Clark

Members-

Posts

311 -

Joined

-

Last visited

About Clark

- Birthday 04/07/1955

Profile Information

-

Gender

Male

-

Location

Leipzig/Germany

-

Interests

Ships, books, jogging

Recent Profile Visitors

-

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

-

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Ryland Craze reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

Knocklouder reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Knocklouder reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

Craigie65 reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Craigie65 reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

Mowzer reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Mowzer reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

ccoyle reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

ccoyle reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

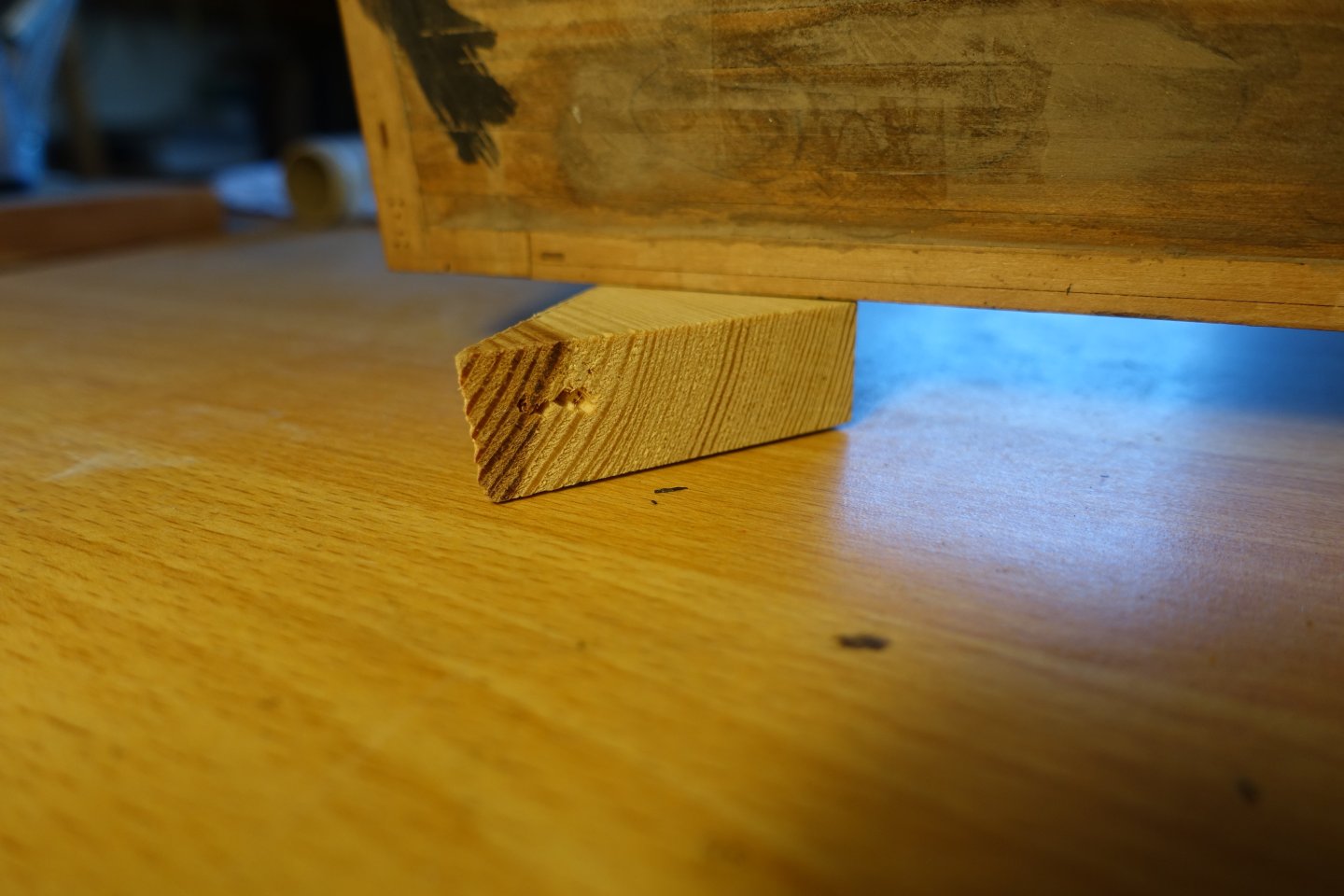

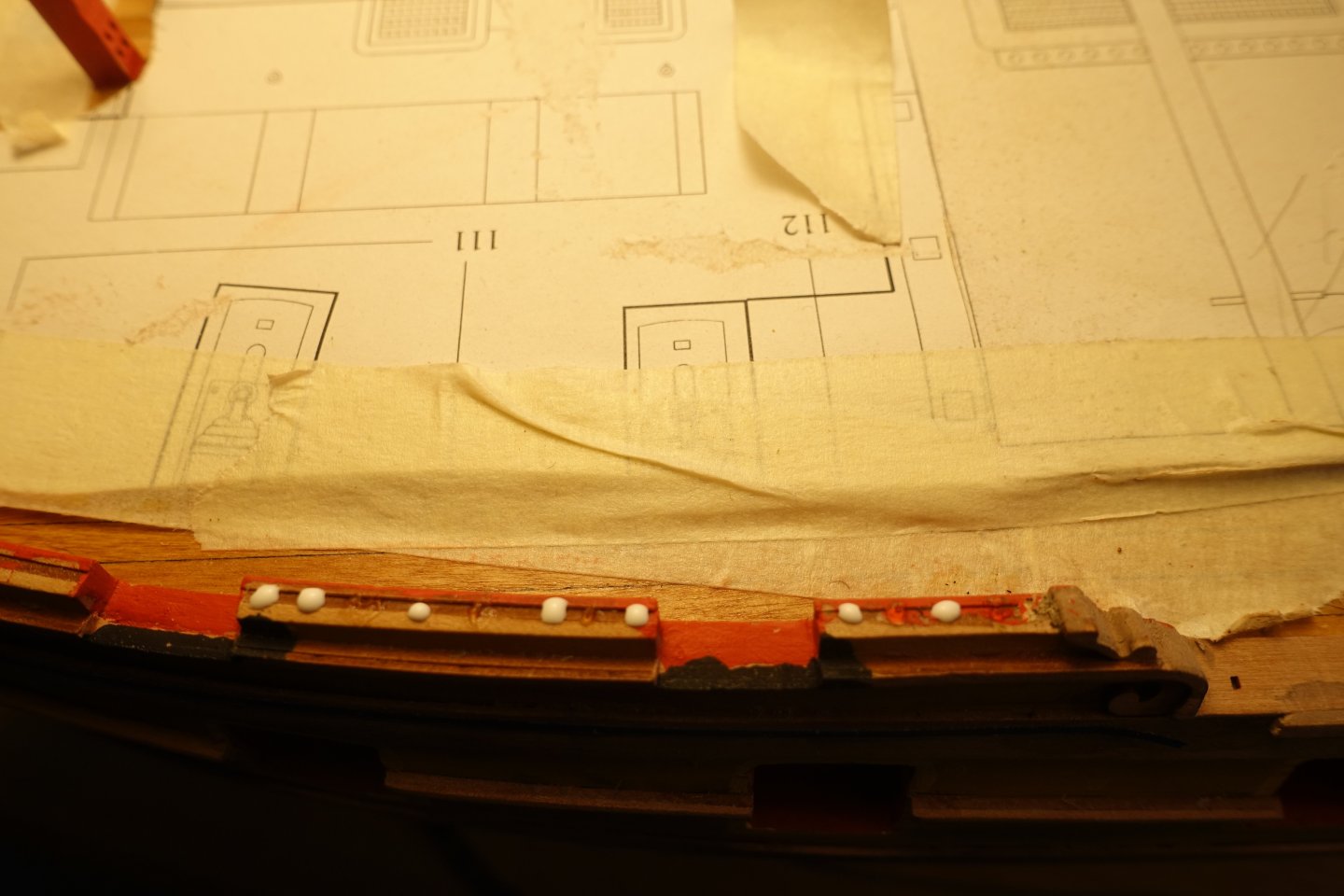

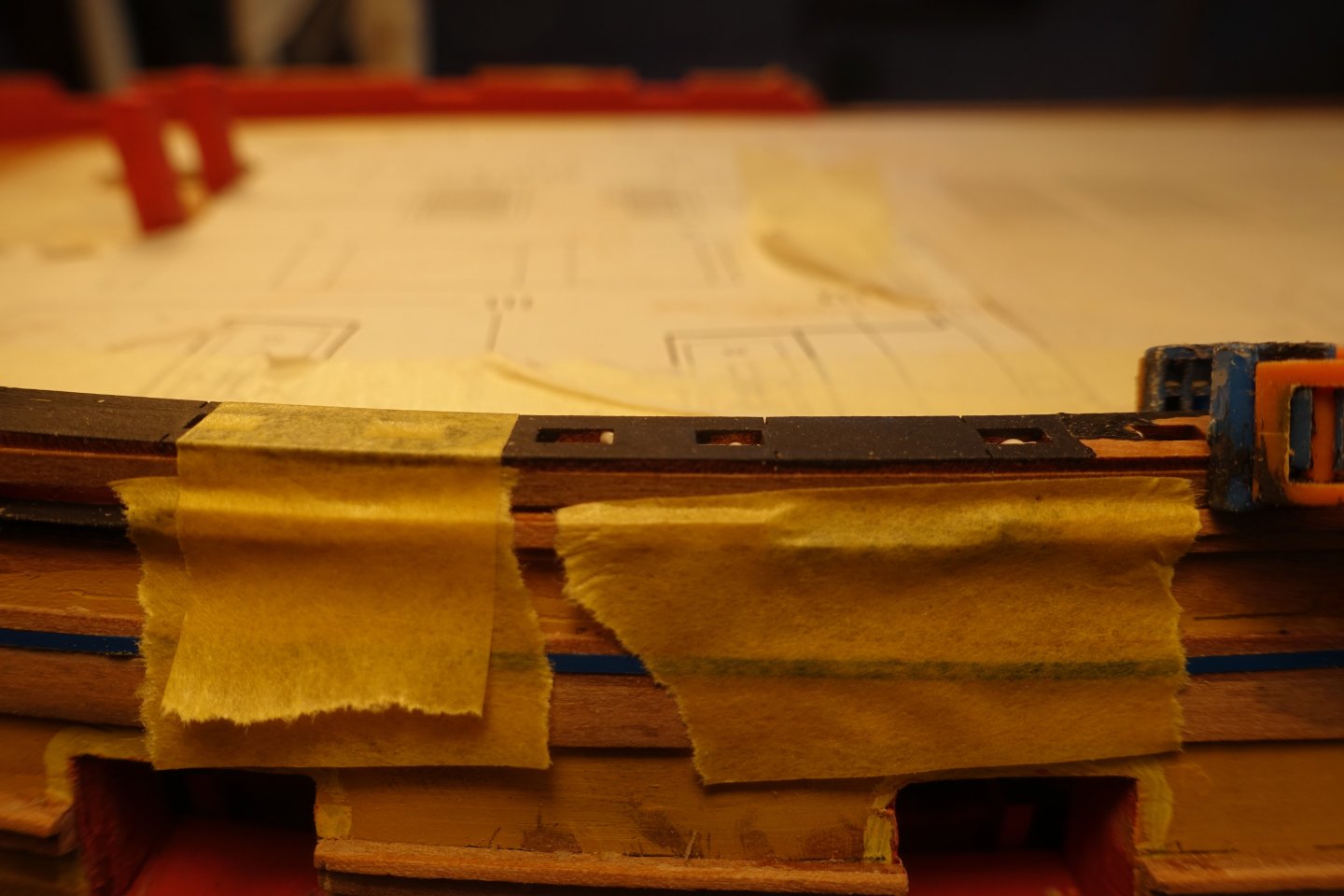

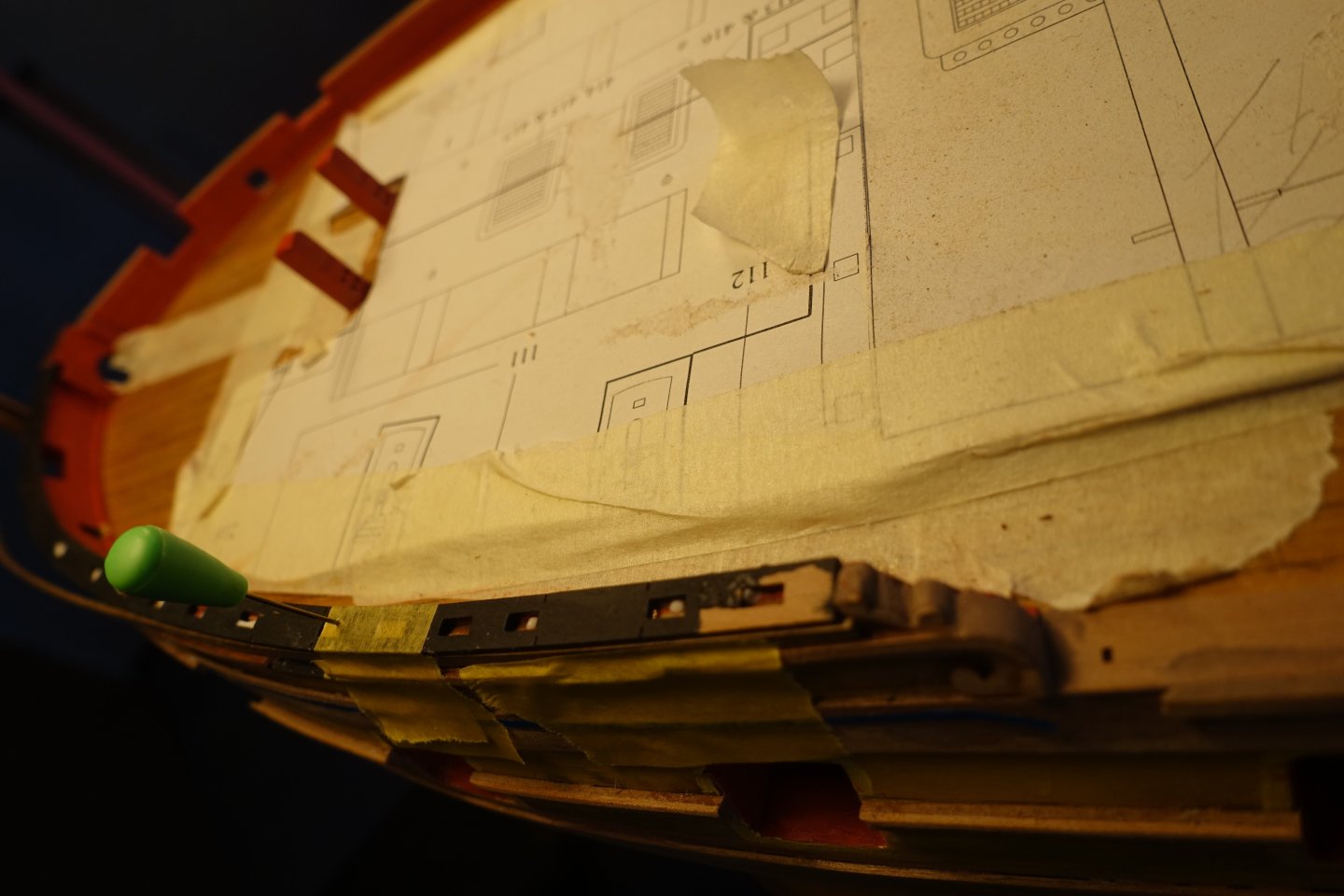

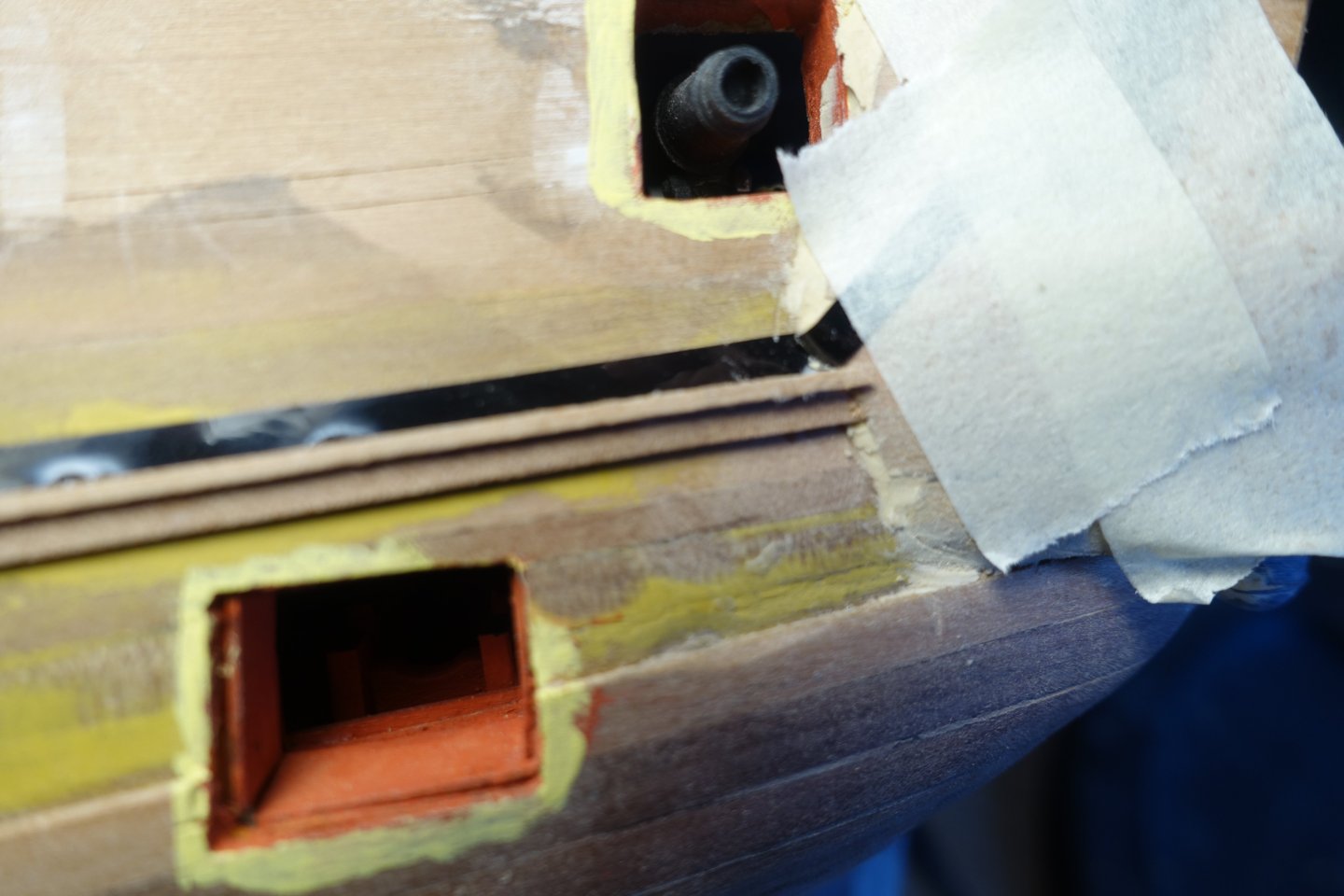

Copper plating of the hull, starting at the keel I didn't want to use the copper tape supplied, but ordered the copper plates offered by Chris. This initially posed the problem of the best adhesion. After several attempts, I ended up with CA for gluing the copper plates. I then used the following. 1. a piece of wood slightly smaller than a single copper plate to hold the plates 2. CA, which was spread wide with a small wooden strip 3. a leftover piece of balsa wood to press the plates onto 4. acetone and cloth to wipe off excess CA gel The piece of wood for fixiing the plates was only slightly moistened so that the plate would adhere to the small piece of wood. The lower small copper strip, which forms the end to the keel base, was problematic. Here I first cut the copper plates with overhang on the keel and glued them on. The keel base was then marked with a thicker wooden strip. The wooden strip also served to fix the cut copper plates in place. The copper plates were then filed down to the height of the strip. The copper plates can be filed well if they are fixed properly. Based on previous experience, further copper plating will certainly take some time. I am also not sure how the other layers should be designed. There are very different approaches in this forum.

