-

Posts

6,135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

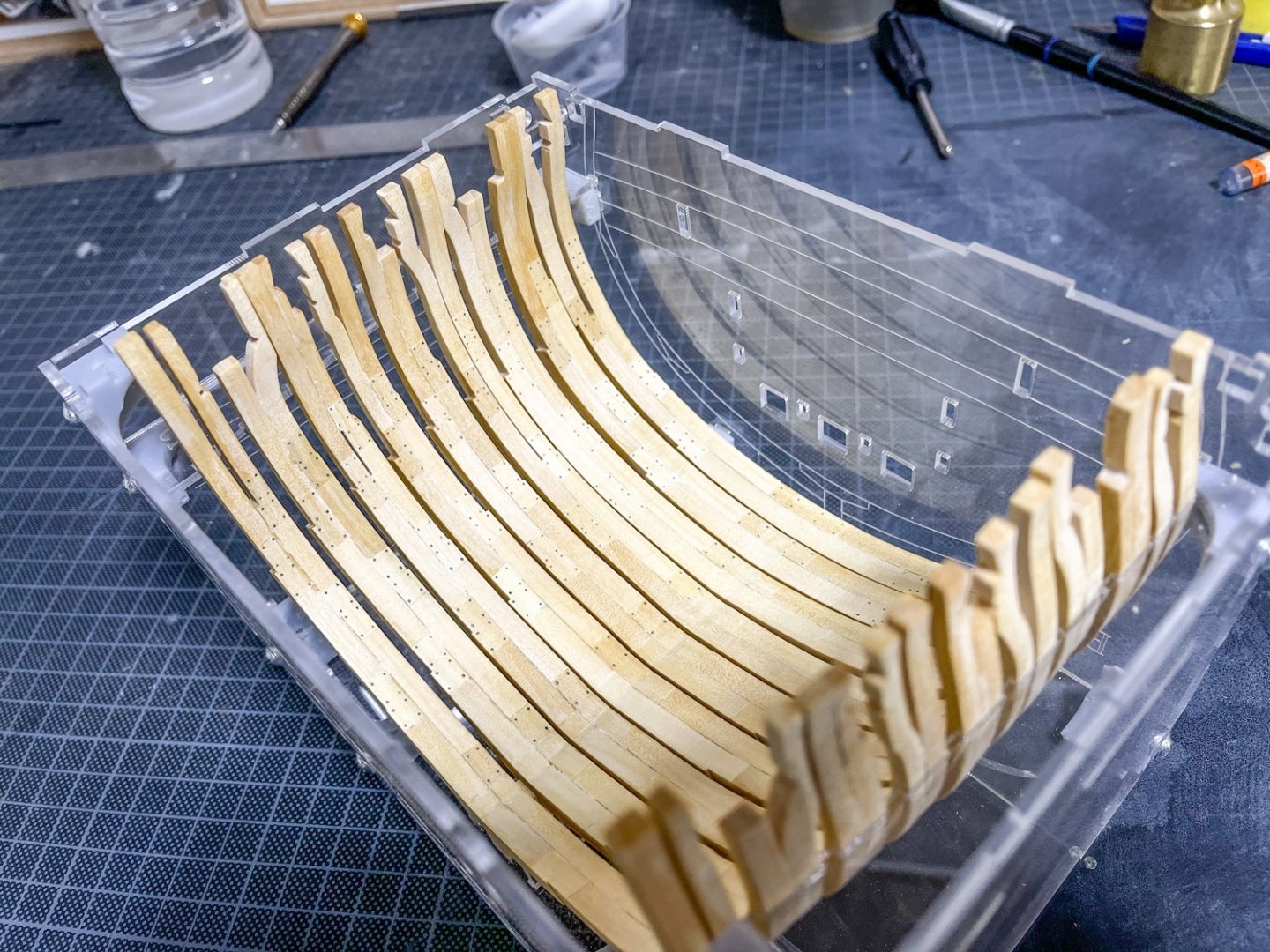

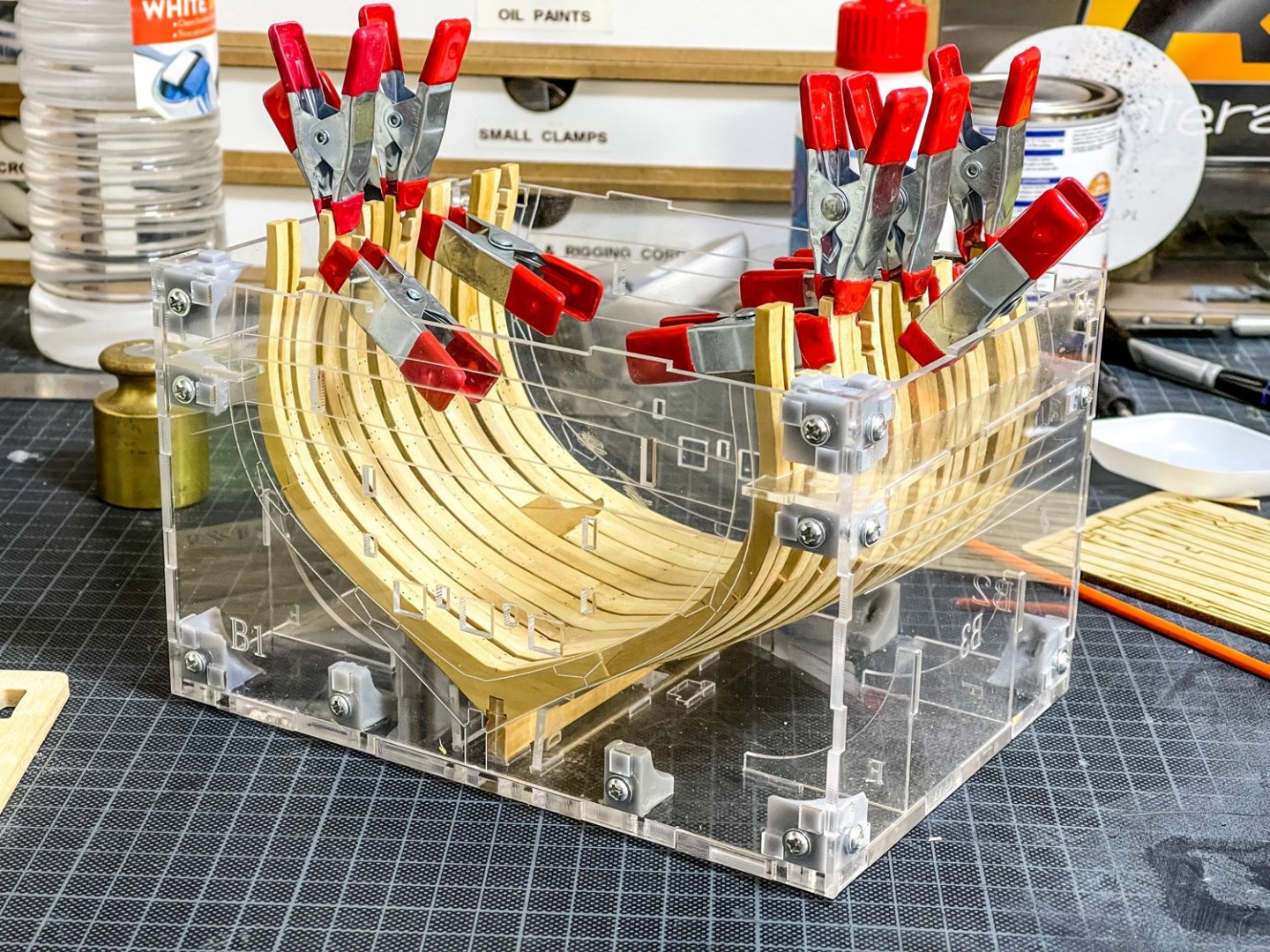

Just a quick update before I take a short break to start work on Sphinx (next week). I'll be splitting my time for this, but will glue and make a few parts while I'm waiting on Sphinx stuff to dry etc. Nonetheless, my priority is Sphinx as you'll want to see it released as soon as possible. For Granado, this is roughly where I'm currently at. On the side which will be exposed frame-wise, I added treenails. My intention was to drill and use black monofilament for these, but I got sick of breaking drill bits, trying to get inside the curve. I then decided to use a jeweller's beading tool to make an impression with a rounded head in the centre. A soft pencil was then used to colour the indent, and any excess removed with an eraser. The keel was then slotted into the jig and the double frames carefully glued onto the keel. I spent a few evenings doing this to make sure it was right and everything was level. A few slivers of wood were pushed into places to ensure an even gap between frames, whilst things dried. Clamps were used to hold the upper timbers in position against each other. The keelson is made from two parts, perfectly fitting, as seen here. I have started to build the riders and their ribs, but I've now stopped work as I highlighted an error to Tom at CAF. The side floor timbers are supposed to be slotted on the underside. This is because some of the internal timbers run through those slots, and they are needed so those planks can be located in the hull. Those timbers are missing those slots, and Tom is now aware and remaking those to send out to customers. I have, however, glued the keelson into the hull, and you'll see that image next time.

- 16 replies

-

I think the Vespucci was the kit I always longed for when I first started, and it passed me by. Nice to see this progressing.

- 273 replies

-

- panart

- amerigo vespucci

-

(and 1 more)

Tagged with:

-

