-

Posts

369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by steamschooner

-

Patrick, Some of them are version 1 which will be put aside (the two that have some paint ) The two that are version 2 will get painted and used on my model.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Like the work boat I ended up making another plug and building a shell on it. If it was a real boat it would leak like crazy, but this is a " paint grade boat ". I am getting a small collection of them, but still need the practice and improvement. First two photos are of lifeboat version 2 still on the plug. Two more of version 2 off the plug. My growing collection And my plugs which you can see the different shapes.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Bob,Good looking boats, they will look great on your project.

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Bob, You have shown us all what you can do so no doubt your boats will turn out great as well.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Thanks Patrick, I think I can make these two work and am glad to get them done to this point. They are fussy little buggers to build.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

OK, I have managed to get boat number 2 ( life boat ) version 1 finished. I think it's a keeper! So now I have both boat shells done. Now comes the easy part, adding the detail to the work boat and making a cover for the life boat.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Nils, She is looking long and lean in those two photos ! Really coming together nicely. I don't envy you having to make so many boats for the boat deck . While I struggle to make two boats for my project

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Bob, your build is coming along nicely, it's all those little details that bring it to life.

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

I was not happy with boat version 1 so I went for version 2 which came off the plug as can be seen below. I still need to add ribs and such. we will see if there is a version 3

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Patrick, she's looking very sweet! great job

- 1,083 replies

-

I like the bandaid on the lower hull Great job, Patrick

- 1,083 replies

-

Steamboats and other rivercraft - general discussion

steamschooner replied to Cathead's topic in Nautical/Naval History

This is a interesting read on the first sidewheel steamer on the west coast. arrived in 1836 and operated on the west coast for more than 50 years. ISBN 0-920663-20-6- 281 replies

-

- Steamboats

- riverboats

-

(and 3 more)

Tagged with:

-

Nils, Nice solid core for the cabin. This will than be "plated" with riveted metal ?

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

I to think it just keeps getting better, if that is even possible. love your updates Nils. Watching your liner come to life is a pleasure.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Well I have made some progress with my ship's boat. I also realized that the two boats that the Cudahy carried were different. So i guess I need to made another plug for the other boat. First one came off with out damage. Adding detail and a little strength to the form. Have a few more things to do with the boat like making a set of oars to tie down in side of it and adding some oarlock blocks.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Bob, Wow is she looking good, nice update. Nothing wrong with nonsail models in my humble opinion.

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Patrick, Major bummer! but I believe you will have her back in shipshape in no time.

- 1,083 replies

-

Nils, Things are looking great! Glad to see you back in the shipyard.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Being from the left coast and interested in work boats my vote would be for something like the C.H. Thayer or Wawona, lumber schooners that have alot of documentation. The steam schooner Wapama would be a good subject as well, as their is allready a good set of plans available. POB or solid hull for cost reasons (thinking POF kits would cost more) Scale should keep the finished kit some what small ( 10-30" ) in length. Price in the 200-500 dollar range. Build time does not matter(To me ) it is not a race.

-

Tim, Looking good so far! Are you going to plate the hull or just paint it?

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

This is a little earlier time frame "1908" but this is a sliding door on a wooden steamschooner. It also had sliding doors on the sides of the engineering cabin.

- 11 replies

-

- 19th century

- Galilee

- (and 6 more)

-

Patrick, a fellow could get lost onboard your vessel. So many things in so small of space, great job!

