ir3

NRG Member-

Posts

336 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ir3

-

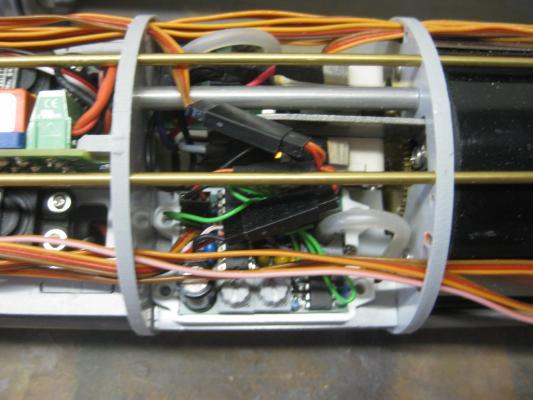

Well after some long thought and research with other Engel Type VII/C builders, the suggested location of the RX is not a good one. It results in very long leads subject to noise and other problems. The question, however, was where to relocat the RX. There were two others but one was very near a brushed motor on one of the ballast tanks and the other was completely aft near the TMAX Ballast Tank controller. This is the spot I chose since the drive motors are Brush Less and will offer no source of interference for the RX. the following pics show the possible locations: I chose the spot near the TMAX Control Module and it results in: The RX is loose for the first photo.This reduces the length of the wiring of 3 channels by 1 meter each. The rest of the wiring will be greatly reduced as the leads for the ESC's are in close proximity. If anyone finds this logic flawed, please let me know ASAP. Making new leads is very tedious. More to follow. Iran

-

The floats have been sealed and installed. The floats at the aft end of the boat are the same size, just that the angle of the picture distorts the image. The WTC tube is in place but not permanently as of yet. The forward end that goes over the internal nose cone needs to be cleaned and silicon grease applier to help the O-ring seal. The picture with the slip rings does not show the O-ring in a groove around the outside. The WTC Tube slides over this cone and the O-ring supplies the seal. I included a picture of the internal nose cone installation to point out a problem. It will not affect the integrity of the nose cone itself. The nose cone contains the forward dive plane servo and signals to that are passed by slip ring contactors on the tech rack (I can't seem to find that picture). The bottom bolt is impossible to put on as the end of the screw almost touches the fiberglass hull and I just can't get the nut on. The upper bolt, however, should suffice. Now it is onto the completion of the Tech Rack wiring and preliminary checkout of all the functions. Until next time, IR3

-

The flotation foam has been carved and test fit. The WTC tube does not interfere so I will be filling the pores with resin and install them. The instructions call for installing them with no air pockets or places where water might collect. Good luck. There is no way I can check for this. I can't even see the fit for the floats in the aft section of the hull blisters. All I can say is that the WTC tube clears them. The kit manufacturer should have made these pieces. They have the molds that created the hull, thus they have all that is needed to make the floats and have a good fit. Having said that, I will be installing them with Gorilla Glue. Gorilla glue expands while curing and by applying aggressively, most of the space and maybe all will be sealed. Next update will be fitting the WTC and putting in the Tech Rack. IR3

-

The decision to go back to the supplied planking material has been made. On another note, the model has been sitting under the workbench in the garage for over three months and is still perfectly straight. The battle of the twist is over. The lower counter planking will now be going in. Hats off to the great builders of this model on the MSW forum. I studied all of the builds regarding the lower counter and noted Ben's problem that became a major headache. I just checked the shape of the stern area around the lower counter and found that it did not conform close enough to the plans. I will be doing some more sanding and shaping to get this area correct before the planking. Until next time, IR3

-

Well, I did try soaking in an 80 - 20 mix of water to ammonia but the results were not much better. Still a lot of spring back and the wood was discolored. I can do the counter in basswood supplied from the kit and this should not be a distraction, especially if I decided to apply a very light finish. What I am warried about is what kind of difficulties I will have when I start the planking. Will I be struggling with some of the compound curves. I know that the boxwood has been used countless numbers of times but I have absolutely no experience in using this material and am wondering if I should just use the kit supplied wood for the entire model. Any suggestions would be appreciated. Thanks, IR3

