-

Posts

2,618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

The first hatch to fabricate is the smallest, the simplest, and the easiest. I’ll use this experience to make the others. Mr. Hunt has chosen to use lap joints which I believe add more difficulty to the task. It is my opinion that the method used by Mr. Hunt is too complicated requiring you fabricate rabbets and dados. These may be fun to make for a skilled woodworker, but I do not have the tools nor have reached that precision skill level. Although a lap joint adds strength to the joints, I don’t believe the added strength is warranted as no stress will be applied to the frames. I am using a simpler butt joint method and if I don’t mess up, the end product will look exactly like Mr. Hunt’s in the end (no pun intended).

-

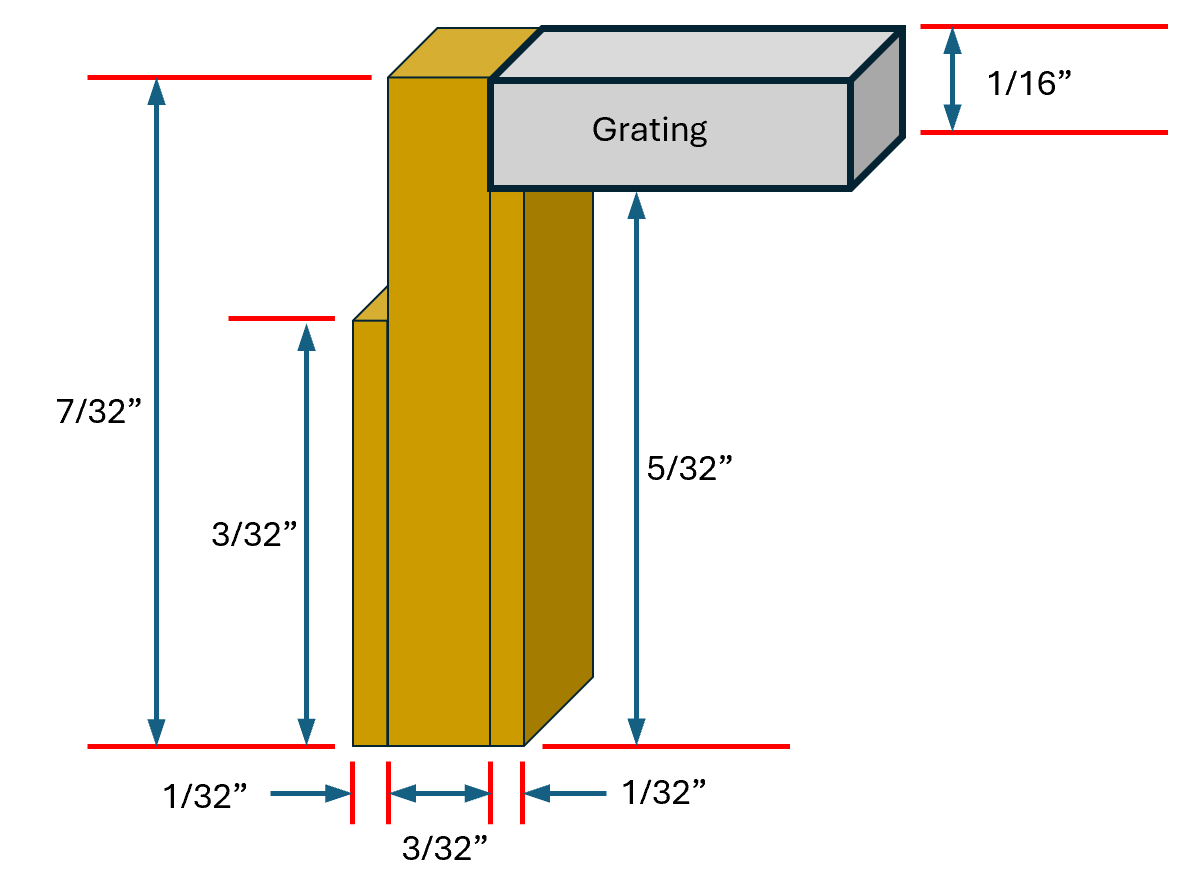

These hatches are one of the items in the supplemental wood package. Mr. Hunt mentions that the MS kit does not have certain sizes of wood stock for the hatches, and you must fabricate your own. The supplemental wood package supplied the proper sizes in boxwood. The basic hatch frames consist of three pieces of wood. Outside: 3/32” H x 1/32” W Center: 7/32” H x 3/32” W Inside: 5/32” H x 1/32” W When assembled you get the cross section shown below. Something like my diagram I believe would have been more helpful in the practicum than his Figures F4.3.1-1 and F4.3.1-2. I’m not knocking the practicum, I could not have started, let alone built this model without it; just some constructive criticism.