- 1,083 replies

-

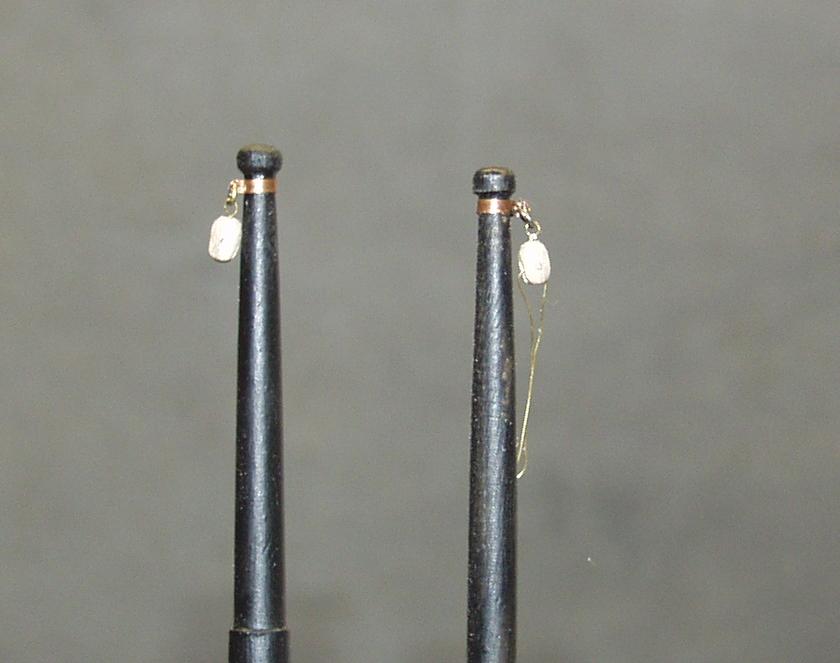

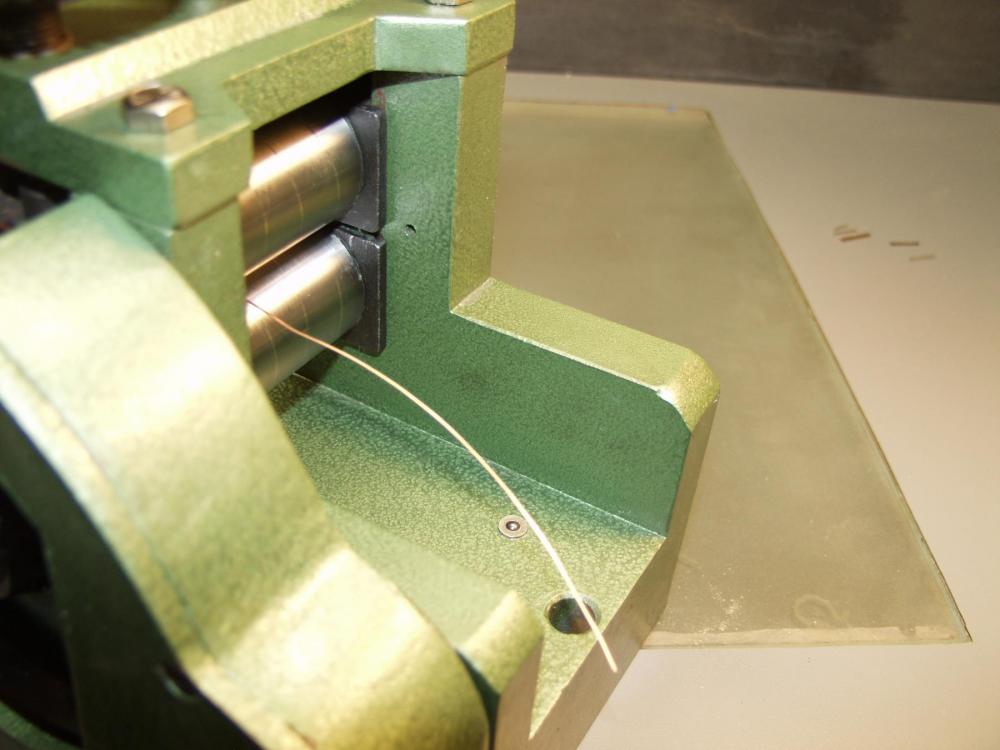

While I work on my boats for my project I have just received a new toy/tool. Its a rolling mill and here is a example of that I can use it for. These mast bands which are for my current project were made from rolled copper wire I just need to blacken them.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

rolling mill

steamschooner replied to steamschooner's topic in Metal Work, Soldering and Metal Fittings

Bill, It does have that grizzly green dosn't it. It's from a jewerly supply called Contenti -

Well I went and bought me a rolling mill so I would not have to pester a friend who had a bead roller I have used. Used for what you ask? A rolling mill purpose is to flatten soft wire, brass, copper, soft mild steel, even aluminium. The rolls are adjustable so one can get different widths and thicknesses for each gauge of wire. The flattened wire can then be used for a number of things like, mast bands, straps. hinges and more. The rolling mill I purchased is one of their economy models (lowest cost ) and weighs 50 plus pounds. It is about 8.5 x 8.5 x 12" with handle.Granted you can make alot of flatten wire in a short time and will not have to use this tool often. But hey you know how us model builders like "Toys=Tools " Here is a sample of flattened wire. Here are some bands I have made for a project.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.