-

Posts

87 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by giantdog

-

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

The bulwarks were a NIGHTMARE!!! I just couldn't figure out how to get them to lie right. I substituted the ply bulwarks that came with the kit and cut ones out of base wood, still getting them to fit was hard. I'm sure I took some photos of how I wrestled them into submission using numerous clothes pegs, clamps, elastic bands, tears, cuss word and force of will. Just can't find them right now. Once I got them on one thing I noticed was they had a concave profile, not sure what I did to get that but there you go. A little bit of filler smoothed them right out.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi everyone, I haven't been on for a while as my mother managed to burn her house down She was unhurt thankfully but it's been a bit busy sorting the rebuild out. But on the plus side my little ship has been my escape, 9 months on the clock and still plodding along So, where am I up to? Well I got the deck done.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

really struggling to get the bulwarks sorted, I'm reading every build log I can find lol.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

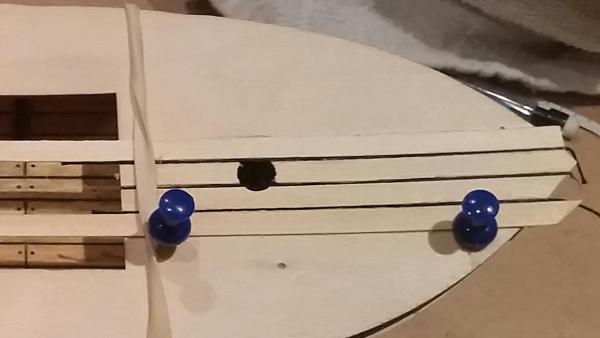

Ok, moving forward. I removed all the laid planks and sanded smooth. I thought about the black paper route but the curve of the deck kinda threw me, sooo. I went back to the thread idea, I bought some 0.1mm and I've used that technique.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

on the lower decks I used 0.1mm black thread which when scaled up gave a chaulk of 5mm (baring in mind I'm not going for total scale accuracy). I need to get to the shops and buy some more I guess. Goodness knows what I've done with it. I'm just in the process of removing the planks.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I have to agree with you David, I can't find the thread I used for the lower decks which was much thinner. I've been undecided about this thread but you've confirmed my thinking and I think I'm going to remove the planking and start again. Thank you for your input.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

So, I've started to plank my upper deck using the same laying in of thread between the planks to simulate the chaulking.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Planking help

giantdog replied to Marvi's topic in Building, Framing, Planking and plating a ships hull and deck

I'm new to building so sadly can't offer any advice as I've only just completed my first layer of planking on my Swift. I've done a build log that shows how I went about it on that model. I will follow your thread to gain some insight myself. -

I'm currently working on my first build and went for the AL Swift. I've just finished the first planking and thus far have found it pretty straight forward.

-

I think the next step for me now is to give the hull a light sand to identify any areas that require filling to get a nice 'line' but it doesn't look too bad. I'll plank the deck next using thread between the planks as I did with the lower decks. Does that sound about right?

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Well, it took a little while longer than I first thought but I've finally got the first layer of planking finished, hurrah!! It's my first build and as such my first attempt at planking, my goal was to try and have no stealers or drop planks. The main thing I regret is pinning through the planks to hold in place while the glue set, but once I'd thought of pinning next to the plank I managed a more appealing look. As this is the first layer I can live with it. What do you guys think? What could I have done better/differently?

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi Guys, I hope everyone is having a Happy Holidays. Just got 2 weeks off work and rubbing my hands together for lots of building when my mother fell and broke her hip at the tender age of 82, so I'm currently living with her whilst making trips home. Actually managed to get a plank fitted today so hurrah.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

