-

Posts

2,876 -

Joined

-

Last visited

About AON

- Birthday November 15

Contact Methods

-

Website URL

https://mson.ca

Profile Information

-

Gender

Male

-

Location

Niagara Region, Ontario, Canada

Recent Profile Visitors

-

Thukydides reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Thukydides reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

druxey reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

druxey reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

Jared reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Jared reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

lawrence101 reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

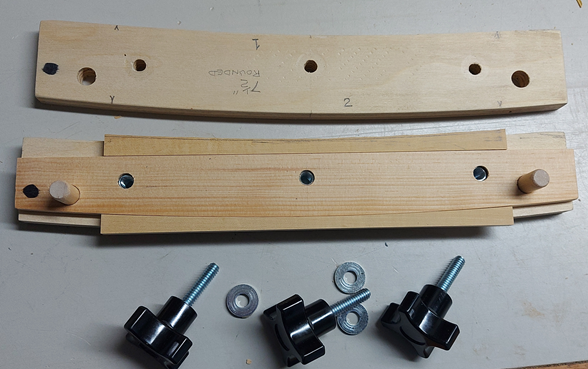

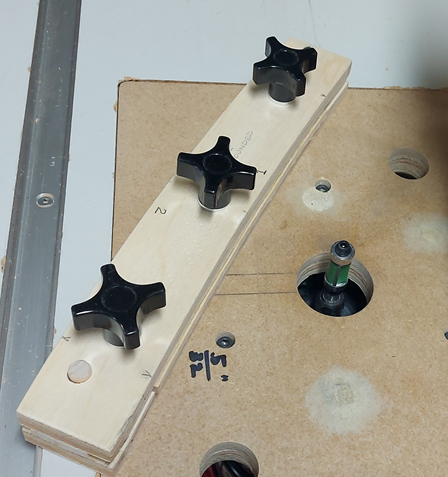

I cut all 28 upper deck beams with the jig and trim bit this afternoon. What an absolute joy! (once I got the hang of it). I inserted the rectangular blank against the flat back in the jig (position #1) and traced the concaved curve from the jig to the blank with a pencil. I removed the blank from the jig and removed the excess material on the blank to the line or very near with the oscillating disk sander. Placed the blank back into the jig and cut the blank with the trim cutter. I then moved that blank to position #2 and repeated the process but used my bench top disc sander to remove the excess from outside the convex tracing. NOTE: 1. the pencil line is by default just outside the jig face so the trim cutter need only remove that wee bit of material. 2. the jig is about 1-1/2" longer on both ends than the blanks so I can get the rollers in contact with the jig before and after the cut 3. if you don't remove the excess to or very near the line before trimming the trim cutter will tear out the blank. It is called a trim cutter, not a hogger (high volume deep cutting tool). Ask me how I know! I started with four extra blanks and now have one. Once I had the piece in position #3 I could also load position #1 so it was a little bit off an assembly line trim process.

-

AON reacted to a post in a topic:

Golden Hind by Rock_From_Korea - 1:48

AON reacted to a post in a topic:

Golden Hind by Rock_From_Korea - 1:48

-

AON reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

AON reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

-

AON reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

AON reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

-

AON reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

AON reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

AON reacted to a post in a topic:

HMS Montague 1779 by garyshipwright - 74-gun Alfred-class

AON reacted to a post in a topic:

HMS Montague 1779 by garyshipwright - 74-gun Alfred-class

-

It has been just over three weeks since my last post and I have been doing quite a bit over this time. I lost half a week due to another eye injection. This is reoccurring, every twelve weeks now. I spent a few days making a sounding board for the Library board Chairperson. They have a mallet that they rapped on the table top, they shouldn't do that, bad for the table. What I made is an oak puck shaped disk, sanded, stained and polished with beeswax. I also epoxy glued a non-skid pad to the underside so it doesn't slide off the table. The dot on top centre is a 3/8" dowel insert... like a target to aim for! I made a deck beam rounding jig (like what Mark - aka SJSoane described in his build of the Bellona) for my upper deck beams. I prepared stock for all twenty-eight beams and purchased a router trim bit from Lee Valley Tools with both an upper and lower guide roller bearing. I've had bearings fly apart and the thought of that happening and ruining my jig is not something I relish. The additional bearing will hopefully be my protection from this ever happening. I am presently awaiting delivery... I ordered two spare rollers. I also ditched the trail board carving and prepared more suitable Castello blanks for the carving. These are ready to go (glued and cured to a base board and put in the clamp). I completed the upper cheek installation (you see this when I install the trail board carvings) and am into the forward gundeck beam assembly and bowsprit step. Lots going on.

-

AON reacted to a post in a topic:

HMS Montague 1779 by garyshipwright - 74-gun Alfred-class

AON reacted to a post in a topic:

HMS Montague 1779 by garyshipwright - 74-gun Alfred-class

-

AON reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

AON reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

AON reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

AON reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

AON reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

AON reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

I find making card stock templates of items that need to nest against others a tremendous help. I also believe the hatch frame covers had lanyards attached so they wouldn't get washed overboard. If this is true you could make the cover and show it removed perched up on one corner of the frame. Maybe someone could confirm the lanyard as I cannot seem to find the source of this information. Great work BTW!

-

Good morning Mark. I want to thank you for your posting #1967 (7 Nov 2020) explaining how you made and use your deck beam jig. I am about to start re-making some upper deck beams that have a noticeable rise but my freehand method was a terrible idea (they've been torn out)... then I recalled you made a jig. It took a bit to find until I decided to do a search with "deck beam jig" and *BAM* there it was. I suspect my curved deck beams will be much better on the next run. Alan

-

HMS ANSON 1781 by albert - 1/48 - 64 guns

AON replied to albert's topic in - Build logs for subjects built 1751 - 1800

DITTO! 😉 -

Jared... something to think about but as you know David Antscherl is a member of the club and is much better at it then I might ever be! Druxey... I had a brain fart and typed boxwood instead of basswood. I've corrected the post. Thanks for catching that. My chisels are quite sharp. It was likely a flaw in the wood. I suspect I will add the foot to the piece separately. If I do it well no one should notice.

-

Hope everyone had a Merry Christmas and Happy New Year! some update pics The Taffrail has been drilled and pinned to the stern, and the counter timbers have been cut back to a proper termination level. The Griffon/Gryphon carvings are coming along but at such a small scale I wonder if I just need more practice or should I use a different wood — Castello versus boxwood basswood (Linden), as I've already lost a hind foot! I tried using rotary cutters but reverted to mini chisels. We'll have to wait and see how the head turns out! 🤔

-

Or the seal to the prop shaft is dry and tight?

- 72 replies

-

- Miss Adventure

- Model Shipways

-

(and 2 more)

Tagged with:

-

Golden Hind by Rock_From_Korea - 1:48

AON replied to Rock_From_Korea's topic in - Build logs for subjects built 1501 - 1750

They look pretty darn good to me!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.