Sheerline

Members-

Posts

92 -

Joined

-

Last visited

-

Knocklouder reacted to a post in a topic:

Garboard plank

Knocklouder reacted to a post in a topic:

Garboard plank

-

Bryantes reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Bryantes reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

catopower reacted to a post in a topic:

Corel HMS Victory 1:98

catopower reacted to a post in a topic:

Corel HMS Victory 1:98

-

Jonesey reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Jonesey reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

GrandpaPhil reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

GrandpaPhil reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

gjdale reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

gjdale reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

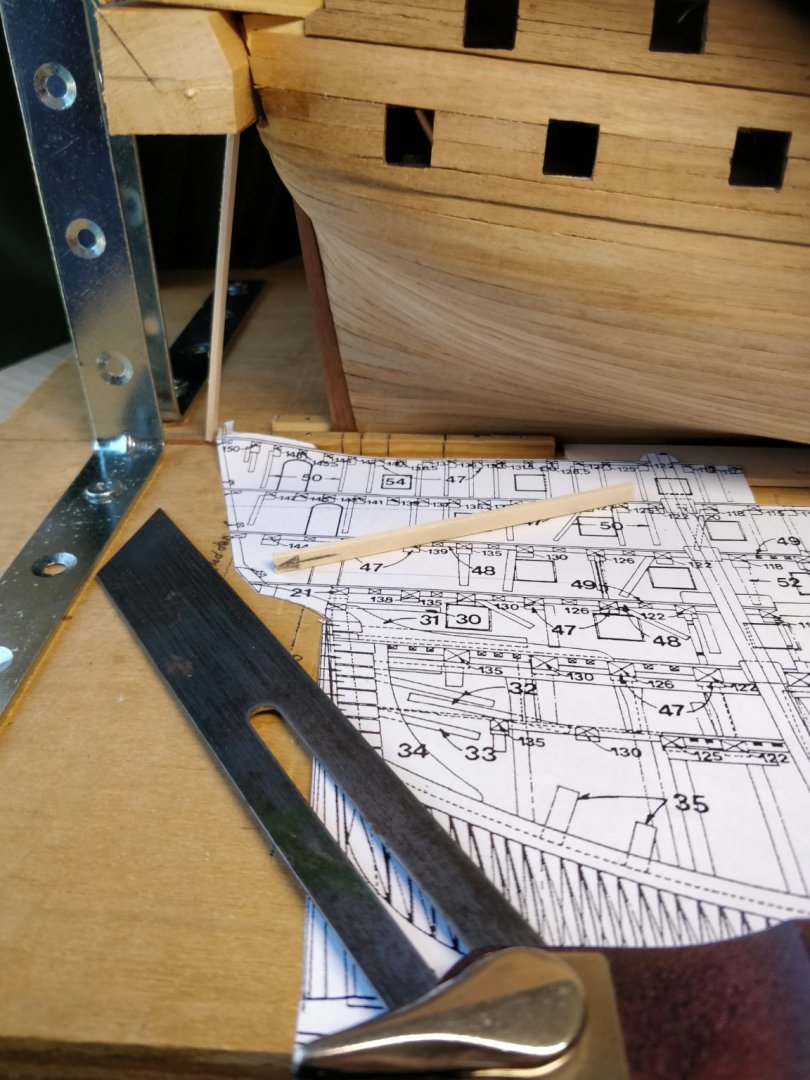

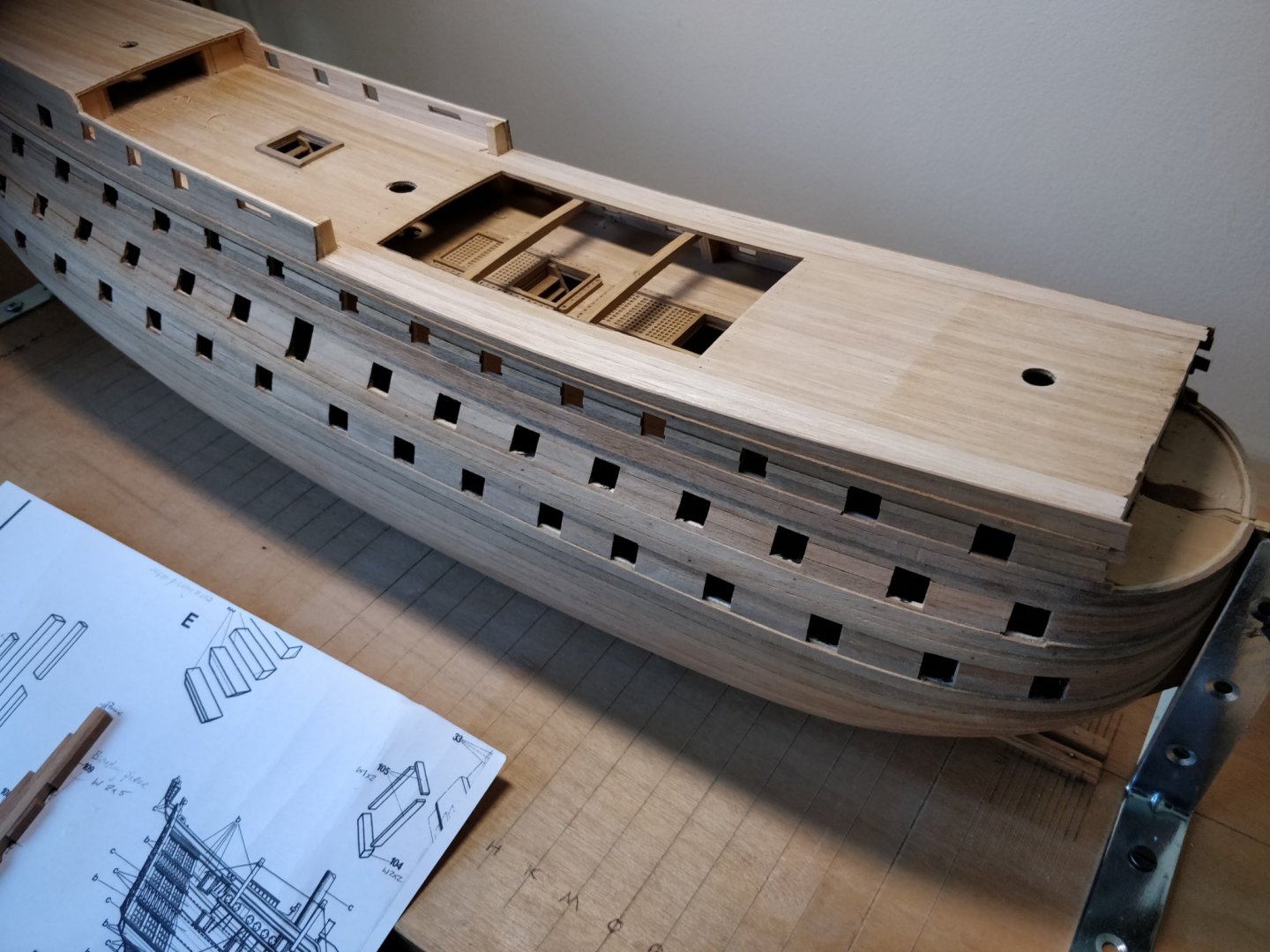

Decided to get some of the gun port frames cut out and dry fitted. Nearly finished one side already. It was an opportunity to square a few up and raise (or lower) a fraction to get a better overall appearance. I did think that there's a lot to be said for lining out ports during early stages of a build! 😁 Things might slow a bit now as there's loads outside to do now the weather is improving. Stay safe. TTFN.👍

-

gjdale reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

gjdale reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

Eugenio Treviño reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Eugenio Treviño reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Sheerline - Corel - 1:98

