yard diameter and the rule of "3,14"... Here without space or distance between the yard and stunsail dummies... The iron for the yard first using clockwise turn I've used a tape to stabilize the two dowels how you see Here is the counterclockwise turn for the iron of the stunsail, from a posterior view And the anterior view Thank you for your comments in advance, just to help me how to proceed.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I'm quite satisfied from my first attempts to stimulate the boom irons. This is my 1st cut strip of 22mm to stimulate the irons. I've tried two methods just to see wha's the best for me in practise... I'm showing you the consecutive steps of the first one. I think that these steps is easy do be understood. Making the iron of the yard dummy and after that the respective one for the stunsail dummy Taken from another angle... Could you tell me what;s the indicative best distance "x" between the red lines, for my Snake?? Another pic And here you are the preliminary result.. Of course in need for iron soldering

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Finally I bought those copper sheets of 0,3mm and 0,5mm. No brass sheet or strips in the area to deal with.. It;s better to handle and cut the 0,3mm using simple scissor, so tha's my choise.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you Jim for the mo I spend my time trying to find the right way for the yards boom irons.....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

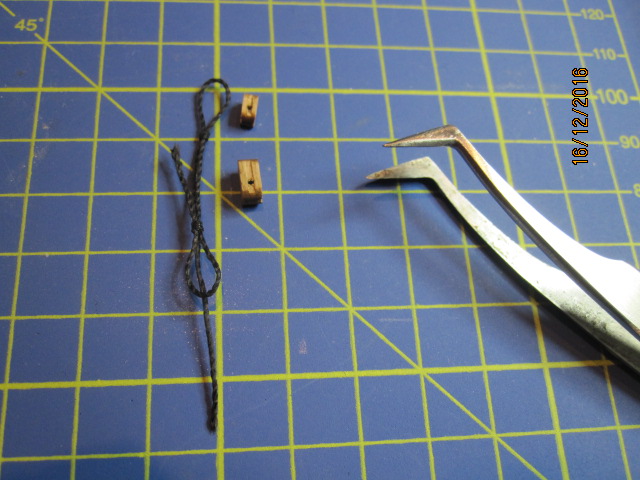

Casting parts of small and large stunsail boom rings (middle) in need for open the respective hole of 1mm

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

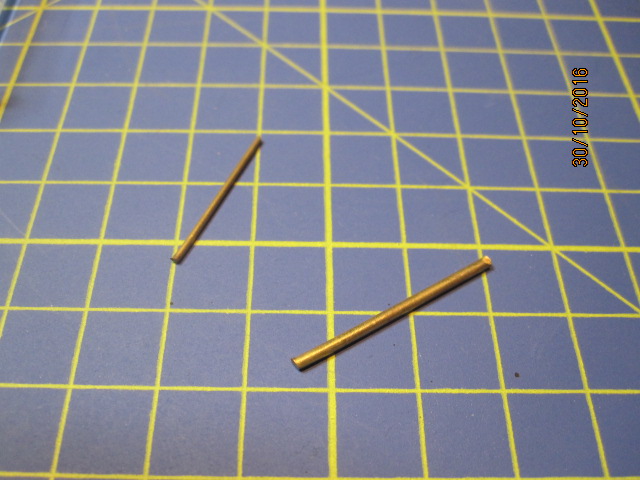

Between two options to drill a hole and pin the yards to the masts. 1mm Vs 1,5 mm wire. Thinking to use the 1,5 mm wire

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

@Jim: Thanks Jim, I'll be waiting... @Jason: by looking your #656 post I see that you decided to replace parts No 152 & 153 with styrene or thin card...

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.