-

Posts

358 -

Joined

-

Last visited

About steamschooner

- Birthday 10/14/1952

Profile Information

-

Gender

Male

-

Location

Western Washington

-

Interests

West coast steamschooners, Tugs, local craft, turn of century vessels

Recent Profile Visitors

-

steamschooner reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - Scale 1:16

steamschooner reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - Scale 1:16

-

steamschooner reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

steamschooner reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

-

FriedClams reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

FriedClams reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

Peerless by Cathead - 1:87 - 1893 sternwheel Missouri River steamboat

steamschooner reacted to a post in a topic:

Peerless by Cathead - 1:87 - 1893 sternwheel Missouri River steamboat

-

mtaylor reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

mtaylor reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

Canute reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Canute reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

steamschooner reacted to a post in a topic:

Okahumkee by Harvey Golden - 1/96 scale - 1870s Inboard Stern Wheeler - post 1892 layout

-

Keith Black reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Keith Black reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

Mirabell61 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Mirabell61 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

Valeriy V reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Valeriy V reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

steamschooner reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

steamschooner reacted to a post in a topic:

SS Klondike II by John Ruy - 1/8” = 1’ - 1/96 scale Sternwheeler Riverboat

steamschooner reacted to a post in a topic:

SS Klondike II by John Ruy - 1/8” = 1’ - 1/96 scale Sternwheeler Riverboat

-

Mirabell61 reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

Mirabell61 reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

-

Harvey Golden reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

Harvey Golden reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

-

FriedClams reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

FriedClams reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

-

KeithAug reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

KeithAug reacted to a post in a topic:

USS Takelma (ATF 113) by steamschooner - 1/96 scale - fiberglass and styrene

-

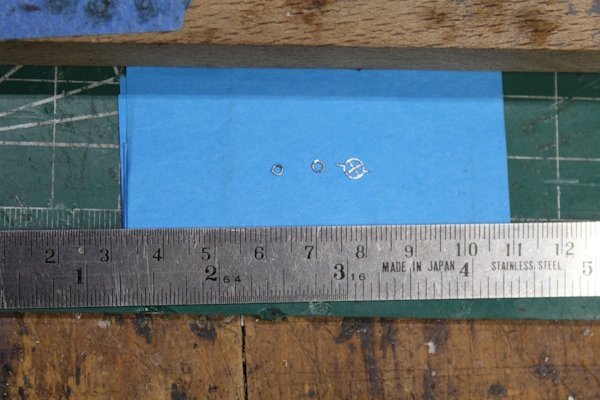

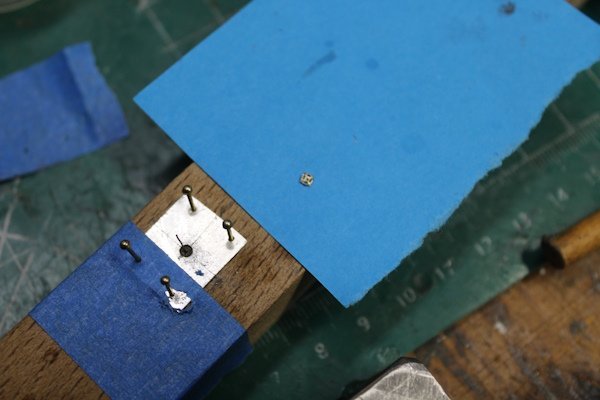

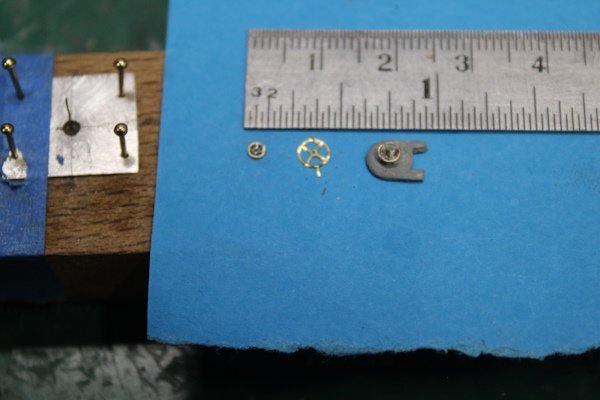

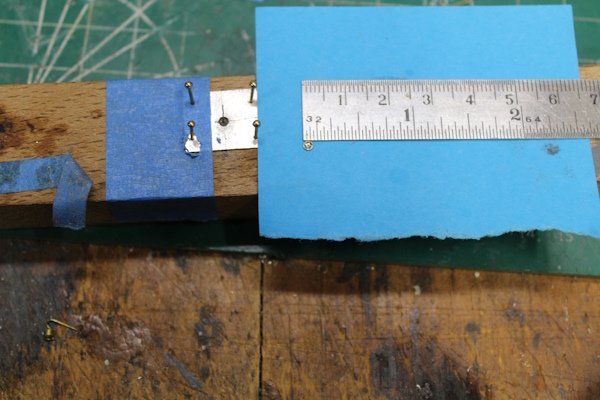

I thought I would show my method of making some handwheels for my project. I start by making some rings of 28 ga brass wire. OD of ring is the size needed for the handwheel I need. I had some P.E. handwheels from a watertight door set. I than drill a center hole for the wheel shaft. The rings and P.E. hw were tinned on one side. I used a jig to center both parts tinned sides facing each other. They were than soldered together in the jig. Once removed from jig they were trimmed up and cleaned up.Only needed a few of difference sizes. Ah the joys of sratchbuilding Steve

-

Eric, West Coast steamschooners used painted canvas as a deck covering. Many ships did I believe. Tar paper covered decks I would think would be a mess on hot days as the tar melts and is tracked all over the place. Course it may have been a different type of tar paper than we use today. Just my 2 cents worth. Steve

- 254 replies

-

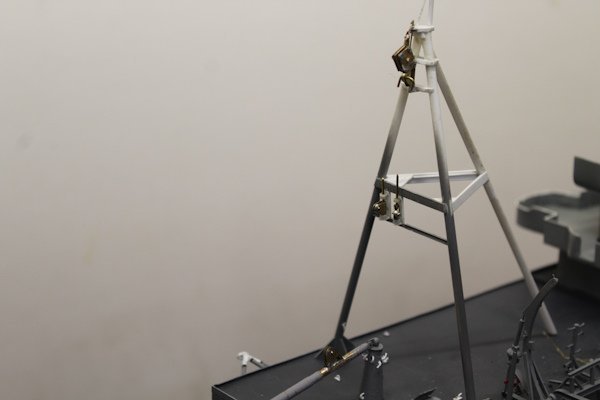

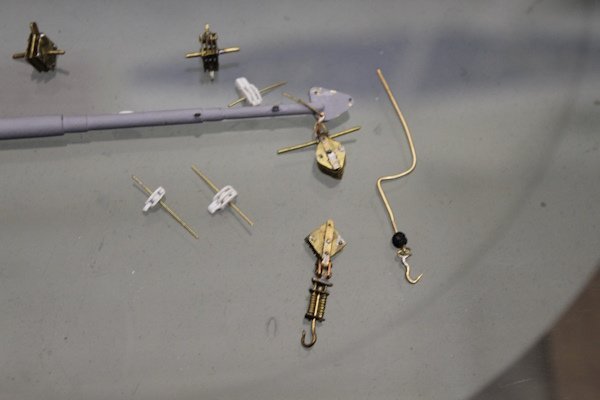

Wow, It's been a few months since I have posted anything. Well now that winter is here I can spend some time in the shipyard. Have spent some time making rigging for the boom. With no measurement drawings it is difficult to determine sizes. Using a number of photos isn't as helpful as one might think. But that is the nature of scatch building. So here are a few photos of what I have been doing. I like to leave pivot pins long so I have a way of removing them until final assembly.