-

Ryland Craze reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Ryland Craze reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

Desertanimal reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

Desertanimal reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

Clark reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Clark reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Clark started following Mirabell61

-

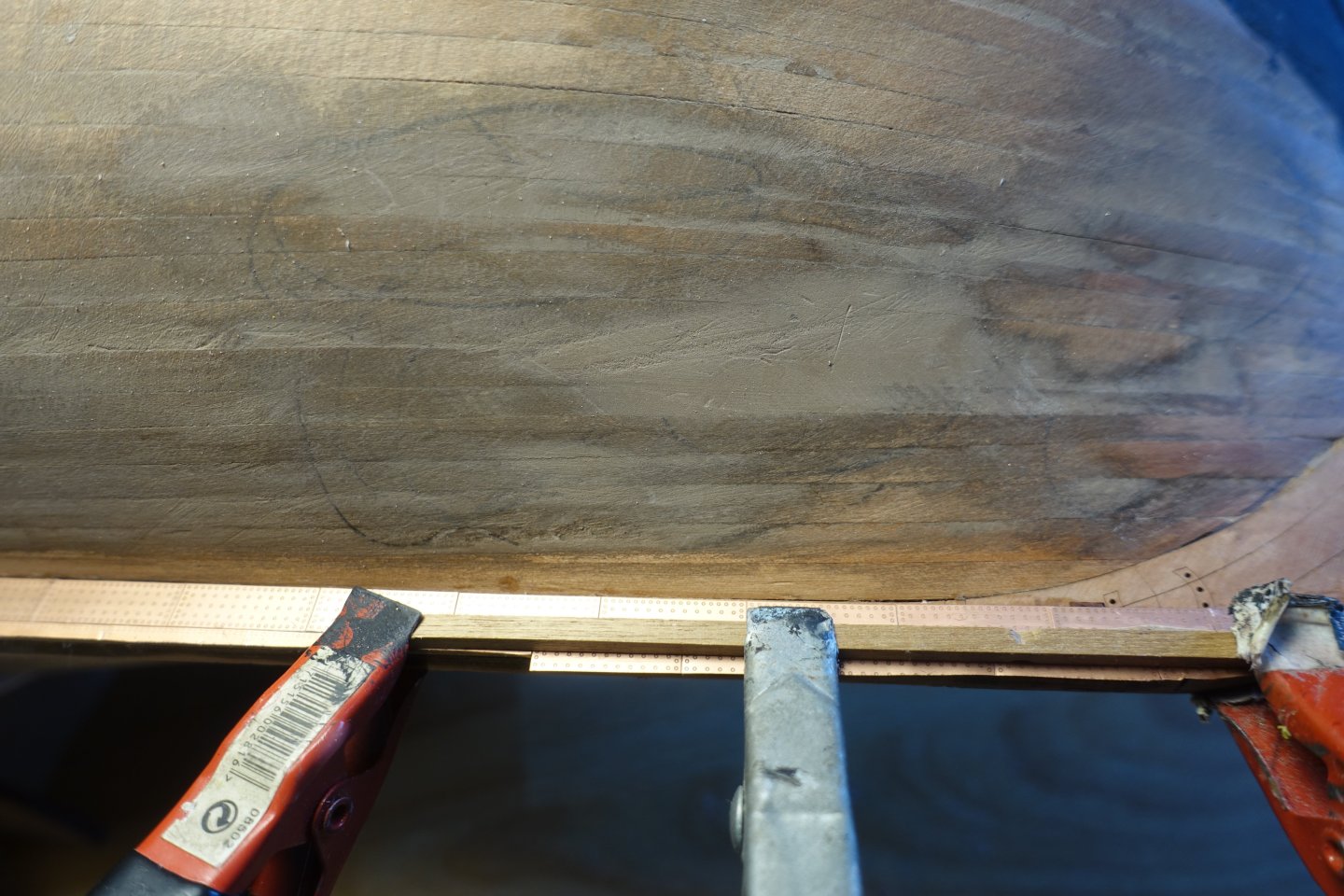

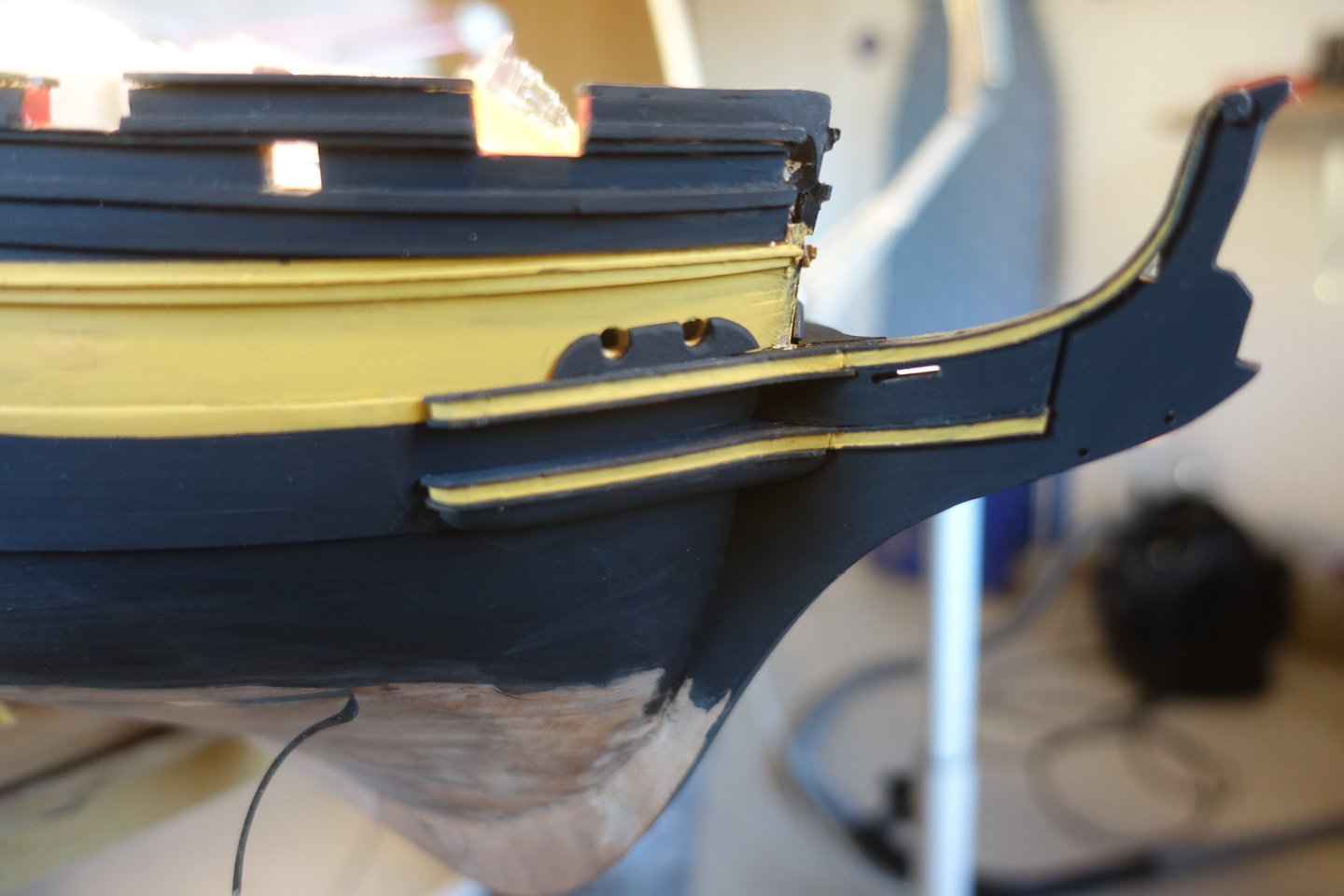

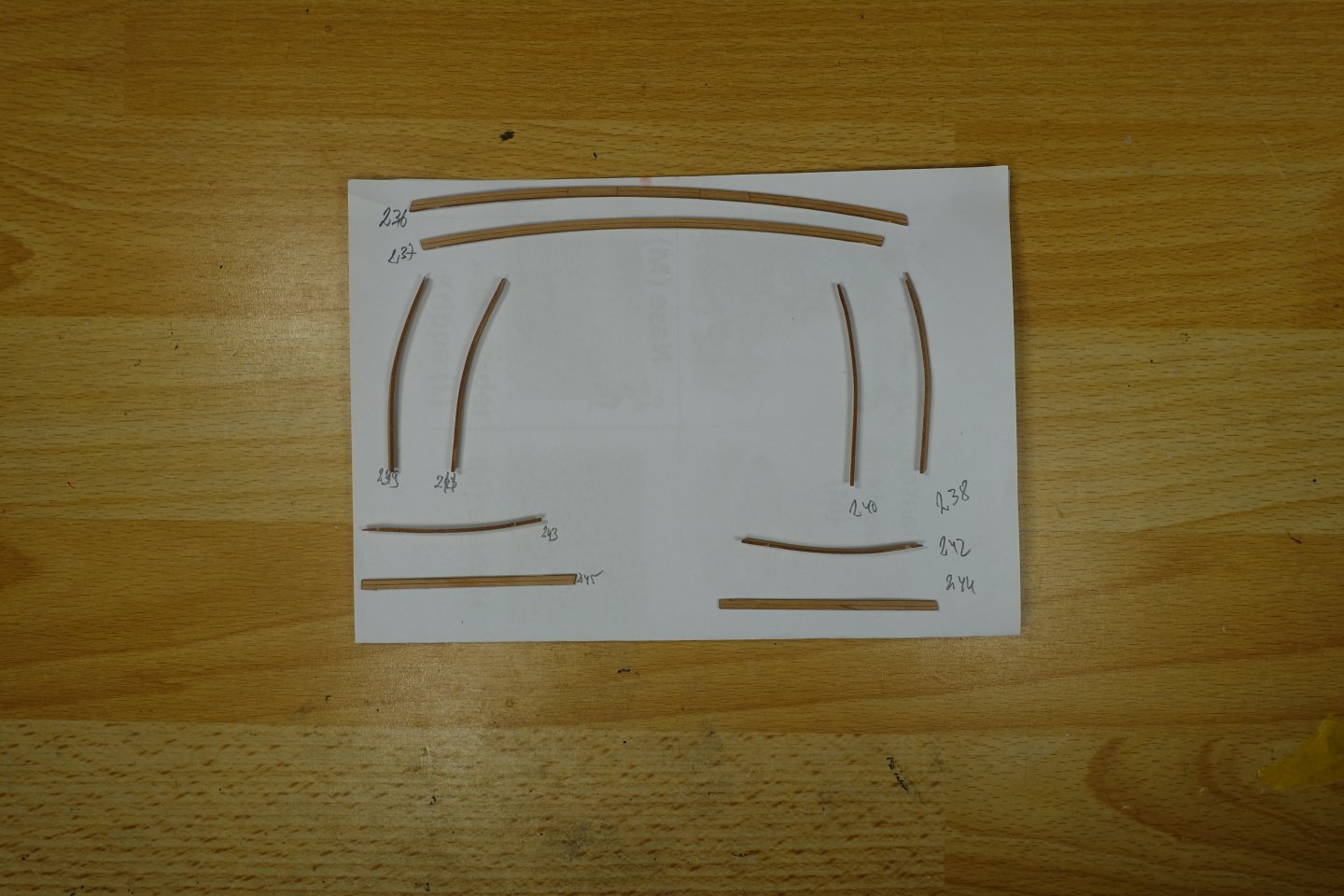

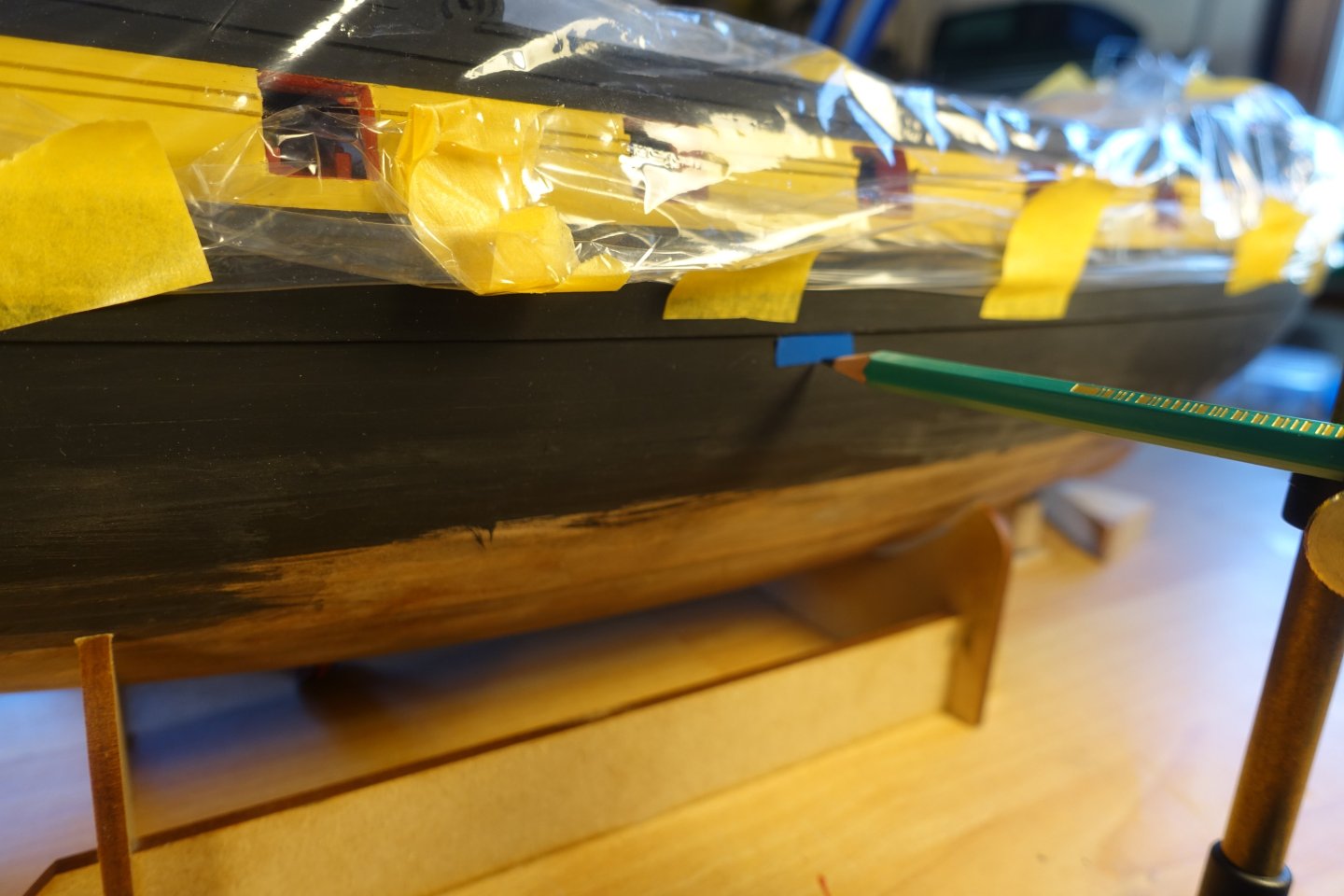

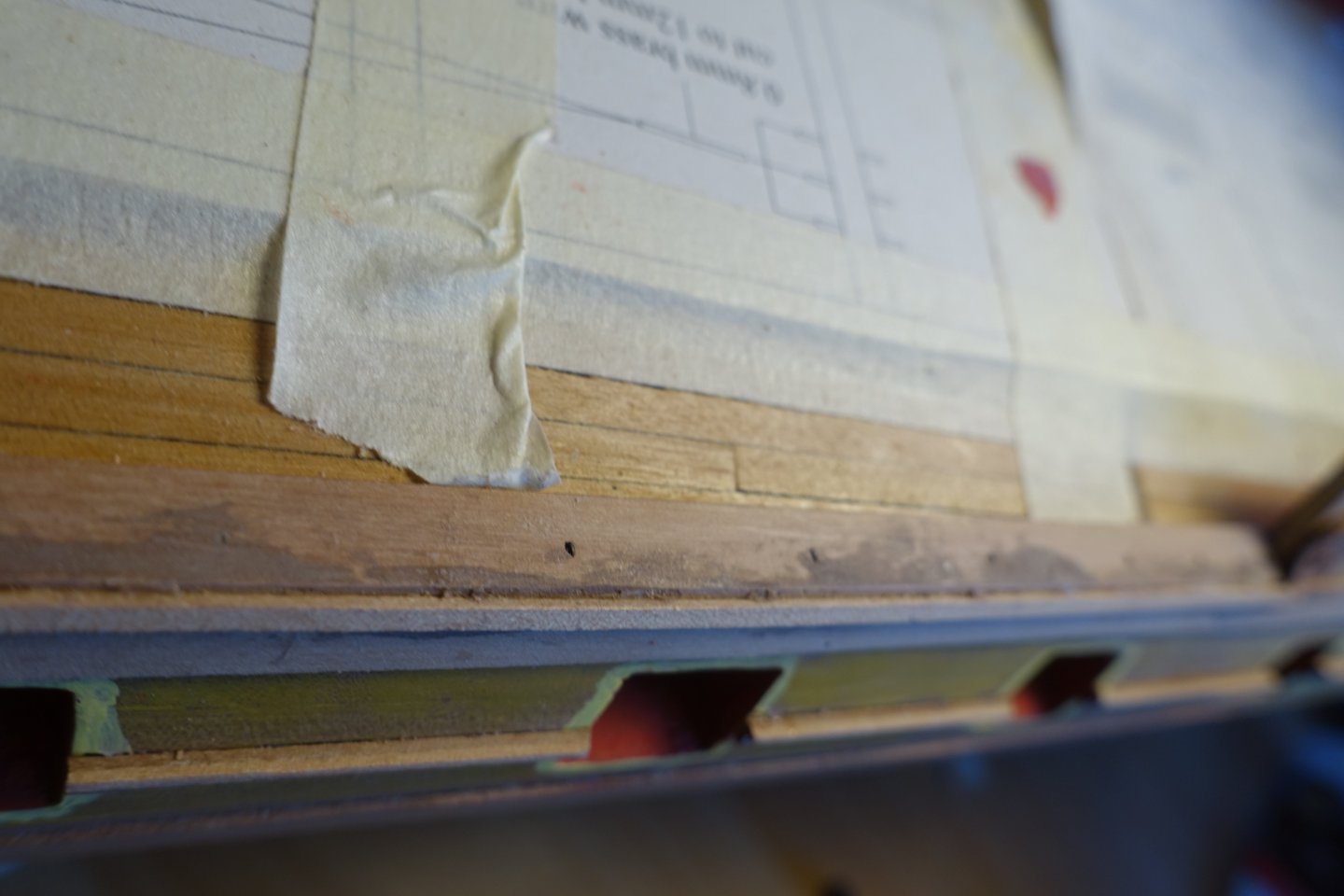

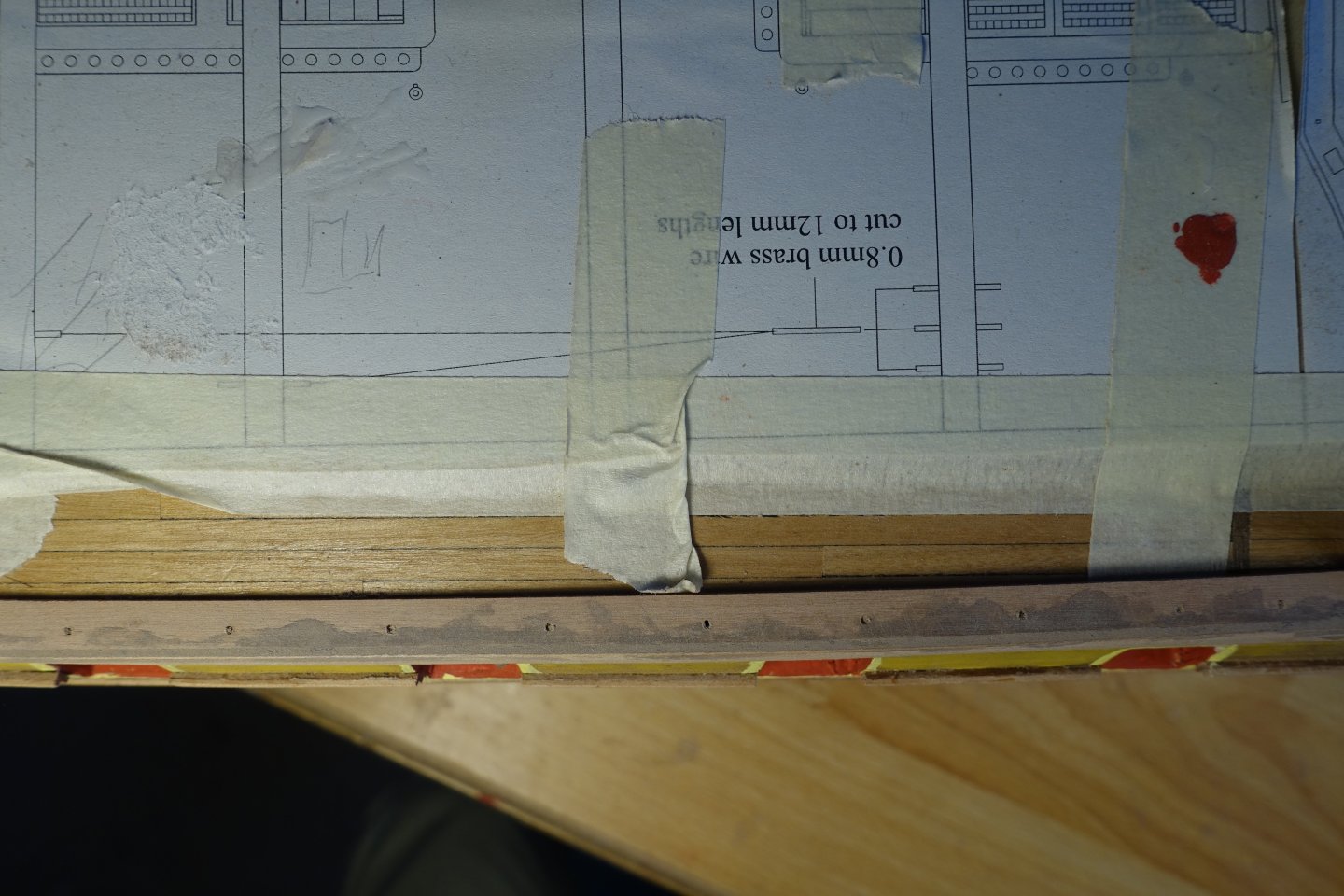

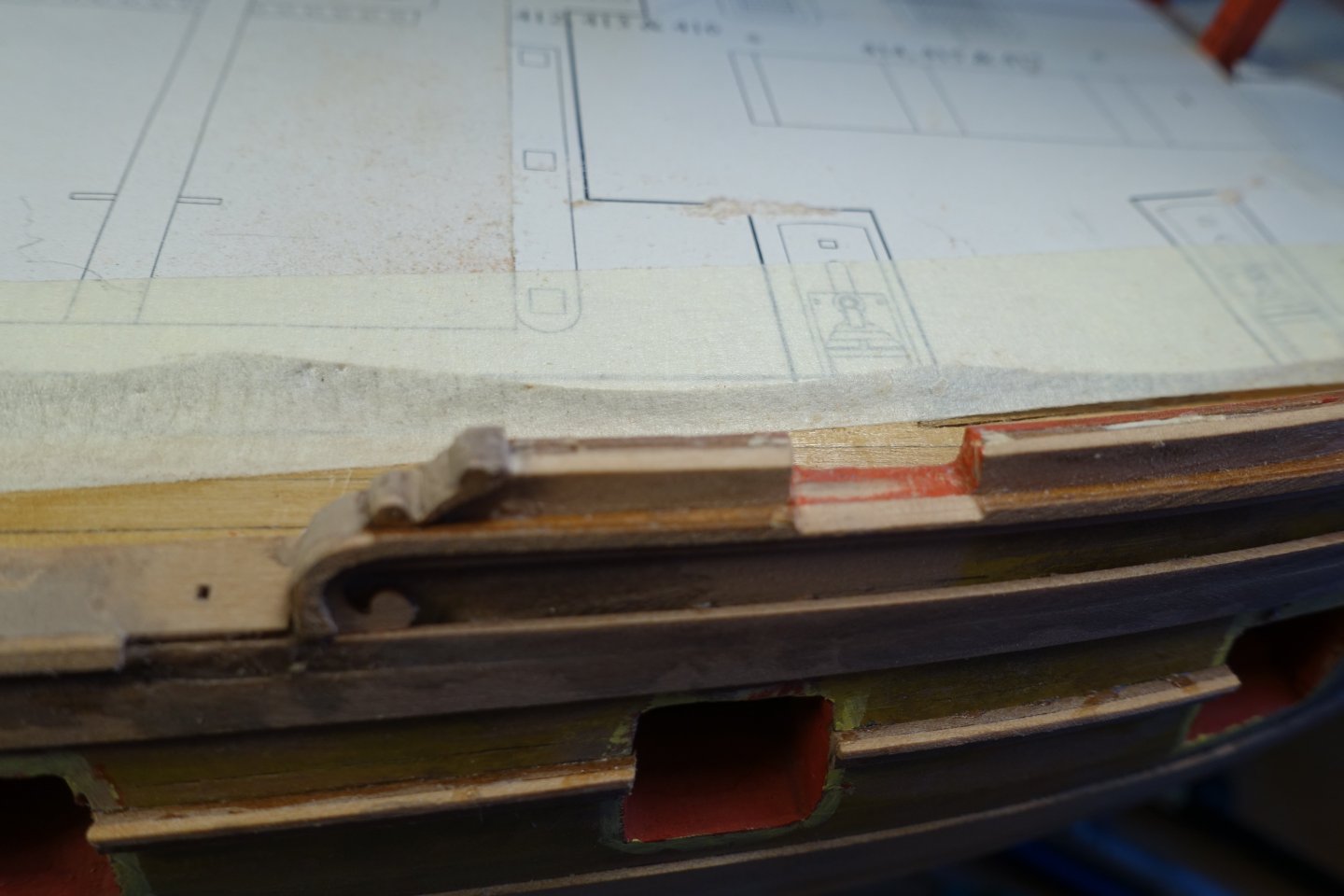

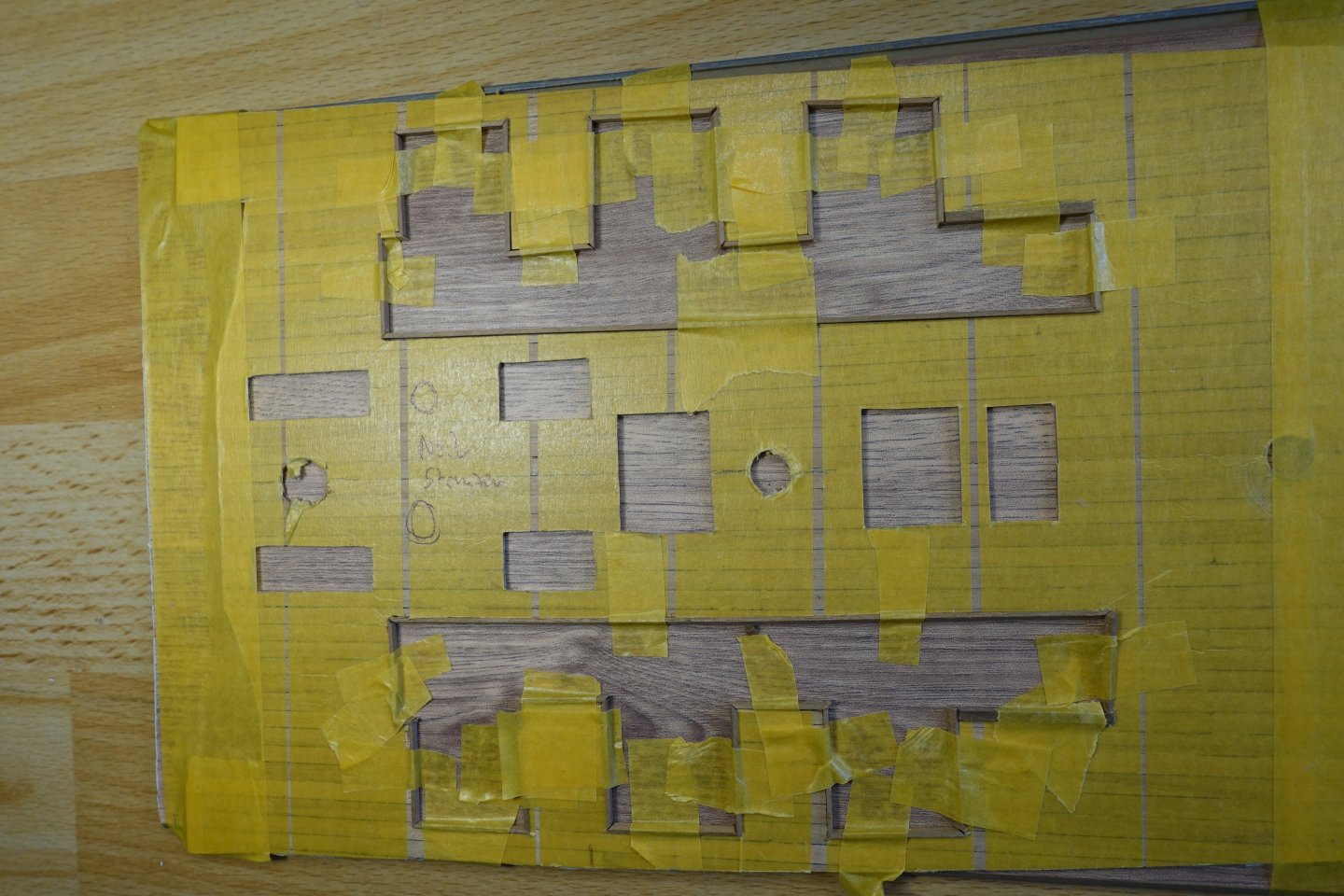

Decorativ strips / wash edge at the bow The strips on the bow only had to be adjusted slightly. After fitting, these were painted, attached to the bow and then covered with cling film. Decorative strips at the stern The decorative strips at the stern were adapted. Among other things, the strips directly above and below the windows of the side gallery were bent with heat. After fitting, these were painted and glued on. Waterline According to the plan, the waterline at the bow is 90 mm from the keel base and 96 mm at the stern. Accordingly, I raised the bow by 6 mm and checked the difference with a remaining piece of 6 mm. Bow: Stern In the centre of the hull, the distance between the waterline and the wale was measured on the plan and transferred to the ship. The waterline was then first marked with a pencil and then re-marked with tape. I am currently trying out the best way to glue the copper plates . I'm not going to use the adhesive copper tape from the kit. I have realised that the copper doesn't adhere so well to CA. Clark

-

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

-

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

Clark reacted to a post in a topic:

HMS Indefatigable 1794 by Mowzer - Vanguard Models - 1:64

-

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

muratx reacted to a post in a topic:

