-

Posts

369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by steamschooner

-

Just to show you all that I have been working on my project. Not alot done but I have made and installed the main cabin roof, cut out for the stack and the engine room skylight. Turned a steam whistle and working on the stack. Did some dry transfer lettering and made a ships bell.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nevermind I see it is stud link chain

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

What? Nils no stud link chain.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

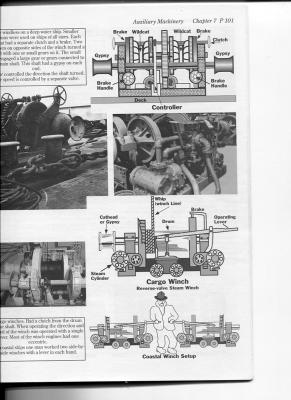

Nils, Here is a page from; Smoke Ash and Steam by R. Sheret That show the different parts of a windlass. Windless having wildcats for chain handling. Cargo winches do not have wildcats just drums and gypsys

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Bob, Been there done that ! I stopped work on a model and stripped it back to the main deck . Some research showed up that had showed me how some things where wrong. Your build is looking good!

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

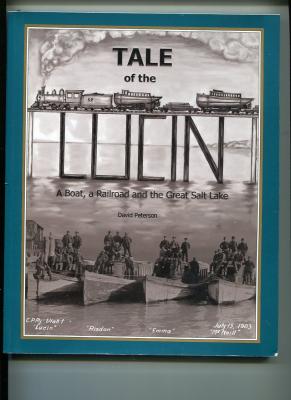

Tale of the Lucin, by David Peterson isbn 0-9706383-0-2 For those that like small boats this is a interesting tale of a small launch that lasted 99+ years. It helped build the Lucin cut off in the Great salt lake, was a tug/freight boat , and ended up a fishing boat. It has ties to my local history and most likely worked with and around the John Cudahy ( My current build )

-

Nils, Are you using safety glass for you case? Do you prefer glass over say plastic? Do you build in some sort of venting for the case to breathe. Someday I will need to build some cases to keep the eightlegged riggers from adding additional lines.

-

http://sanctuaries.noaa.gov/news/press/2016/lost-whaling-fleet-found.html No pictures but interesting.

-

jbshan: Yes now days three lights are required. The time frame of 1900-1930 there were only two mast lights ( see photo at the begining of my log ). The laws did not change until later, the Cudahy(now the Henry Foss ) likely had three when she was lost in 1952

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Yes, thank you Mark, and a great New Year to you and yours.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

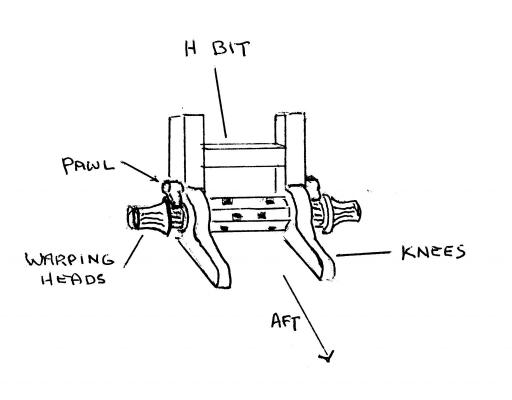

I posted this in another area as well. I am working on some of the deck gear/fittings and this is one of the puzzles that has come up. photo shows the forward side of one side of the H bit with what looks like a pawl mounted on the right. Than just below and to the right is a warping head ( looks like it has whelps ) The other stuff is part of the steam gear that was also on the fordeck. That's another project in itself. This is what I think I might be looking at. Any thoughts , ideas ,

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Patrick, I am just catching up on your project, it's looking really great. Have a Merry Christmas and best wishes for a hew year.

- 1,083 replies

-

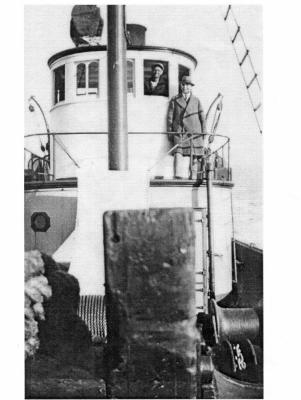

Spent a little time in the shipyard and got a couple of things done. First is the anchor davit, which I will need to blacken or paint. I turned my masts, painted them and installed a couple of mast lights that I had made for this build.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nils, What a stunning project your "Pegasus" turned out to be. Thanks for letting us tag along.

-

Thanks for the comments everyone. Bob, The one I use is one that was built for automotive work. A friend built it for building his hotrods. In the "Ship Modelers Shop notes" there is a small roller shown with notes on how to build it.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

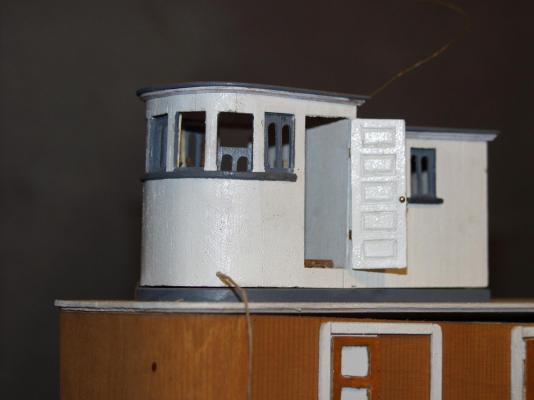

I have been jumping around on my project getting little things done. The last couple of days it has been some metal work . Made and installed a stem strap with a shackle at the top, and both port and starboard mast stay straps. Had to pierce the caprail to do that and was worried I would mess something up. I make my straps from mild steel wire that I run though a bead roller to flatten it out. I use copper wire and brass wire the same way. Depending on how many times you past it though you can get an assortment of thickness and width. For pinning the straps I use some railroad spikes I got at a hobby store once. They are small dia. nails with a off set flat head. I file the heads to more or less a round shape and cut to length before starting them in a pilot hole. And I got the doors on the pilot house

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

It is nice to have detailed plans to follow. Your build is coming along nicely Bob.

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

John and Bob Thanks for checkin things out.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Thanks Patrick , I am glad it's behind me as well. Now maybe I can get some things done on my project.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Thanks Nils, It's nice to make some progress.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Well after dealing with walking pneumonia for the last three weeks I have gotten a little bit done on the pilot house. After a few tries I got a roof I liked, others were to big or to thick, Also made crown molding for the lip on the roof. Made and installed window sill below cabin windows. Working on cabin doors which I will mount in the open position.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nils, There is a steep learning curve. So I am learning every time I make a mold and do a cast. Most of the time it works out and some times not! I do enjoy the challenge.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nils, I agree with the rest of this bunch your model is looking just great...

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Wow, Bob From frame to fully planked in about 10 days? But it is a small scale so the planks are also small. What did you use to plank her with... Bass?

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Bob, I think I will pull up a stool and watch as well. Guys just don't get upset if I get popcorn all over.

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.