-

Posts

541 -

Joined

-

Last visited

About FrankWouts

- Birthday 10/08/1968

Profile Information

-

Gender

Male

-

Location

Breda, The Netherlands

-

Interests

Trumpet playing, modeling aircraft and ships, Heller and wood.

Recent Profile Visitors

-

westwood reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

westwood reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Rustyj reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Rustyj reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Freebird reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Freebird reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

PaddyO reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

PaddyO reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

tmj reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

tmj reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

Trussben reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

VolkerB reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

VolkerB reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

FrankWouts reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

FrankWouts reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Greg M - 1/48 scale

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Greg M - 1/48 scale

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Greg M - 1/48 scale

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Greg M - 1/48 scale

-

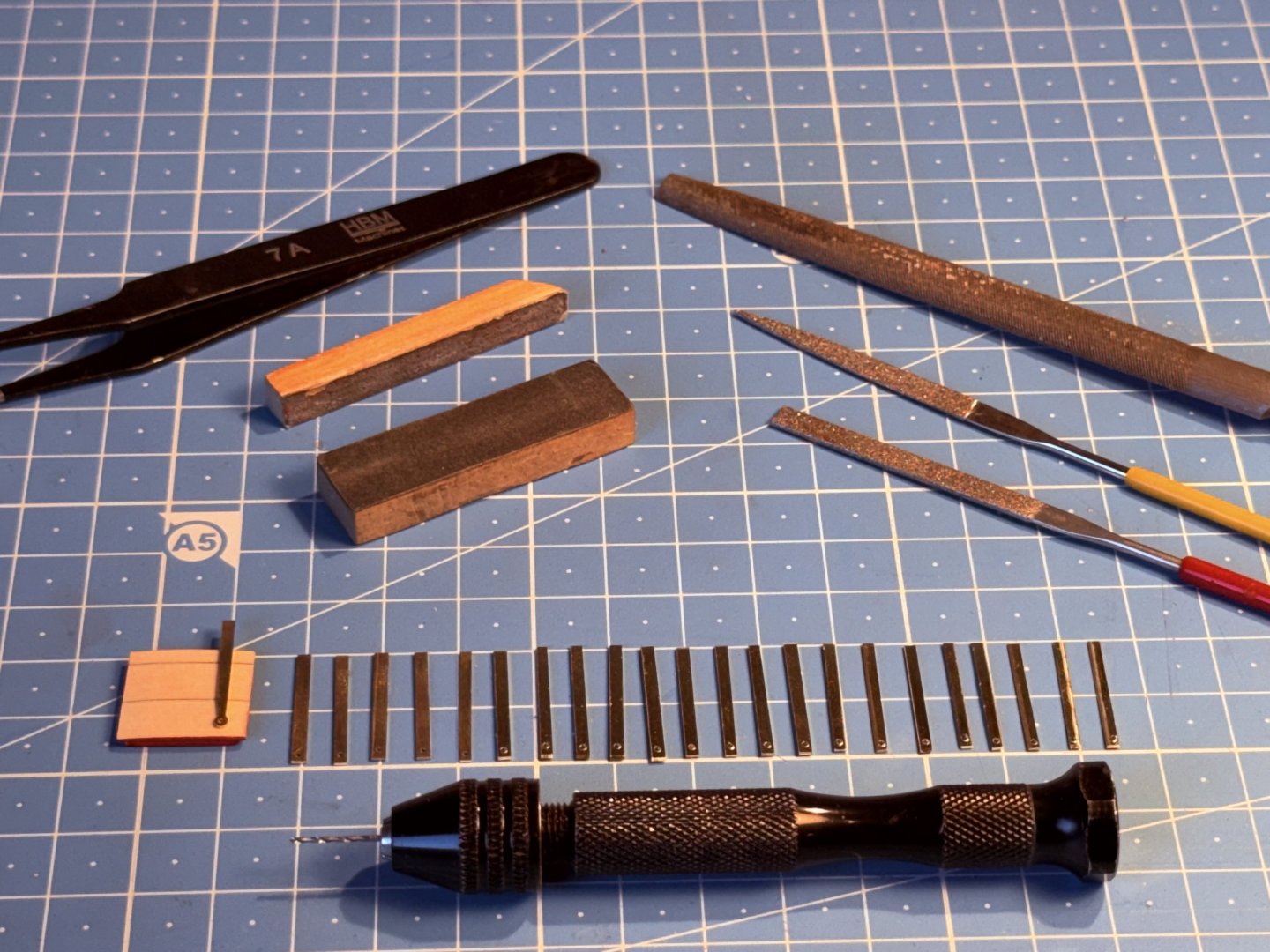

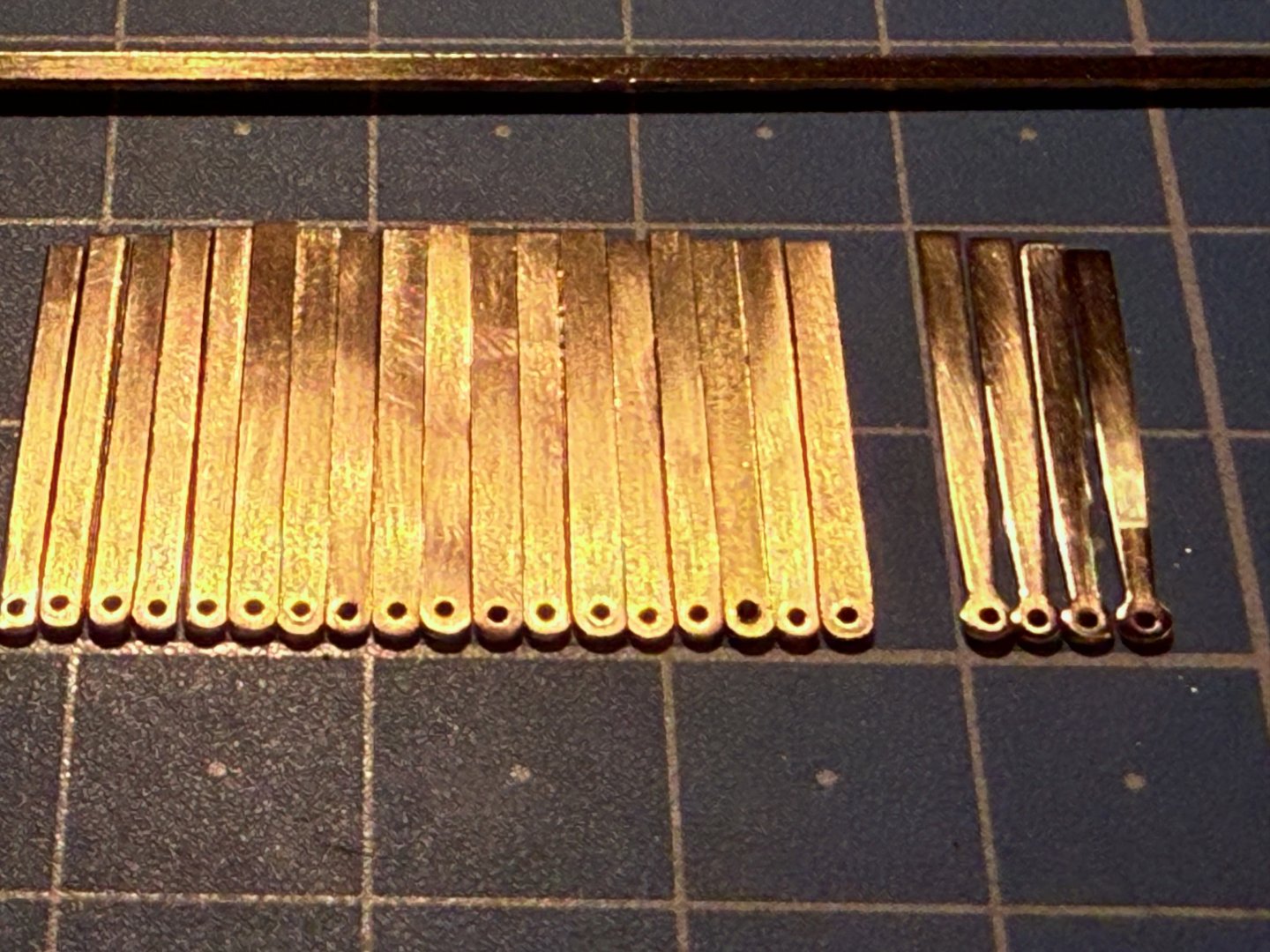

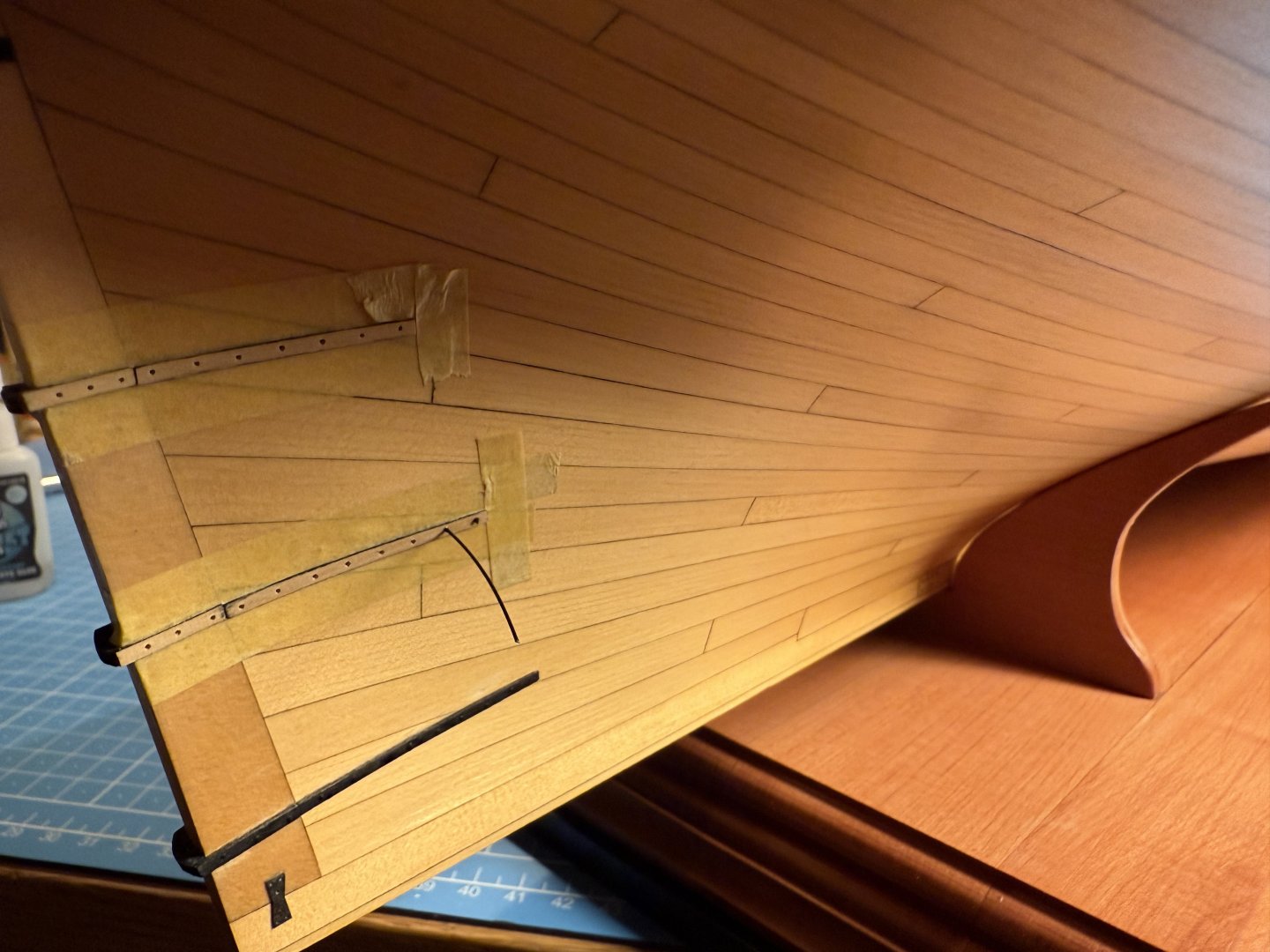

Today I made a start with the hinges for the gun hatches. With a strip of wood under a 20x40cm 0.4mm thick piece of brass it can be cut in strips of 1.6mm wide. Without the wood the brass slams hard under the saw and bends in an ugly way…the scratch piece of wood underneath it prevents that. After that cut the strips in the length of the hinges as found on the plans and reserve 4mm for the curled hinge piece. More tomorrow… Frank.

