-

Posts

7,179 -

Joined

-

Last visited

About CDW

- Birthday 04/16/1954

Profile Information

-

Gender

Male

-

Location

Tampa, Florida

-

Interests

Scale model building of all types; American and world history; science; religious studies; flight; grandchildren; travel; antique car and motorcycle restoration

Recent Profile Visitors

-

Old Collingwood reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

Old Collingwood reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

-

gsdpic reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

gsdpic reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

-

CDW reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

CDW reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

CDW reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

CDW reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

CDW reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

CDW reacted to a post in a topic:

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

-

Ferrari Dino 246gt by gsdpic - Fujimi - 1/24th scale

CDW replied to gsdpic's topic in Non-ship/categorised builds

You are going to love this kit, Gary. I built it long ago when it was offered by Testor's, and could often be found at deep discounts in big box stores such as K-Mart. I don't recall having any fit issues with it at all and it was beautiful when finished. Along with several other built models, I loaned it for display at a local hobby shop. When the owner sold the business, I lost my built models as the new owner claimed it as part of what he purchased. I do have another one in my stash. It came in two versions, one like yours and the other as a spyder with the top removed. -

Haliburton reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

Haliburton reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

-

Jack12477 reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

Jack12477 reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

mtaylor reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

mtaylor reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

Old Collingwood reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

Old Collingwood reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

gsdpic reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

gsdpic reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

Egilman reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

Egilman reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

CDW reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

CDW reacted to a post in a topic:

Sopwith Camel by gsdpic - FINISHED - Artesania Latina - 1/16th scale

-

Imperialist reacted to a post in a topic:

USS Arizona by popeye the sailor - Revell - 1:426 scale - PLASTIC

Imperialist reacted to a post in a topic:

USS Arizona by popeye the sailor - Revell - 1:426 scale - PLASTIC

-

Canute reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

Canute reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

-

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

-

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

-

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

CDW reacted to a post in a topic:

Ferrari 288 GTO Yellow by CDW - Fujimi Enthusiast Series - 1:24 Scale

-

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

-

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

-

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

CDW reacted to a post in a topic:

NASCAR Asphalt Modified Racer - Woody Pitkat by CDW - SalvinosJR - 1:25 Scale

-

Similar situations in the South. Many tracks that were once filled to capacity on weekends and Friday nights are gone. There are a few that remain but only a handful compared to earlier years. Average guys were the ones who campaigned those race cars of old. The sport has become far too expensive to keep a car on the track anymore. I had a friend we called "DLD", an acronym for dead last Danny. The fellow had a literal junk-yard on his rural property where he salvaged car parts to build his racers. I always gave him props for having the fortitude and determination to get in there and race because he rarely ever won, placed or show. Always at or near dead last. Last I heard not more than a few months ago, he's still racing. My dad was a huge racing fan. He loved auto racing, motorcycle racing, horse racing, buggy racing, trotters, you name it. If it raced, he went to see it. I was blessed to have him take me with him all the time except when he travelled out of town to races like Indy. My fondest racing memories were of the fairgrounds clay track where they raced sprint cars and motorcycles. Man, I saw some thrilling, hair-standing action with some of the best drivers on the planet for those type races. Back in that day, Offys were king in the sprint cars and midgets while Harleys ruled the motorcycle events.

-

In the past, I have seen a single, lonely tire and wheel combination lying around somewhere in my modeling areas (I have a large building and one smaller area in separate places) and I would not have thrown it away. But for now, I just cannot recall where I saw it. Eventually I will run across it again, but it may not have been this Ferrari item. Not going to sweat it, just roll with it. 🙂