HMS Indefatigable 1794 by Clark - Vanguard Models - 1:64 scale

-

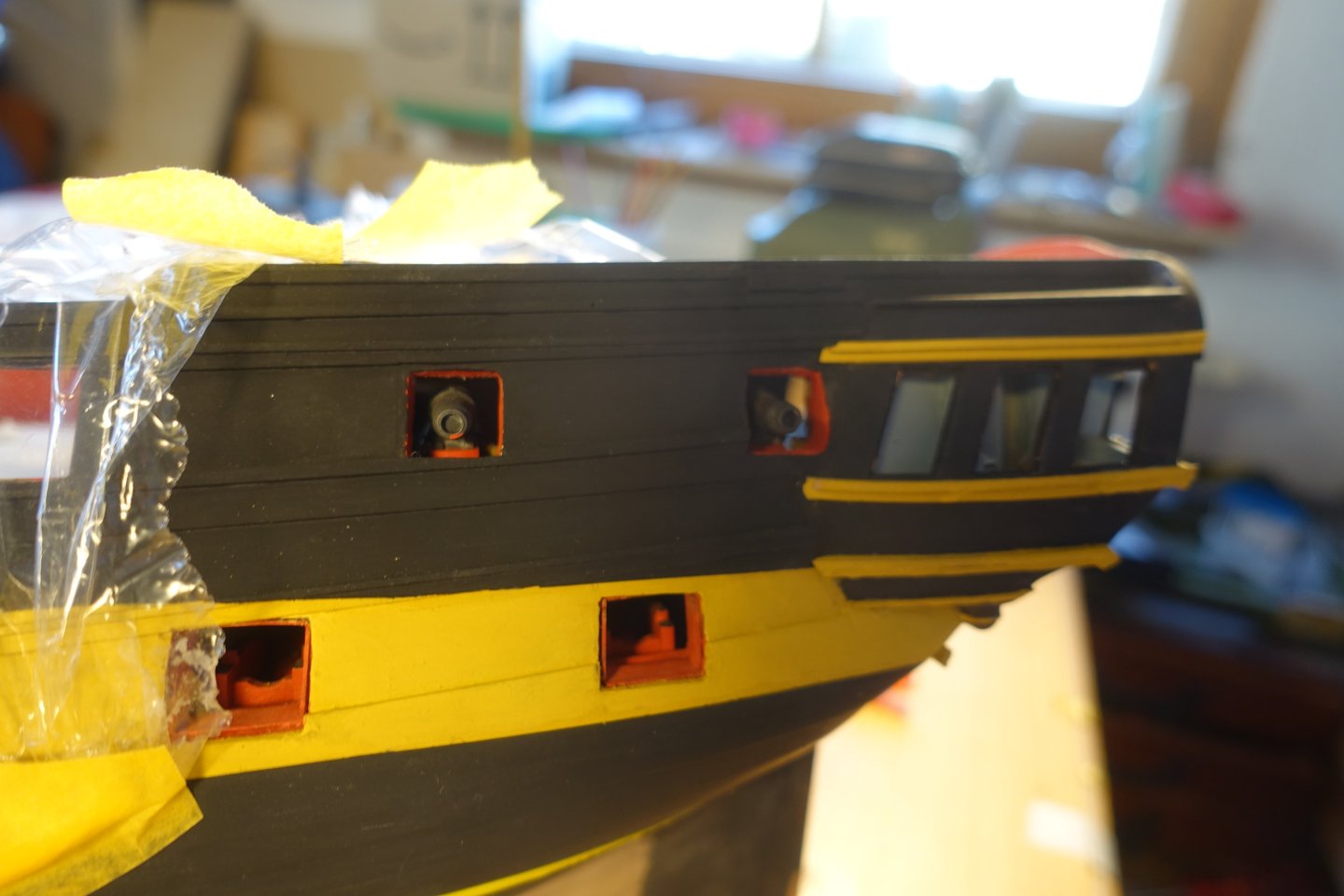

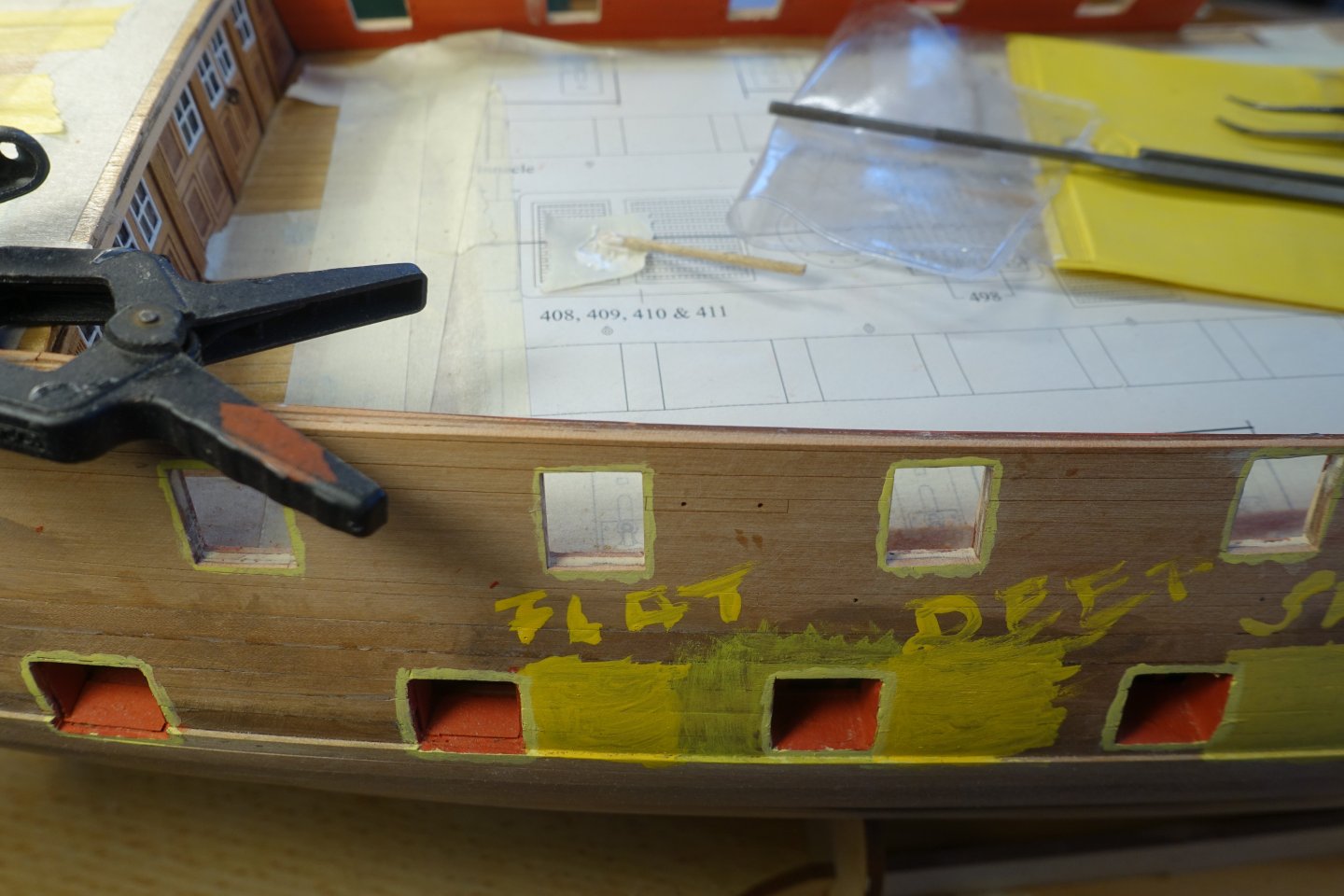

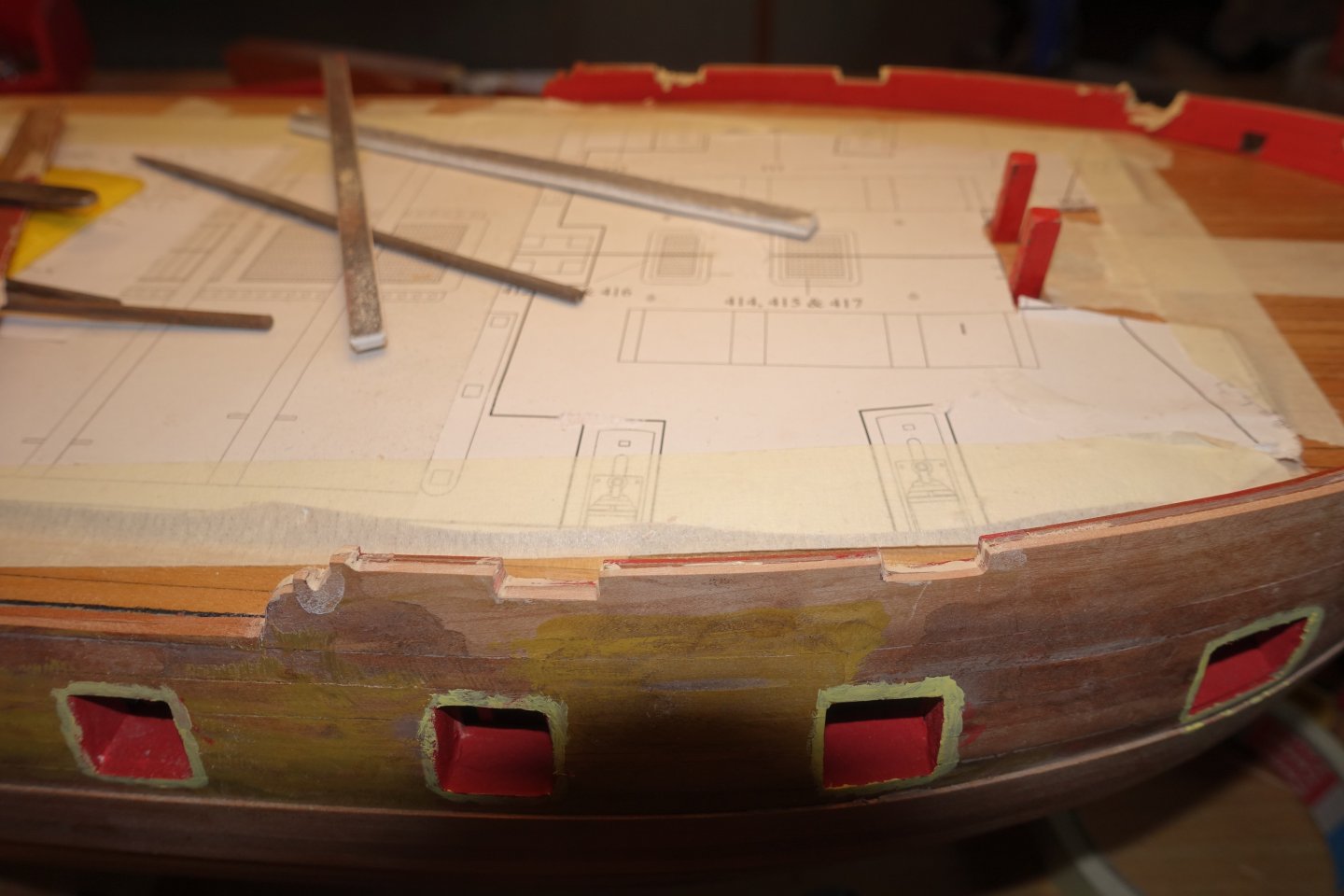

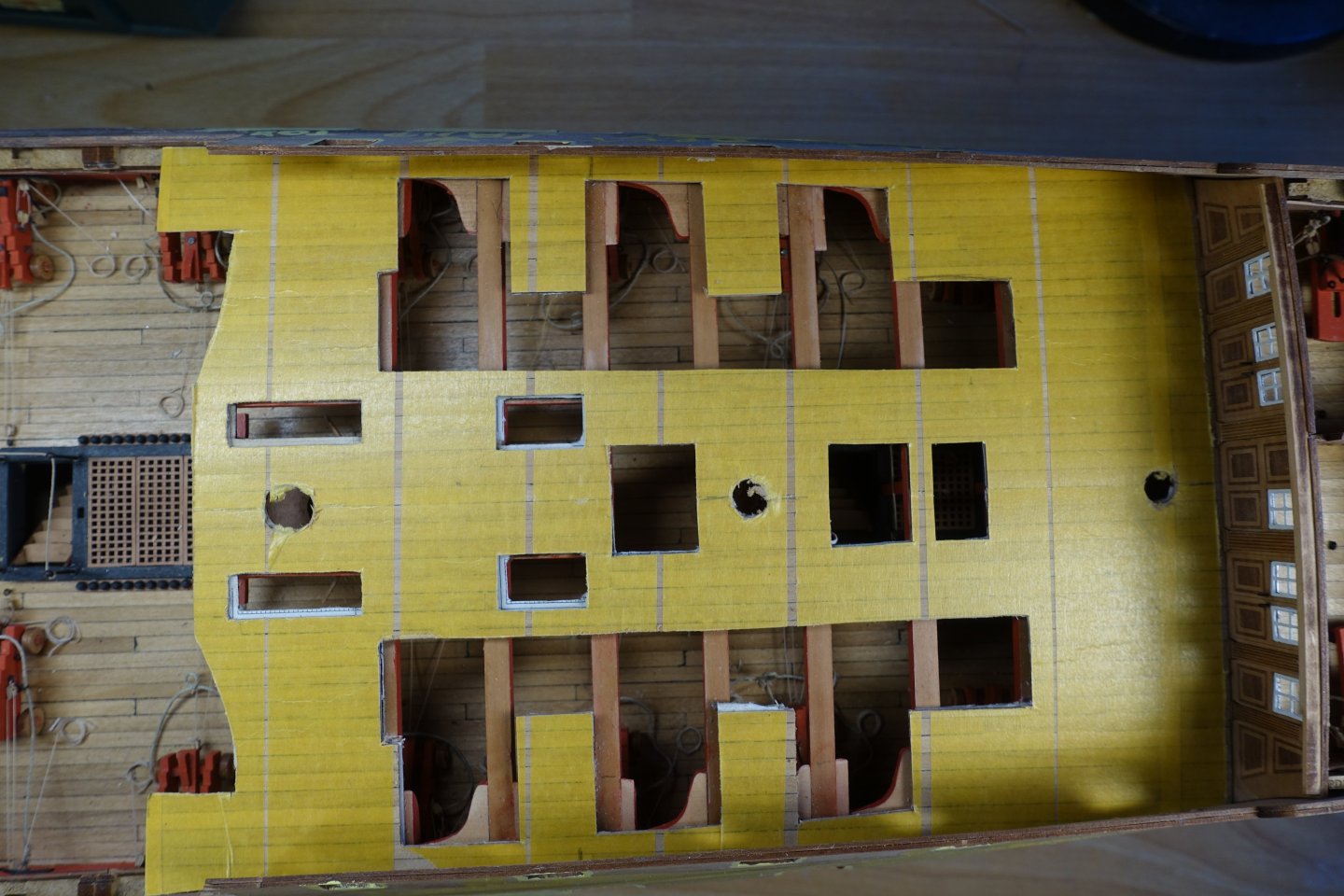

Painting the hull I tried out several shades of yellow and involved my grandchildren in the decision-making process. In the end, we opted for a simple yellow ochre. The paints were diluted heavily with water (approx. 30% water) and then applied in a total of three coats. I don't have an airbrush. First, the ochre yellow was applied and then the (overpainted) red in the gun ports was touched up. To apply the black paint, the yellow areas were masked off according to the plans and the transitions were sealed with matt clear varnish. The large amount in the picture was still being spread. First, the port side was painted black. After applying the black paint, the gun ports were touched up again. Then the side was covered with cling film. 6385 The starboard side was painted. I had the impression that the paint was still too shiny, so I coated the entire paint job with ultra-matt clear varnish. You can see the difference in the photograph against the light. The upper part is coated with ultra-matt clear varnish. The lower third towards the keel is only painted with black paint. The ship after completion of the painting. 6388 Next, the decorative strips have to be attached to the stern and the stem post.

-

Clark reacted to a post in a topic:

Brig Le FAVORI 1806 by KORTES - 1:55

Clark reacted to a post in a topic:

Brig Le FAVORI 1806 by KORTES - 1:55

-

Clark reacted to a post in a topic:

HMS Spartiate by Admiral Beez - FINISHED - Heller - 1/150 - PLASTIC - kit-bashing the Heller Le Superbe

Clark reacted to a post in a topic:

HMS Spartiate by Admiral Beez - FINISHED - Heller - 1/150 - PLASTIC - kit-bashing the Heller Le Superbe

-

Clark reacted to a post in a topic:

HMS Spartiate by Admiral Beez - FINISHED - Heller - 1/150 - PLASTIC - kit-bashing the Heller Le Superbe

Clark reacted to a post in a topic:

HMS Spartiate by Admiral Beez - FINISHED - Heller - 1/150 - PLASTIC - kit-bashing the Heller Le Superbe

-

I'm curious to see how it continues. Clark

- 7 replies

-

- card

- De Zeven Provincien

-

(and 1 more)

Tagged with:

