-

Posts

6,145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

She's so so pretty! Hope you'll add the completed photos to gallery.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

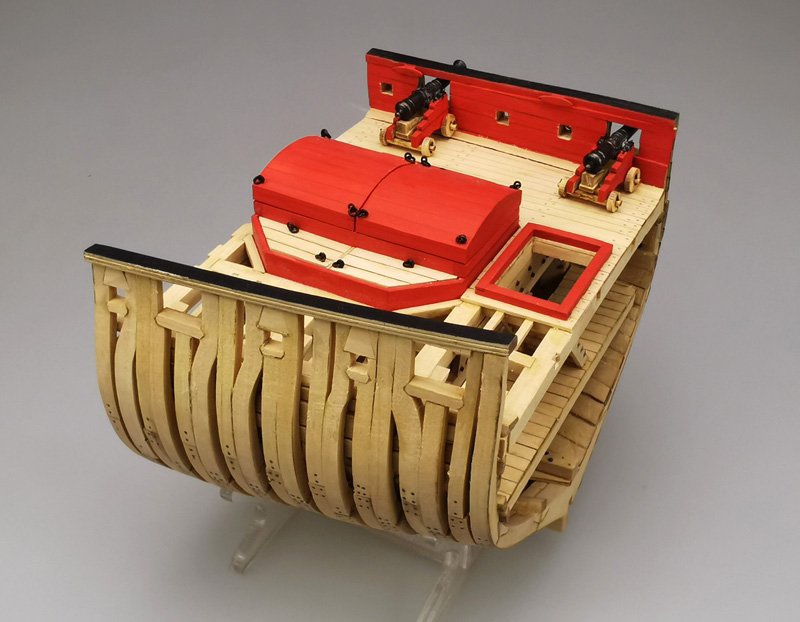

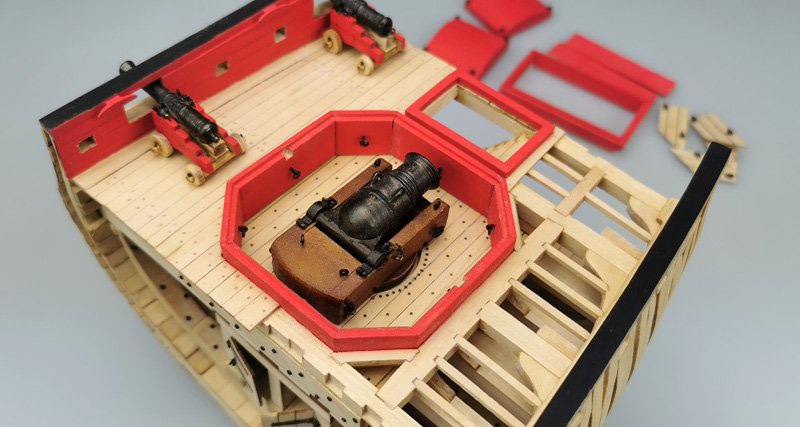

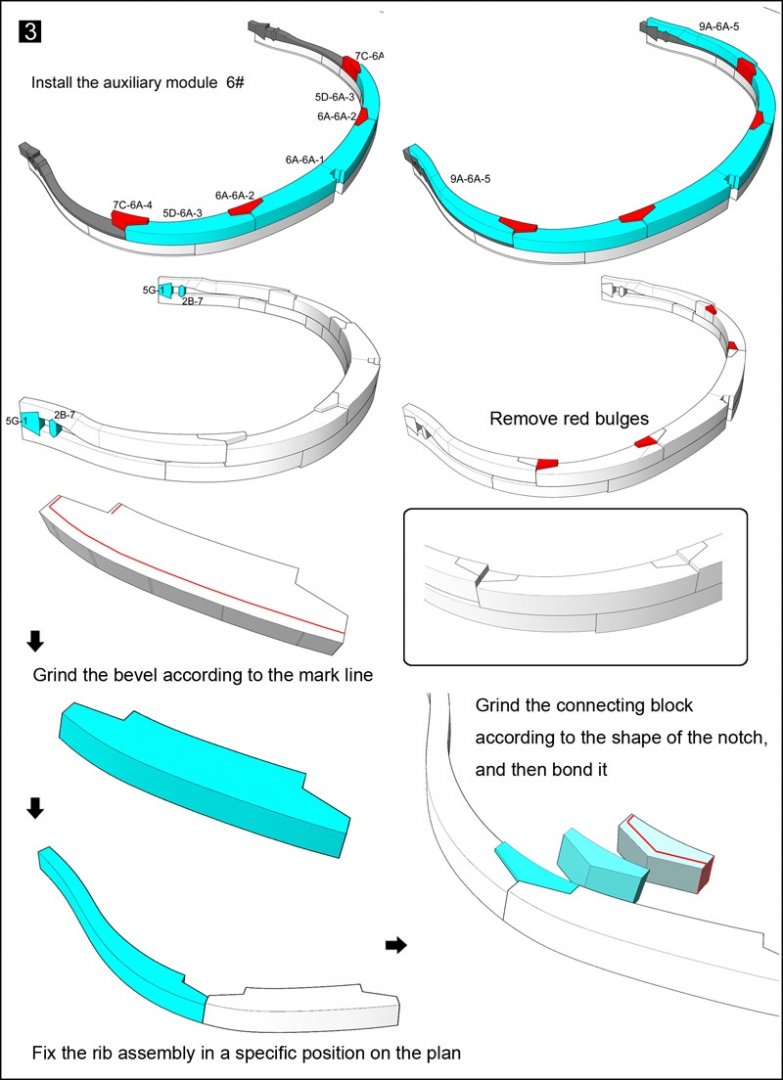

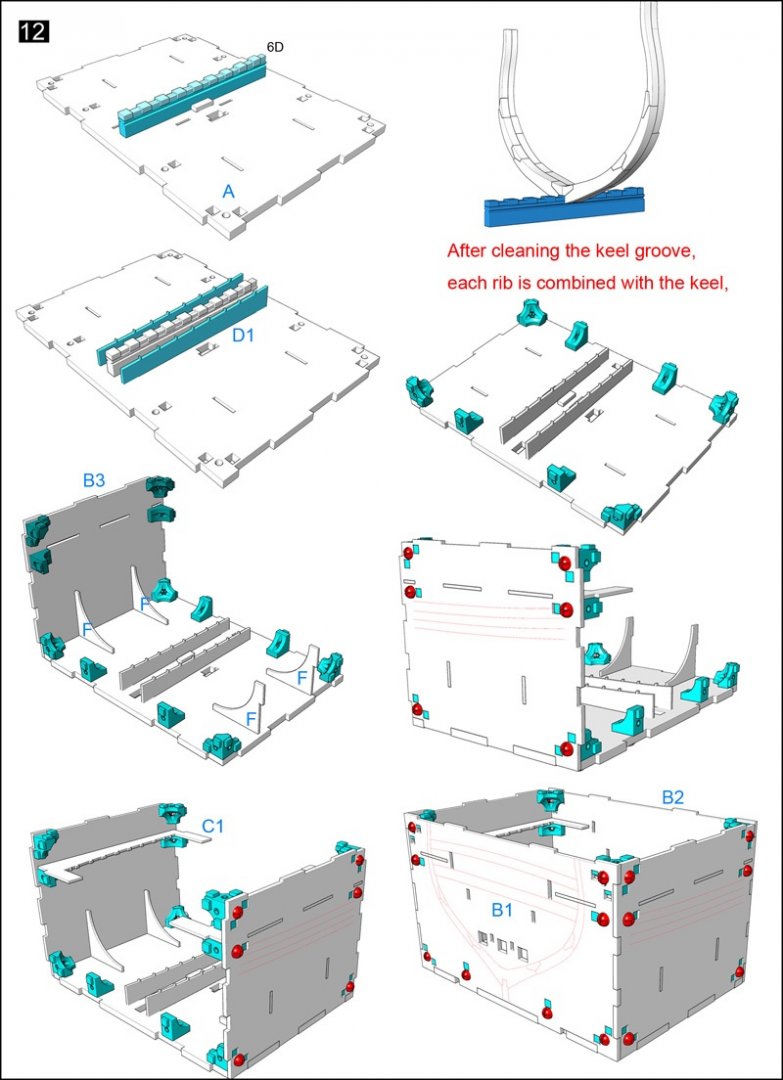

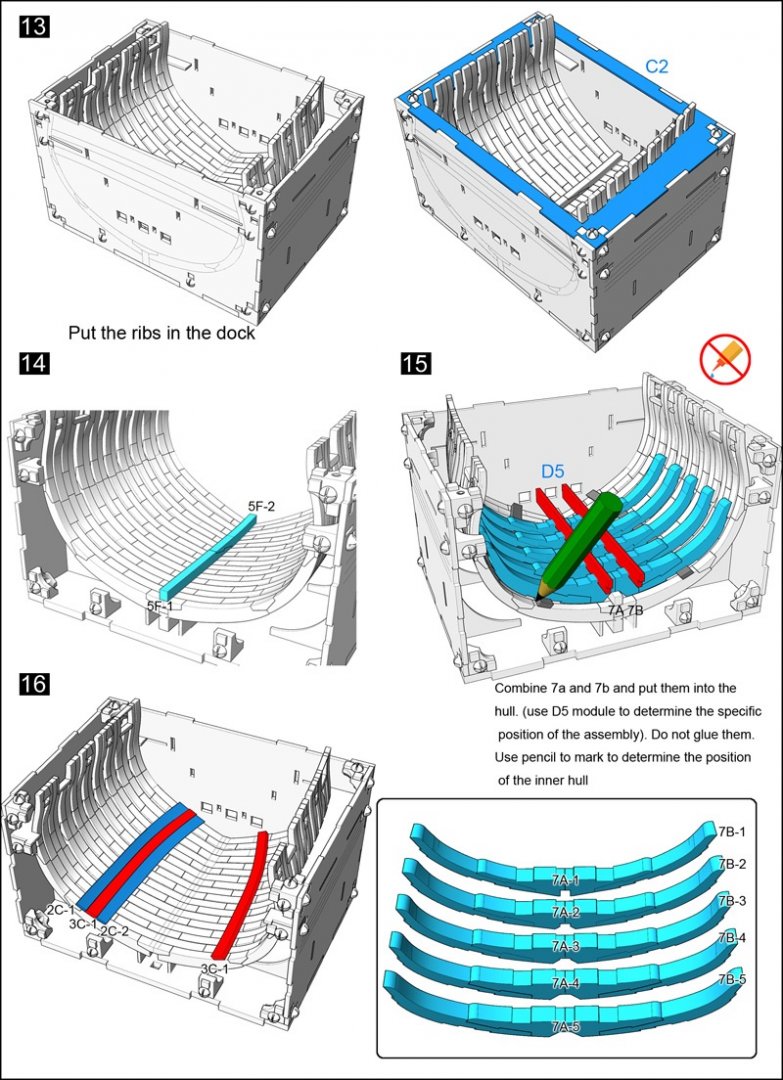

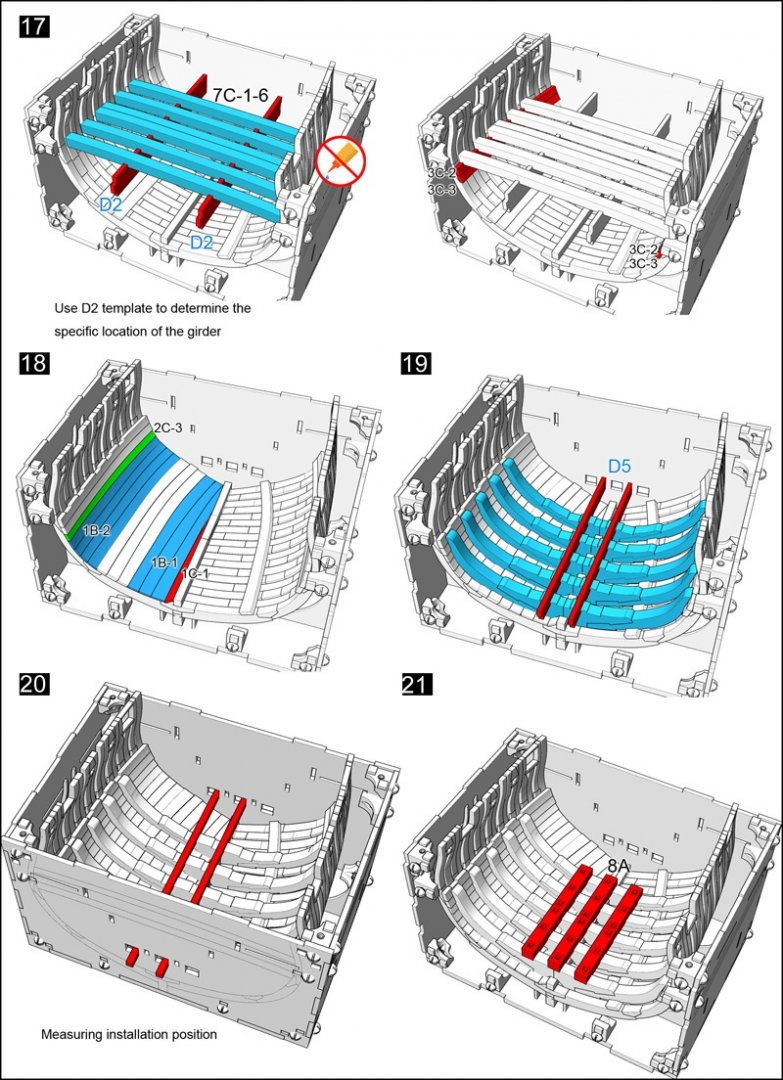

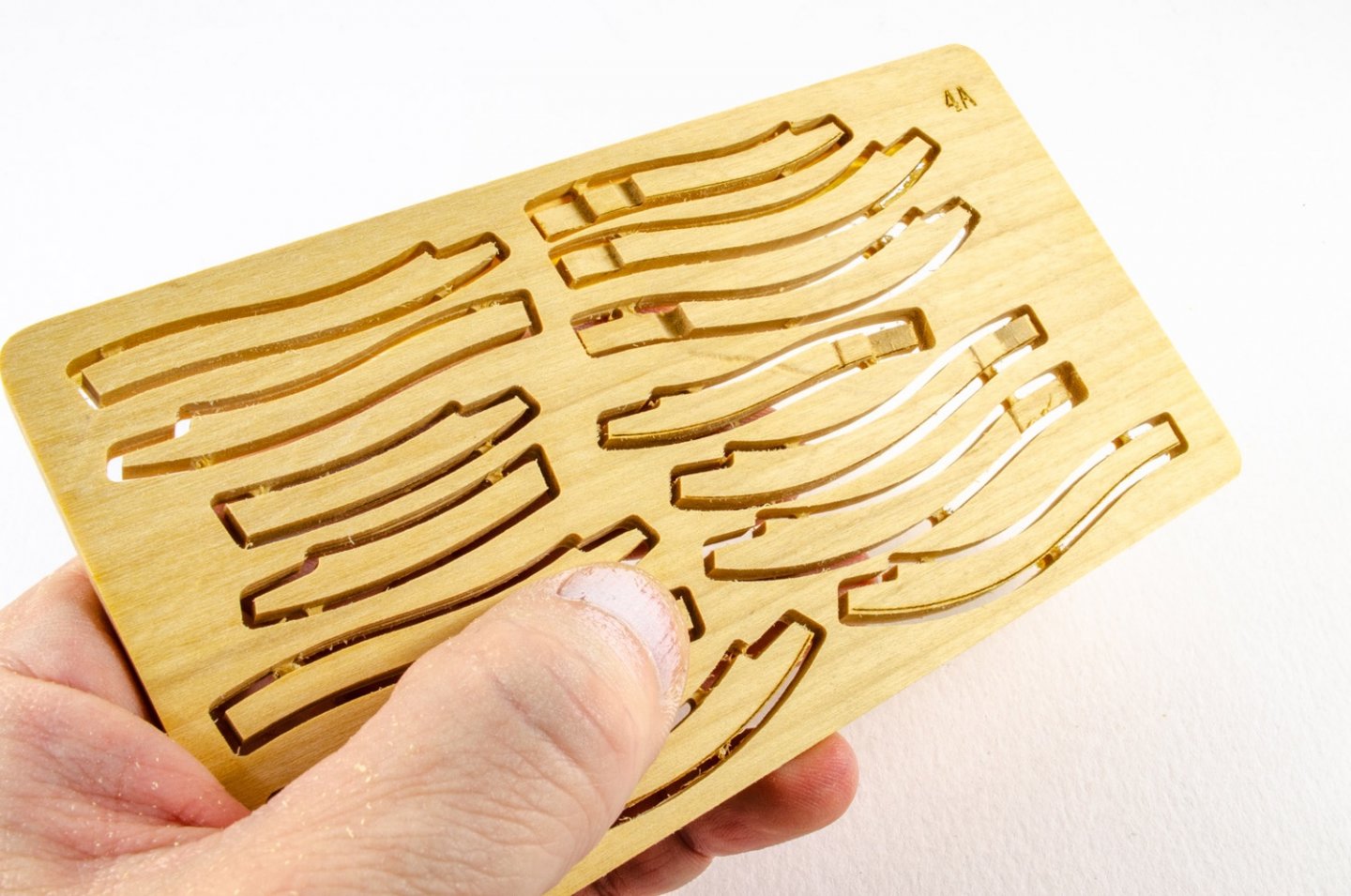

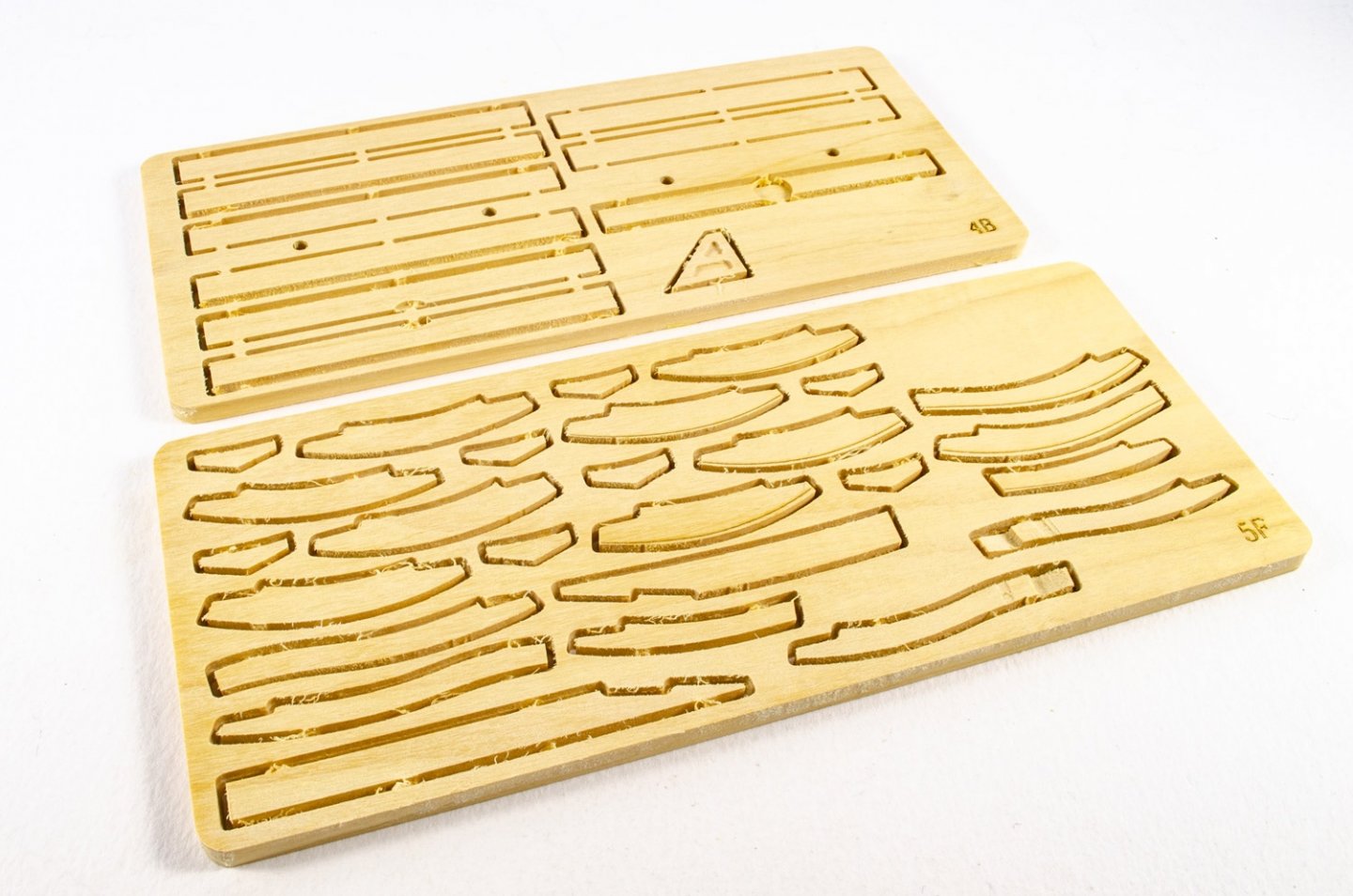

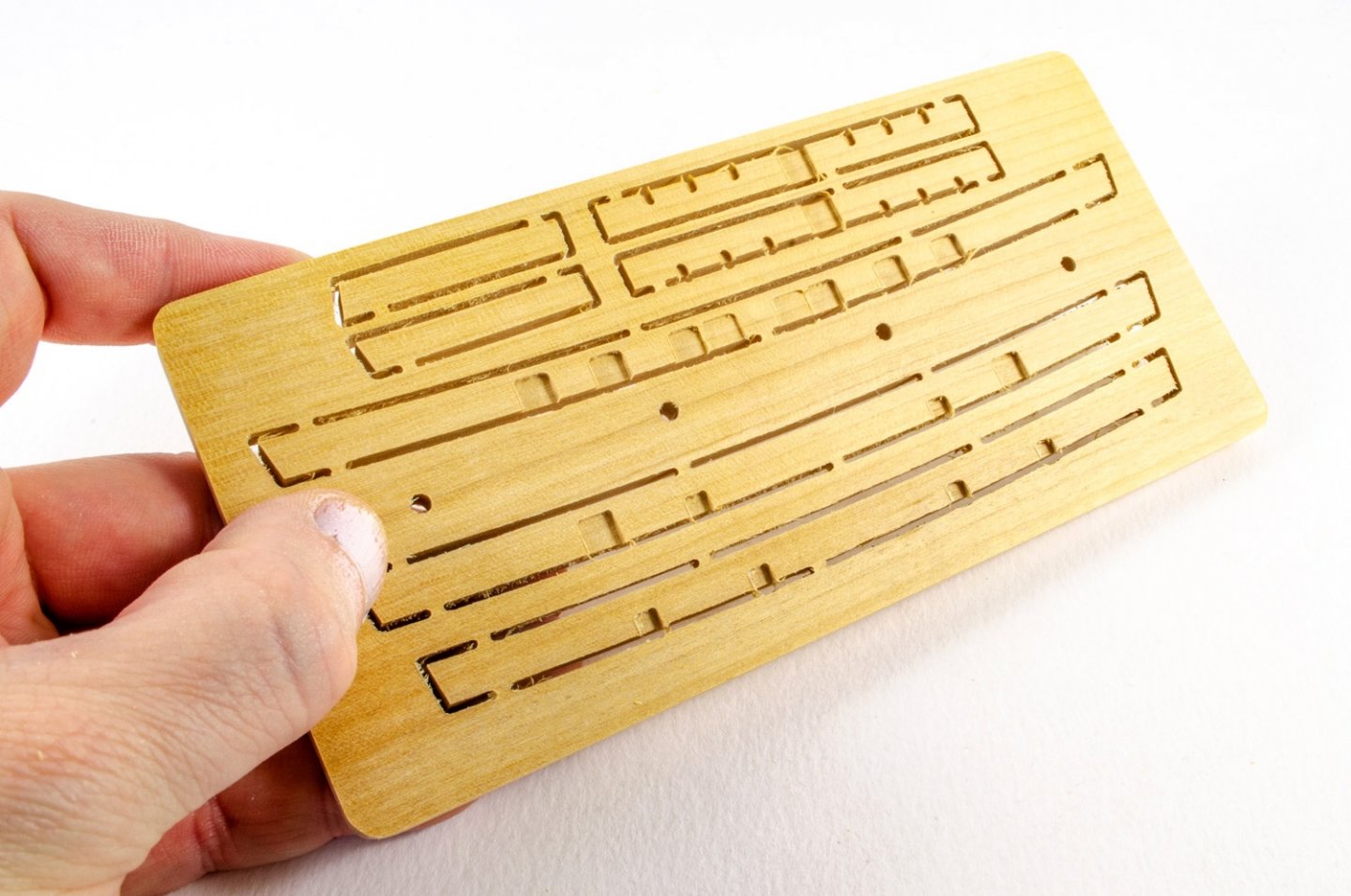

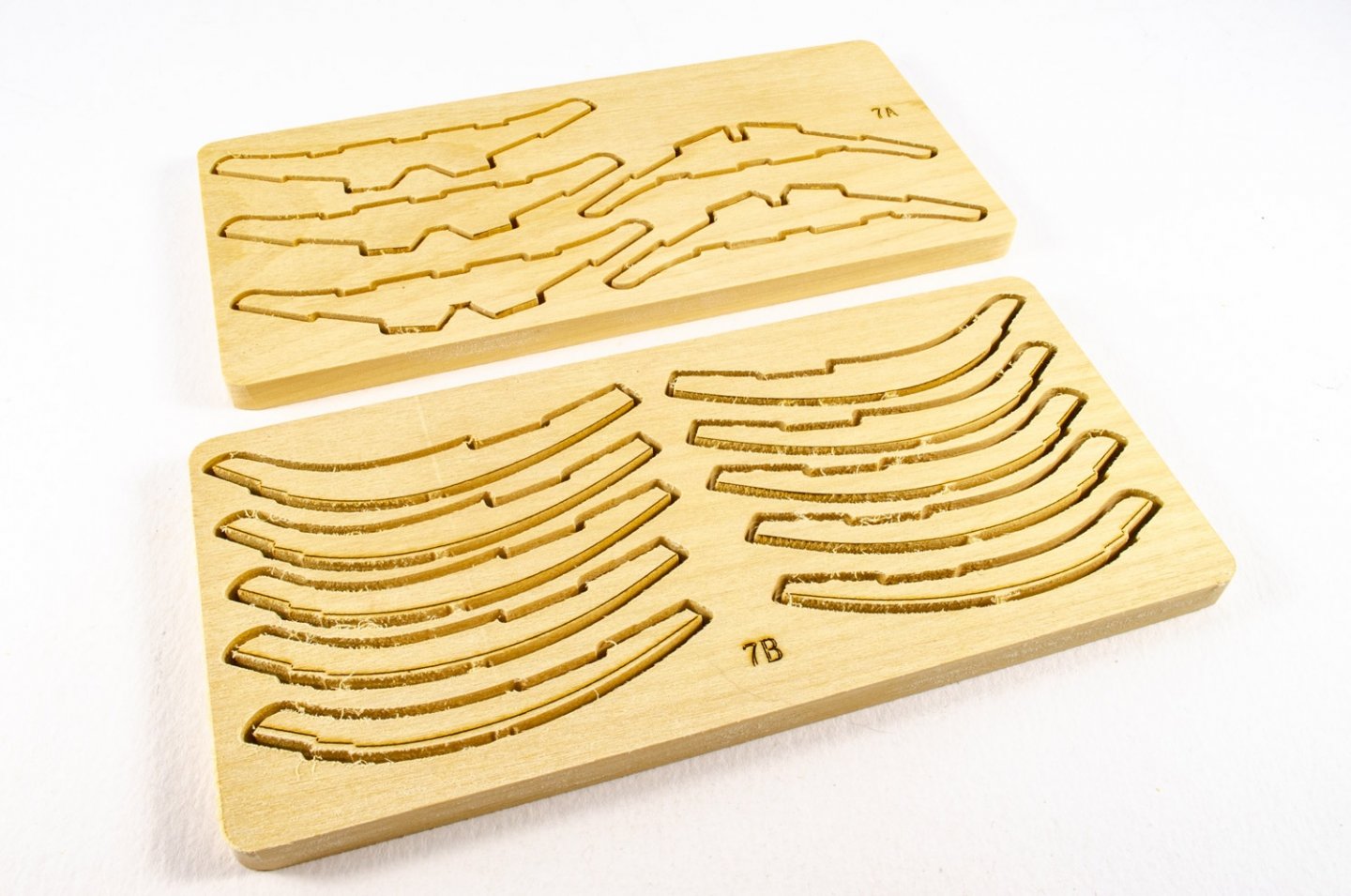

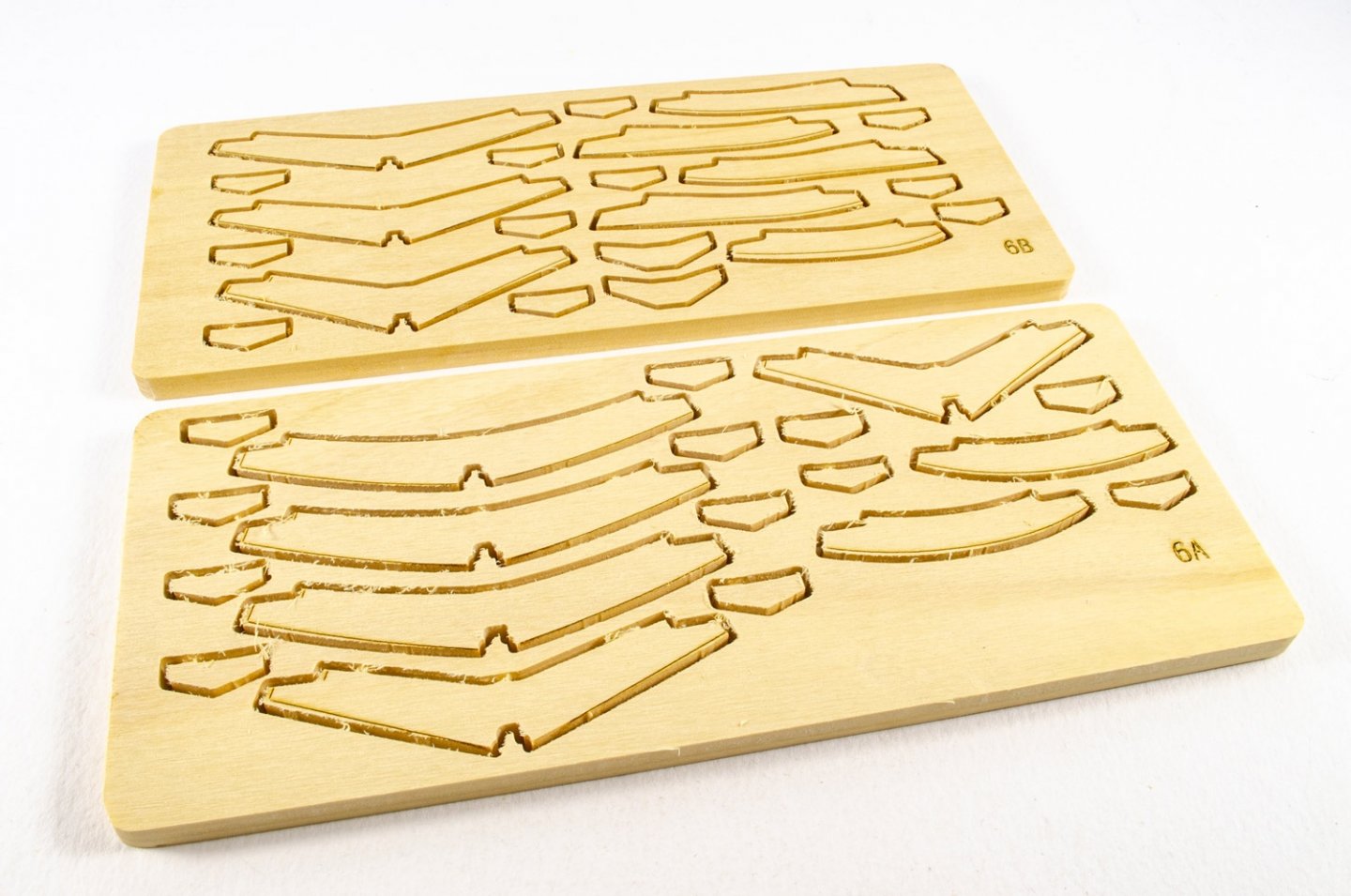

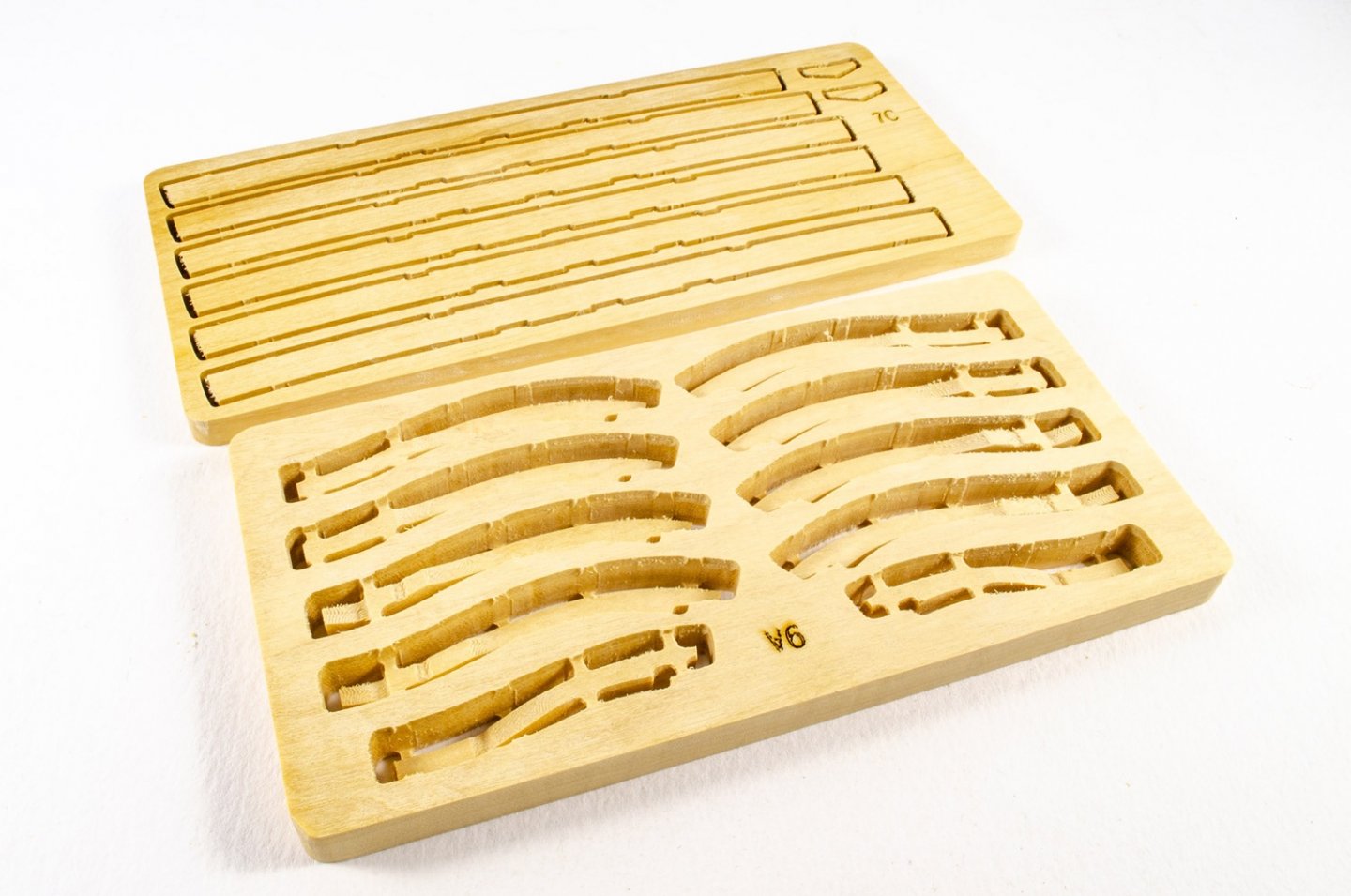

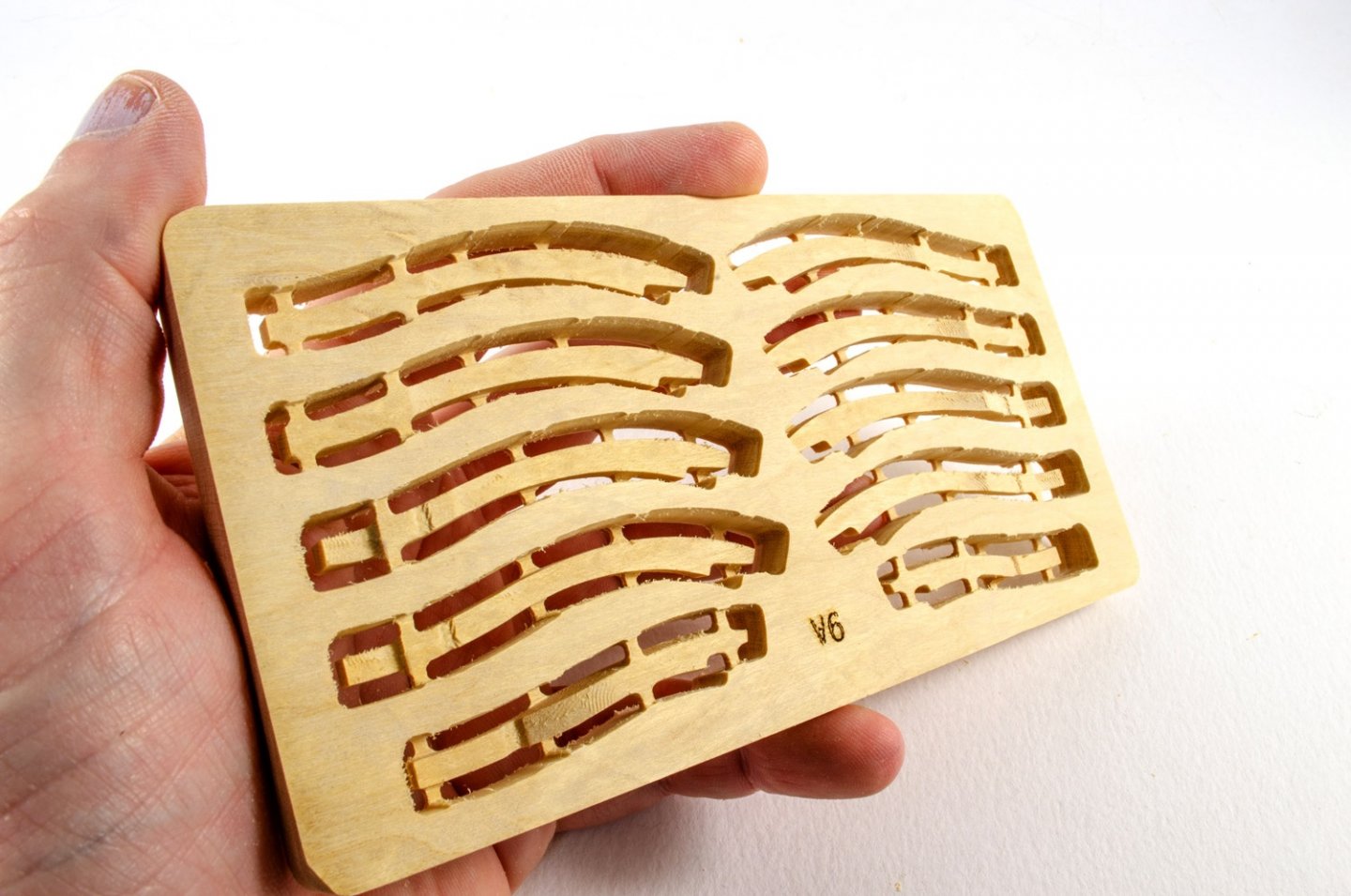

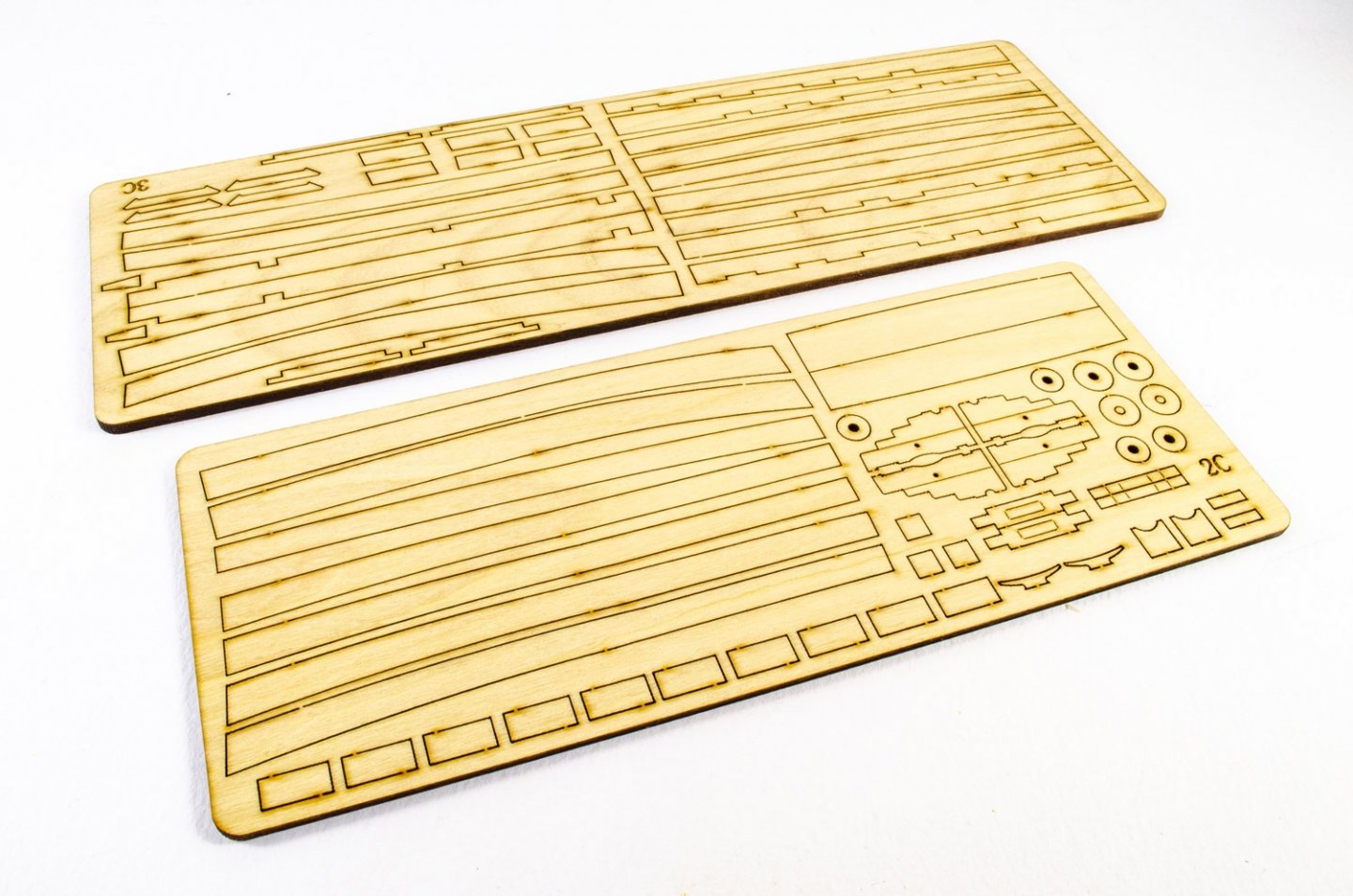

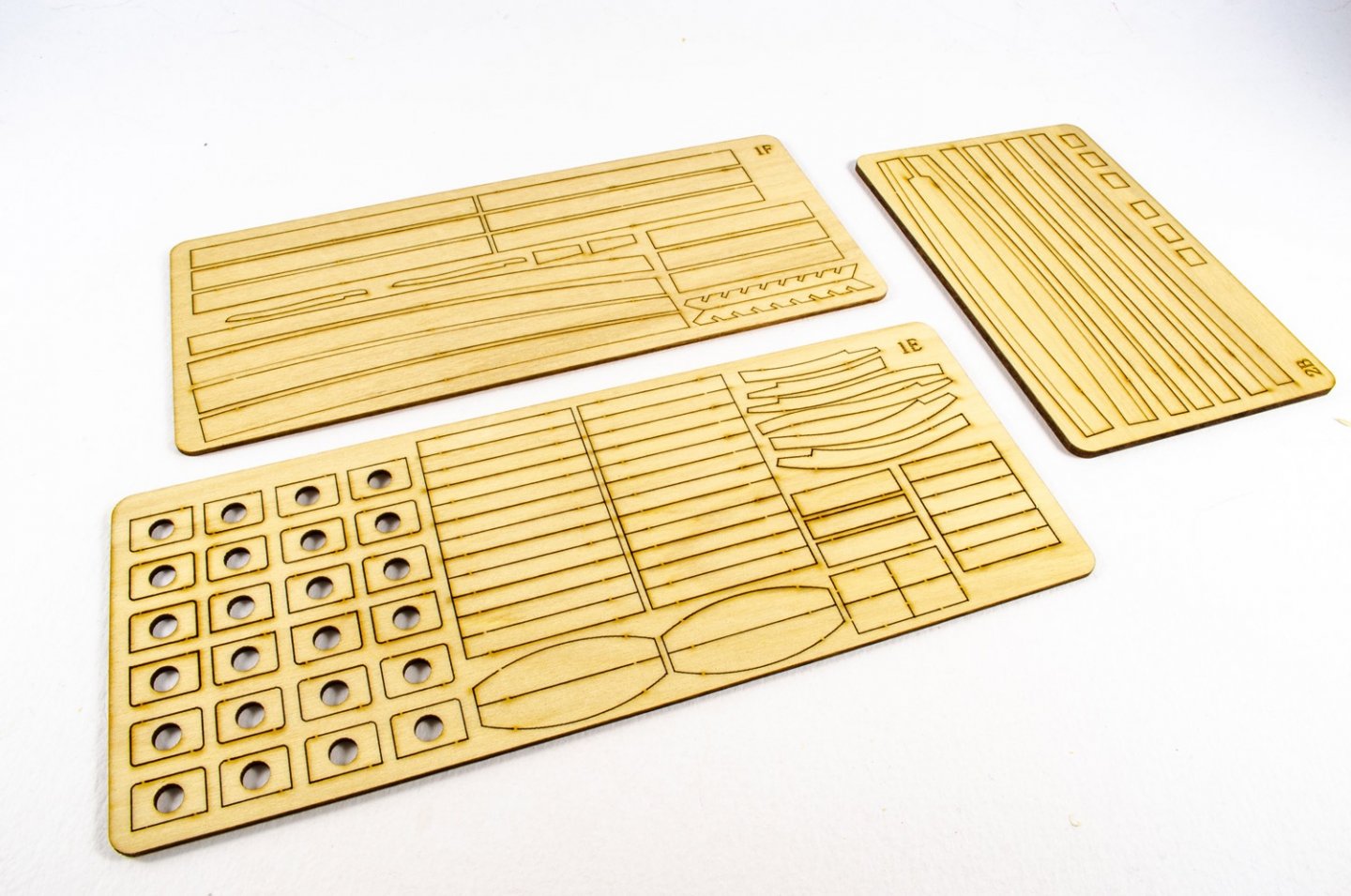

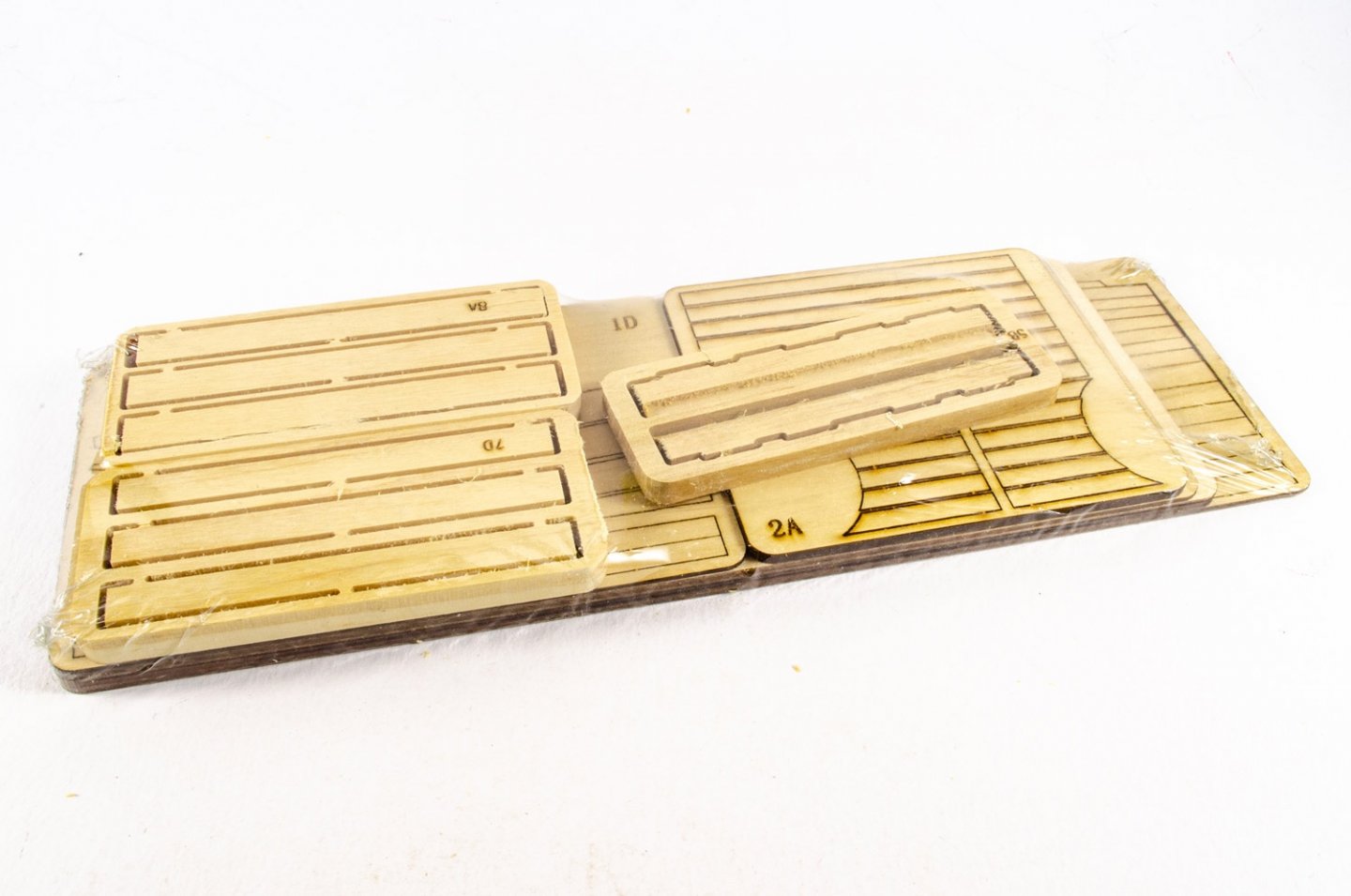

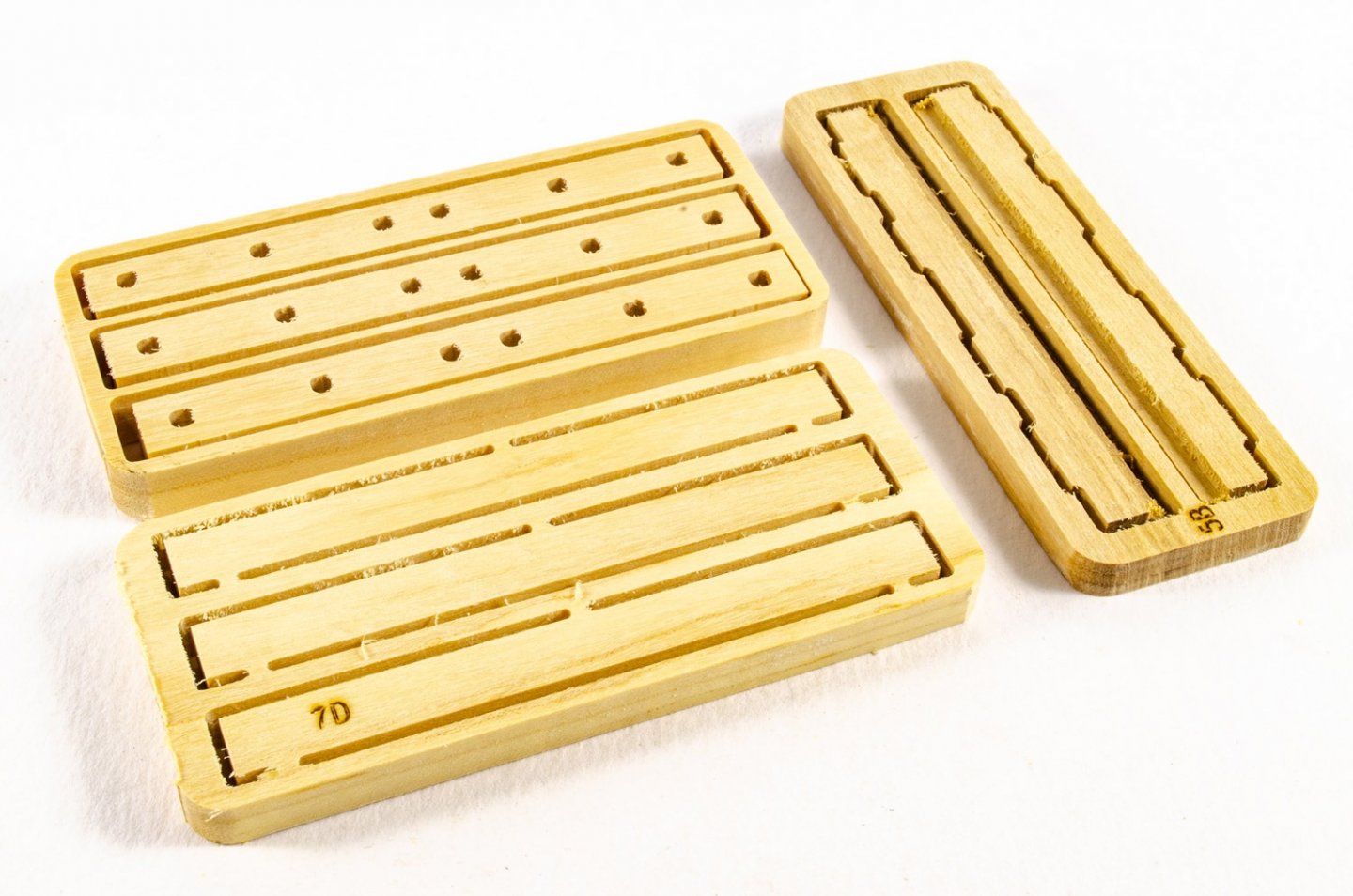

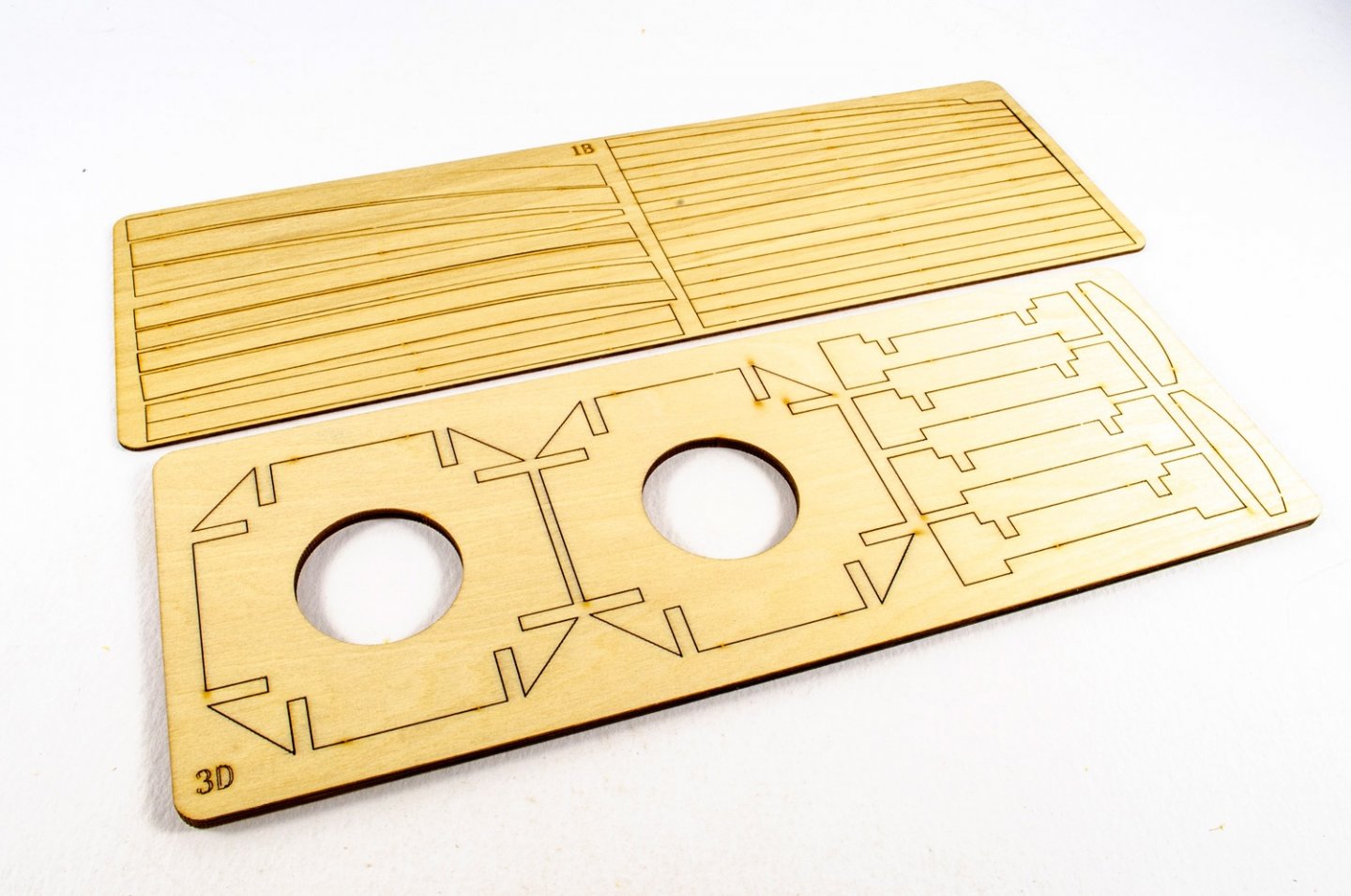

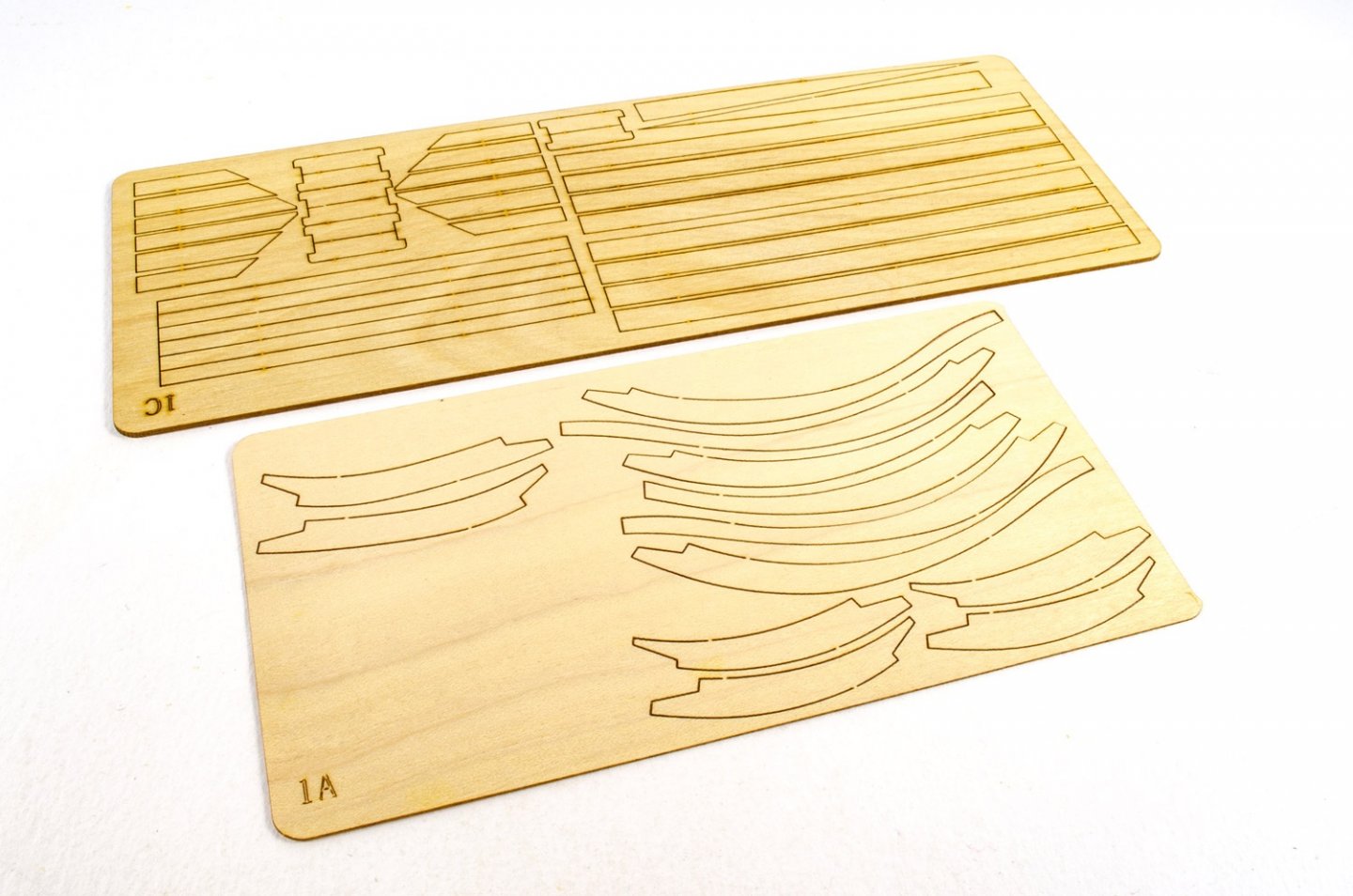

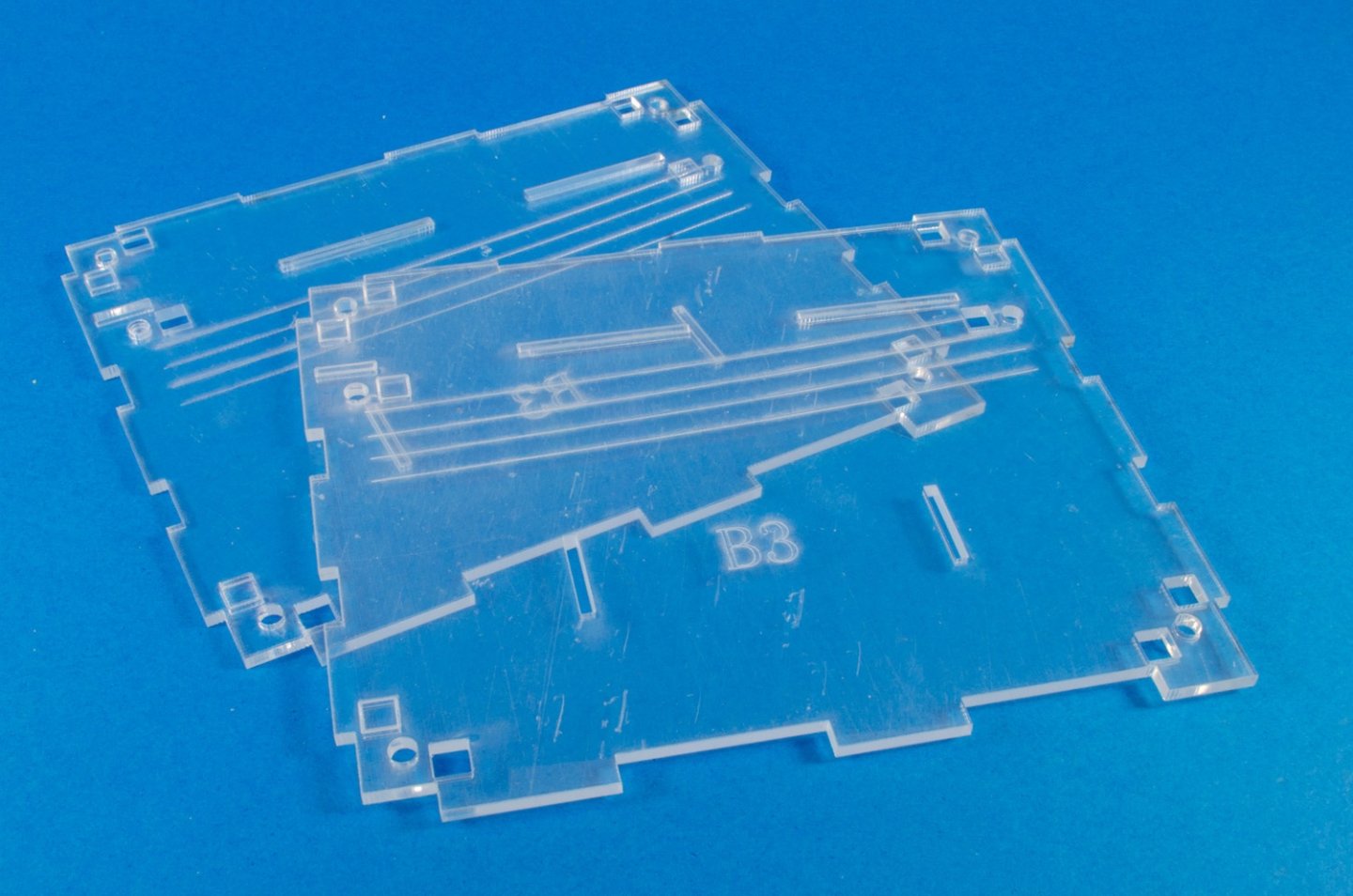

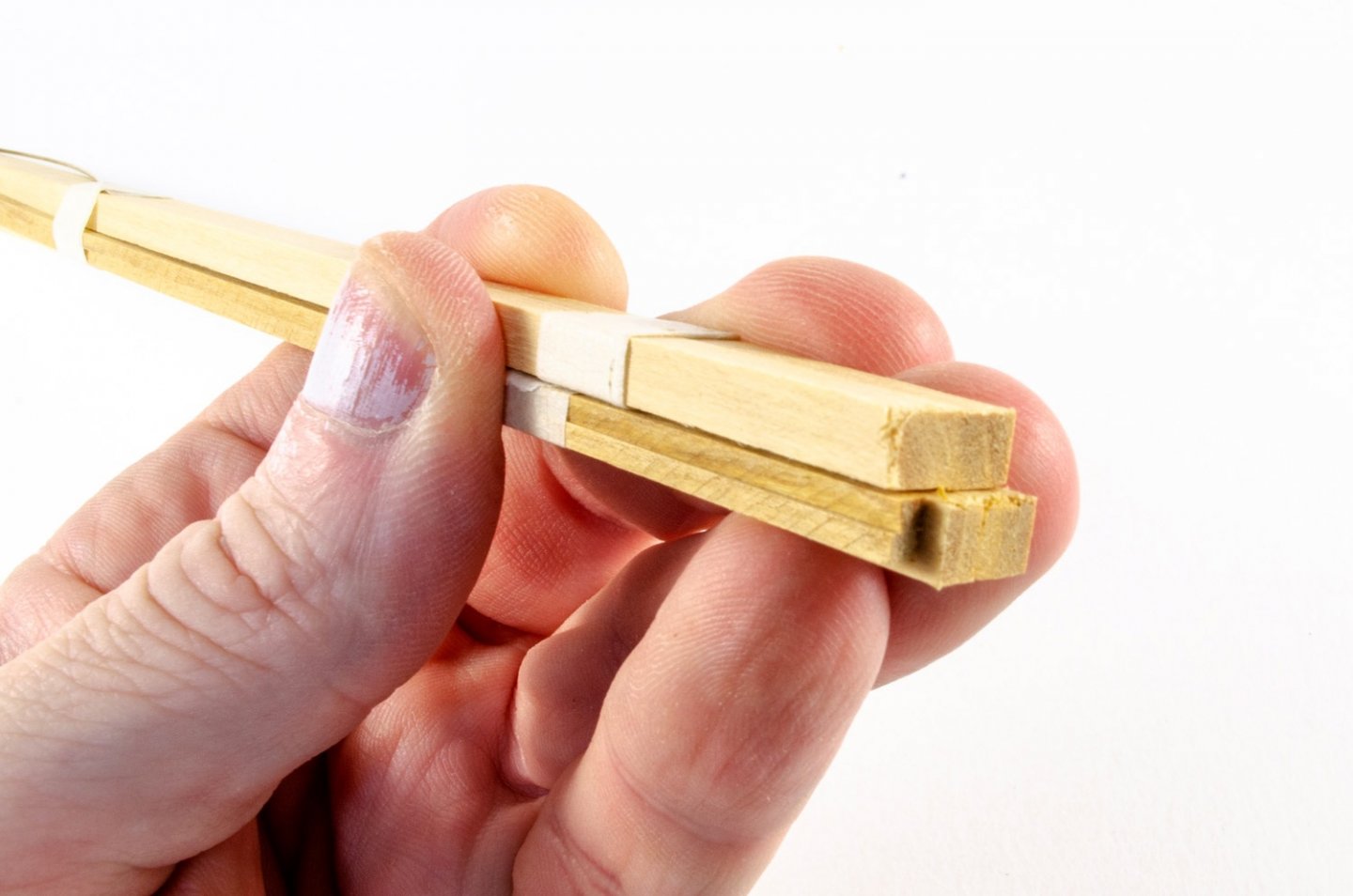

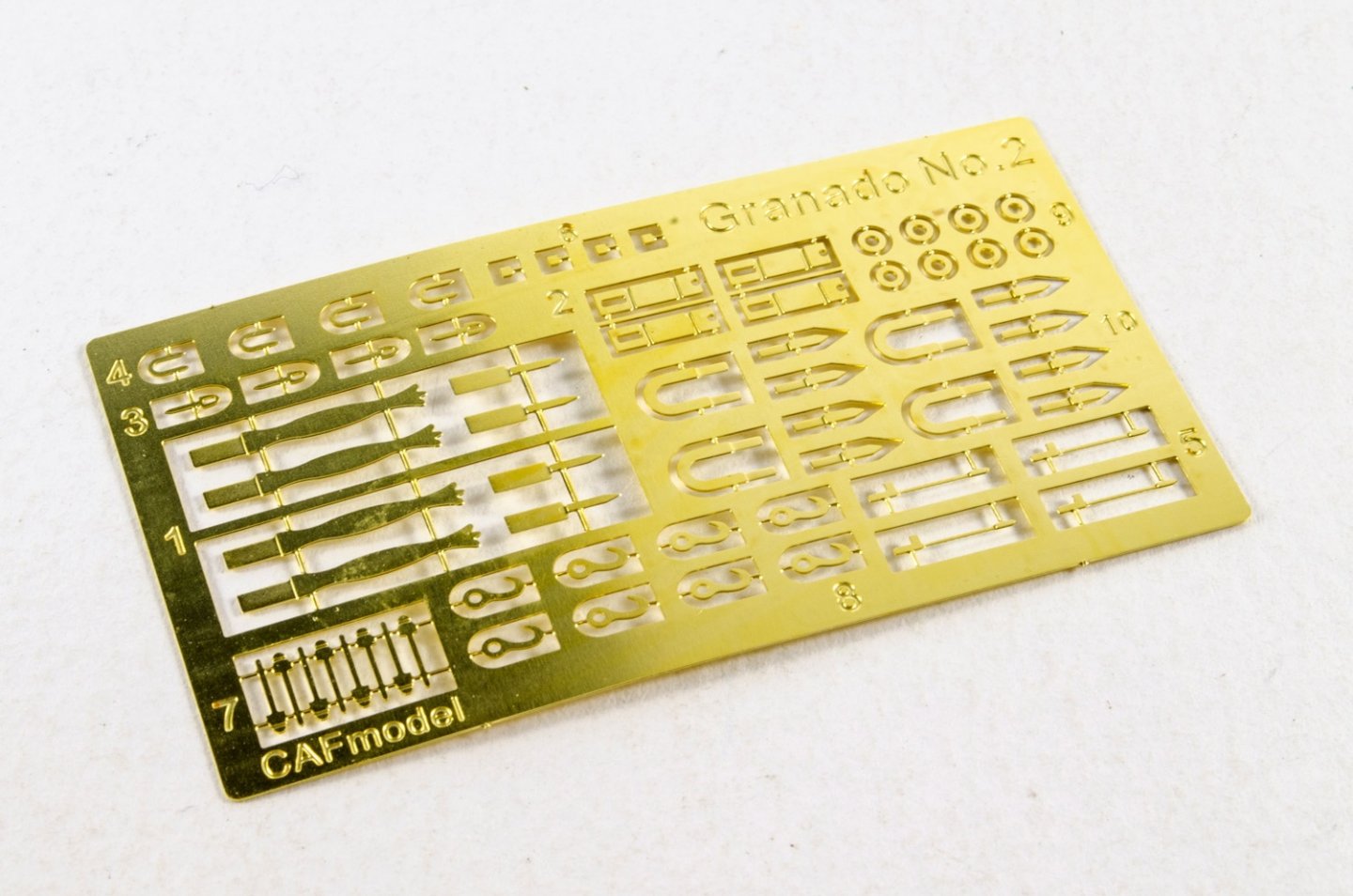

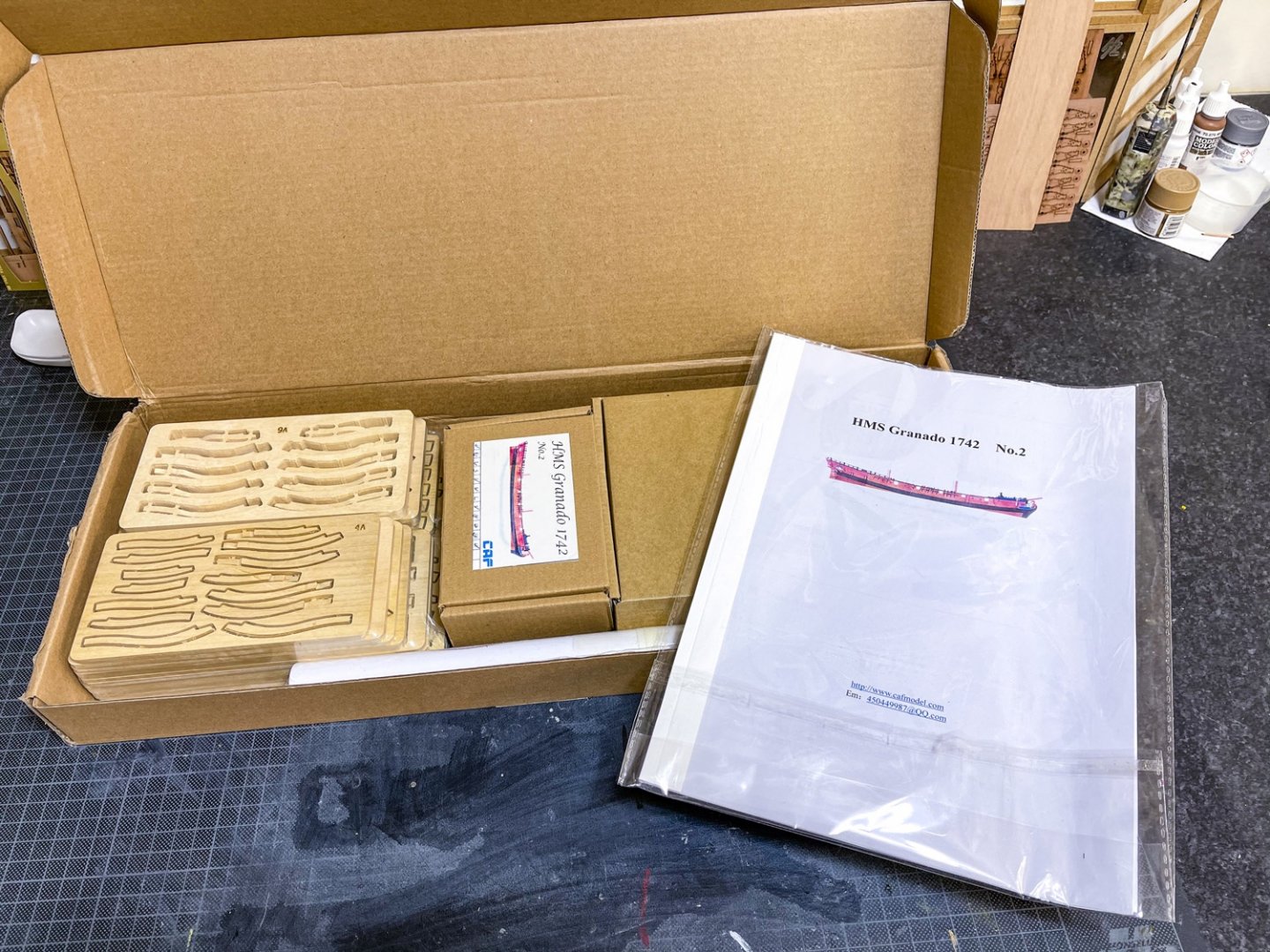

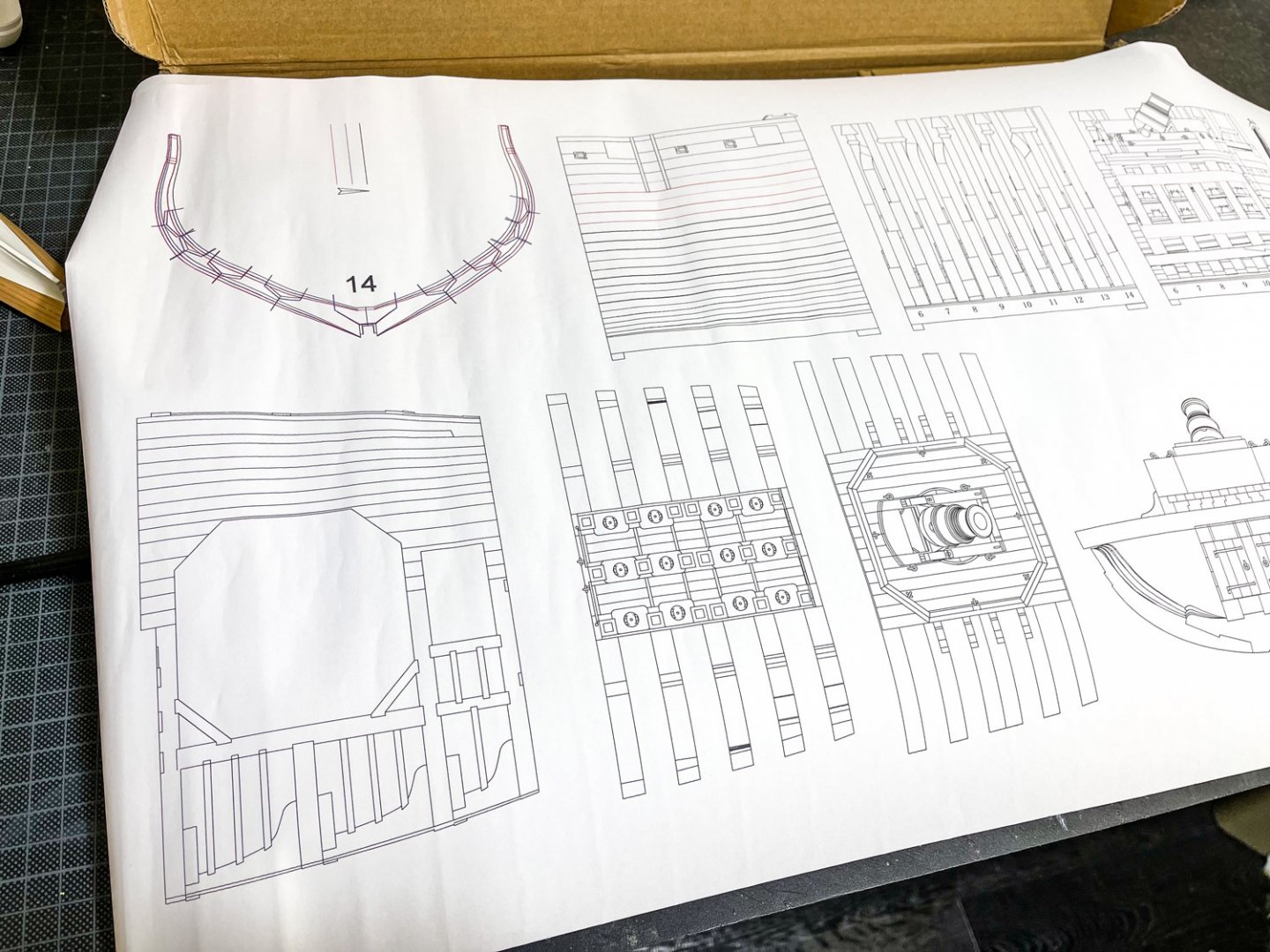

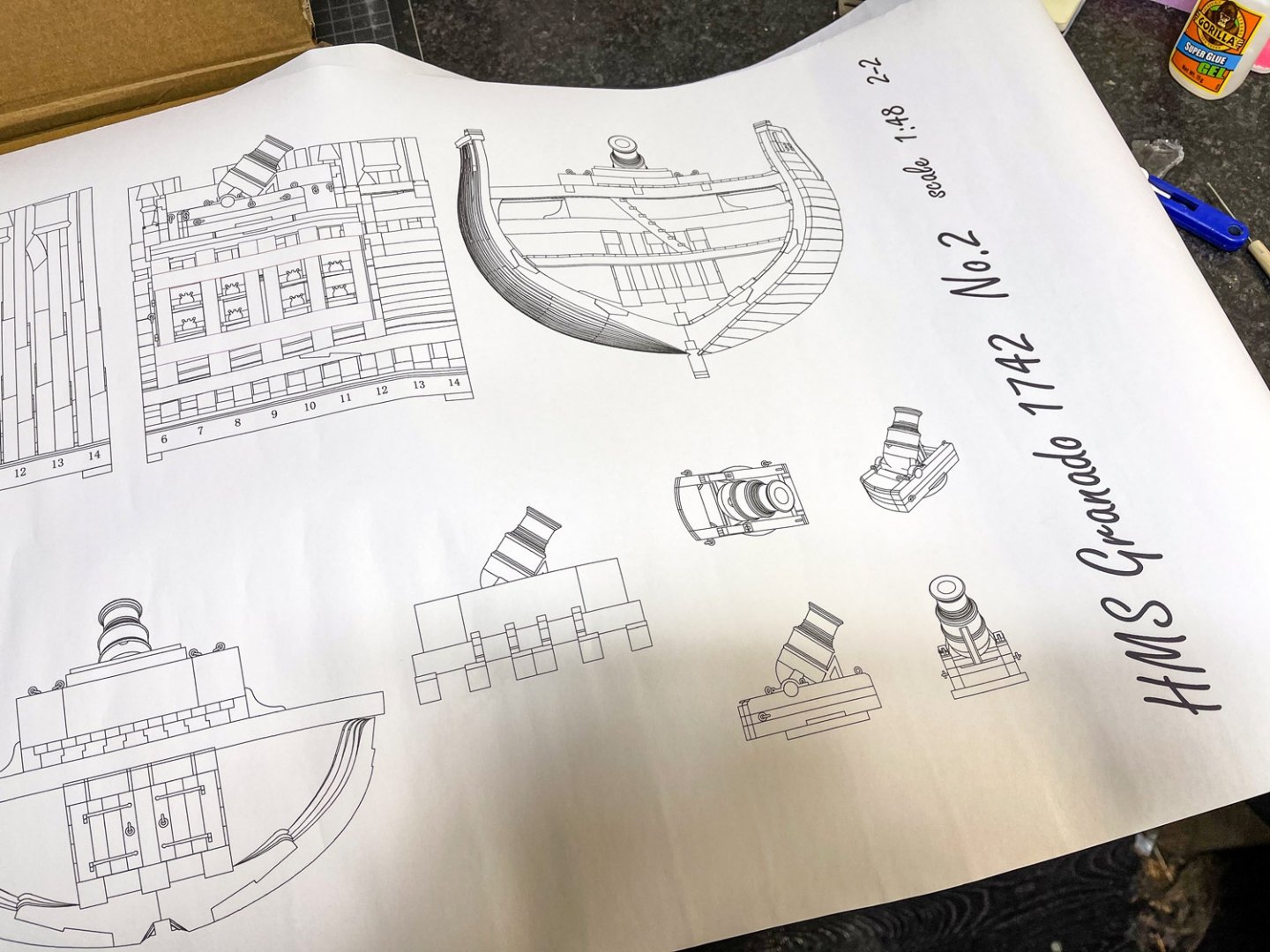

1:48 HMS Granado ‘Cross Section’ CAF Model Available from CAF Model for $325.00 The Granado, a bomb-vessel that was originally fitted out as a sloop (and ended her life as a sloop, also) was thought to have been designed by Thomas Slade. She is definitely a subject which has proven quite popular over the last 20yrs, with POB kits of this released by Amati etc. CAF Model’s intention to create a POF of this model was met with much interest, but before an eventual release of a full hull model, they have released a cross section kit in the same 1:48 scale. For only a section of a complete vessel, the box for this release is quite heavy and still of