-

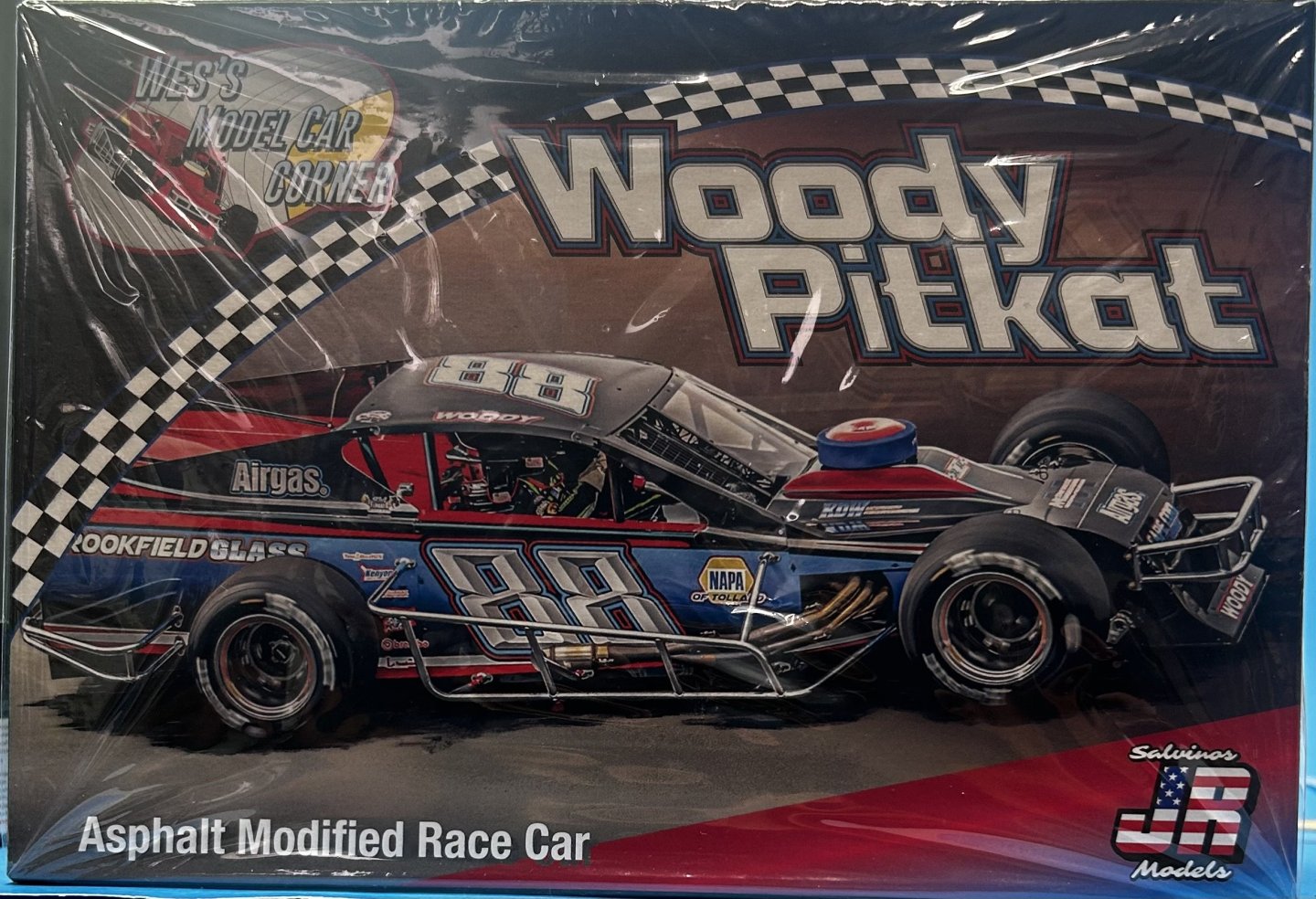

SalvinosJR is one of a few(?) companies who manufacture model kits in the USA these days, located in California. To this point their focus has been on NASCAR kits where they offer them for sale at major NASCAR events throughout the country as well as online. Recently, the kits have been finding their way into local hobby shops as well, including my local haunts. I've never been a big fan of NASCAR kits, but seeing the Asphalt Modifieds piqued my interest, so I bought one at a local shop. When I checked out the contents of the kit, I was very pleased at the quality of the model. When you pick up the box, you know it's substantial from the weight of it. Lots of plastic parts. Here is an interesting and informative video that explains the NASCAR Asphalt Modified series, it's history and the current cars racing in that division.

-

If you laugh at me for what I'm about to tell you/show you, I won't blame you one bit. I'm laughing at myself, just to keep from crying (in a metaphorical sense of course). After owning this particular kit for close to 30 years, bought it second-hand, I'm only just now realizing I'm missing one front wheel and tire. Was it missing when I bought it? Did I lose it somewhere along the way since I bought it? I have no idea, but I do know that it is gone now. Hmmmm....what to do next. I guess I'll start looking for a suitable replacement, or maybe an entire different set of wheels and tires? I'll just have to see what I can find and what's reasonable. I do know this kit has become more costly and difficult to find and it wouldn't make sense for me to buy an entire kit just to rob one tire and wheel. Sheesh. What a goofy lack of attention and consequence. Had I known this was missing, I would have never gone this far building and painting it. Or then again, maybe just display it in the Fujimi garage, with it jacked up and one tire off for repair? That could be a potential, reasonable solution.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)