-

Posts

2,610 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

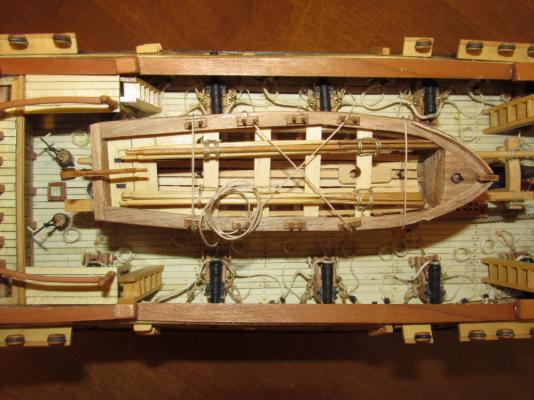

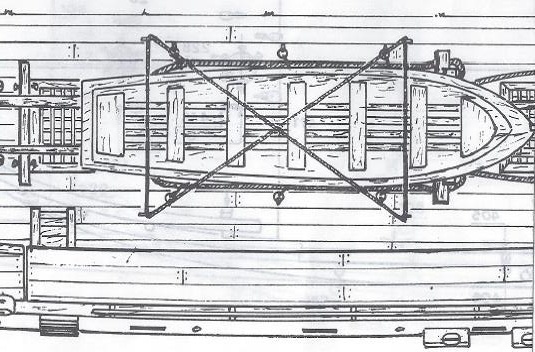

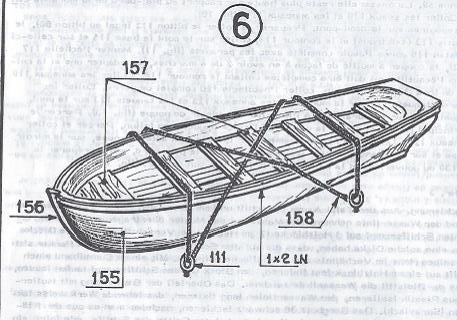

First the hooked end is hooked to a deck eyelet and then crisscrossed over the boat through the other eyelets as show in the diagram where it comes back to the starting point. Here I added the hooked block, but what to do with the bitter end? I tied it back onto itself and laid the remainder of the rope on the boat. Not being a sailor I’m clueless to the accuracy of this arrangement.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Well I knew the rope had to have a beginning and an end however I could not find either a clear detailed image or description as to how this was configured. The Practicum just show the boat sitting on the spare masts without any ropes, the MS plans show the boat in position but didn’t explain or show the lashing at all, and the Hahn plans were totally silent about the boat altogether. So I took my best shot. I decided to start the lashing with a hook at the end of a rope line at one end and a hook block at the other. As an aside, the shafts of the eyelets that were cut off are not thrown away. I save them because they are useful for making construction pins and other odds and ends. I also use broken drill bits, but they are harder to trim.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Meanwhile…Back at the Ship’s Boat If you may remember, I decided to forgo the boat shell that came with the Mamoli kit and elected to build a Plank-On-Frame boat from Model Shipways and document that build on a separate log. http://modelshipworld.com/index.php?/topic/5430-ship%E2%80%99s-boat-by-jsgerson-model-shipways/ The ship’s boat has now been completed. All that was left was to lash it onto the ship. According to the Mamoli plans, a continuous rope loop crisscrosses over the boat while sitting on the spare masts through eyelets in the deck.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

I appreciate the scan effort. You might want to let the scanner default to what ever format it wants (usually pdf) and attach the file(s) in an email to me. I'll see if I can convert it to jpg and share it with the rest of the readers. I too have the Karl Marquardt's "Anatomy of the Ship" as well as the plans that came from my Model Shipways (unopened) model. It's always helpful to have actual photos of the real thing as the final judge as to what really exists on the ship. Right now I'm gathering up my resources for the Conny build once I complete my Rattlesnake. Thanks Jon

-

The "missing pictures" has happen twice (so far...) to my Rattlesnake log in the past month or so. I've had to contact my readers to have them replace their images they used in their comments. Even if they send the missing images directly to me, I cannot edit someone else comments. They must be kind enough to repair their comments themselves.

-

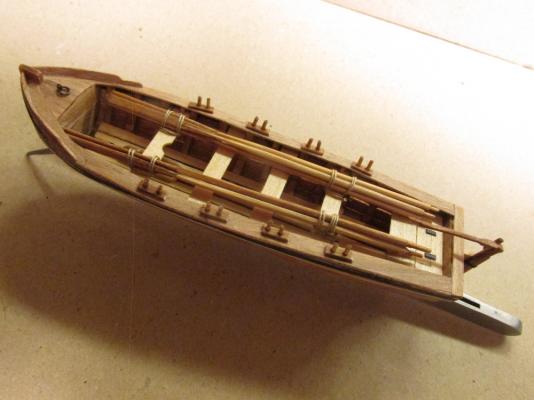

The oars have been bundled and lashed to the thwarts. This completes the Model Shipways’ Typical Ship’s Boat building log. The lashing of the boat to the spare masts on the Rattlesnake’s deck will be covered in my Rattlesnake log.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

I might have tried the bamboo forks, but I did not find any immediately available. The oars were not difficult to fabricate in any case. It's a good idea though. Maybe when I finally build my Conny in the next millennium I'll use that idea.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

That's fairly close to what Steel has (if I read his chart correctly). An inch or two difference at 1/64" scale isn't going to amount to much so I think I'm OK. Thanks for your input,