-

I should mention here that at the time I purchased the MS kit back in 2016 or 2017, I also purchased a supplemental wood kit from HobbyMills (a company Mr. Hunt worked with and recommended) which substituted boxwood (among other wood choices) for certain elements of the MS kit’s basswood. Unfortunately, HobbyMills is no longer in business as the owner retired, so getting the supplemental wood packages from them now is impossible. Check with Mr. Hunt to see if he lined up another suppler. USS_Constitution_Wood_Supplement - HobbyMill.pdf

-

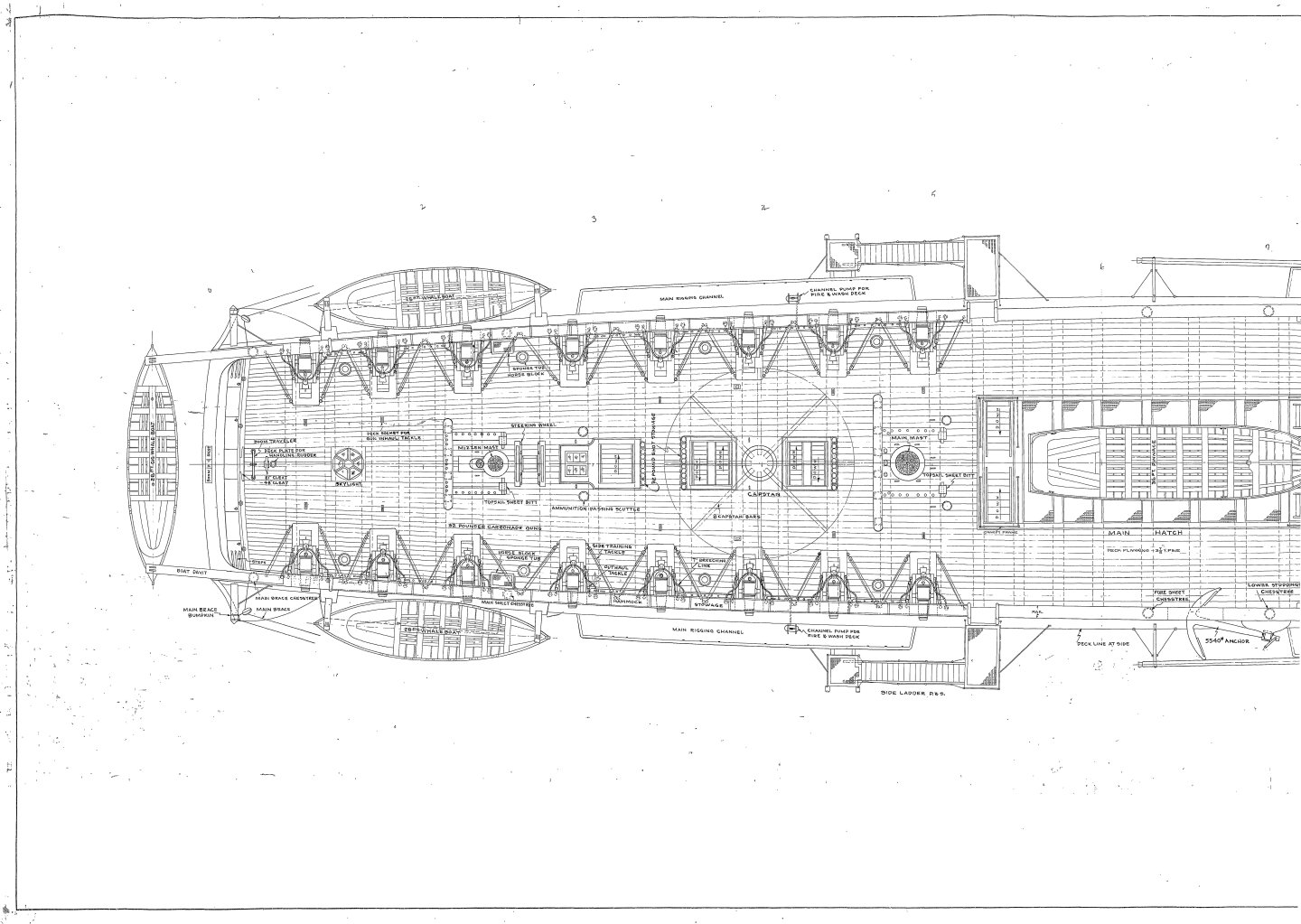

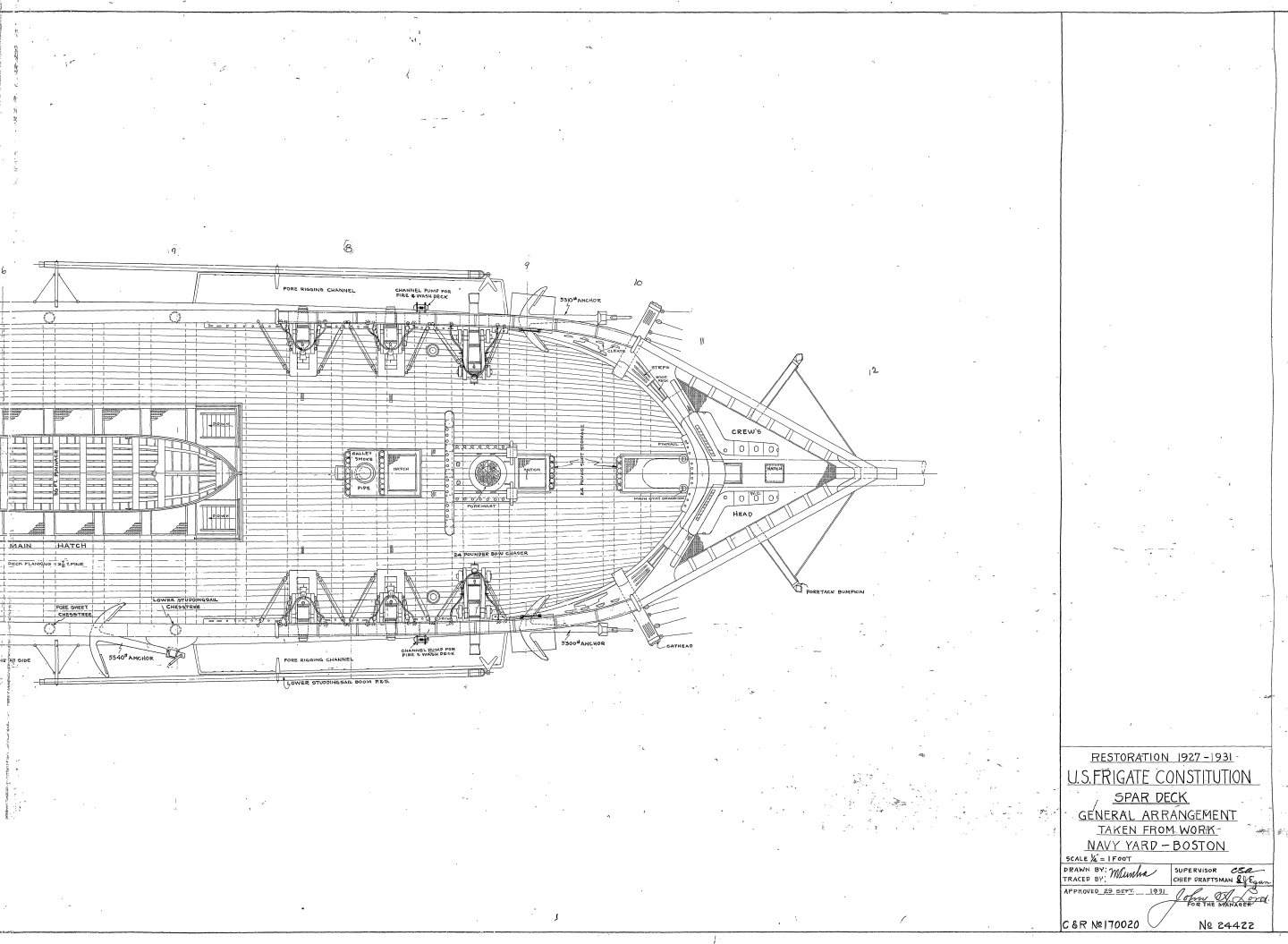

This brings to light that some or all my support knees may not be positioned properly. I may have to fudge a bunch more. Because the main grating on the spar deck (under the pinnace) will be partially opened to allow viewing of the gun deck, the supporting beams below it must be aligned with the grating’s cross beams precisely. For that reason, I will pause installing the additional gun deck bitts and previously fabricated furniture (i.e., capstan, pumps, casks, etc.) until I have fabricated the spar deck hatchways and gratings. They will be dry fitted to ensure the key beams below are properly positioned. Where to begin? I had several false starts trying to figure out how to fabricate the various grating using Robert Hunt’s practicum. Per section 4.2.2 Hatch Coaming Framework of the practicum, I installed the framing supports for the bowsprit hatch and foremast hatch just aft of it. These supports will allow the hatchways to be dry fitted.

-

To install the wood column at the forward end of the furthest aft gun deck hatchway, the spar deck beam had to be installed directly overhead of that column so it could support the beam. This beam is also supported at its ends by knee braces previously attached to the bulwarks which the gun riggings are now attached. Unfortunately, when the beam was dry fitted on the knees, the beam did not center directly over the column. It was about a beam’s width aft off. To dismantle and reposition the knees meant removing the gun rigging as well. I could do that or fudge it. Because where the knees and the beam ends join will be hidden when the partial spar deck is installed, the beam was moved forward just enough to get it centered over the column, just not sitting directly on the knees.