a reasonable size. Packed into a slimline corrugated box with a Granado label affixed to the lid, the kit reached me in the UK wrapped in a thick layer of extra card to protect it and reached me unscathed. Tom at CAF Model sent this kit minus two small sheets of parts which are now en-route to me, as he wanted MSW to be able to feature this as soon as possible. When those parts arrive, I’ll update this article with those extra photos. I quite like innovative features in model kits, and we’ve certainly got that here with the unique (at least I’m pretty sure!) building jig that accompanies Granado. Remember, that like all my reviews, this is an ‘in-box’ review and is designed to show you the contents of a kit as it comes, with any observations etc. How a model builds will be dependent on various other factors, but I will be featuring this as a build log on MSW in the coming days. CAF kits now have a break seal on them that needs to be cut through before opening, and when the lid is up, this quite heavy box can be seen to be totally chock-full of parts and other components. This kit has four heat-shrunk packs of timber in both laser and CNC cut types, a pack of strip wood, a box of detail components, a box containing the build jig, two sheets of rolled plans, and an instruction manual in a sleeve, also containing a small fret of photo-etch parts. I’m not too sure what timber this model is made from, but it has a nice pale-yellow hue and a very fine grain that’s certainly akin to some of the fruit timbers I’ve used over the years. As stated, all the parts sheets are sealed in shrink wrap. This is quite thick and needs a sharp knife to break through. Many of the parts sheets are just a few inches long, ranging from some quite thick sheets, to one which is just a veneer. Most are CNC cut and also pre-shaped on a multi-axis machine. Two similar packs to this are included