-

mystery clamps

steamschooner replied to steamschooner's topic in Modeling tools and Workshop Equipment

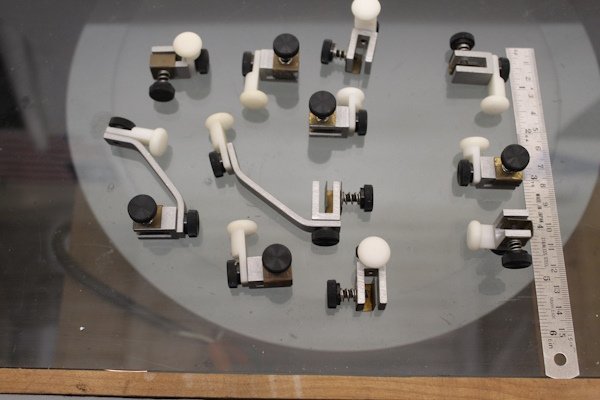

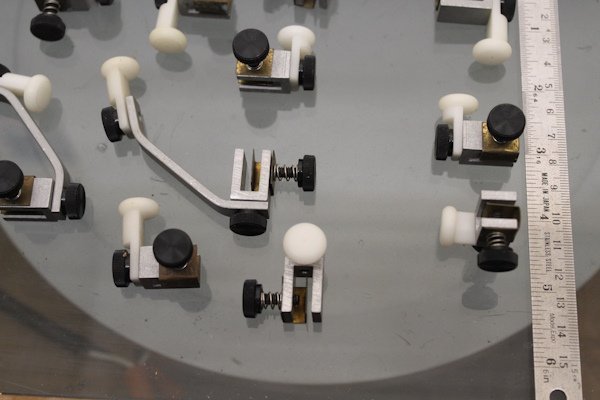

Dave, Thank you for identifying them as planking clamps. Was not too sure on how they worked. Steve -

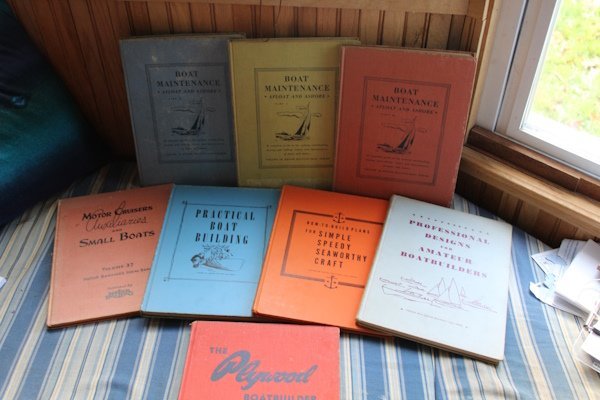

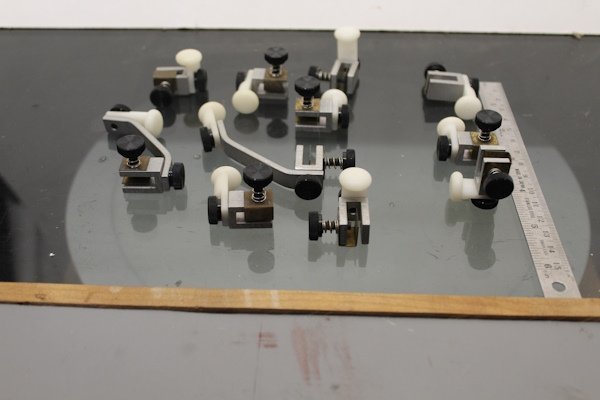

Couple days ago I bought a small box with ship modeling wood and a few hulls. In the bottom of the box was a mixture of parts and tools. Well I didn't think 5 bucks was a bad deal. Included were some clamp like items. I do not know if they are for model building or not. I have never seen this type before. Any idea's ?

-

Wonderful new project Cathead, I will be checking it out. Steve

- 254 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.