-

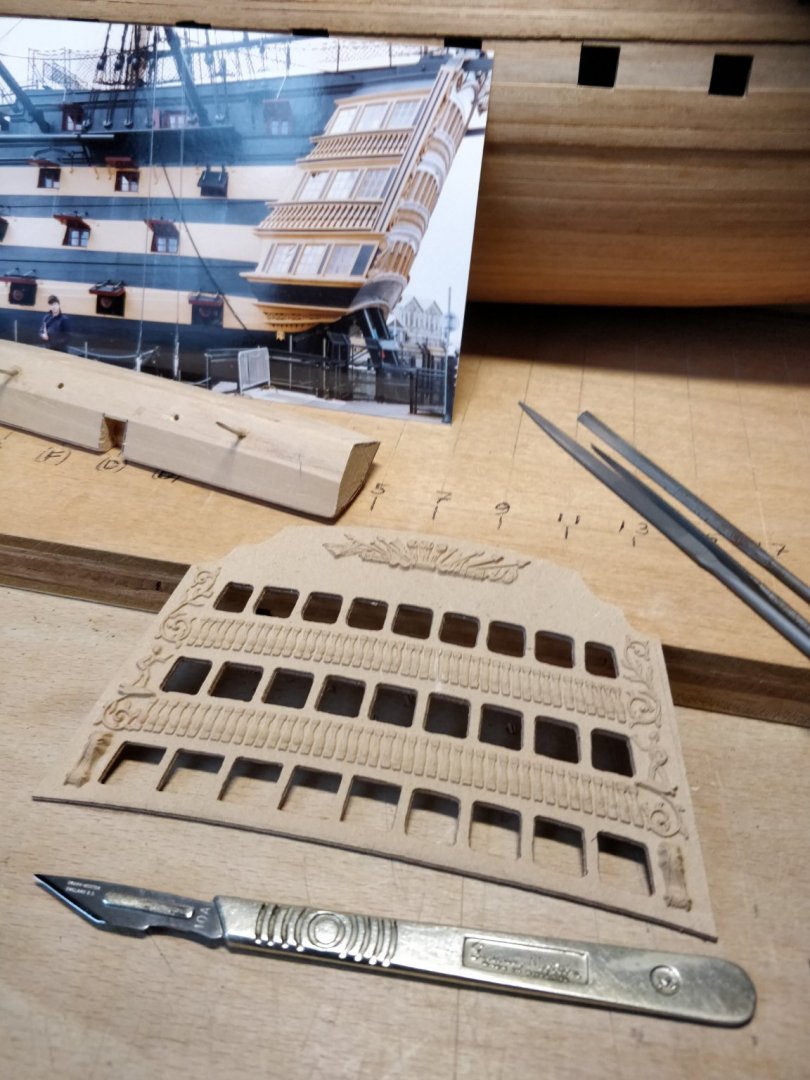

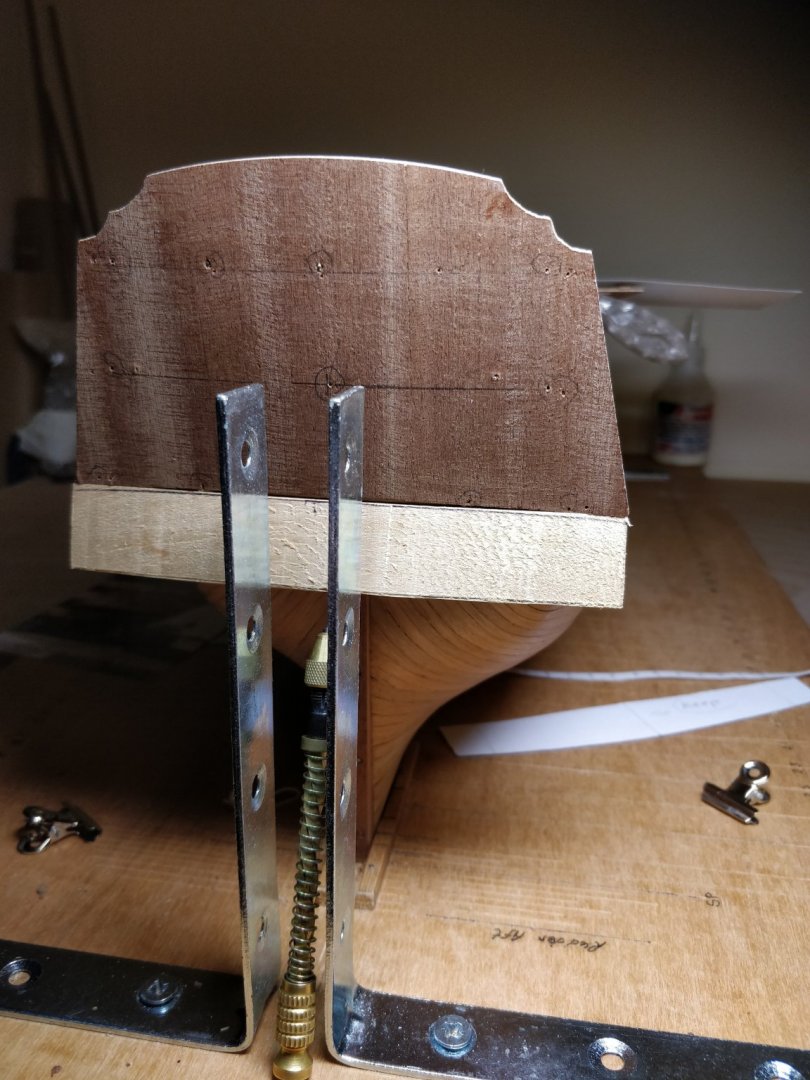

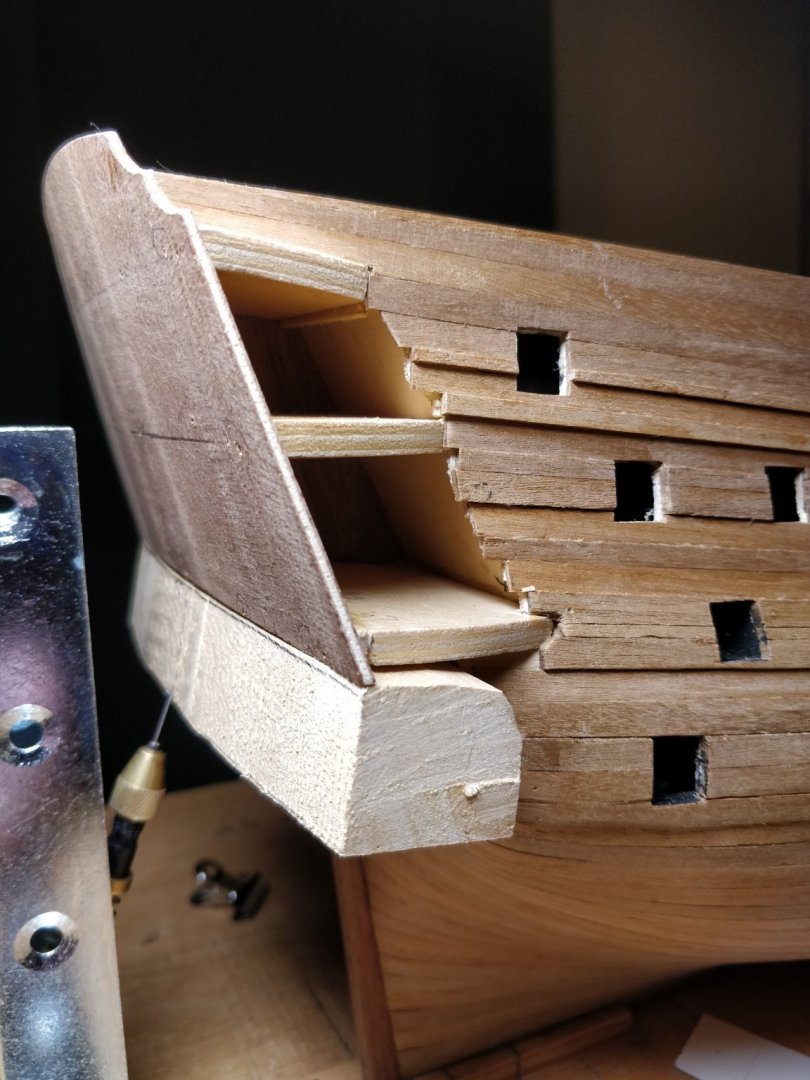

Well, I've more or less finished the main part of the stern work. Curving the planks for the counters went well enough but under the quarter galleries was a little fiddly. I found that the pressed wood lower finishings under the counter a complete nightmare tbh. I don't know if it's because I've gone off piste but they seemed too large and overly curvy. Anyway, I've hacked them around a bit and got a reasonable fit. No way could I create them from scratch! Need a break, so will move on to another part of the build for now. All the ' lining out' with decorative strips I can do later. Over all I'm pleased with the results so far and the key thing I've learned is to slow down when necessary! Pics so far..😃