in the parts total, and all contain exclusively CNC-cut/routed parts. The steel rule in the photo will give a good idea of the size of these sheets. Here you can clearly see the CNC routing and the extra shaping on some parts. Also note the laser engraving too, for the bevelling lines. These lines are also engraved on the rear of some of these sheets. All sheets are clearly numbered with laser-engraved marks too, but the actual parts numbers will be checked against a part plan in the manual. This helps to save precious production time as engraving the sheet would doubtless add extra expense to the modeller. The fames for the model (18 in total), are constructed in the same manner as their real counterparts, and also include the ‘bends’ in them that were typically seen in vessels of this period. This is where the CNC routing comes into effect, producing those complex shapes for the modeller, saving not just time but also the complications that result from recreating such parts by hand. To be able to position these frames against each other accurately, a series of temporary resin inserts are also included. We’ll see those shortly. Here you can see the breakdown of the frames into the various components including futtocks and chocks. A nice enhancement would be to use something that would represent fastenings in the complete frames…maybe black fishing line/filament which would look like nail heads. Deck beams are pre-cut to shape, including rebates for deck support timbers etc. More frame timbers with their engraved position/bevelling parts. Here you can also see the frame sections (top) which form the bottom of the frames that sit upon the keel. These photos give an excellent idea of the CNC shaping of the most complicated timbers, allowing this to be a nice introduction into POF modelling, whilst removing what would be the most frustrating elements. Two longer