-

Posts

231 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EKE

-

I've been swamped with work and other distractions, so progress has been slow, but I am chipping away at the second pearwood planking layer. Per the suggestion of Chris and Jim, I've been preparing each plank, tapering and beveling as required, and then gluing it in place using thick CA gel. This works very well. The gel gives you the delay in set-up time that's necessary to get the plank into correct position before it hardens up. Here's a few progress shots. I've been working my way up from the garboards, and down from the gunwales, alternatively. I've been beveling the edges of the planks where necessary to allow them to fit closely together without large gaps. I've been using this big sanding block to bevel the planks. It's long enough that I can sand in a bevel over a long length easily. Here's a couple more shots of the start of the second planking. Slow and steady.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Your Zulu is looking really excellent, BE. Thanks so very much for the inspiration!

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

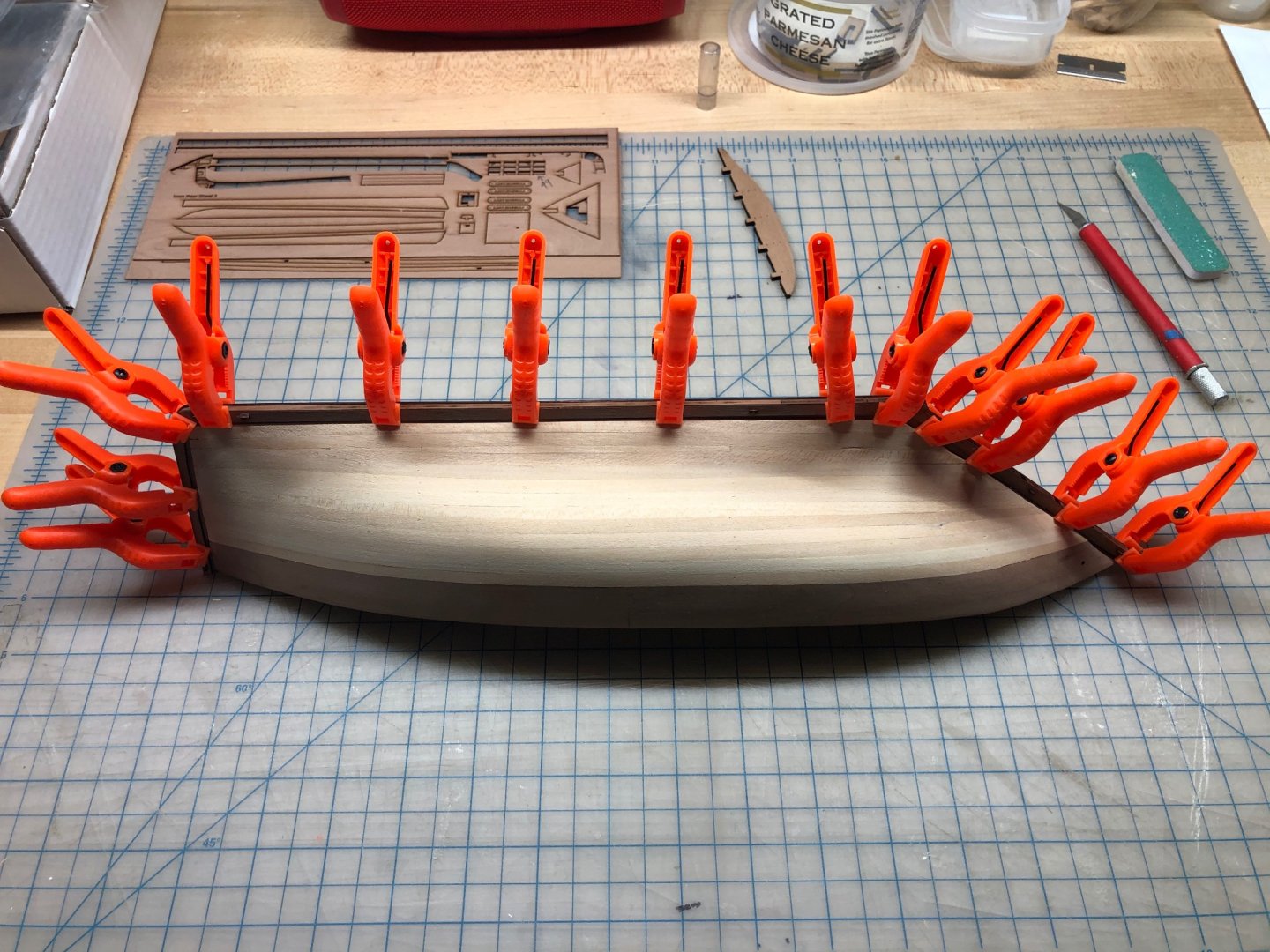

Quick update: Been very busy with work this week, but I did install the stem, keel and rudder post facing parts. They are laser cut pearwood, and sandwich the stem, keel and post creating a nice rabbet to accept the ends of the second planking. It’s a great detail, I think. You can’t really screw this up, because Chris had designed it with little flat biscuits which fit into slots laser cut into the facing pieces. So the correct alignment is ensured. All this fits together perfectly. I glued them in with PVA white glue, and clamped them to ensure they were properly laminated to the core pieces. Below are a couple of shots after the glue had dried and the clamps were removed. The facing pieces for the rudder post create sockets that the tongues of the rudder fit into. In the photo below I’ve tested the rudder’s fit. Perfecto. The shape of the rudder is very elegant, and the overall form of the hull is completed beautifully with it in place. On to the second planking this weekend!

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks Jim! Great information. Are you using a tool to apply the gel, or using the nozzle of the glue bottle to apply?

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Question for you Jim, regarding your technique for the second planking. You have said you used CA gel to attach the planks, and you described placing spots of CA periodically along the back of the plank, and progressively pressing and holding the plank into position while the gel sets. What about the edges of the plank? Are you gluing the edge of the new plank to the edge of the last one?

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks so much Jim. I'm really grateful to Chris for his engineering on this kit. He has really set the newbie up for success.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks for the encouraging words and the support, guys. I've learned so much here on MSW.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