-

Shipyard sid started following Sheerline

-

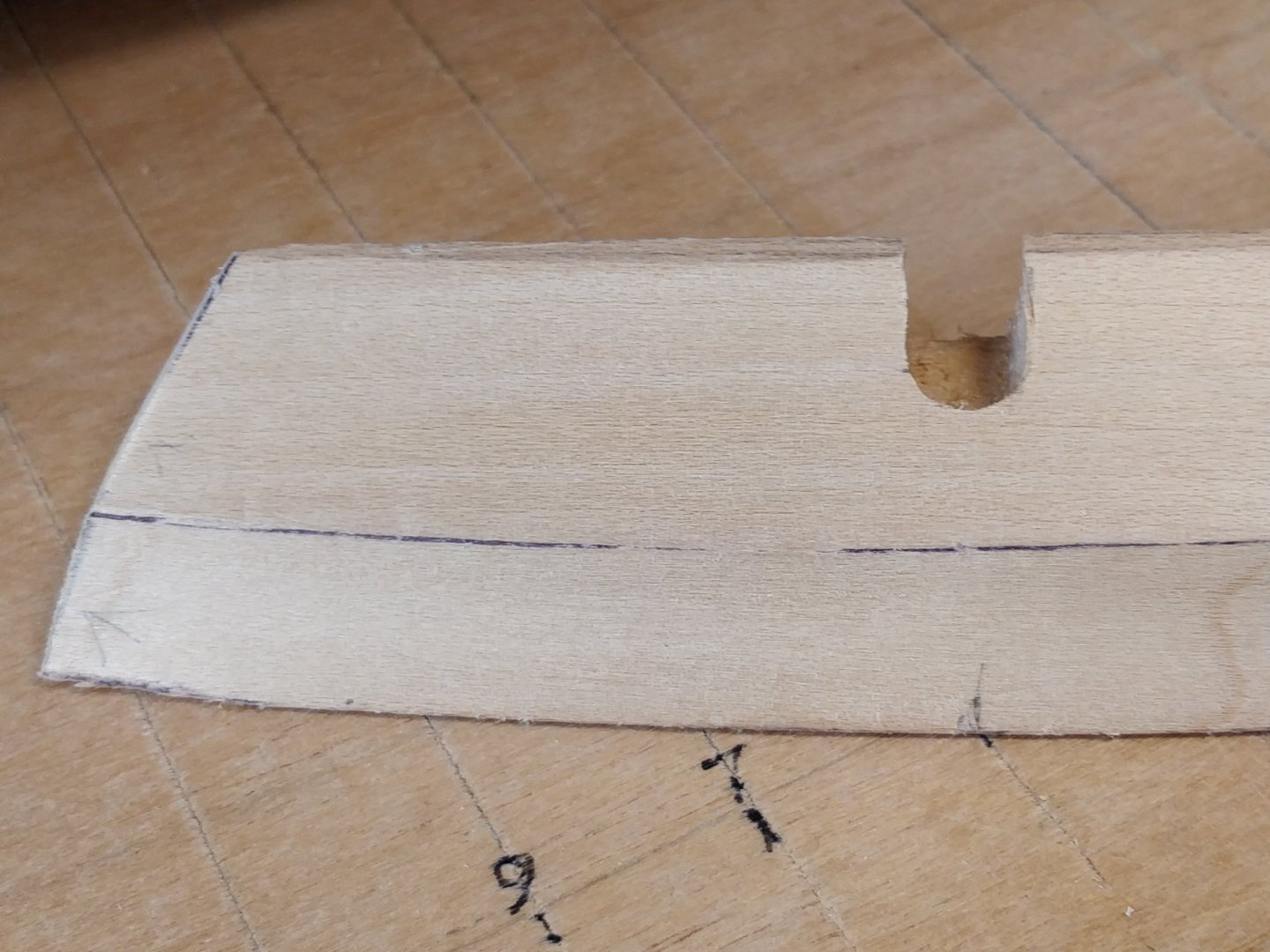

Wetting and shaping of curvy counter planks. Haven't quite fathomed out how the 'fashion piece' on the lower counter will work yet. Might need a bit of reshaping. Sources vary; some show it hanging more or less straight down, others show a small wrap around at the stern. It's certainly too curvy to sit nicely under the quarter gallery so I'm trying paper templates to find the best fit.😃

-

More work on the revised counter block before pinning and gluing in place. Started some work on the bow section while glue was setting. I've now started to over plank the counter under the quarter galleries, not with the deck planks but walnut planks. I'm trying to maintain the same wood colour throughout as I still just want to varnish rather than paint the hull. My plank nipper came in really handy for obtaining the curved profile for these short planks. Lots of pics to show progress so far. 😃