-

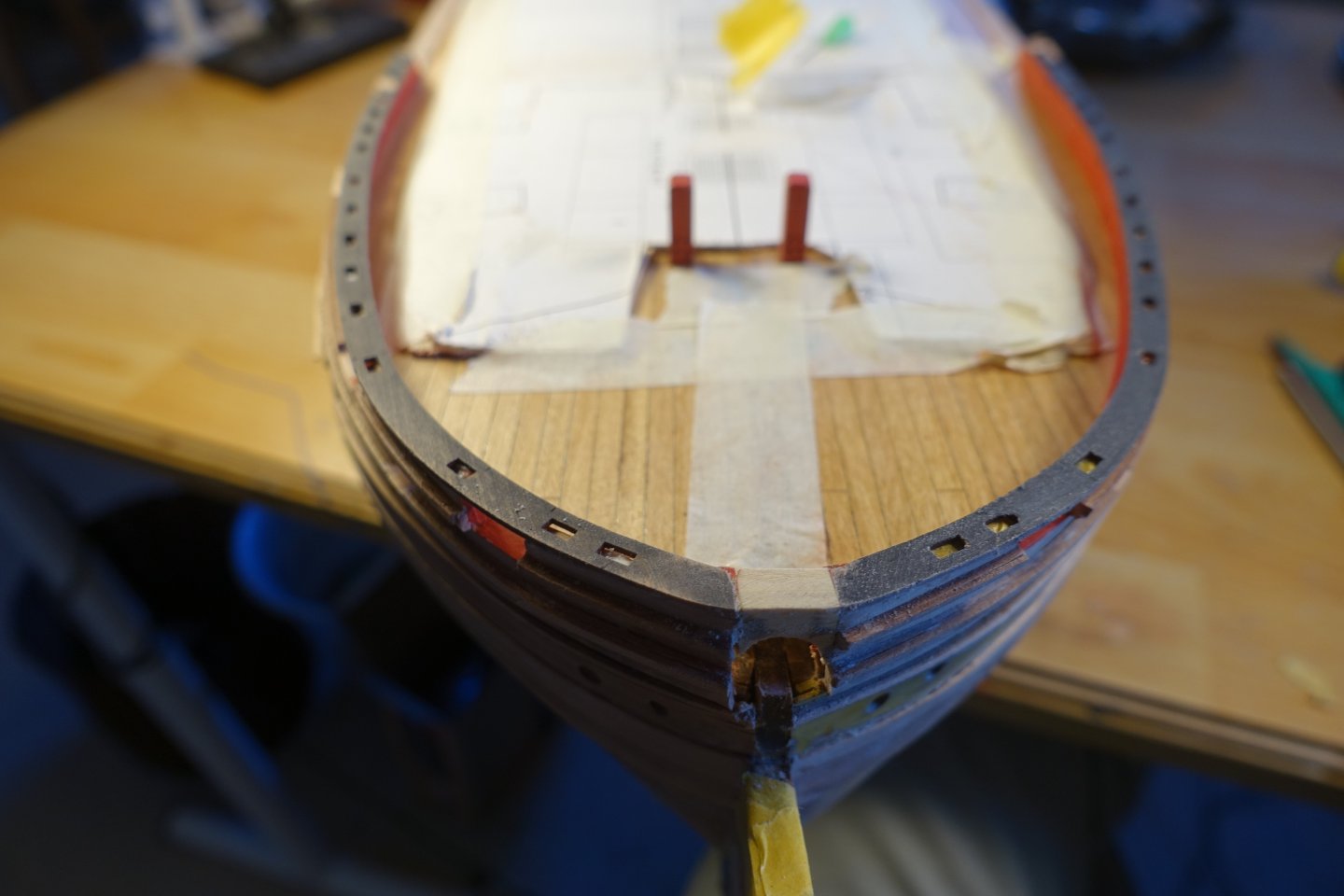

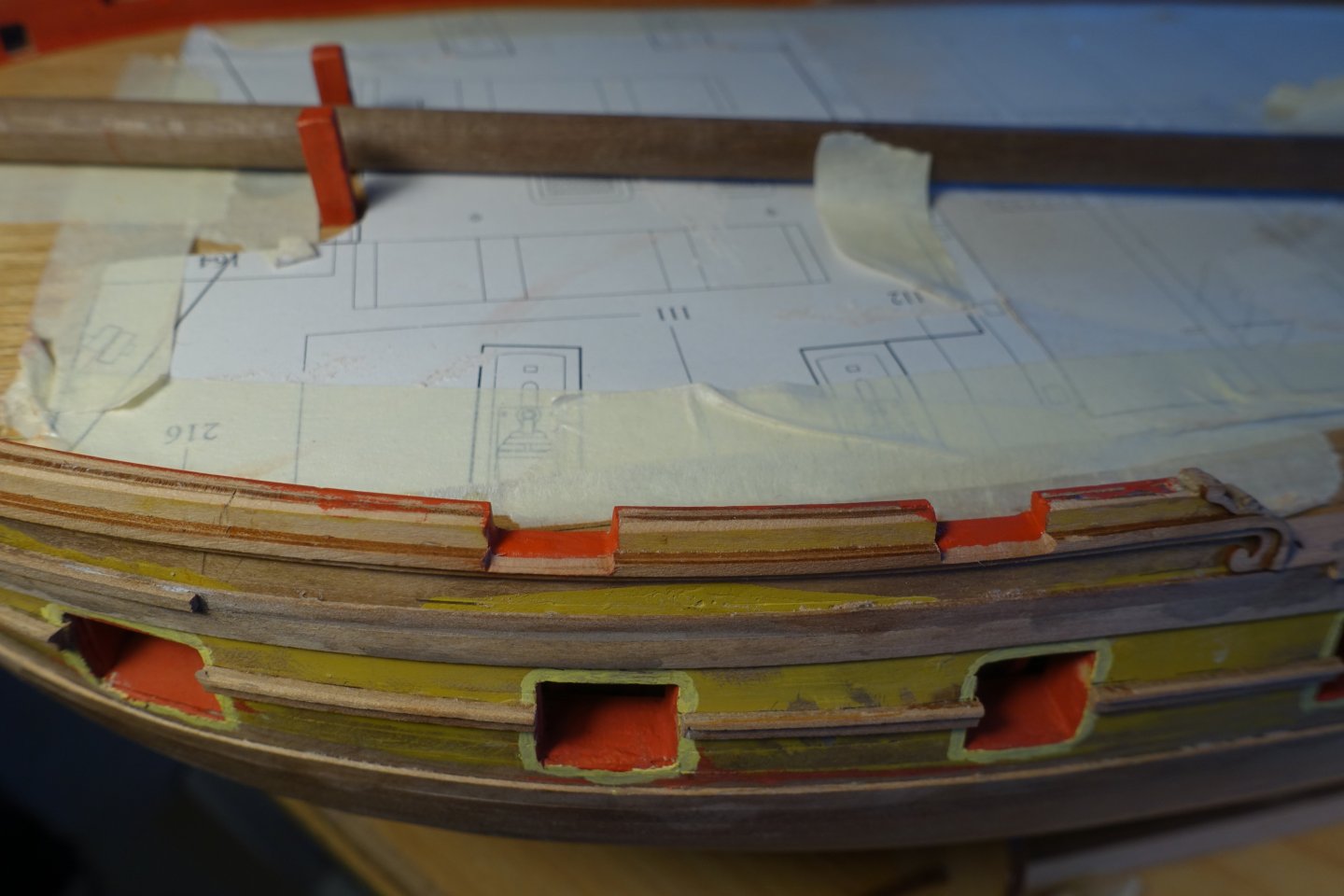

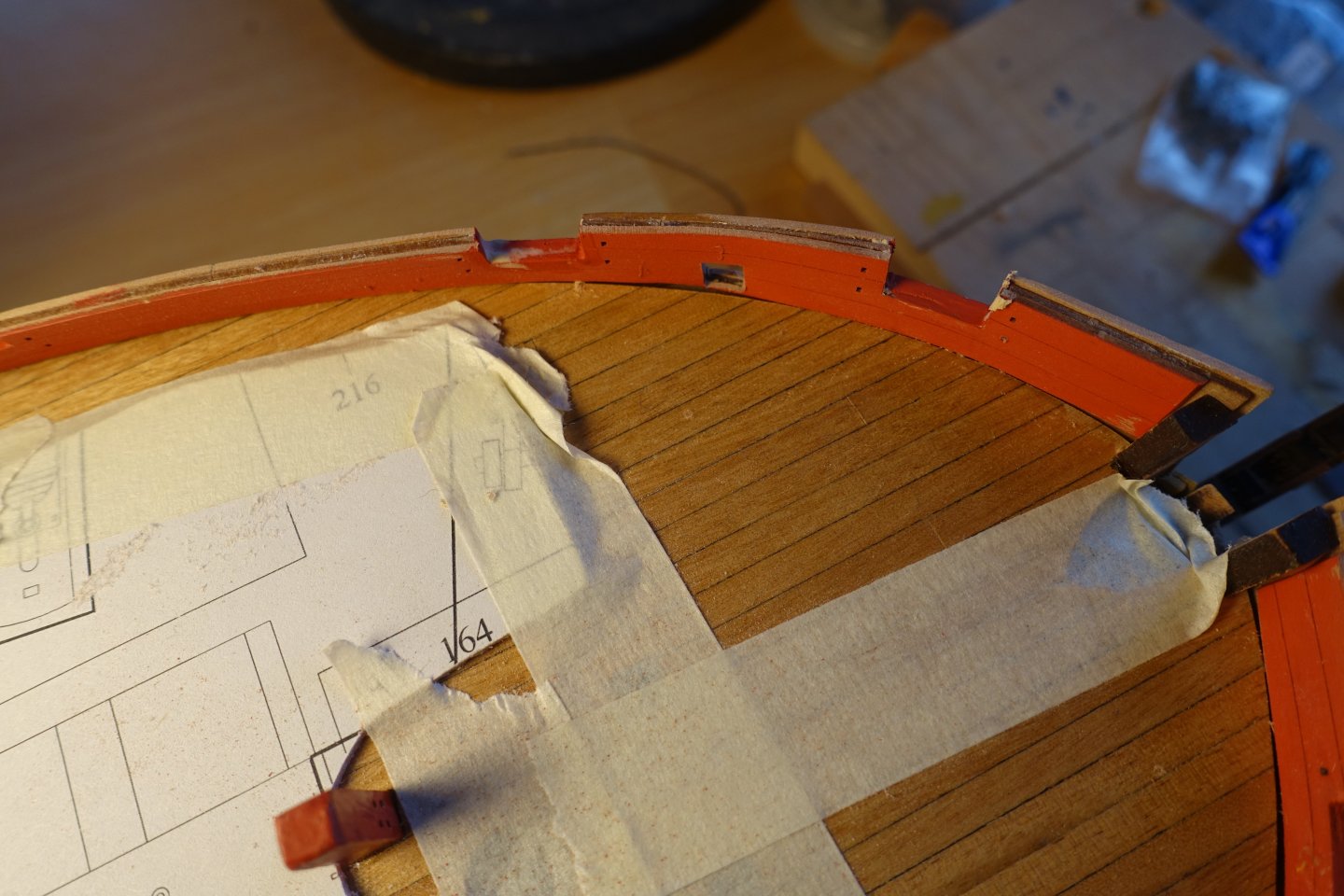

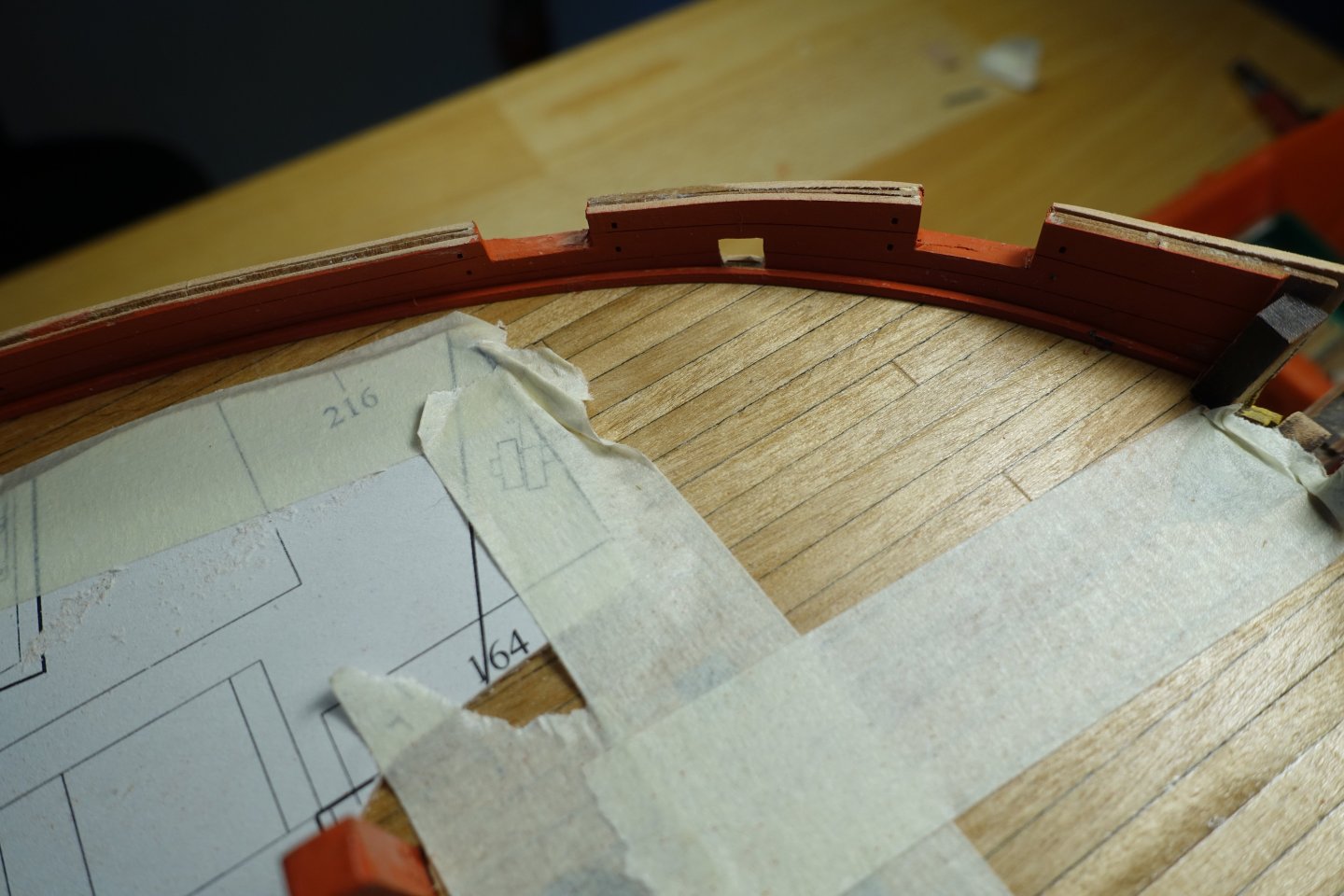

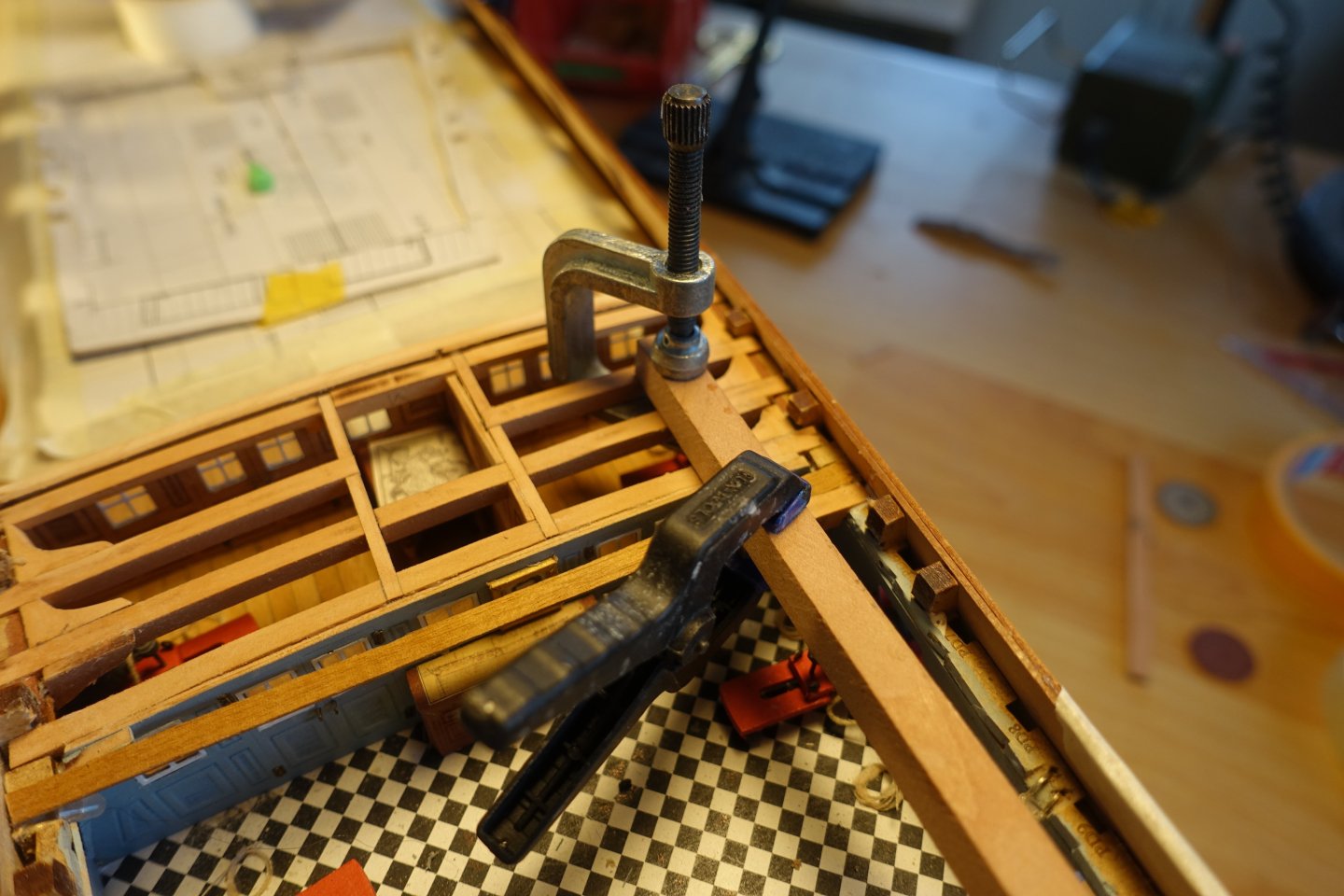

Gunwales To attach the gunwales, I applied PVA and CA alternately. The gunwales of the poop deck were applied flush with the inside. The bow end was slightly bevelled to create the transition to the bulwark. The gunwales of the quarterdeck were applied with the same overhang on the inside and outside (overhang estimated by eye). There is no adjacent upper decorative strip on the forecastle, so the overhang is correspondingly larger. For adjusting the forecastle gunwales, I used a strip approximately 2.4 mm wide and 1 mm thick to standardise the overhang. These were applied to the outside and then the gunwales were glued flush with them. At the bow end, the gunwales were adjusted to fit the inserted filler piece. Next, the planking on the hull must be checked again before painting and copper plating can begin.

-

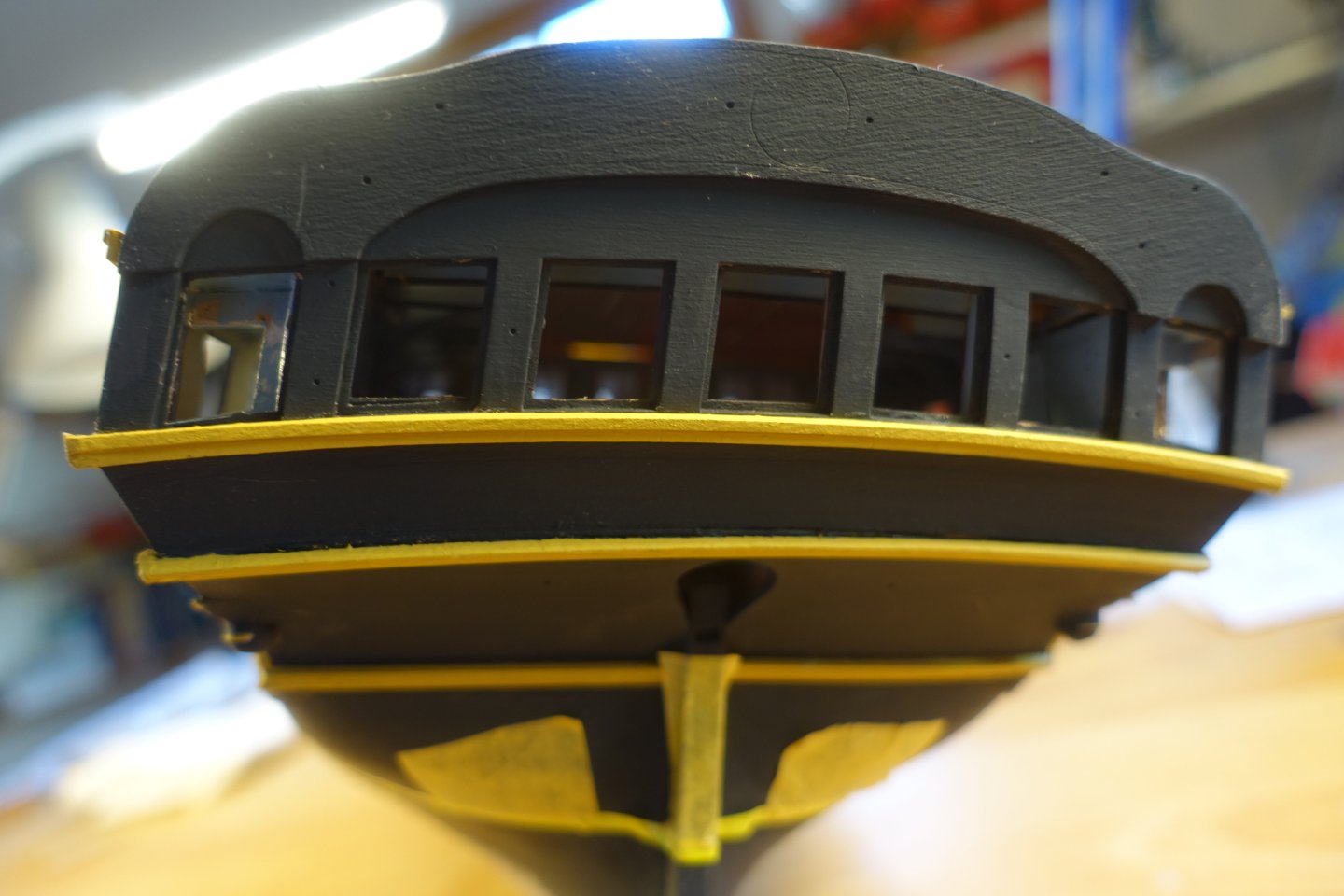

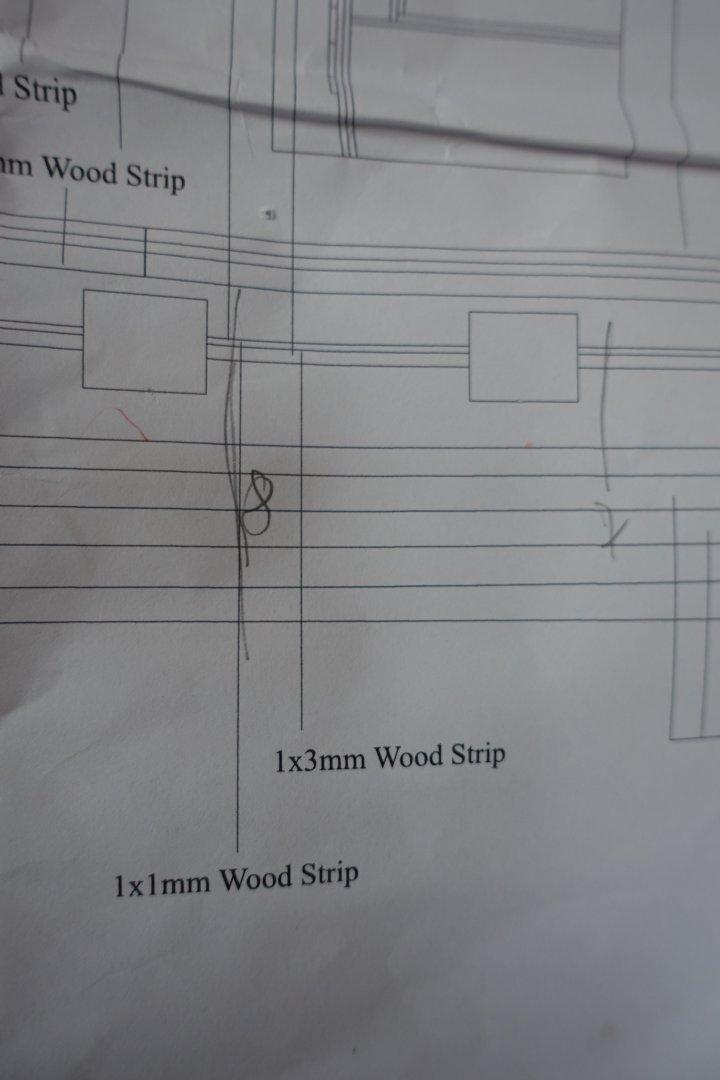

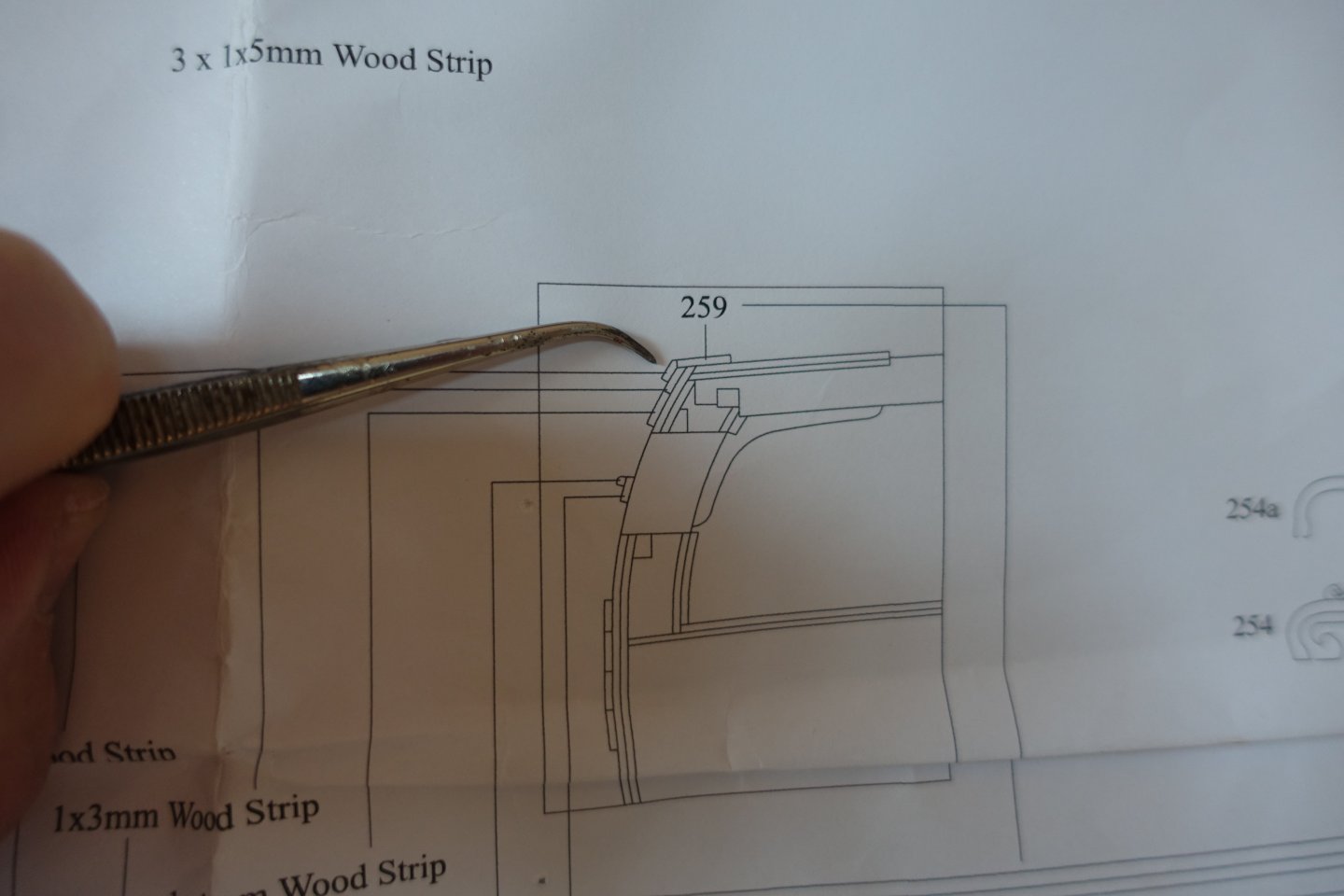

Decorative strips. I started with the strip directly above the wale, which runs partly over the gun ports. At first, I was a little confused because the manual describes that it is composed of a 3x2 mm and a 2x1 mm strip. Logically, these would then have to be bent over the short side. In the plan, this is corrected to 3x1 mm and 1x1 mm, which fits better. To standardise the distance to the wale, I first adjusted a 14.7 mm wide strip and marked the distances. I then glued the two strips together and shaped the bow area with heat. I then divided the entire strip into two parts so that I could adjust it to the bow and stern. I then joined the bow and stern sections together over a gun port. The other strips were attached according to the plans. To glue them in place, I applied small drops of PVA and CA glues alternately at intervals of approx. 10 mm. In order to align the gunwale correctly in the gangway area, I first applied a 2x1 mm thick strip directly to the roll-ups of the decorative strips. The plan shows that both the gunwales and the strip on top are slightly bevelled at the edge, creating a mitre. I wanted to attach the strip without a mitre. It seemed easier to me to fill the small gap with filler afterwards. The gunwales were glued flush with the orientation strip. Then the 3x1 mm strip was glued on. A 4x1 mm strip is glued under the 3x1 mm strip. I didn't do a very neat job in the stern area. A small gap appeared. The gap was filled with filler and sanded down. A 2x1mm strip is then glued onto the upper 3x1mm strip, which runs between the channels. This must be stepped down for a length of approx. 