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

Actually Scott, this is fairly recent stuff that went missing and it happened twice.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

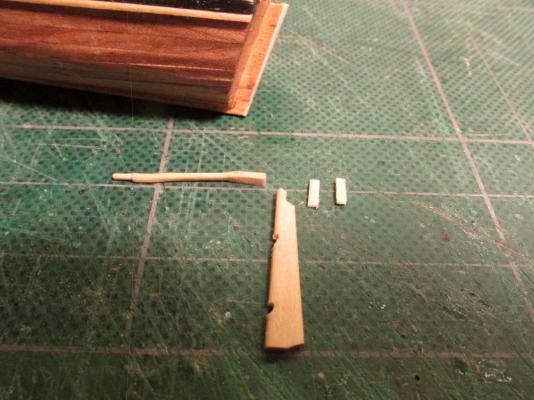

The dimensions were based a chart in Steel for a boat breadth of about 6 feet. Everything was reduced down by about 1/64 The materials for the oar were bamboo barbecue skewers and 1/32” x 3/32” basswood for the oar blade. After splitting a skewer to about 3/32: square, a draw plate was used to reduce it down to about 1/16” diameter. Unfortunately I couldn't use the Byrnes draw plate because it was for finer holes only. I had to fall back to my larger pre-Byrnes drawplate which left something to be desired. The skewer was then cut to about 3” in length, and tapered to match the shape shown. A handle was carved on the blunt end. The tapering was flattened so it would slide into a very narrow V-notch in the blade. The two pieces were then glued. Once dry, final shaping was done to the blade and the whole assembly was stained with Early American Minwax Wood finish. A total of 8 oars have to be made. As you can see from the image below, I completed one; and started the remainder.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

Boat Oars What is a boat without oars? The kit was for the boat only; any accessories, you were on tour own. I based the oars for this boat on The Art Making Masts, Yards, Gaffs, Booms, Blocks and Oars as Practiced in the Royal Navy and According to the Most Approved Methods in the Merchant Service, 2nd edition, printed for Steel and Goddard, London, 1816. It’s English Royal Navy and published later than the Rattlesnake 1781 commission date, but it was the best reference I had. I’m guessing that any differences between an English boat oar and an earlier American boat oar would be minor and not too noticeable at this scale (I hope).

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

PLEASE NOTE Dear Readers, it has been brought to my attention that more than a dozen or so images in this log have vanished for some unknown reason. You can see the frame, but no picture. Twice now I've had to go back and replace the missing images. If anyone knows how to prevent this, please let me know. If anyone notices images missing please let me know so that I may replace them. Unfortunately, some of those image were provided by you, the reader in your comments to me so I can't replace them. If they are yours, please be so kind to repair your comments. Thanks Jon

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

I'm working on the oars, so stay tuned

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

FINAL THOUGHTS Here are some final thoughts based on a question I received from bandlc4 This was my first small boat build, as well as my first upside down build, and my first Plank on Frame build, so I was learning as I was going. The problem with the kit was that it was a $5 kit (on sale from $8). The Kit instructions stated that the keel was made of airplane plywood - it wasn't. It was basswood, the plywood would have been much stronger. The ribs on the jig had to be bent to form, I would have preferred that they had been cut to shape and there were all of ribs at the beginning and not stuck on later. That would have provided the planking strips with more support and insured proper shape. I would have preferred boxwood which is hard wood instead of the soft basswood. Another builder on the same model started over and replaced all the wood with boxwood and pear. Neither one of us planned to paint the boat. When I went to create the top cap, I realized that my bow stuck out further on the stem than the plans showed. I thought I was following the plans meticulously, but because the plan's pictures were of such low resolution, you couldn't see the detail in the bow clear enough. As a result, my bow bulkhead ended up too small for what I built - my bow should have curved more tightly to the stem and then the bulkhead would of fit (I assume). Although this is a small, "simple" model, I would not call it a first timer's model for it requires some boat building experience. If I had to build it again, and I could because the plan shows all the parts to scale, I'd cut the ribs to shape, which I find much easier than to bend, and add more of them to the jig. The hard part would be to create the additional ribs where the hull curves toward the bow. Not sure how I would determine the correct shape for the ribs there. That would ensure the bow bulkhead fits. By the way, the other builder I mentioned ran into the same problem with that bulkhead. That all being said, it was a fun build and a good learning experience. I hope I answered your question and I wish you the best in your endeavor. Jon

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

After the pieces were assembled, the basswood parts were stained with Early American and I added paper hinges colored black with a Sharpie pen. Because where the rudder post edge and the rudder edge meet are rounded, it made for a poor mechanical glue point. I added a couple of pins for a strong joint.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

I had noticed that a lot of tillers pivoted vertically either for storage when the rudder was removed or for easier access to the boat. Although I didn’t plan on mine being functional, I wanted it to look like it could move. This required two short pieces to be added to the tiller post. The tiller itself was carved with a slight S-curve.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

After looking at a lot of small and ship’s boats, I came to the conclusion that most of the boats I saw did not have the high stem post, so I chose to leave it off. Had I straight glued the broke piece back on, it would have remained fragile which would mean I would have had to pin it and risk breaking it some more. All that being said, the rudder was now too tall for what I wanted to do so, the tiller post was cut down a bit.

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

-

The Rudder The kit provided a precut basswood rudder which I used. However, you remember I broke the top of rudder stem where it protruded above the transom. The two images below show the before and after the break

- 93 replies

-

- ships boat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.