-

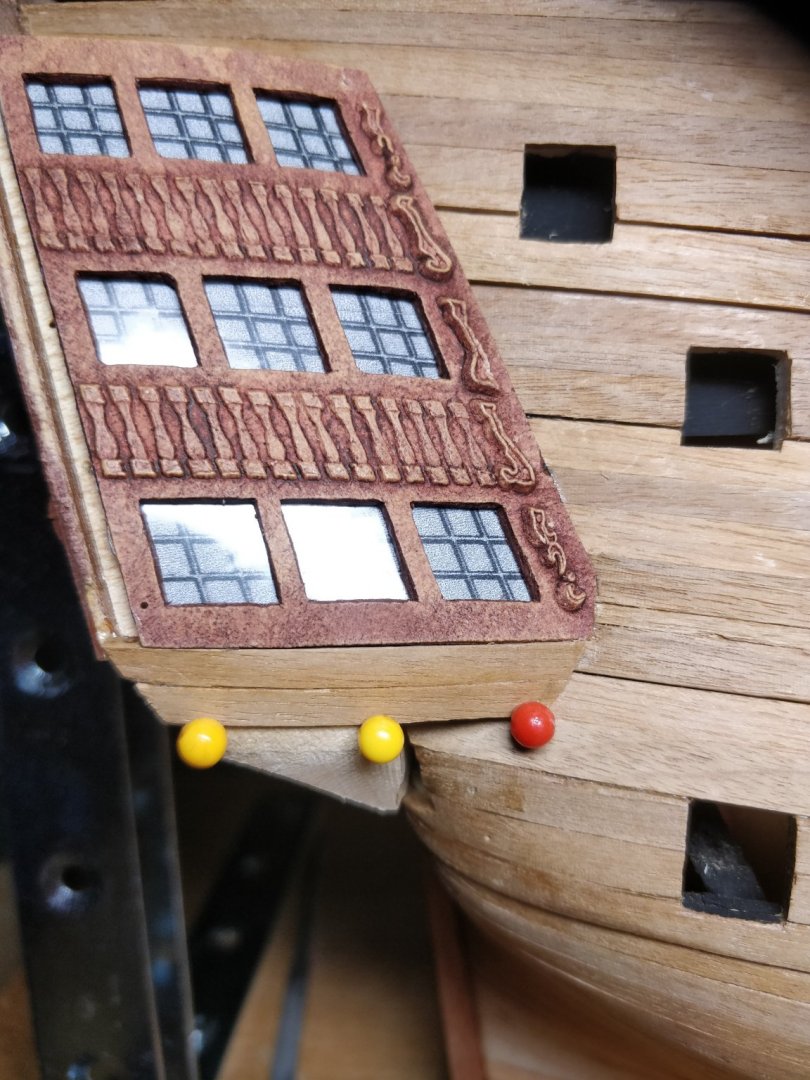

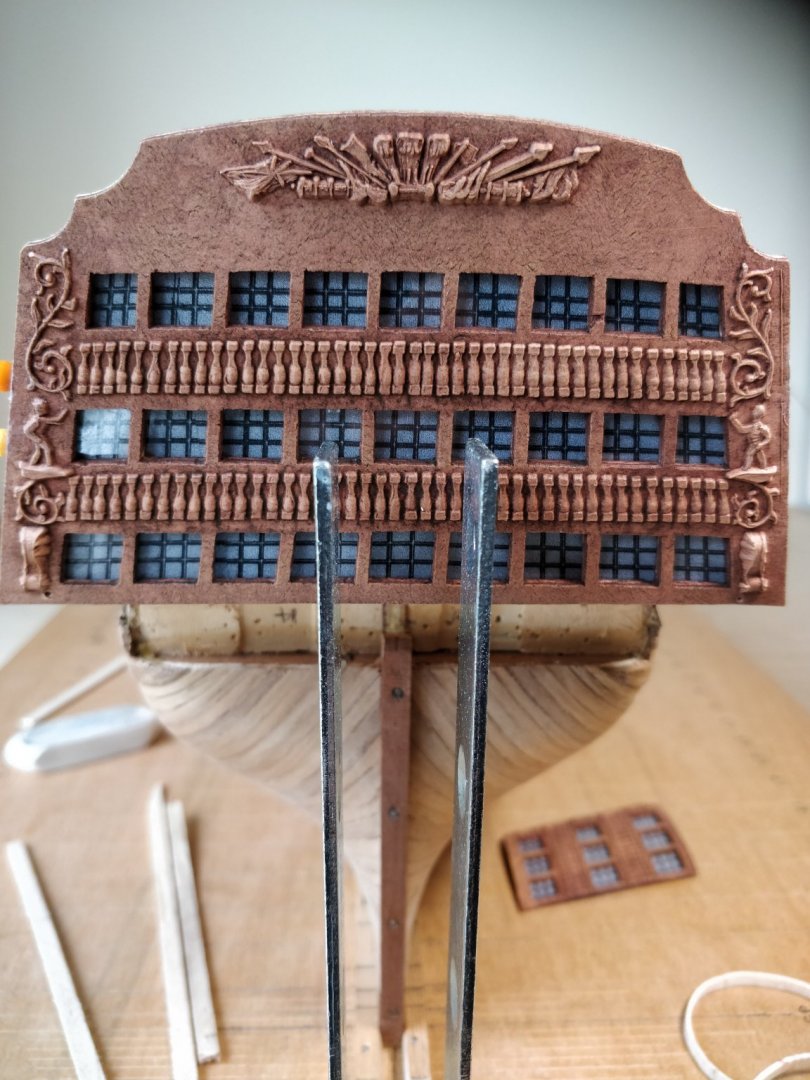

Update on the galleries. I decided to glaze these with some flexible, thin plastic from a carton I found in the kitchen! I photocopied the yellow coloured window film provided. Had to cellotape it together first. So now I've got grey lattice windows protected by the plastic which doesn't look too bad. Yellow seemed a bit OTT. Got the bits glued on now which was a bit fiddly but pleased with the result. I noticed just in time I needed to shift the quarter galleries fwd 4mm to accommodate the items 55 edging strips which helped the fitting and gives the correct pitch up to the decorative pillars. 😃

-

After a lot of fiddling managed to get the quarter galleries glued and pinned in place. I found I had to use a fair bit of heat from the iron after soaking the ply. The forward edges of these pieces are not the easiest things to fair in given the shape of the hull - tumblehome? I had to chamfer the mating face to get a flusher fit on these. After the eventual fitting of the compressed wood galleries I think I will still need to make and fit some wedge shaped small pieces to fair in the leading edges and make it look tidier. Most of the window appetures have rounded corners from the tooling so I've been squaring these off slowly and carefully. In the end I found a sharp scalpel point more effective than needle files. The yellow coloured window impressions have all disintegrated after long storage so will be using clear thin plastic instead. Trying to think of a suitable backing to this rather than just looking at the plywood. Thinking of cutting up matchsticks for the window framing possibly? 😃

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

Sheerline reacted to a post in a topic:

HMS Victory by Roberts Orca - Corel - 1:98

-

I marked the counter angles from a scaled up drawing section of a well known book which seemed to agree nicely.😃 Using my very basic school compass I scribed the curve lines deep enough to follow with a biro as my sight is not what it was! Some time was spent trying to get an edge on a chisel using an oilstone but it was like me - quite old! I've invested in a diamond stone and a whetstone and the results were much better and a lot cleaner to use. Anyway, some photos to show the various stages follow. It's not quite finished as I'd like to groove/dish out the upper counter a little bit to get some curvature. This time round I've left enough material to chamfer the bits of counter that sit under the quarter galleries which will be cut later on. 😃

-

Hello again! Well, what can I say, the counter piece I made off plan must have been for a different ship.😆 It was fine except it was too rounded in plan view for the curvature of the Corel stern gallery assembly. Had I just carried on the quarter galleries would have been way out too. I'm in the process of marking out for kit bashing a new double curvature arrangement that will fit much better. This time it will be wider too do I can cut in the upper counter wings. Learning as I go and realising that nothing can be taken for granted. Don't want to use those four little blocks of wood supplied really... I've found a piece of box wood just enough for two attempts!🤣 I dare not look at the bows yet...🤔