packs include more CNC-machined/routed parts, but also a series of laser-cut sheets. Clearly seen in this photo are keel parts, knees and parts for the gun mount. And now some laser-cut wood! One thing you won’t need to worry about is shaping any planks, especially internally, where that is a little more complicated. Granado is planked internally and externally, on one side only, giving the viewer the ability to see a complete hull on one side, and skeletal on the other. You will also see cannon carriage parts here too. This is the last pack of timber parts, again comprising both CNC and laser cut elements. More planking here, and also parts comprising the gun deck and hatch covers. Sheet 1A is a veneer. These appear to be facing parts for at least two frames. This is a highly prefabricated kit, making it perfect for that intro to POF, as can be seen from more pre-shaped planking etc. Whilst a gentle sanding of all laser parts is a good idea to remove any surface heat marks, you would need to see how the edges look when together as far as the char goes. Instead of using this for ‘caulk’, it could be a good idea to remove this char and simply use a pencil to represent caulk, as it’s less stark. The largest box inside this kit contains that unique feature I mentioned earlier. That is a clear acrylic building jig. Not only does this take over from the traditional ply jig we are used to seeing, but it’s also engraved so you can check alignment from every conceivable angle. This is assembled using short screws which also fasten into a series of specially cast resin blocks which keep everything square. The jig itself is a work of art. It’s a shame it’s disposable. However, more acrylic parts are included for a final display stand, engraved with the ship’s name. All acrylic parts are protected with a layer of peelable film. The second and last box contains all the various