Those particular marks are to bevel the chock area, but I never bothered with angling those sockets to fit the chocks in at an angle. I couldn't see any gain for the effort. Also, the chocks are the same thickness as the other timbers, so angling them will cause at least one area to be lower than the proper surface when fitted, as I found out when I did them on frame #6. You'll also note the joints between timbers are shown angled. They aren't. I just fit them as simple horizontal joints. Nice to see someone else working on this one too, and your second post on MSW in 8yrs! 😜

- 3 replies

-

- HMS Granado

- cross-section

-

(and 1 more)

Tagged with:

-

Wow, you sure this is your first ship model? She really is looking very nice, and I'll follow along. I know what you mean about CD instructions. My MacBook Pro doesn't even have a CD, and if it did, I wouldn't have it lounging around in a dusty workshop.

- 43 replies

-

- Bluenose II

- Artesania Latina

-

(and 2 more)

Tagged with:

-

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 48: MOUNTING BOX AND MAIN SWITCH Another switch! This time a toggle for the car's on/off circuit. This pushes into place as seen here and a clip/screw used to secure it. The switch took a little effort to seat evenly. The mounting box is now fitted with pipes and the united screwed into position on the underside of the car. A little lid is also supplied. No surprise that this is where the batteries for the electronics will eventually fit. Last up is another cable management clip that helps to hold down the cable that I originally taped down for safety. That's it for another month! -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 47: ACCELERATOR PEDAL & SWITCH, BRAKE PEDAL & SWITCH, CLUTCH PEDAL, FLOOR PLATE The pedal floor plate just pushes into position on top of the driver's floor mat, and then the accelerator, brake and clutch pedals are fitted as seen with screws from the reverse. Microswitch assemblies are now fitted for two of the pedals. A switch is just pushed into a holder and the holder screwed to the cockpit reverse. A quick test of the switches with the pedals shows a positive action. No problems there! Cable management clips are now used to route the cables along the underside. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 46: GEAR LEVER, HANDBRAKE AND U-BAR This simple pack adds the hand brake and gear levers, plus the console u-bar. The hand brake just pushes into the side of the interior while the remainder screw into place from underneath. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 45: COCKPIT REAR WALL Same for the cockpit rear wall that is now carefully offered up to the cockpit interior and secured with four more screws. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 44: RIGHT FLOOR SECTION AND FLOOR MATS More delicate interior work now that I try so hard not to touch with my fingers! The passenger and driver floor mat just push neatly into position. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 43: CENTER CONSOLE AND LEFT FLOOR SECTION Some internal work I always find these a little hard to photograph as they are so black and have a velvet texture to them which can be easily marked with just touching. I find a piece of de-tacked tape is useful for removing any skin flakes or stray fibres/hairs from the surface. The two main sections are screwed together as shown and a cable clip fitted into position on the underside. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 42: DASHBOARD DIALS AND SWITCH More dashboard goodness now as the dial stickers are affixed to the holding plate. The clear lenses board is now pushed into position on the rear of the chrome surround. Then the dial faces holder is sat on top of this, behind the lenses board. Remember the free-floating switch? This is what it operates. A microswitch is pushed into position in the dial holding plate, and this fitted to the dials assembly I just made, before being fitted to the rear of the instrument panel using three screws. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