-

It has been a long while since the last update. Too much in the way but now pretty clear to continue on the Kingfiser. I have all of the boxwood I will need and I must say, not being an expert on woods, it seems quite nice. I am at the point of planking the lower counter. I tried to end bend the boxwood but it looks like it will not happen. I tried two methods to soften the wood, the first being soaking for about an hour. When they came out of the bending jig, the spring back was almost straight, with very little bend. The second method was to soak the planks, wrap them in a wet paper towel and microwave the package to try to get some steam penetration but alas to no avail. It looks like the boxwood does not like to be end bent. This worries me a bit when it comes to planking. Of course the wood will not be end bent for the most part but there are some planks that will have special treatment. So for the lower counter I am using the 1/8 x 1/16 planking material from the kit. This worked quite well. I am not going to apply it until I get more information on preparing the boxwood as this is the wood I would like to use. Is there some special way the boxwood needs to be treated to get the appropriate bending? Until next time, IR3

-

I mixed up some finishing resin and made a soup of 3lbs of shot and resin. It was poured into the center area between the lead strips and smoothed out. A check was made to ensure that there would be no interference with the WTC tube. The pics show the shot in place and the tiered assembly of the lead strips per the plans. One of the pics is slightly out of focus but the idea shows. The rings are the clamps for the WTC tube. Next step is to get the foam cut and placed into the fuel tank blisters. Apparently there is a balance between the ballast and the foam and I have not found an explanation of this that I fully understand. I just hope that Engel is correct on the amount of foam and ballast. Next update will be installation of the foam. Until next time, IR3

-

The lead ballast showed up today so it's on with getting it into the hull. Unfortunately I did not get feedback on the weights of the battery packs so I had to do a little averaging. The 8000Mah D cells range from 135 to 145 grams. I used the average of 140 grams to get 2800 grams for the old 20 cell pack. The Sub-C cells range from 55 to 65 grams. I used an average of 60 grams to get 1440 grams for the the new 24 cell pack. The difference being 1360 grams or about 48 ounces. The final trimming of the boat, both to the water line and fore/aft will have to take place once the boat is finished and in the water. The picture shows three bags of lead shot at 1 pound per bag. I need to add the rest of the bar lead per the print and then spread the shot evenly between. An addition of resin to keep the shot in place will probably add and ounce or so, well within the margin of error on the battery weights. Who knows. Next update will show all of the ballast in place. Until next time, IR3

-

Lovely work Remco. Pebbles is adorable as all kittens are. My cat didn't chase parts all over the workshop but did have one pesky habit. She continuously needed to be the center of attention and would lay down on anything I happened to be working on at the moment, demanding some attention. You've got to love em. IR3

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Roger, great work on the R. E. Lee. I built several of these in years past and I see from your build, not much has changed in accuracy. When you first started, was the hull perfectly straight? Thes kits tended to have hulls that had a slight warp in them. Also, I see that you have run into all of the other little 1mm errors here and there but have taken care of them as you go. When they add up, it's a nightmare to get everything to fit properly. This is a great kit but does take a lot of planning and measuring before gluing up the next step. Looking forward to your updates. I am particularly interested in seeing how you handle the railings.

- 94 replies

-

- robert e lee

- amati

-

(and 1 more)

Tagged with:

-

The sub has been ignored long enough. I am now working through the next problem to solve. Having switched from the D-Cell battery pack to the Sub-C cell pack, the weight difference is dramatic. I do not have the exact specs of the actual battery weights since they vary based on capacity, a rough approximation makes the difference somewhere between 1200 and 1600 grams (42 - 57 oz). This represents a lot more lead ballast than was supplied. The plans and lead ballast layout, I am sure, is based on the older D-Cell pack. I have an email to Engel abuout how much extra lead ballast to put in and how to distribute it. He has the exact weights for the battery packs. I would like to avoid experimenting to get the boat to the water line since working within the hull is very cramped. More to follow after I get some specifics. IR3 OOPS, forgot the picture. The first layer of lead strips is in but I need more infor before continuing. The space in the center will be used to add the extra ballast as needed.