fittings etc. These are the resin blocks which are used to construct the clear assembly jig. I mentioned earlier about resin inserts which temporarily sit between twisted frames, to help with their positioning in relation to each other. These are those. When the frames are set, these are disposed of. Screws for assembling the acrylic building jig. These parts are very obvious. Here you see not only the main mortar with its beautiful detail including royal crest, but also the two cannon for the framed side of the hull. The other pack contains the capsquares for the mortar, and these are actually workable! Casting really is very nice and there’s minimal clean up. As these are brass, that aspect will be very simple with a nice set of files. More packs contain eyebolts, bombs, deadeyes, eyelets, swivel gun mount, rigging cord etc. There isn’t too much strip timber in this kit, but there really doesn’t need to be. A small length of brass wire is also included. A single fret of PE is included. Production is excellent, with small connecting tabs. You’ll find cannon and hull fittings here etc. Plans and instructions Two sheets of plans are included. One of those covers all the frame assemblies, whilst the other also has various illustrations of the completed hull to help with overall assembly. These are quite long sheets and need double rolling to remove the curl in the sheets as they are quite tightly rolled. The instructions are line drawing format but also contain colour. These look pretty easy to follow and the writing is clearly understandable. Conclusion As well as being an interesting subject of a popular vessel, this is going to be a perfect introduction to the world of POF. Being 1:48, this is also a nice size too without being too large for your shelf. I know some modellers would like to build in 1:48 but could find it restrictive when it comes to displays. This