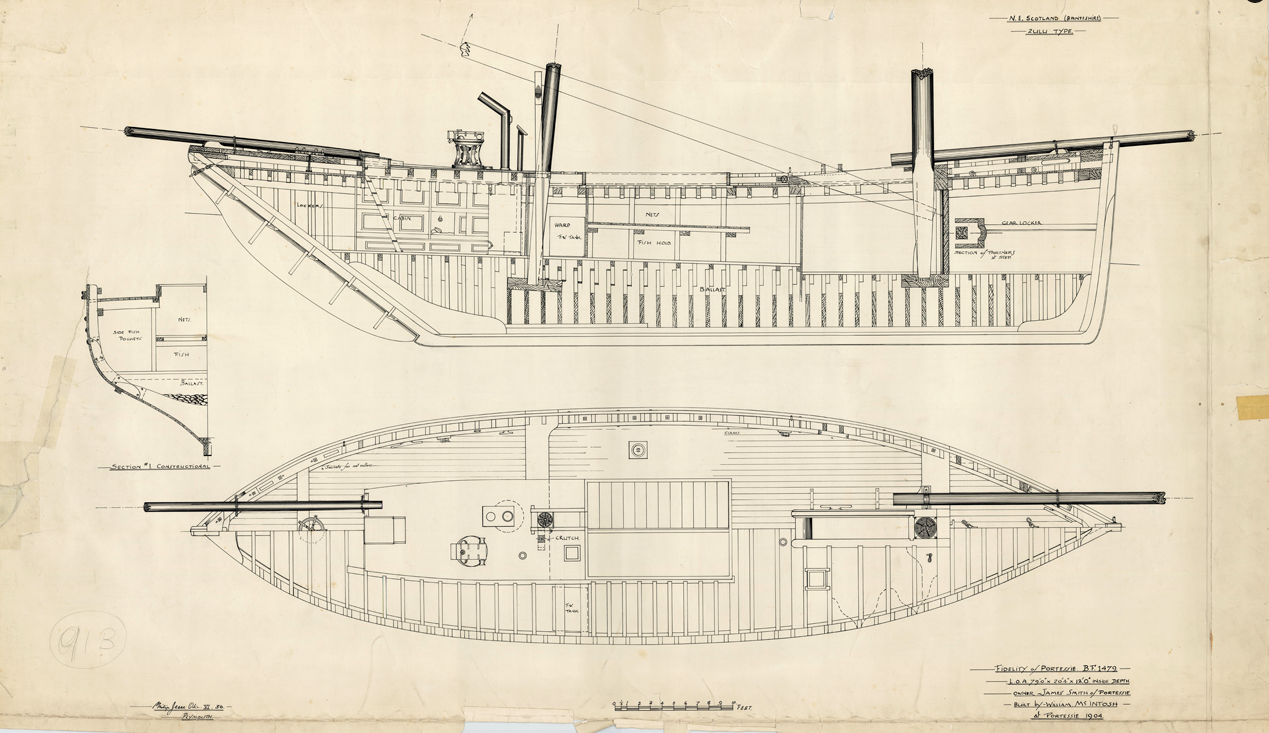

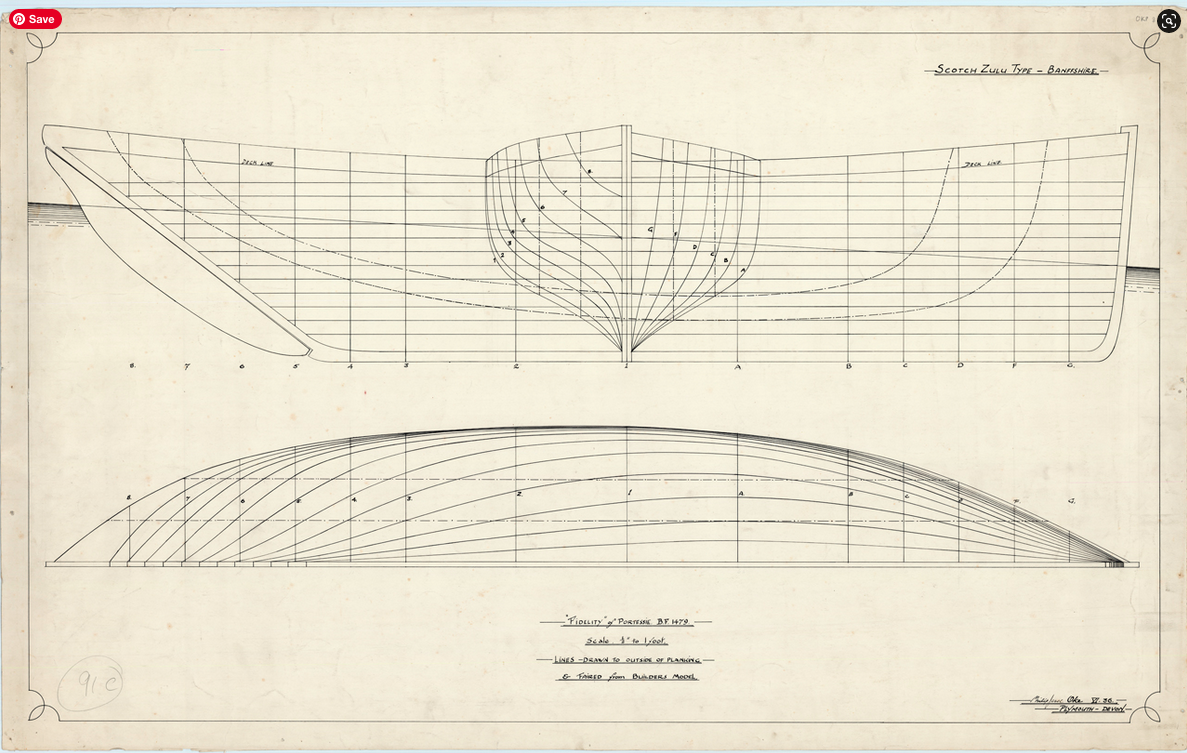

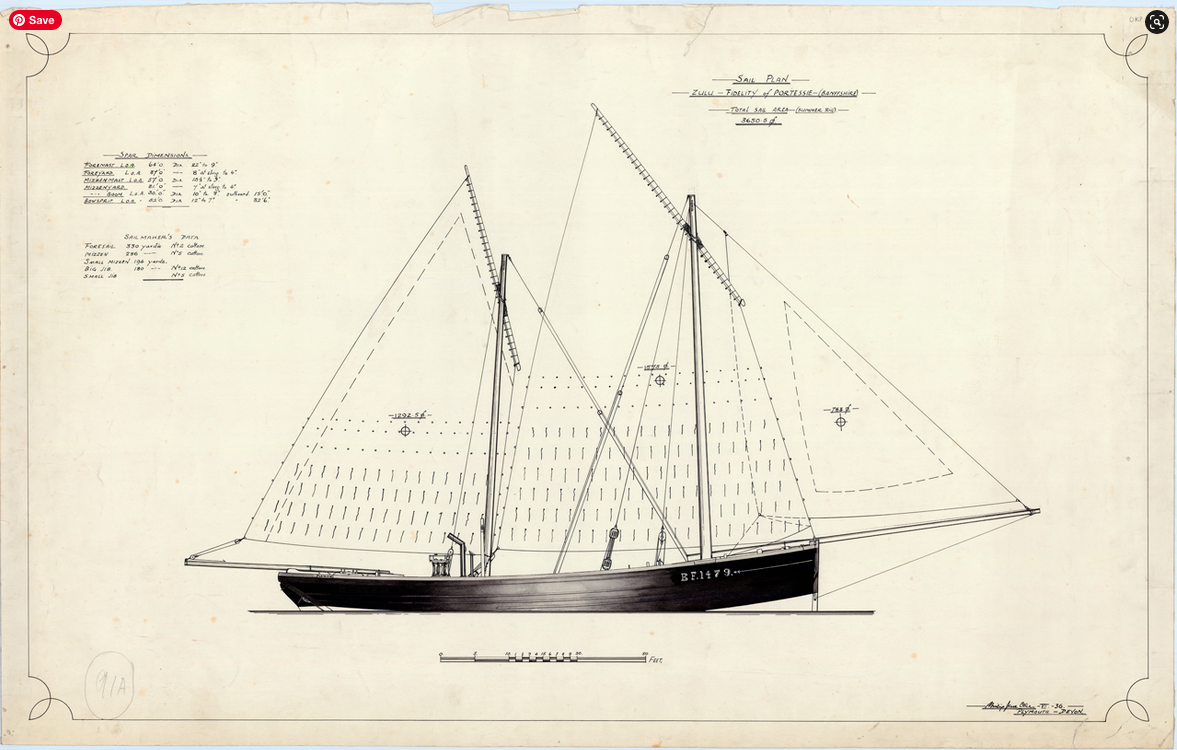

As an aside, during a pause in construction (), I have been doing some online research on the Zulu type. I came across these vintage drawings on the Greenwich Maritime Museum website. They are design drawings of the Zulu Fidelity (BF1479), launched in 1904. Beautiful draftsmanship, and it seems to me typical of design documents of the era. It's interesting to look at the interior elevations in the longitudinal section, and to imagine what the saloon of this boat must have been like. Also fascinating is the way the mast trunk and step accommodated the lowering and storing of the main mast. Adjacent to the mast step in the section is a small detail showing the plan of the mast trunk as three sided, and open facing aft, so that the mast can be raked aftward and laid down. The section also shows the tip of the mast seating down into a pocket in the mast step. I'm wondering how they would have raised the mast up out of the socket in order to stow it. Maybe that wasn't necessary...perhaps it was designed to simply rock backwards out of the socket. The deck plan and the rigging of BF1479 Fidelity shown here are very close to Lady Isabella. Chris, I'm wondering if these drawings were among your source material for the design?