5mm before the gangway area, as it then covers the outer edge of the gunwale of the gangway and is therefore higher in this section. The small gap between the gunwales and this 2x1 strip was filled with filler and sanded down. In the area of the channels, the 2x1 mm strip was attached with an approx. 1 mm overhang. Once the channels are finally attached, it can still be reworked. The decorative strips in the areas of the gun ports were filed down. The gun ports were then painted. As already presented by Blue Ensign, the gap in the bow area was filled with a piece of wood, which was also painted. Otherwise, the cut lines are visible. The part would then have to be integrated into the gunwales later. All in all, attaching the decorative strips was a little more complicated than I had first thought. Next, the gunwales will be attached.

-

Clark started following HMS Indefatigable 1794 by alex791 - Vanguard Models - 1/64

-

Brief update. Inner bulwark. The patterns for the inner bulwark were relatively easy to fit. The gun ports were lightly filled. 6305 Openings were sanded . After painting the gun ports, it became apparent that there was a gap between bulwark at the port side and the deck in the bow area. 6312 The gap was covered with a 1 mm x 1 mm strip. Subsequently, a strip was also added to the starboard side and the quarterdeck. Next, the outer decorative strips will be attached.

-

Gallery As already described in the other blogs, the gallery is not that easy. I had my first surprise after installing the inner panel. The window supports were bent, perhaps because I had wiped off the excess glue with a damp brush. The wood is very sensitive to moisture. The indentation was levelled out with filler. The outer panel was slightly bent with heat. However, I had problems making the transition from the outer panel to the hull smooth. At least in my build, the panel was too short to be sufficiently bevelled. Here, too, I used filler to create the transition. As suggested by Blue Ensign, I bent the lower panels also slightly with heat. A simple hairdryer was sufficient. The kit includes resin drops. However, if you adjust these according to the plans, they protrude quite a bit. These need to be set back to fit reasonably well. The kit also includes MDF drop moulds. However, I wasn't entirely happy with these either. I therefore decided to set the drops back, which meant that they protruded above the counter. To continue the protrusion, I first glued the MDF drops to the resin drops. However, when I continued sanding, the MDF-drops fell apart, so I glued on a 4x4mm wood strip. This was then sanded down further. After cutting to size, the drop was glued on. The gap is caused by the drop meeting the wale in the upper section. The gaps were filled with filler. Next, I will adjust the inner bulwarks. I think this is a little less complicated than the gallery.