should alleviate that problem! Overall, this looks a very nicely designed and produced kit with some very nice and innovative features. Most importantly too, it looks to be real fun to build! Head over to CAF and snag yourself one. My sincere thanks to CAF Model for the review sample seen here.

-

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 31: BRAKE PARTS FOR THE REAR RIGHT WHEEL Lastly, another brake unit is built. This time for the rear right wheel. That's it until next time! -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 30: LEFT LOWER SUSPENSION ARM AND SHOCK ABSORBER Using another serrated pin, the cylinder body is now fitted into position. Now, the cylinder piston is connected to the lower arm. With the coil spring in place, this unit is then offered up to the assembly and pinned into position. At this point, there's a lot of tension in this! -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 29: REAR UPPER SUSPENSION ARMS More serrated pins are used to connect the rear upper arms to the arm holder. The differential unit is now loosely sat in place and connected to the engine by the propeller shaft. With this is situ, the arm holder is screwed into position, trapping the differential unit, and the arm is connected to the brake unit with another serrated pin. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 28: DIFFERENTIAL HOUSING COMPONENTS AND PROPELLER SHAFT The rear differential housing cover pushes into housing unit, and then the top of the housing unit is screwed into position. The propeller shaft is carried over onto the next stage. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 26: BRAKE PARTS FOR THE REAR LEFT WHEEL As with the right brake unit, the left one is now built. Oddly enough, the wheel hub is shown as silver in the manual, but this is a nice black coated metal part. STAGE 27: DIFFERENTIAL HOUSING