-

If you don't need to make the rudder move, make your own pseudo hinges and pin the rudder to to the post. Or, if you do want the moveable rudder, that will take some skill and creativeness to make your own working gudgeons and pintles. My MS model is a larger scale (1:76.8) and I made the working rudder with some effort. I don't know if I would have tried it at 1:96. Jon

-

Well, creating the remaining six stairwell hand ropes did go quicker, just not quick. Because I had to use PVC glue both to allow me time to position properly the 24 stanchions and as a filler material at the base of some of the stanchions, I had to wait at least an hour or so before I could move on to the next steps. During that wait I couldn’t touch the model for fear of upsetting the drying setup and process. If I had done this sooner (which I did) but more robust (which it wasn’t), this installation could have been much simpler to do. There is still a bunch of stuff that needs to be installed on the gun deck but requires the installation of more spar deck beams and those beams must be in the proper position to line up with stuff on the gun deck. It’s almost like which comes first, the chicken or the egg. So, I be installing both gun deck and spar deck items alternately.

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I cheated on mine by printing the panels, but then again, I don't expect them to be readily seen. Yours however, are wonderful and will probably be more visible. Well done! Jon -

Very nice! You are going to have a great looking model when you are done. One thing caught my eye, If you plan on installing the spar deck capstan stove pipe before you install the spar deck, make sure you leave space under them for the spar deck planks to fit. Oh, one other thing, It appears your anchor rope is tied (instead of wrapped) around the riding bitts. There is no way the anchor rope can be pulled in either direction to raise or lower the anchor. The riding bitts apply friction to the rope to maintain control of the ropes movement. The way you have it shown, the rope can't even be untied if it were on the actual ship. Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

When I responded to you, I checked Cookster's site and saw that there were a lot of images missing and those were the images I was referring to. You want the images for anything subsequent to his last relevant posting which was post #261 (Sep 8, 2014). I checked today to see what pictures were missing that you needed and to my surprise, the only images now missing, were on the first page of his log. If you want those, I can still send them to you. I don't have any more relevant images after his post #261 (Sep 8, 2014) which you stated you downloaded. Sorry for the misunderstanding. Jon

-

Read your post about following Cookster, and his comment about is log being broken, I just want to let you know that I have all of his images that he posted. When I follow a build log dealing with the Constitution, I don't just read it, I copy the log and store it on my computer. BTW, I did the same thing when I was building my Rattlesnake. I don't trust the internet to keep websites forever or maintain original addresses. I've seen websites crash and lose everything (e.g., ModelShipWorld and ModelShipBuilder). So even though Cookster himself seems to have vanished in a puff of smoke and his log is starting to slowly disintegrate (images have disappeared), I have a copy of his log and all of the associated images. Should you need images from his log, just let me know. Jon

-

The stanchions were stung together with 0.12” (.30mm) black rope prior to installation so that I wouldn’t have to thread them on the model. Mustafa used tan rope which I must admit looks great, but the real ship uses black rope; but it doesn’t have the visual impact like the tan. So be it. It was slow, tedious, tricky, and time consuming That one stairwell down, six to go. Hopefully these will get installed quicker.

-

If you look closely at Mustafa’s model. His stanchions fit into holes drilled into the top of the hatchway walls. For what ever reason, the walls on my hatchways ended up being too narrow to drill holes for the stanchion poles. To support the stanchions, I decided to use brass brackets on the inside corners of the hatchway. Hopefully these would provide sufficient physical support and glueing surface to hold the stanchions in place. Making the brackets was simple but installing them was a little tricky. Due to the installed beams, the most forward hatchway was the most difficult to access. My fingers were too fat to fit between the beams, so I had to do everything with tweezers. I couldn’t use CA glue because I couldn’t get the bracket into position, hold it there, at the same time applying minute drops of CA glue. PVA glue allowed me to stick the bracket in close vicinity of where it needed to be and maneuver it into the proper position (still not easy). Once it dried, then I could add more glue for proper strength. Once the brackets were in place, then the stanchion could be set into them. This was a time-consuming process because I had to wait for the glue to dry solid before I moved on to the next step. I also made a stairway plug to prevent anything from falling to the hatchway, like a loose bracket. Once anything fell in, there was no way I could get it out. It was a black hole.