-

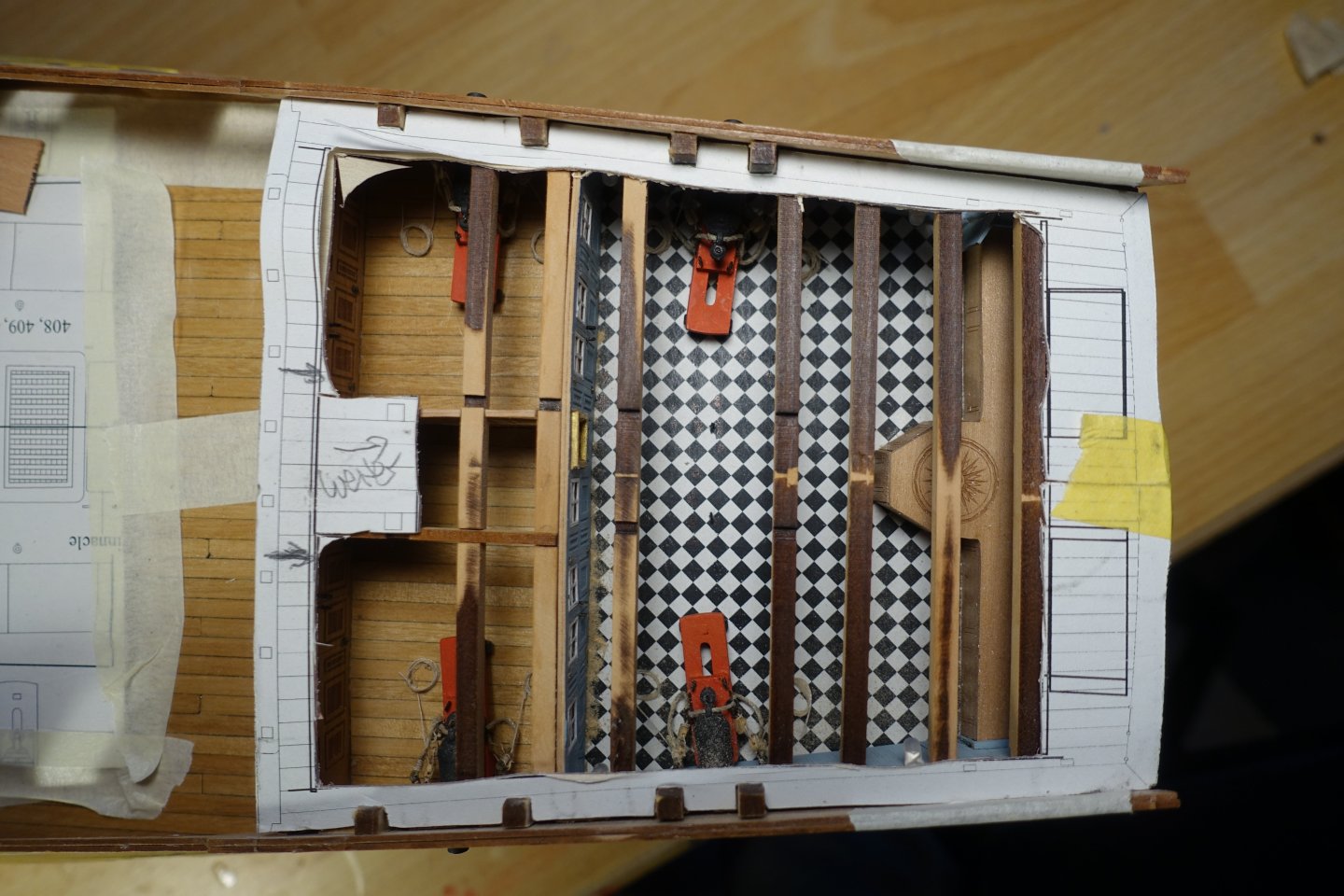

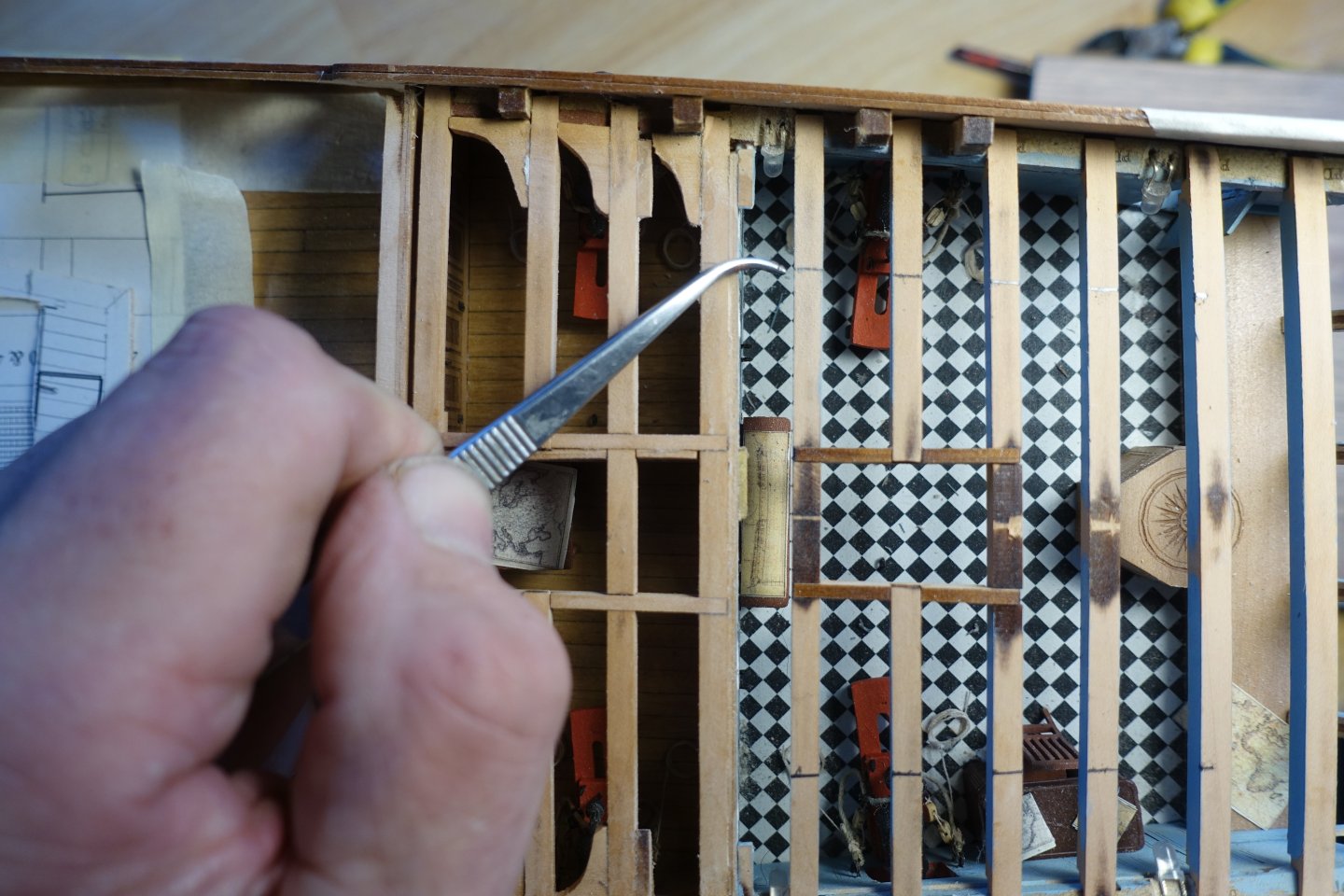

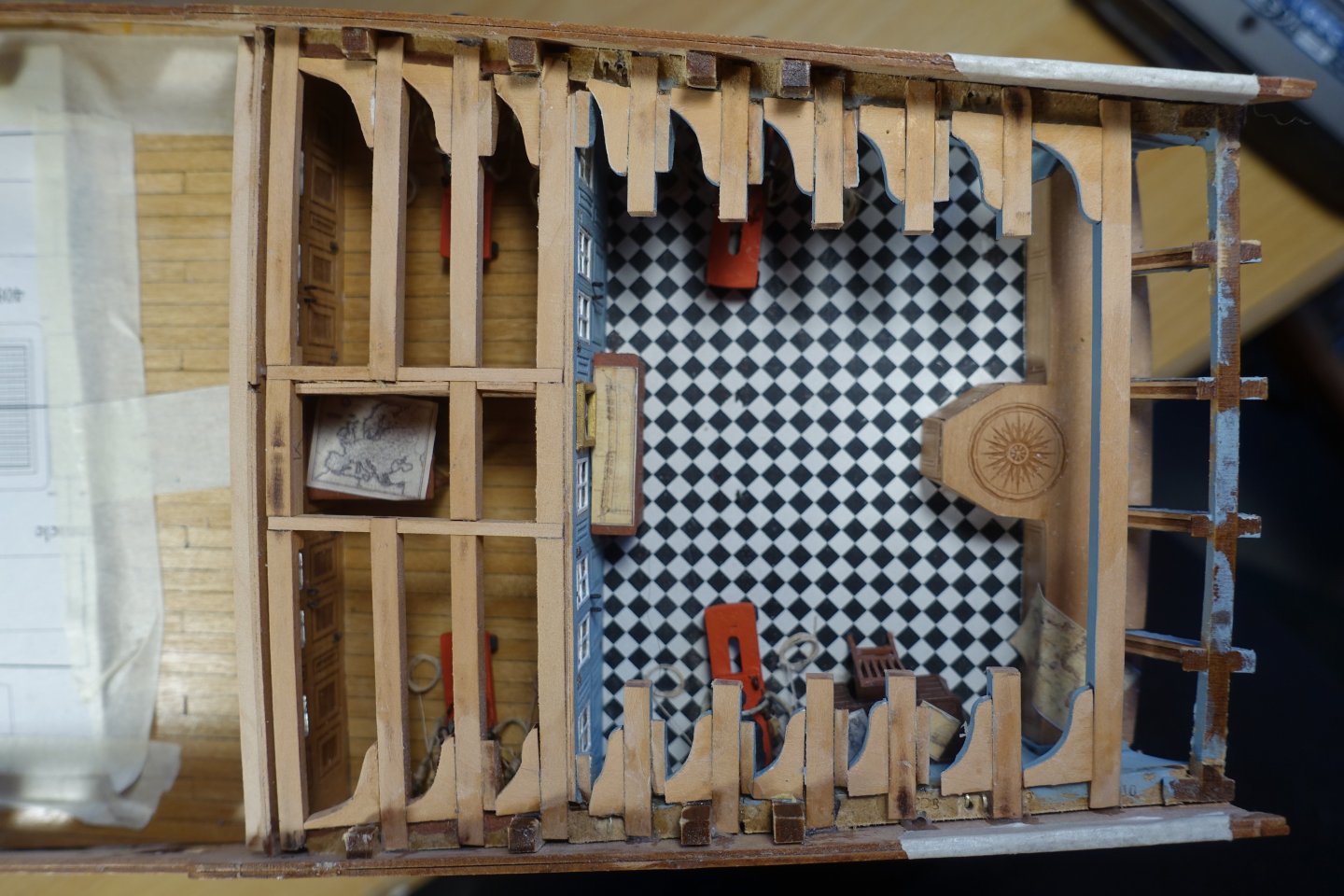

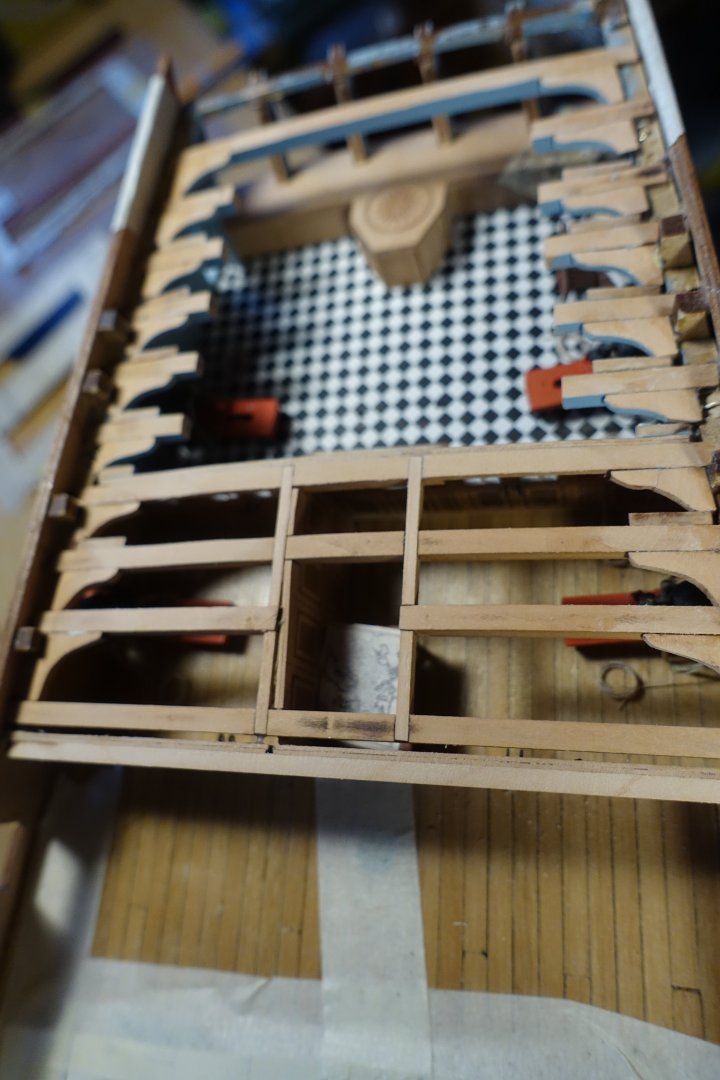

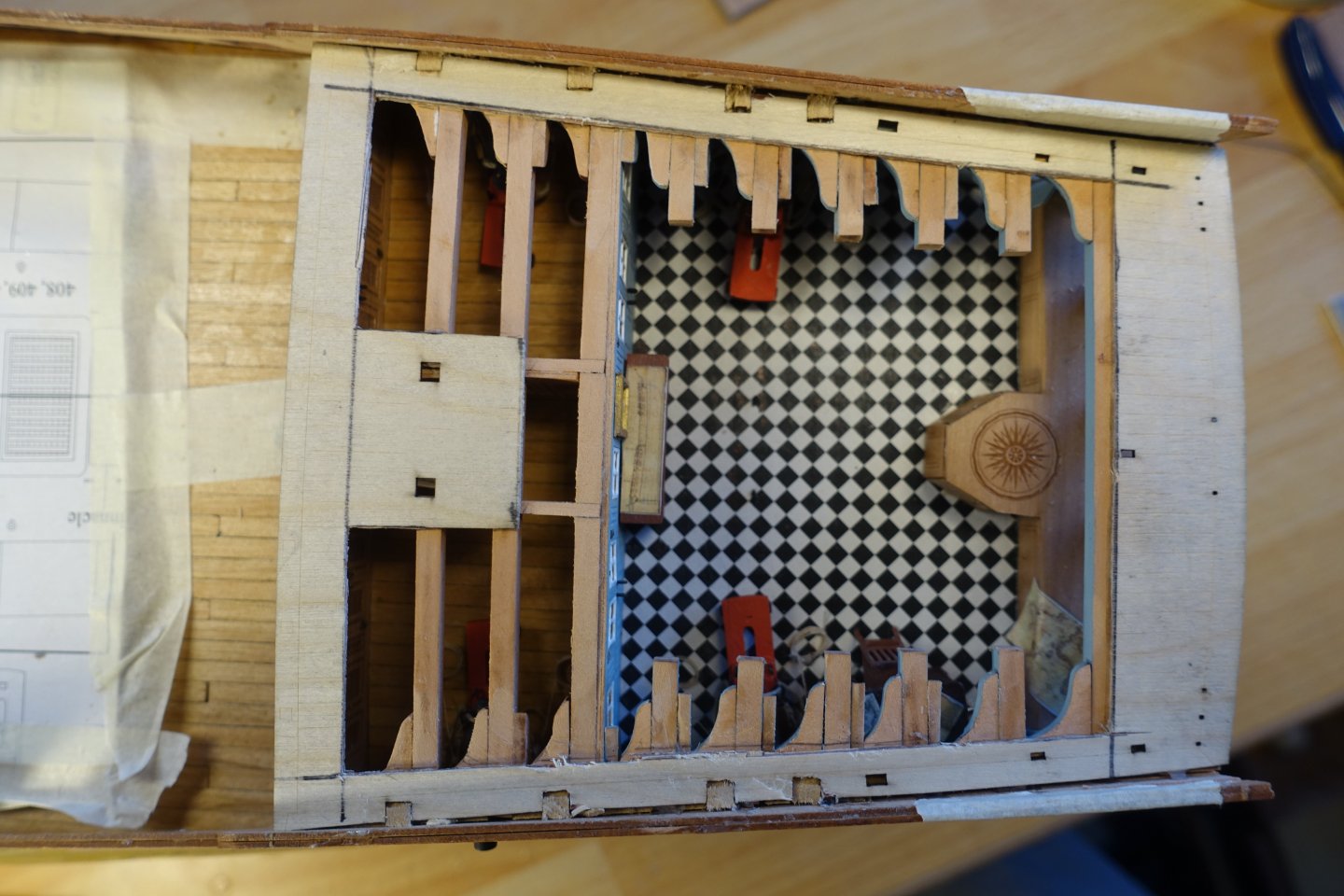

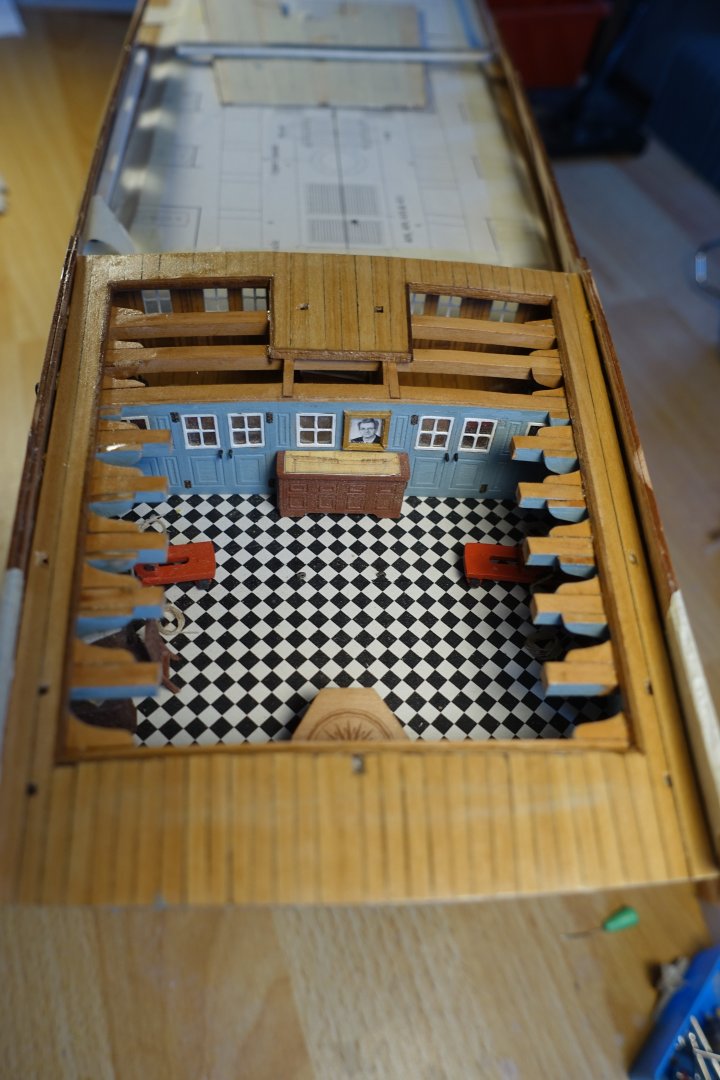

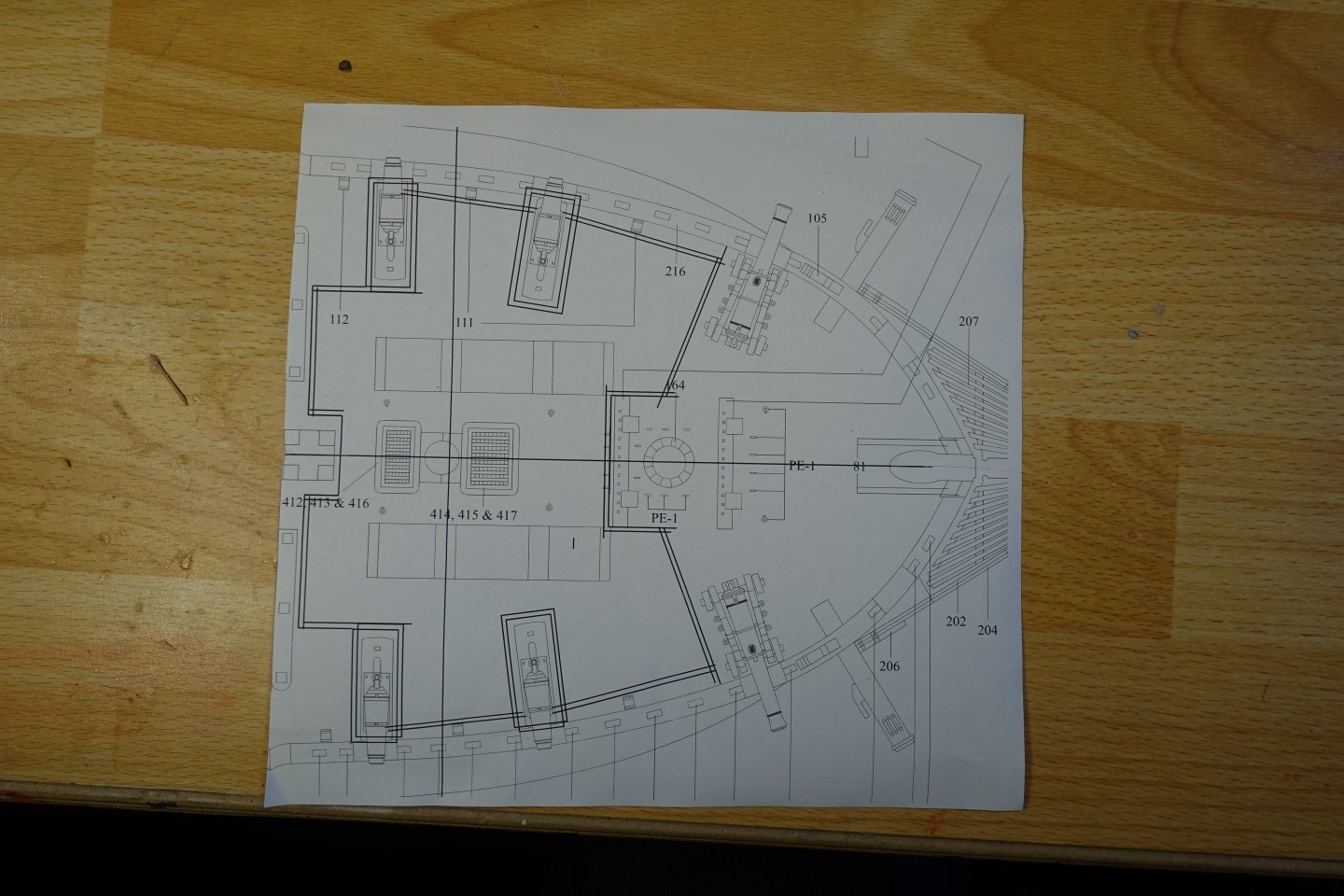

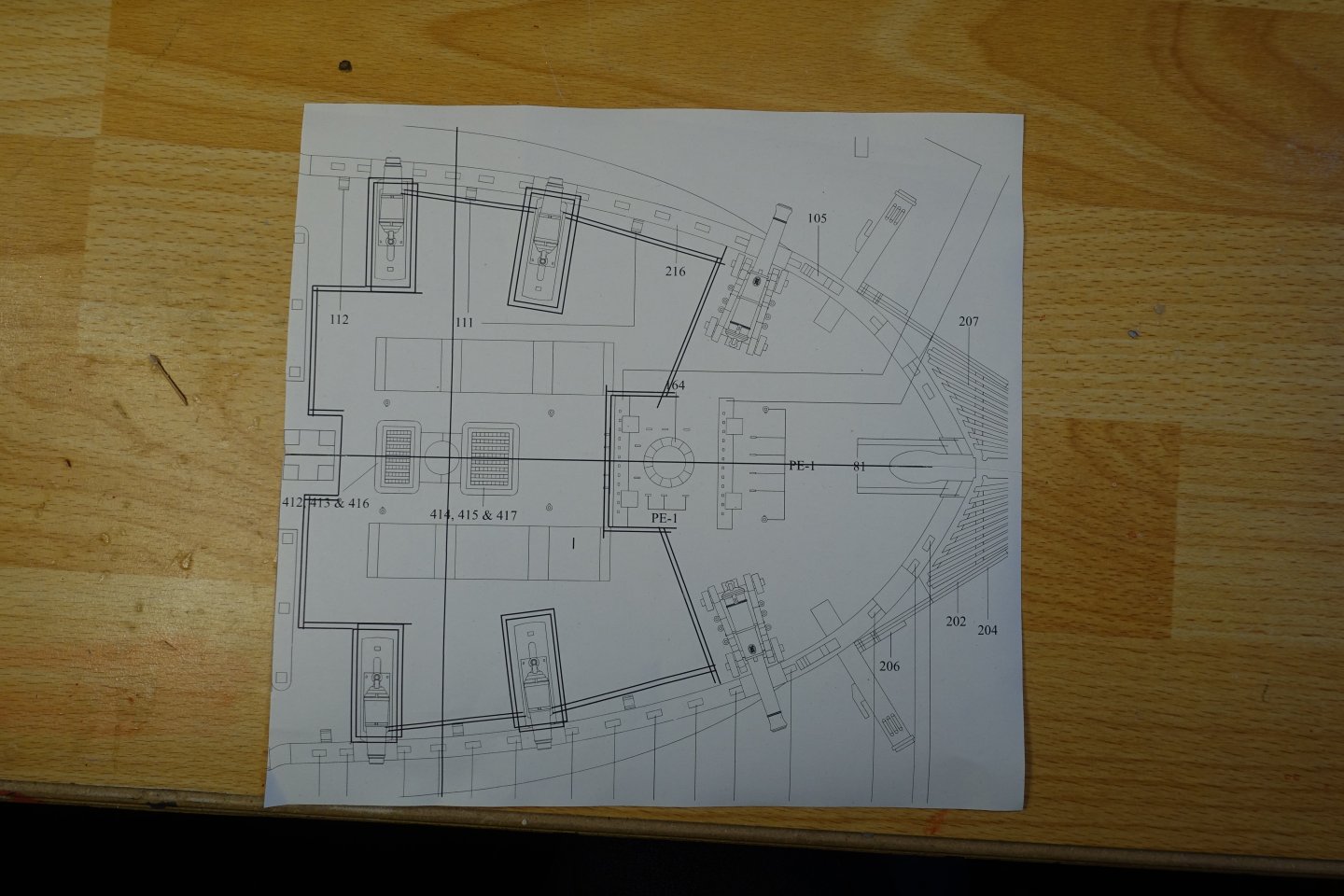

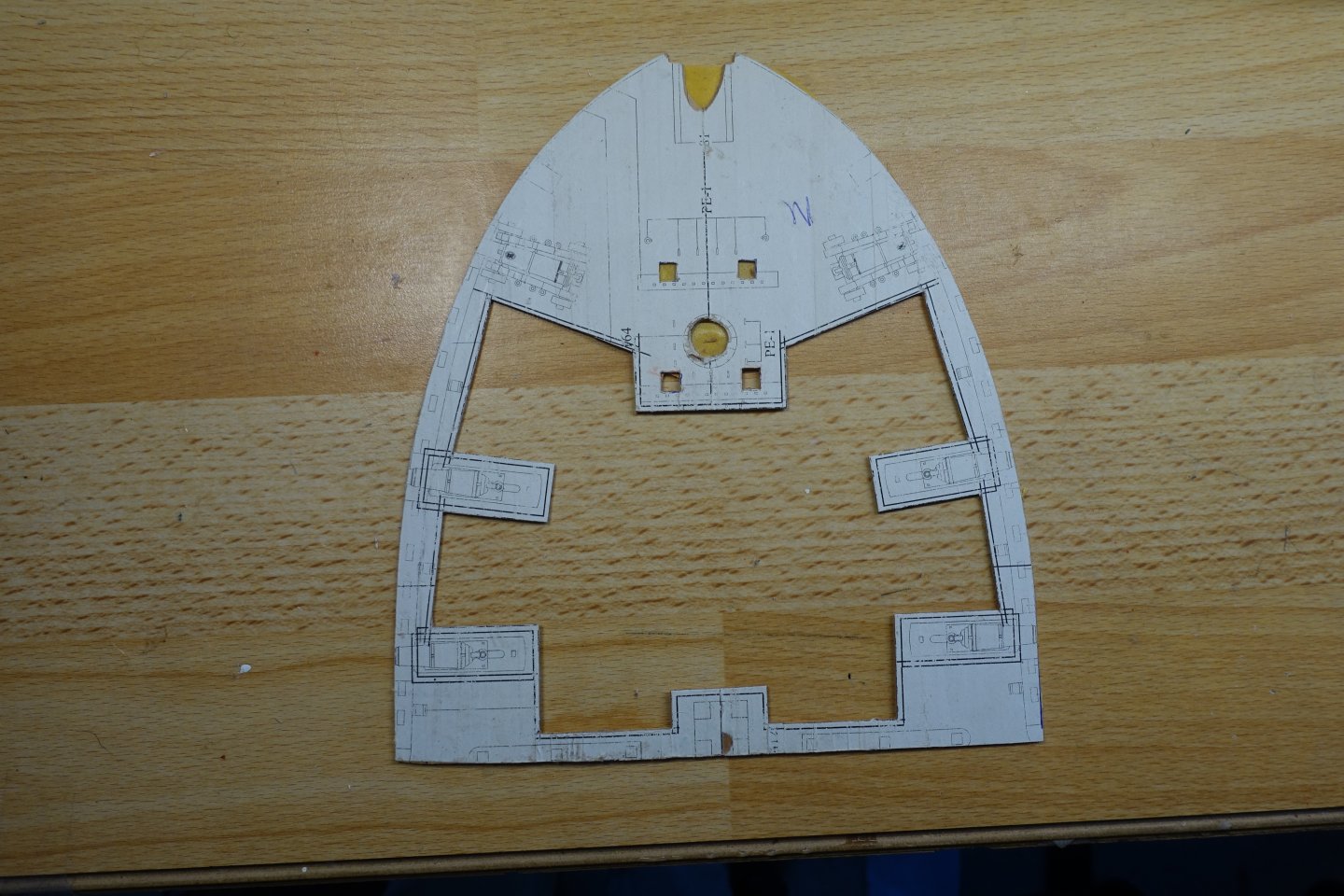

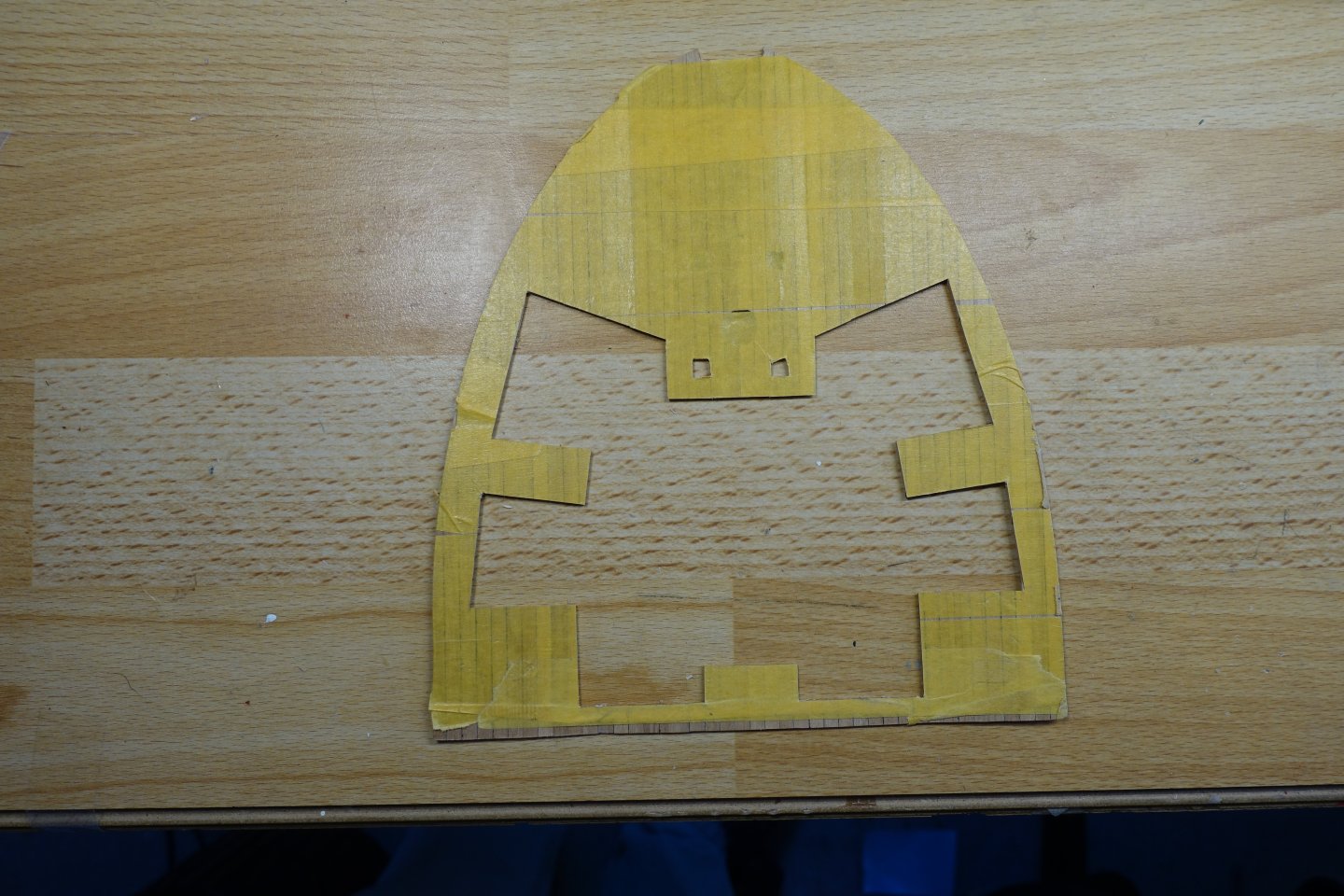

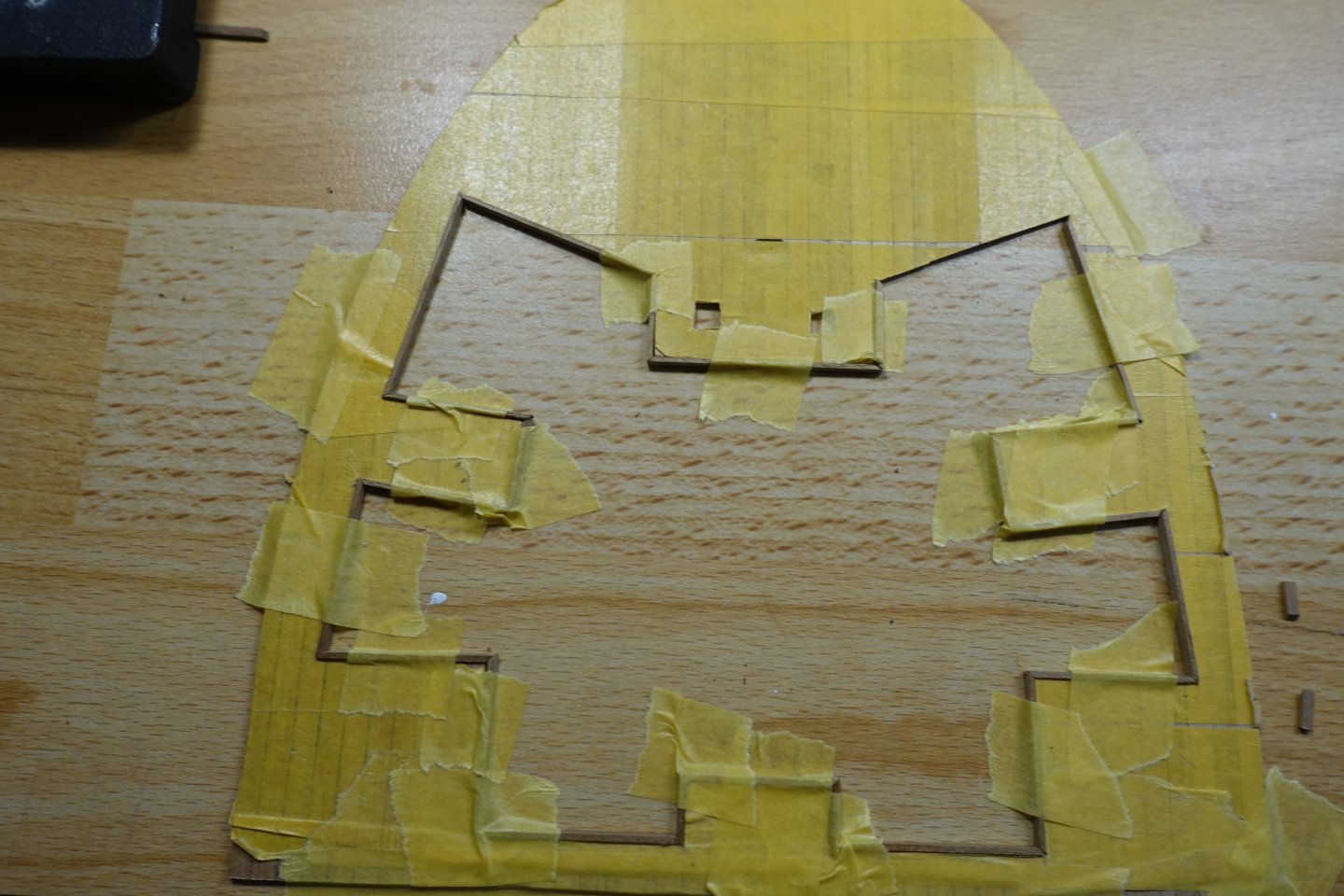

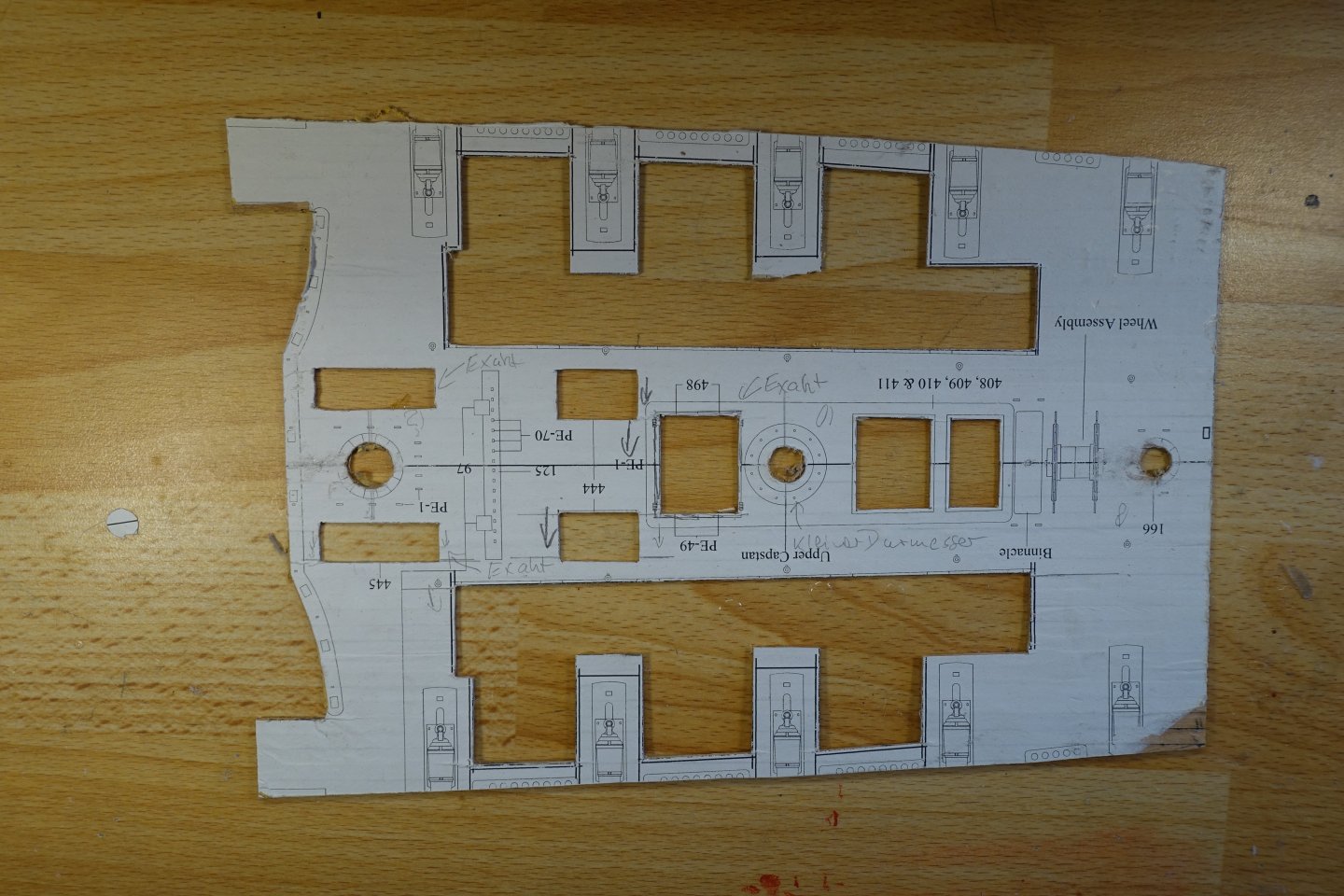

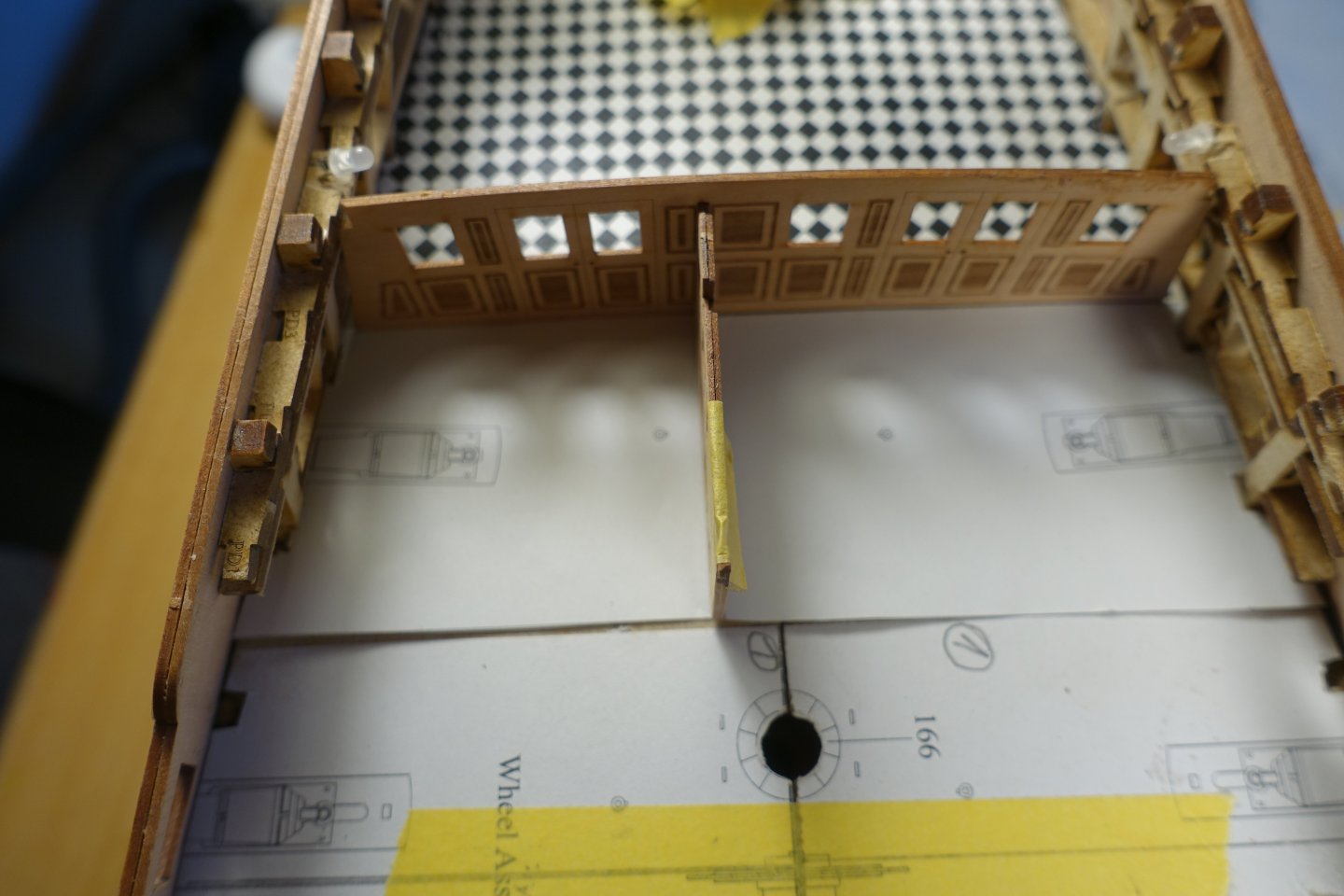

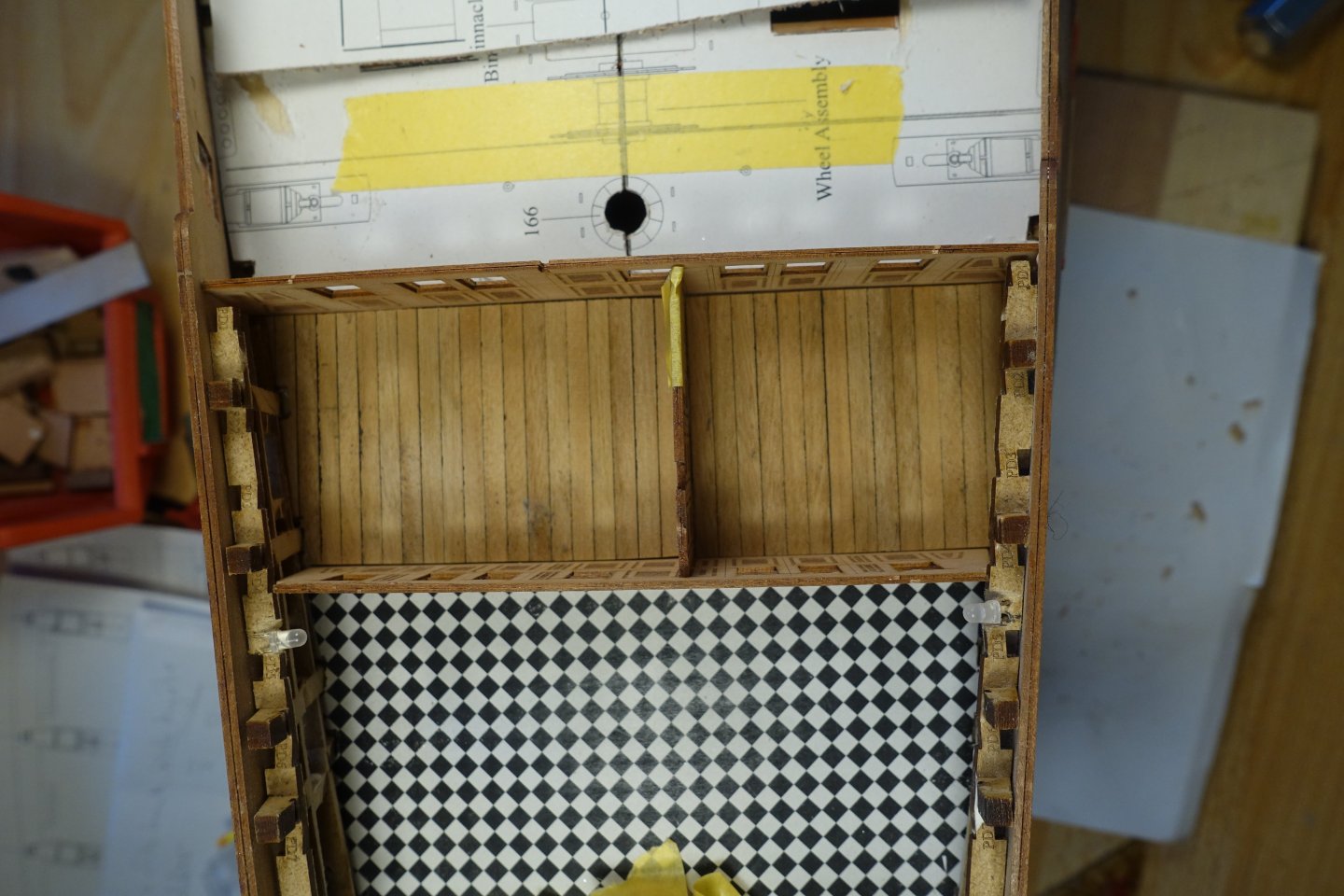

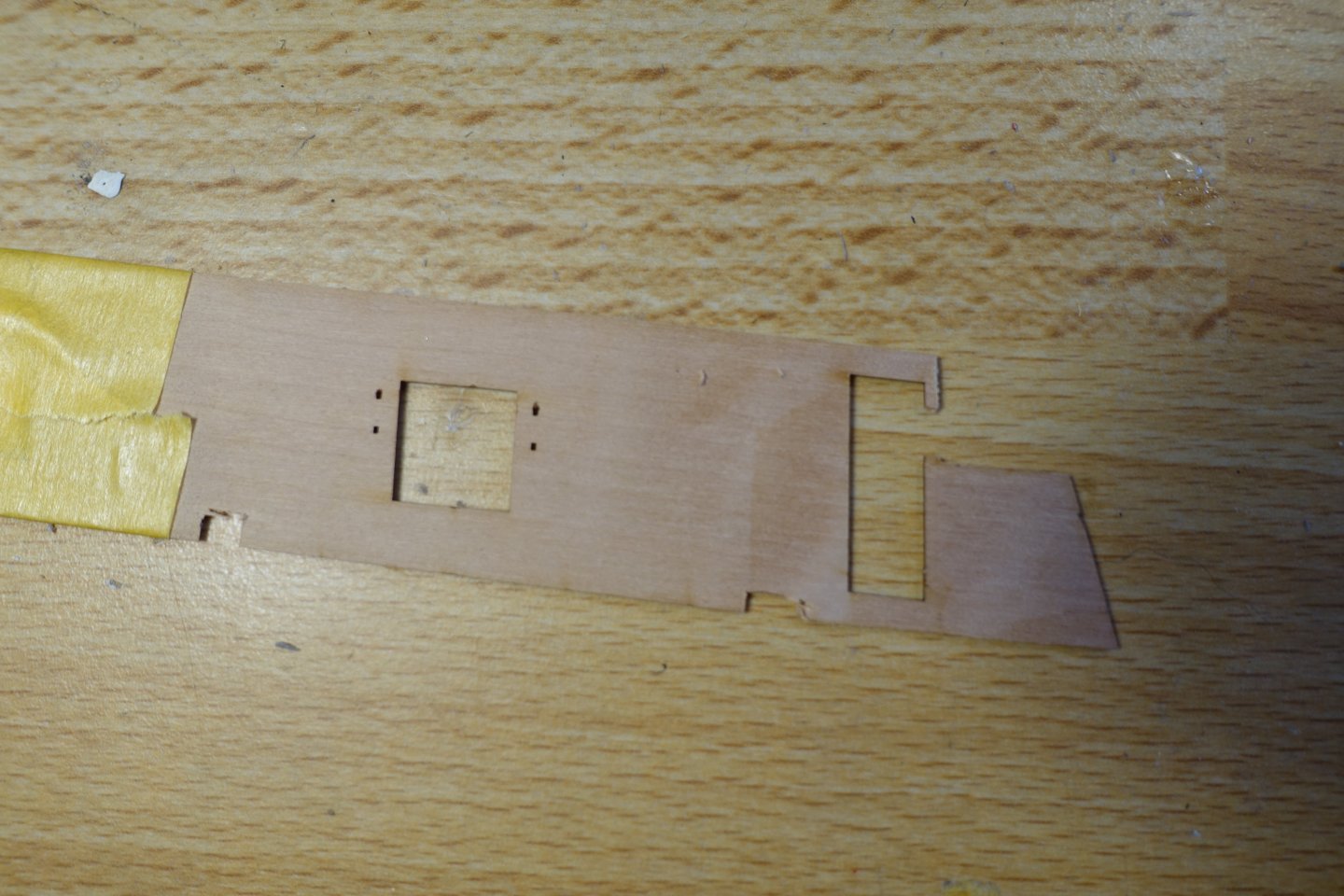

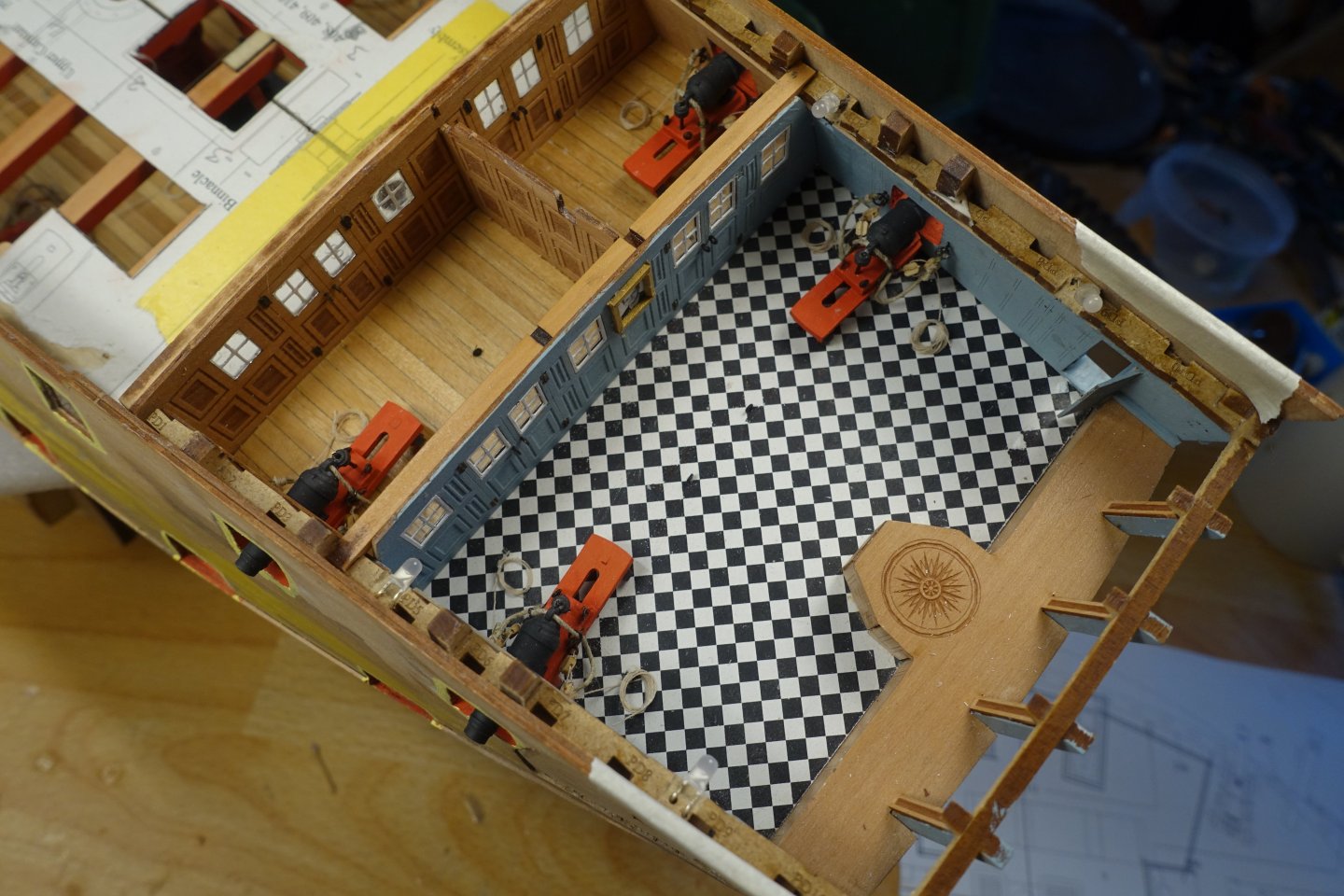

Poop Deck I wanted to make the poop deck as open as possible and also shorten the deck beams to ensure a clear view into the captain's cabin. First, I designed a template for the deck and put it on the untreated deck beams: The knees were prepared, whereby the knee on the bulkhead had to be reduced in size to ensure an unobstructed view of the windows. A door hinge came loose and will be replaced later. The untreated subdeck was fitted. The existing cut-outs were used