COMPONENTS The inboard drive shaft connectors are screwed to the bottom of the differential housing. Both drive shafts are now fitted and held in position with a serrated tipped pin. The drive shafts are labelled L and R to make sure they go on the correct sides. This is important due to the various offsets in each part. The left rear wheel brake unit is now pinned into position pin the same way. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

STAGE 25: LEFT AND RIGHT FLOOR PANELS Before any work starts here, it's a good idea to use a bit of tape to hold the battery box line down on the part. I saw this on a build on the Agora forum, and it's a great idea! The two floor panels are now screwed to the chassis with 4 screws each. The fit is perfect. And now the good bit...the engine is installed! Just two screws for this. I also took the opportunity to tidy up the cables a little as I left it a real mess last time. -

1:8 1965 Shelby Cobra 427 S/C - Agora Models

James H replied to James H's topic in Non-ship/categorised builds

Pack 4 STAGE 24: BRAKE PARTS FOR THE FRONT RIGHT WHEEL In this stage, we simply build the brake unit for there front wheel. To start with, the spinner and hubcap are first pushed together. No glue needed here. The wheel hub now inserts through the brake disc so that it freely rotates. The brake calliper then screws to the wheel hub whilst entrapping the brake disc. The brake unit can now be fitted to the right wheel. This will only go in one way, and then a screw from the outside holds the two together. The spinner/hubcap them sits over the screw using its magnet. -

Hello JB Daykin, Welcome to Model Ship World™. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask. JB Daykin joined on the 02/02/2021. View Member

-

Hello Stickman, Welcome to Model Ship World™. Please feel free to browse around and get to know the others. If you have any questions please don't hesitate to ask. Stickman joined on the 02/02/2021. View Member