Pack 6 Hot on the heels of the last pack come this next one which looks at building up some of the driver's office. STAGE 41: DASHBORD SWITCHES AND STEERING ROD GUIDE Definitely one for those detail freaks 😁 First, dashboard plates 1 & 2 are pushed into place. I actually used a little CA on #2 as it was a little sloppy. Plate #3 is then pushed into place and secured by a screw from behind. Just look at the detail on that 🤗 Now, the steering rod guide is screwed into position from the rear, A number of injection moulded switches and knobs are added, some of them printed with details. These look excellent. one of these is quite clearly for a switch as it's left free-floating. -

What a nice job. Looks super smooth too. You can sort of get away with a few plank marks on a wooden hull, but not a Vaporetto. 👍 Can't get Plastikote? Never heard of Amazon Prime? 😆 If I'd thought about it, I had a spare here you could've had.

- 54 replies

-

Beautiful! Your effort sure paid off. Such lovely lines too. I know what my missus would say to me if I asked her to sew my sails 🤣 Also told Amati's FB admin too.

-

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 40: FRONT FENDER LINERS & AIRFLOW INTAKE PANEL Two screws hold each fender liner to the silver floor base sections, and another screw holds each to the metal chassis making everything very rigid. The car is then flipped over and the airflow intake panel in place before flipping over the correct way and adding two final screws. As I have Pack 6, I'll post this real soon, and it looks another wonderful project! -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 38 and 39: FRONT LEFT/RIGHT CONTROL ARMS It's now the turn of the front suspension to be completed so the front wheels can be fitted. Again, pins are used throughout to hold everything together while allowing the various joints to move about. The wheel can now be slipped onto the connecting rod, and then a serrated pin used to lock the rod to the control arm. This was done for both left and right wheels. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 34, 35, 37 and 37 (WHEELS!) These built up exactly as the front wheels, just four screws per rim. You definitely need to soak those tyres in just-boiled water for 5 mins to make it pliable enough to pull around the rim. The fit is superb! Both rear wheels are built over these stages. A single screw is now used to fit the wheels to the rear of the car. These were done one after the other so I wasn't putting any stresses on anything for too long. When attaching the wheels, the fins on the brake unit need to fit into the slots in the rear rim. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 33: REAR FLOOR PANEL The rear floor panel drops into place as shown and is secured by six screws. Two of these secure the floating driveshaft bracket securely in place giving that area some needed rigidity. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

PACK 5 I have to say Pack 5 went together very quickly and was a very satisfying project. For me, this one is miles ahead of the beautiful GT500 I'm also building due to all the metal parts and general construction. STAGE 32: REAR RIGHT LOWER CONTROL ARM In this stage, we can continue with the suspension stuff that was built in the last pack, and tie some of those literal loose ends up. All of the parts in this are held together with serrated end pins that are pushed home with pointed pliers. The wheel hub built in the last pack can also now be attached. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

https://www.agoramodels.com

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.