to mark the shortening of the deck beams (see pencil marks). To position the shortened deck beams, a 10x10mm piece of wood was placed over the intact deck beams and locked in place. The deck beams were shortened at the markings and glued in place with the help of the 10x10 mm piece of wood. The knees were then attached. The subdeck was cut to size and attached. The subdeck was planked and, as with the other decks, the cut-out was bordered with 1x2 mm strips. The cabin will later be furnished with additional furniture, accessories and people.

-

Planking of forecastle, gangway and aft deck. For the forecastle, I transferred the cut-outs onto paper again, indenting the lines by 1 mm compared to those for the subdeck. After the planks had been glued on, they were cut or punched out along the specified lines. The cut-outs were to be masked later with a 1x2 mm strip. The length and mitre of the strips were adjusted outside the ship. The deck was fitted and the prefabricated boundary strips were glued in place. The procedure for the aft deck was the same as for the forecastle. I wanted to fit the gangway now and glue the knees in place first. However, one of the knees conflicts with a cleat. In the end, I decided not to glue any knees in place. The planking of the three sections is now complete.

-

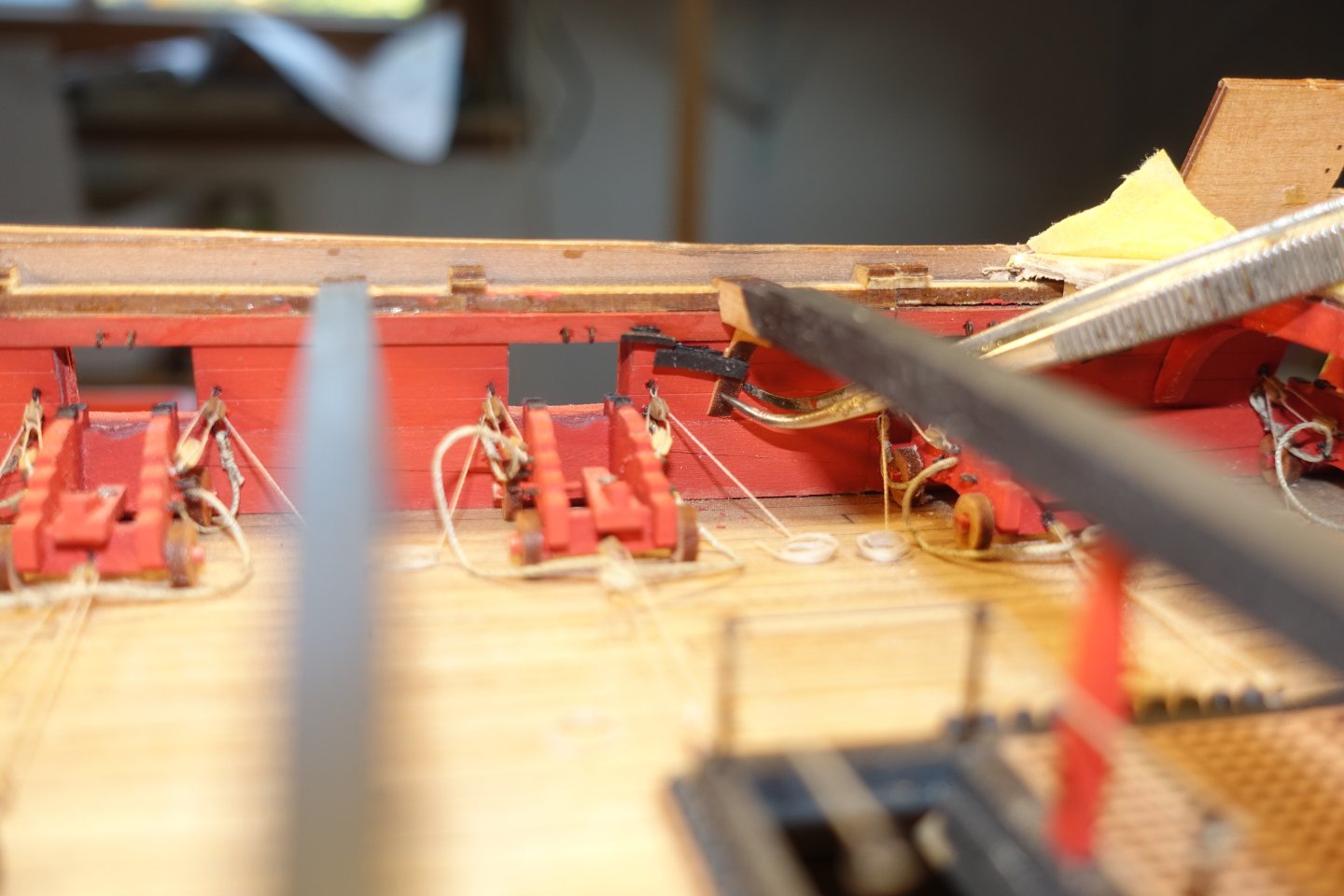

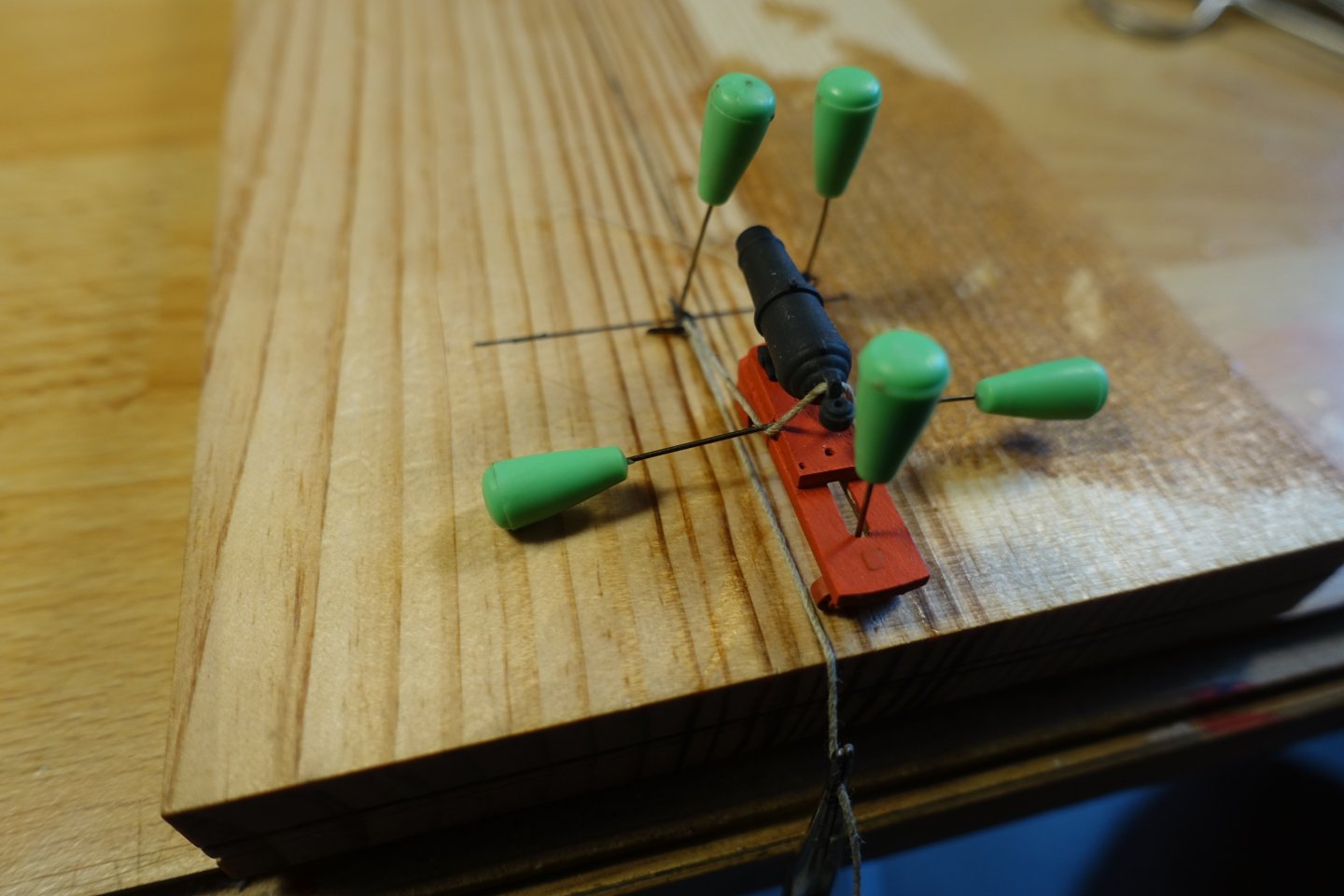

Captain's cabin The bulkheads were adjusted and had to be sanded down slightly. To create the planking between the two bulkheads, I first cut paper to the appropriate size and then glued strips onto this paper. The two groups of strips were then adjusted again. A strip had broken off on one of the side panels. I later covered this (and the other side) with a 1x1mm strip. I wanted to tackle the carronades and first measured the length of the breech rope. Due to the tackle, the slides had to be firmly attached and fixed in place at this stage. In his instructions, Chris recommends making them sliding at first. The captain's cabin is now finished for the time being. As I want to design the poop deck completely open, I will add the furniture later. I am also undecided as to whether I want to add Pellew and officers (doll's house).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.