-

I've been using Swann Morton scalpels to cut timber for models for 20yrs, and for plastic/resin for almost 40yrs...BUT I sometimes use the No.10a for heavier work as they are less likely to break. However, I rarely get an SM No.11/15 blade break on me. I've probably had a couple break last year, so not many, and I use a lot of these.

-

I've used Swann Morton scalpels since I was about 12yrs old, so I'm very used to them. A few years ago, I switched to their retractable handles which hold the same blades. For blades, I use 10a, 11 and 15 (the latter are small curved blades which are great for awkward cuts and scraping). https://uk.rs-online.com/web/p/scalpels-craft-knives/8477580/

-

@DaveBaxt it's still shown on their website: https://www.hobbyzone.pl/en/3-boat-building-tools/ but temporarily unavailable. Might be worth emailing them direct.

-

STAGE 88: ASSEMBLING THE LEFT HIP JOINT As with the right hip, the inner joint case is slipped into the hip, followed by the ball joint. On top of that sits the outer plastic joint case. The thigh is sat up to the T-800 so the ball joint engages with the hip. This is then screwed into position. The outer cap is then screwed into place with four screws. At this stage the hip will STILL be loose. This is normal.

-

STAGE 86: ASSEMBLE THE SHOULDER, AFFIX THE LEFT ARM TO THE BODY A hip joint is included here, but that is reserved for the next stage. Fitting the arm to the body is very simple. The arm slots into position and a ratchet disc is glued into the shoulder joint connector. An Allen key is used to tighten everything up, and this is then used to slacken joints off later to pose the T-800. For now, I'll keep the pose fairly neutral.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.f9cf4ba7a148e91bc456ec282964a6f2.jpg)