-

On the subject of battle damage, none of my models are fresh from the builders yard. They are always after the first refitting and are always done in a very hasty manner to get them back in service. Iran

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi augie, Love the planking and what are rules for. :) And when you send out the two cases of beer, could you please send Justin Bieber with them. Keep up the great work, Iran

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

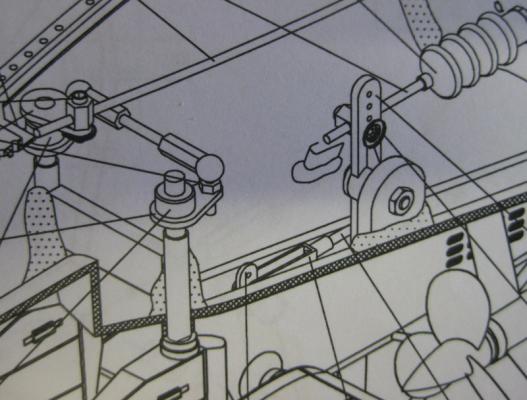

I did a little bit more work on the stern plane geometry and I am now getting about as much stern plane movement that you have achieved. Looking closely at the Engel assembly manual, the linkage is well into the opening in the stern plane support. NOTE THAT THE LINKAGE IS COMPLETELY CHANGED. IT HAS BEEN ADAPTED FROM ANOTHER TYPE VIIC BUILDER, JAN AKA HORSEMAN ON RCG, AND I THANKED HIM FOR AN EXCELLENT IMPLEMENTATION. I shortened the control arm and placed the ball link in the center. In that way I will not get any interference from the sides of the stern plane support. I am now getting about +- 18 degrees of deflection. This should be more than enough. I also plan on linking the bow plane into the LTR6 allowing for more help when changing depths. I have a lot of hours in this and I will do no more on this linkage. As the famous Porky Pig always says "Deb-ebe-de-deb-de that's all folks!" This has been a lot of work and a good deal of it very frustrating. I am actually sorry I tackled this boat instead of one of the Merriman 1/72 scale boats, which I juts might go back to. His boats operate very nicely in reasonably sized swimming pools. There is actually no clear water pool large enough for this sub in my area. The most I am going to be able to do is use the largest swimming pool that one of our friends has and do a little surface movement, drop to periscope and do a bit of under water movement. The turning radius is so big that I probably will not get a complete turn without backing one of the props. There is no pool in the area large enough to test the full functionality. I will be checking with some of the other U Boat drivers here where they run their boats. IR3

-

There is not much to report with visual looks but the prop shafts are now aligned and spinning in opposite directions. Now I just have to make sure I have the props on the correct shafts. :unsure: Getting the shafts aligned is quit a process. If the stern cone was exact, the strut supporting the dive planes bearing, and the prop hub is accurately brazed then everything might just line up properly with no friction to speak of. Not so fast. It took about 6 hours of fine bending on the prop hub, filing the fairings where the prop shafts exit the hull, and making adjustments to the center strut (I believe it might be called a skeg) and aligning the prop hubs themselver (adjustments in 3 dimensions), makes it quite a task. But the work on the aft section of the sub is complete. Now it is into the WTC and I can set up the forward planes. I have some mechanical advantage issues to work out. I used the notches recommended in the plans for the dive plane bellcrank but I am not getting much deflection with full 90 degree servo motion. Hopefully this will be a simple change of where I connect the dive planes pushrod on the bellcrank. Lots of work!!! I think this is the toughest of the Engel boats to set up. I guess I am just a glutton for punishment. Until next time, IR3

-

After doing all of the work to create a removable tail cone, at 3AM I awoke with an epiphany. Why not just add a few flood holes in the tail cone to get access to the grub nuts on the prop shaft couplers. A little touch up paint and one will never know. That being done I can now get started on setting up the props and make sure they are turning in the right direction. Until next time, IR3