-

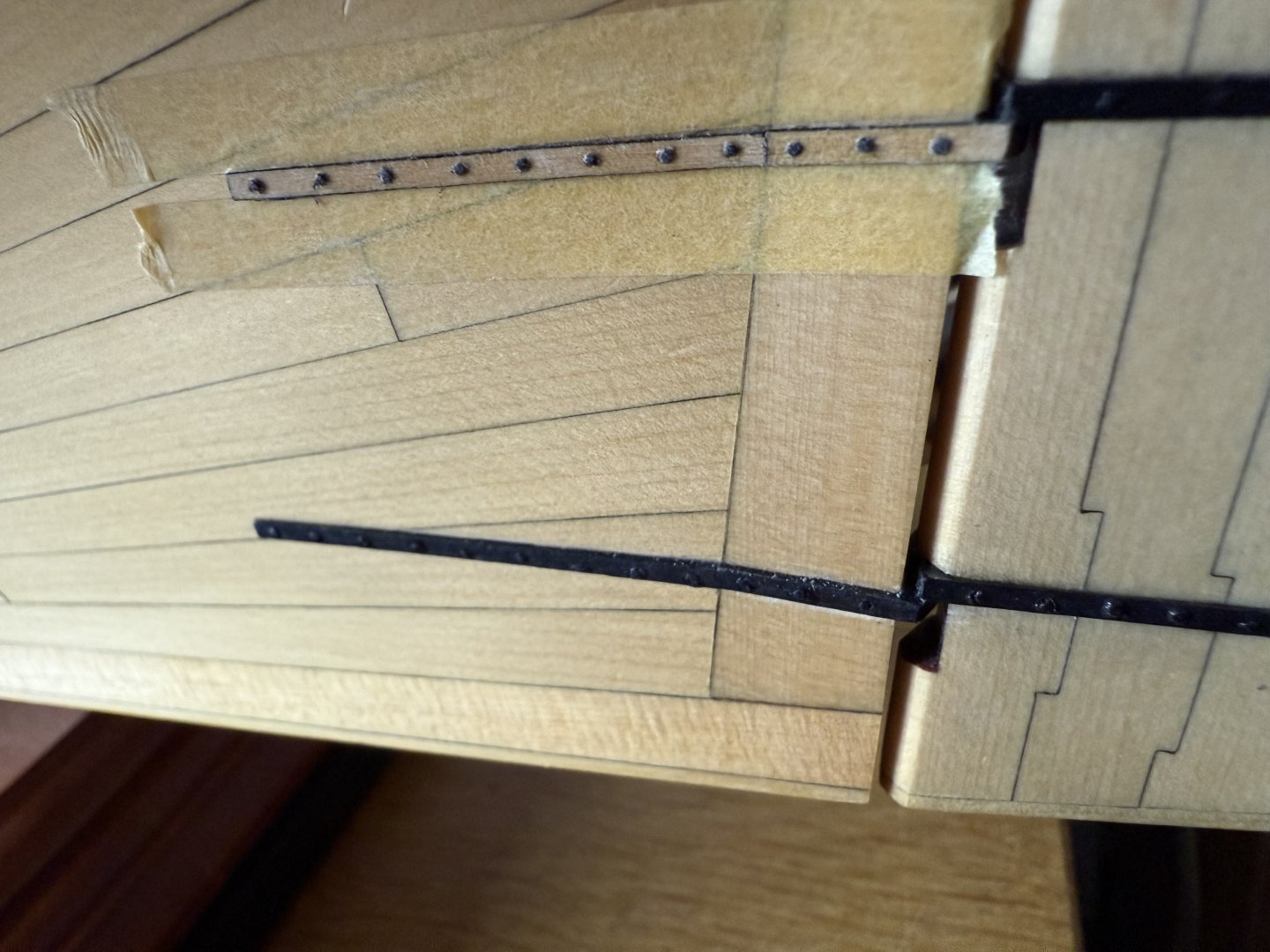

Hi, I need help. I have two questions: 1: It's not explained how to make the eyebolts that are drilled into the lid through the lid hinges' hole. Is there a tutorial how to make these and how big should they be made with the 28 gauge wire? Is it just a ring that let's the 24 gauge wire split ring go through with a little pin on it to be glued in the drilled hole in the port lid? 2: Where can I buy this Japanese saw like the one Chuck uses to saw his split rings that go on the cannon port lids? Thanks, Frank.

-

Thank you Steve, Yes I’m afraid I have that detail, fit & finish syndrome which slows me down a lot, but only then gives me full satisfaction. Lots of techniques and detail also is new to me, so I’m also very careful not to ruin Chuck’s lovely parts. Today, Sunday, I have some time to make some progress in chapter 5 again. I’m now at making the port lids fit… Frank.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.