-

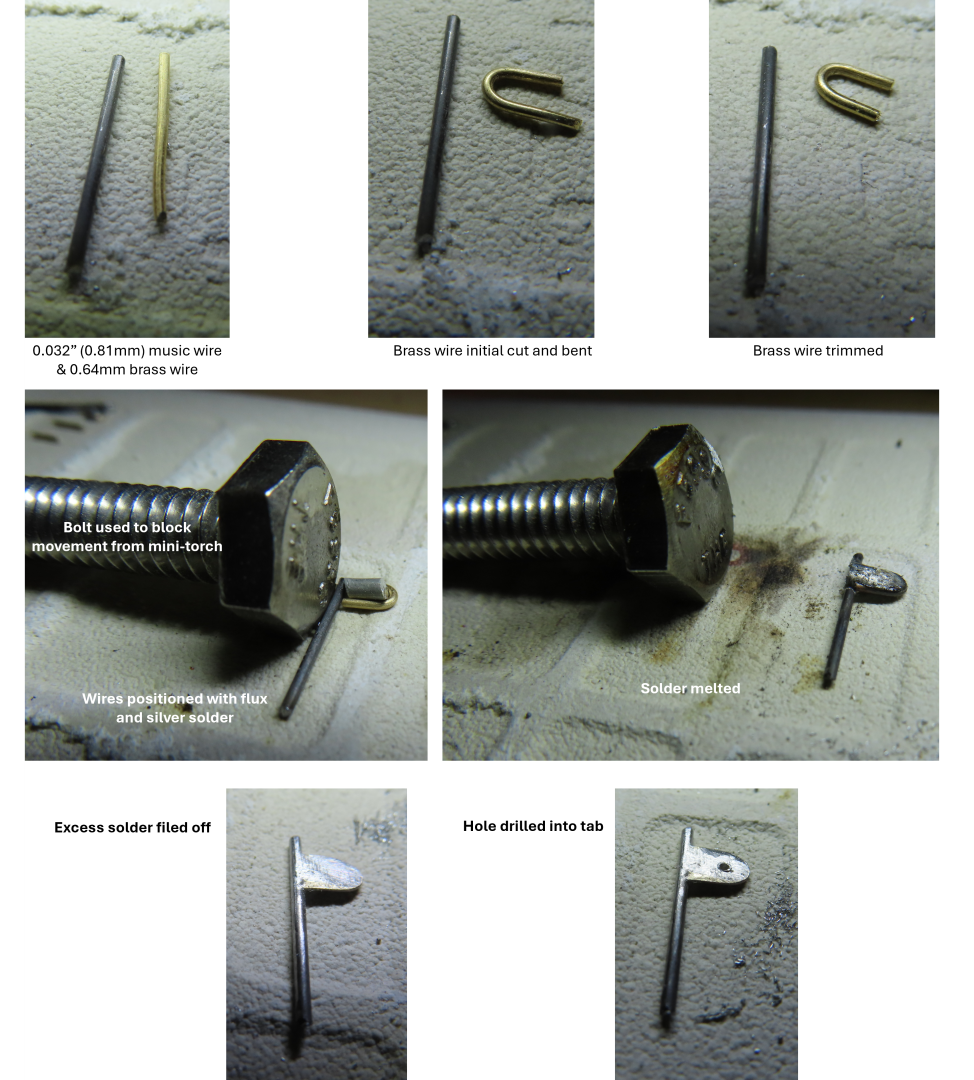

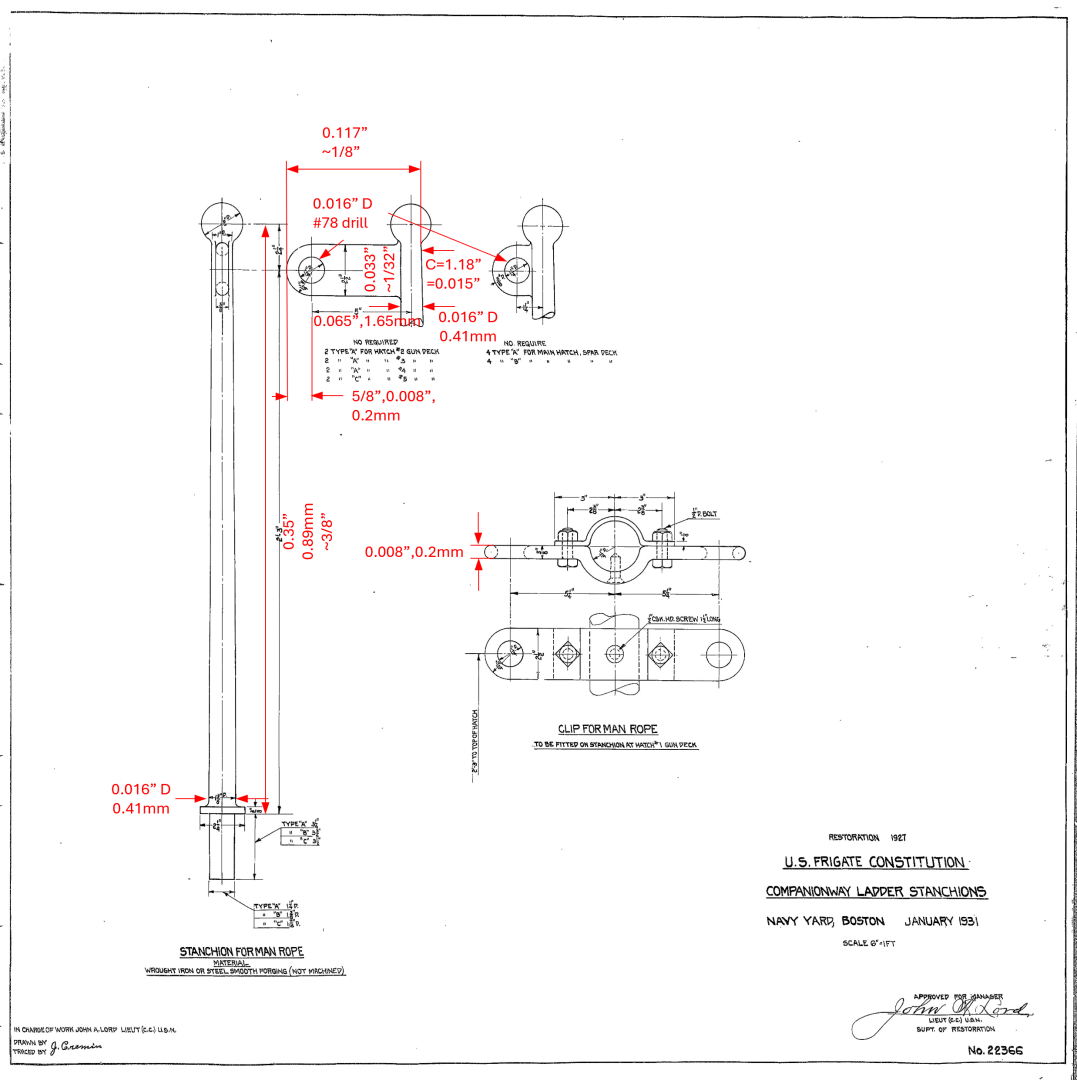

What to do? So, for my second attempt, I messaged Mustafa (mtbediz), the man who inspired me to do this over again. He very graciously gave all the details which I followed with some minor modifications. First, He used exclusively 0.8 mm brass wire, but I stuck with the 0.81mm music wire for the stanchion for reasons mentioned above. He used a short piece of 0.81mm brass wire to create the rope tab. I used a short piece of 0.64mm brass wire which was cut and formed into a U-shape like he did. It was trimmed so the ends were even and placed near the top of the music wire piece like a flag with the open ends of the brass wire touching the music wire. Mustafa used lead solder paste (I believe) to fill the interior of the “flag” and secured the two pieces of wire in place with metal weights. I had silver solder paste but found mine wasn’t sticky enough to stay in place when I tried to fill the “flag” void (paste too old?). As a result, I used soldering flux and silver solder wire. The surface tension of the flux held everything in position. It was backed up with a bolt so it wouldn’t move during the heating process. To heat the assembly so the solder would melt, Mustafa used a heat gun which I don’t have. I used a mini-butane torch which worked quite nicely. The excess solder was filed off and a hole was drilled through the solder without any problems. The stanchion were painted black, threaded with miniature rope.