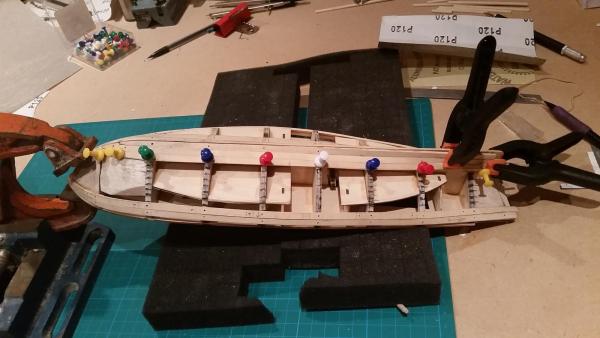

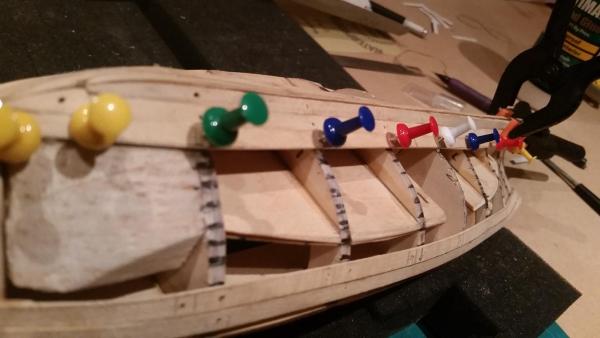

Thanks Keith, right at this moment the promotion feels more like a curse than a blessing I'll recap how I'm going about shaping the planks on the next one I fit. I've been thinking about the holes when pinning in place and you're right I don't want hole in the 2nd planking. I have a cunning plan which I wish I'd done on the 1st planking. As I've done in a couple of places already, with the 2nd planking I'm going to put the pin 'next' to the plank not through it. I'm pre-drilling each pin to prevent splitting the bulkhead. By putting the pin next to the plank not through it I'm hoping the pin itself will hold the plank up against the previous plank while the plastic head of the pin will hold the plank down. If you look at the nearest 3 pins in this photo that's exactly what I mean. I'll try this method on the next plank so watch this space.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Steady progress, I'm currently in the middle of an intensive promotion course at work so struggling for time at the moment. My Swift is my treat at the end of the day if I've got enough course work done

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I'm loving building it. It's taking all my efforts to build as is but I'll see if there's any extra I can do when I get top side. The thread inbetween the planks seemed to work well so I'm thinking I'll do that on the main deck.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Thanks for the very kind comments Keith, I'm really pleased with how it's coming on. I'm taking 2 days to fit reach individual plank, one day to spill and dry fit. One day to final fit. Please extend my deepest sympathies to your sister-in-law from this side of the pond. Dogs really do break your heart, they take a piece with them when they go but that's ok because your heart is that bit bigger for having them in your life. I am taking mine to the pub now for a couple of beers and shall raise a glass to your sister-in-laws beloved dogs. The pub I go to dates from the year 1135.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

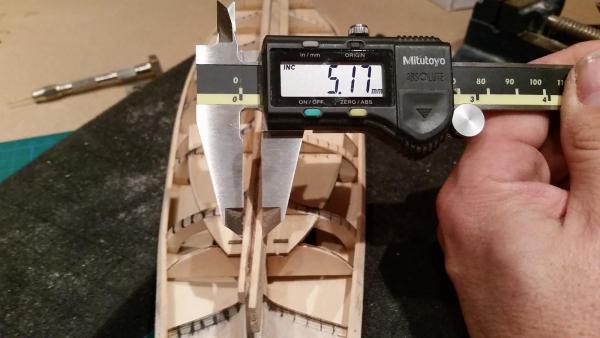

I thought about that and am hoping that the step I took in post #78 will help this problem. I thinned the false keel down from 4 mm to 2 mm to reduce the amount of sanding I have to do. I cheat and read everyone's log then use the information I find, taking a bit from here and a bit from there then have a go at apply the lessons learned from you guys. I spotted that adivedog (I think it's in his log) he mentioned he had an issue with the false keel being too wide and I couldn't see anyone else had thinned there keel down. So, I took a leap of faith and went for it. Fingers crossed it pays off in the end. I'll keep you posted. Thanks for the supportive posts, I love how yours is coming along. Building these babies is rather addictive.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Thanks guys, just flying by the seat of my pants. Reading and re-reading your logs and copying, so it's all thanks to you. Not looking too bad so far and pretty happy with the line the planks are taking. I'm trying to go for no 'drop planks' (is that the right term?) i.e. each plank runs the whole length of the hull.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

still plodding on. I've not given up pre-bent and dry fitted Pretty much simply continuing as I've done with the previous planks. It's at times like this I wish I knew what on earth I'm doing.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

This enabled me to trim/sand the plank to this shape (sorry, taking photos with one hand with my phone is a little difficult so there a bit blurred) Once happy (ish) glue in place. In a earlier post I mentioned that I had thinned the false keel down, I hadn't noticed this done on other builds but was worried that the keel would end up being rather thick once all layers of planking where in place. With the first layer of planks mine measures 5.17mm Here are a couple of photos of the first next to garboard plank.

- 153 replies

-

- swift

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.