-

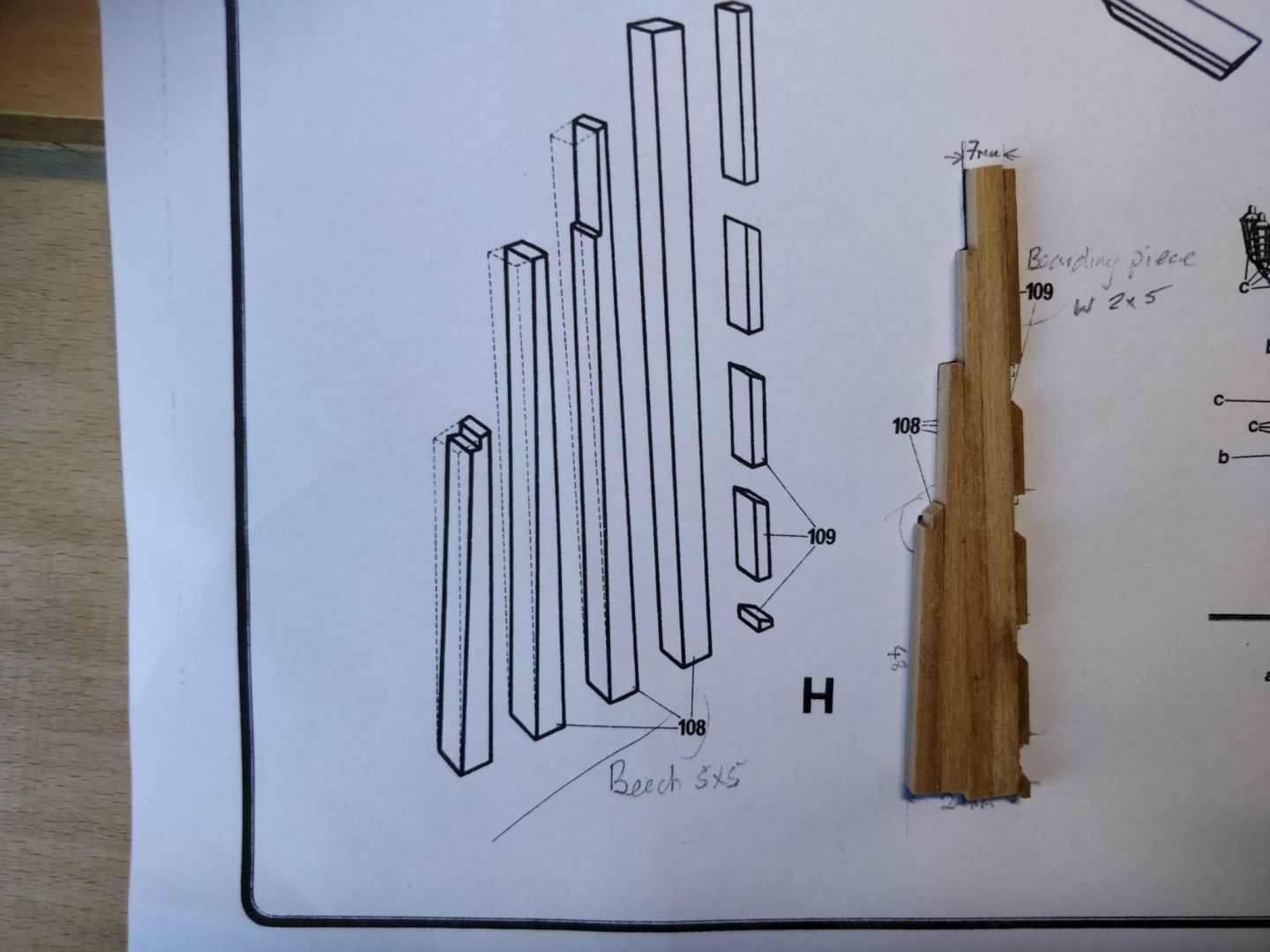

The rudder. Pieces made and stuck onto photocopy of dwng section for sizing. Walnut 2x5 carefully positioned for the accurate placing of pintles. Finished lining the inside of bulwarks with deck planks to pretty it up a bit. They're only 0,5mm thick so shouldn't affect anything. Taking a long hard look at the stern arrangement now and parts 22, 23 and 24 which don't look quite right as things stand. Were I to build this model again I would take a great deal more care with all the slots as provided and the general alignment. For instance, by my reckoning there is slightly too much upsweep on the decks and the pieces mentioned above aren't quite in line. Still, the combination of filing and packing should sort it out! Might have to fettle the transom piece that I made off plan too but it's all part of the fun I guess.😁 Aut facium aut venium!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.