-

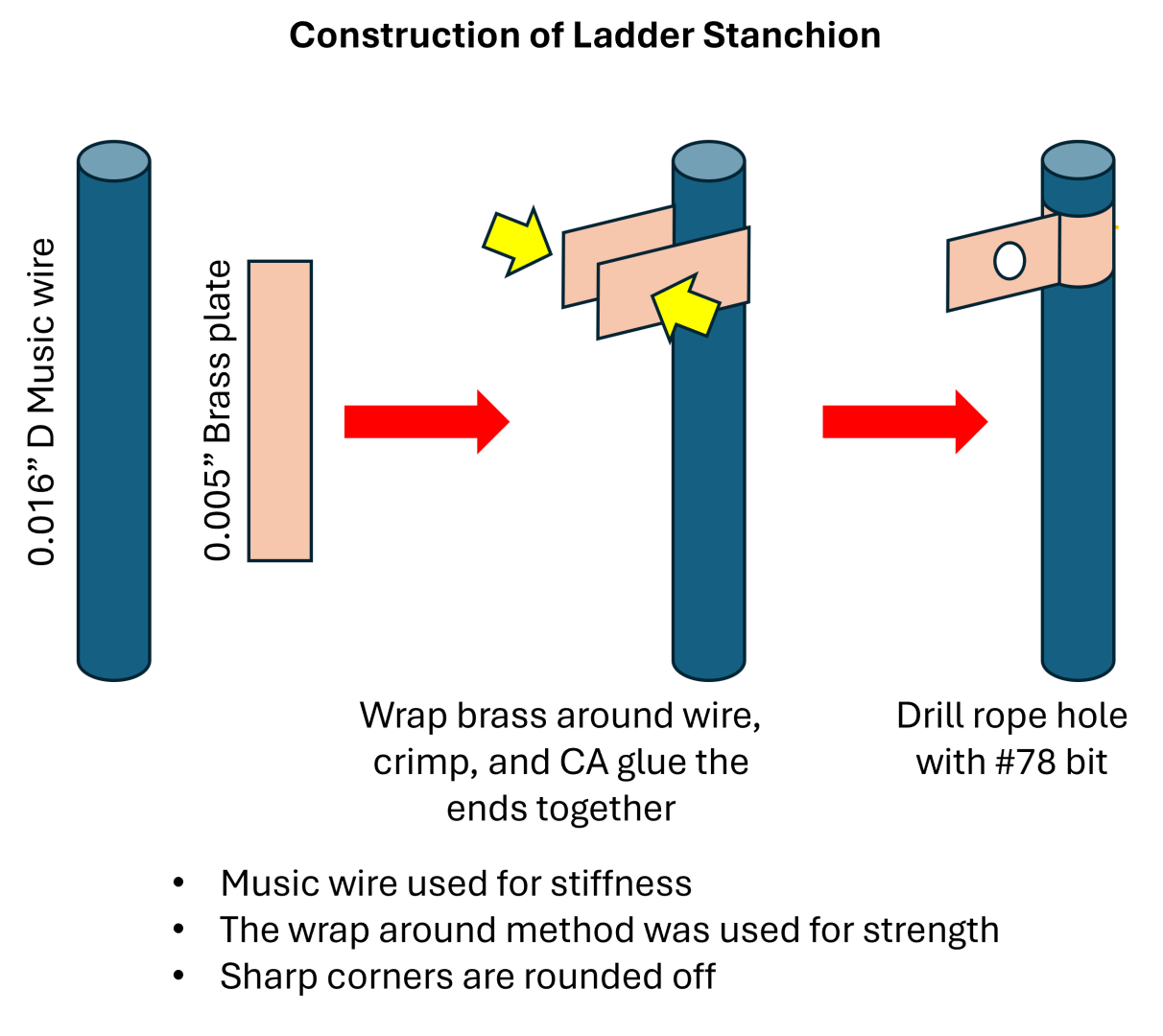

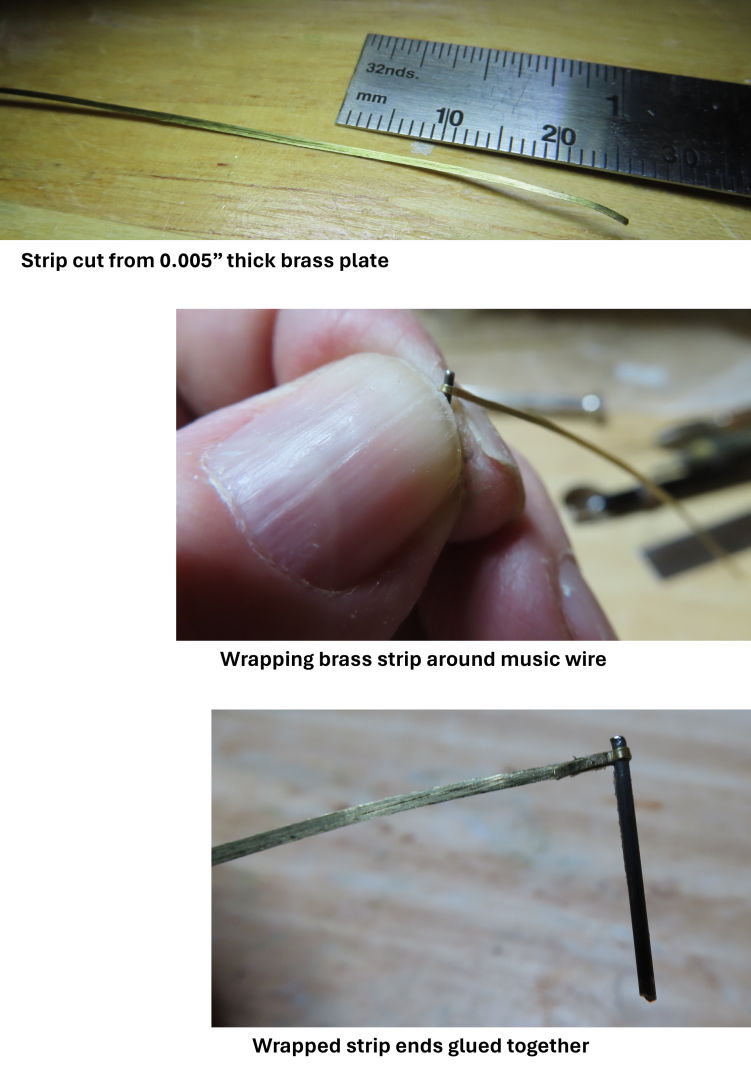

So, I chose 0.032” (0.81mm) music wire for the stanchion because it won’t bend with normal handling. For the rope tab, the idea was to wrap a 0.005” thick brass strip around the wire and then glue the ends together to form the tab. Lastly, drill a hole in the tab with a #78 drill bit to create a rope hole. Everything went according to plan…until it didn’t. For the life of me, I could not create the rope hole. My drill bit bent if I applied any pressure. (Cheap bits, I don’t know?) I tried creating a dimple into the brass with a needle for the bit to bite into, but all that did was deform the thin strip. I even tried using a very fine cone shape grinding bit but couldn’t keep it perfectly centered on the brass strip. It would drift and eat away one side or the other of the strip making the strip useless.

-

Waaaaayyyyy back in July 2018 when I was first installing ladders from the gun deck down to the pseudo berth deck level, I made and installed the associated ladder stanchions and hand ropes. They didn’t last long due to my inadequate fabrication and installation skills; and they were being battered about by handling the model installing other stuff. Well, due to my admiration and inspiration of Mustafa’s (mtbediz) fine workmanship of his model, I’m giving it another go. If I’m going to do it, it must be now before the gun deck becomes too inaccessible for this detail. My first attempt, I tried to maintain the scale based on the US Navy’s plans and I wanted my stanchions to be robust enough to handle any jarring due to my manipulation of the model.

-