-

The problem with the dive planes servo is solved. The LTR6 is a very clever device. It is internally set for a depth of .4 meters or about 1.3 feet. It has a very sensitive pitch sensor and a depth sensor. The pitch sensor, when at periscope depth, helps keep the boat on an even keel. The LTR6 has a connection for a 3 position switch which allows 3 modes, off, relative depth, and absolute depth. With no switch connected, the device is in absolute depth mode. Since the Tech Rack is on the bench it is not at a depth of .4 meters. Therefore the device is commanding the planes to achieve the absolute depth and thus very little control from the TX. With the switch connected and in the off position, complete control of the dive planes comes from the elevator stick of the TX. These Engel devices are very well thought out and it takes a bit of time to fully understand how they operate. Until next time, IR3

-

Well, after giving the rudder problem a lot of thought the problem has been found. The geometry was wrong on the horn. It should have been on the other rudder post. This not only makes the line of the push rod correct but also has the rudders following rudder stick on the TX. It was quite involved since I needed to redo the cross coupling between the rudders. A very lengthy process. The problem with controlling the dive planes is that the LTR6 needs to be calibrated. It does not know what level is as of yet so it has no reference to level the dive planes. The servo is just fine, just an LTR6 calibration. Until next time, IR3

-

With the hull painted it is time to get back on the mechanics. The rudders and dive planes are in as well as the prop shafts and props. Lots to do on the props. There is one right hand and one left hand. I need to determine which side of the boat the props should go and then I will need to reprogram the Brush-less ESC's to get the shafts rotating in the right direction. With the limited space to work on the rudder and planes installation and my meat hooks for hands it is quite a struggle. After getting everything set up, two problems showed up. For the planes, the servo for the aft planes does not center properly. I swapped the rudder and planes at the RX and the problem persisted with the aft dive plane servo. This will have to be replaced. It is a Robbe 110 BB MG but I think the Futaba S3001 is the correct replacement. I might look for the Robbe locally. Another issue is a bit of back lash in the rudder system. I do not get a good return to center with the rudders. One of the rudder posts seems to be a slight bit oversize causing the rudder to be a bit on the loose side. I am not too worried about this as I can fiddle with the stick on the TX a bit to get them centered. Replacing the rudder tube is not an option at the moment. So, the servo will be replaced and then it is off to setting up the props and the dive system. Until next time, IR3

-

Once again incredible work. Late response due to not having a computer for a bit over a week. I can't imagine how the cellphone addicts would get along with out for a week or so. The cold weather is settling in again here in Southern California. Yes, we do get down into the high thirties once in a while. I welcome all of the modelers to move out to Southern Cal. As for the cold weather I do have a source of firewood :D . Keep up the great work as usual. IR3

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

With the computer down for a week and waiting for the delivery of a part from Engel it was slack time for me. The replacement for the Pitch controller LTR5, the LTR6 finally arrived. The installation is very clean and now it is off to recharging the batteries and starting the setup of the electronics package. The new LTR6 just arrived on Saturday and it is time to install it. It is a very nice design in that it eliminates Y harness to control the aft and forward planes. Not only does it eliminate the Y harness but supplies both +/- servo outputs if the servos are not moving in the right direction relative to the pitch stick on the TX. The first picture shows the LTR5 clutter and the second shows the clean LTR6 installation. I will now get started on recalibrating the electronics. Until next time, IR3

-

It's just about ready for planking with just a bit of fine sanding to get good runs for the planks. A little heavy on the gun port red but thats what planking is for. I will be using boxwood which I will not have until around the first week in April so this will be set aside and full attention can be made on the Type VIIC. Until next time, IR3

-

The hull is painted so now I can get back to finalizing the WTC. It is very difficult to get a full view and if I use close ups all of my dismal painting will be exposed. Still waiting for a new LTR6. It's functionality is improved and includes extra servo plugs. Anything that reduces the wiring clutter is welcomed and it eliminates a Y harness that connects the fore and aft planes. It also has a slightly smaller form factor which is alway welcome in this highly cluttered WTC. Until next time, IR3

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.