After I finished my Rattlesnake (Hunt practicum), I wanted a change of pace before I started with the Constitution. I decided to work on the Conny's boats first. They were a lot of fun and you can load them up with as much or little (especially if you're going to cover them when they are finally installed on the ship) detail as you want. I relied a lot on the US Navy plans for the details. Surprisingly, the MS plan details were very close to the US Navy's. They were like eating potato chips - "you can't just eat one." Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Need I repeat myself, beautiful workmanship!! I'm curious, do you plan on covering the complete hatch coaming area with the hatch work, or are you going to leave one half uncovered so the observer can look down to gun deck like I've seen others do? Jon -

I saw your comment to mtbediz today and thought I would give a welcome aboard from a bunch of us USS Constitution active builders. We've been sharing our knowledge and comments with each other and we range from beginner to the more experienced. Although, as near as I can determine, there aren't many Mamoli builders for the Conny at present. There is one active (last post in January) builder, Oscardeuce and an excellent builder, Bill Edgin (Robnbill) who completed his Mamoli kit in 2021 that you might want to check out as you work on yours. Good luck and have fun Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

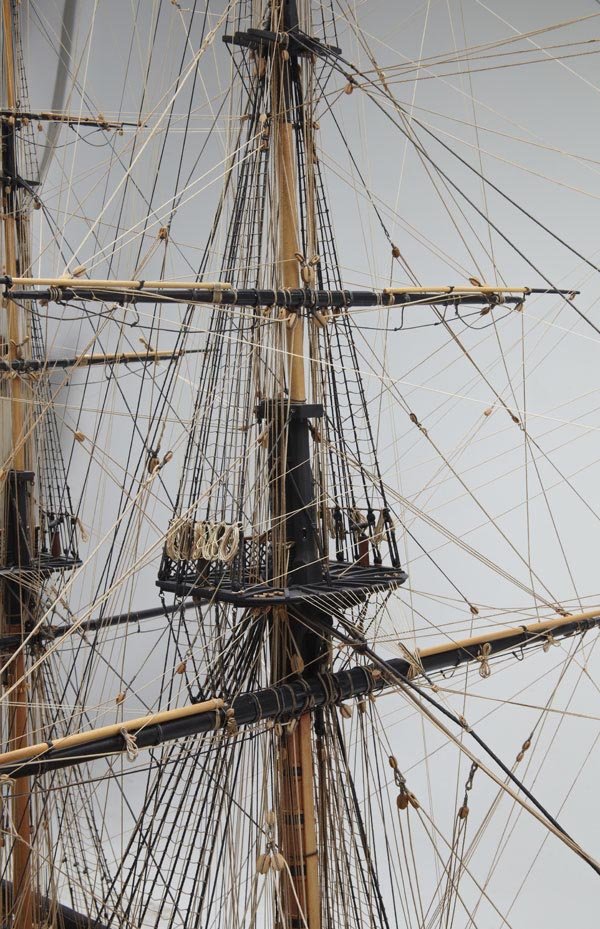

Peter, I found the images of this model by Mark Antczak on Shipmodel.com, a company that sells boat models. Unfortunately, this model is not displayed any more at this site. However here is a limited blurb about this model from this Shipmodel.com at the time I down loaded the images: I will post the seven addition photos of this model that I have on your blog so as not to intrude too much on Mustafa's beautiful instructive blog.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.