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

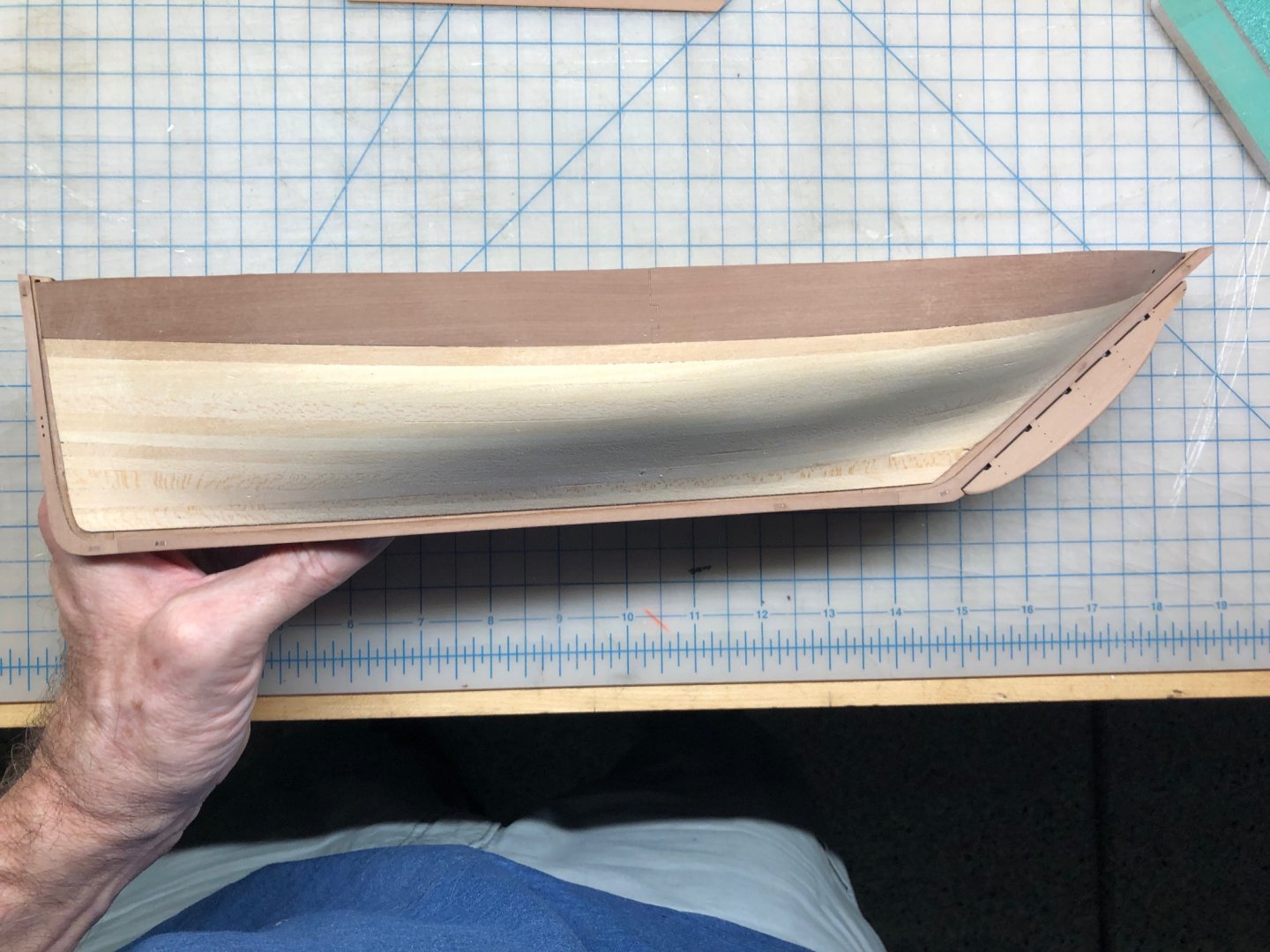

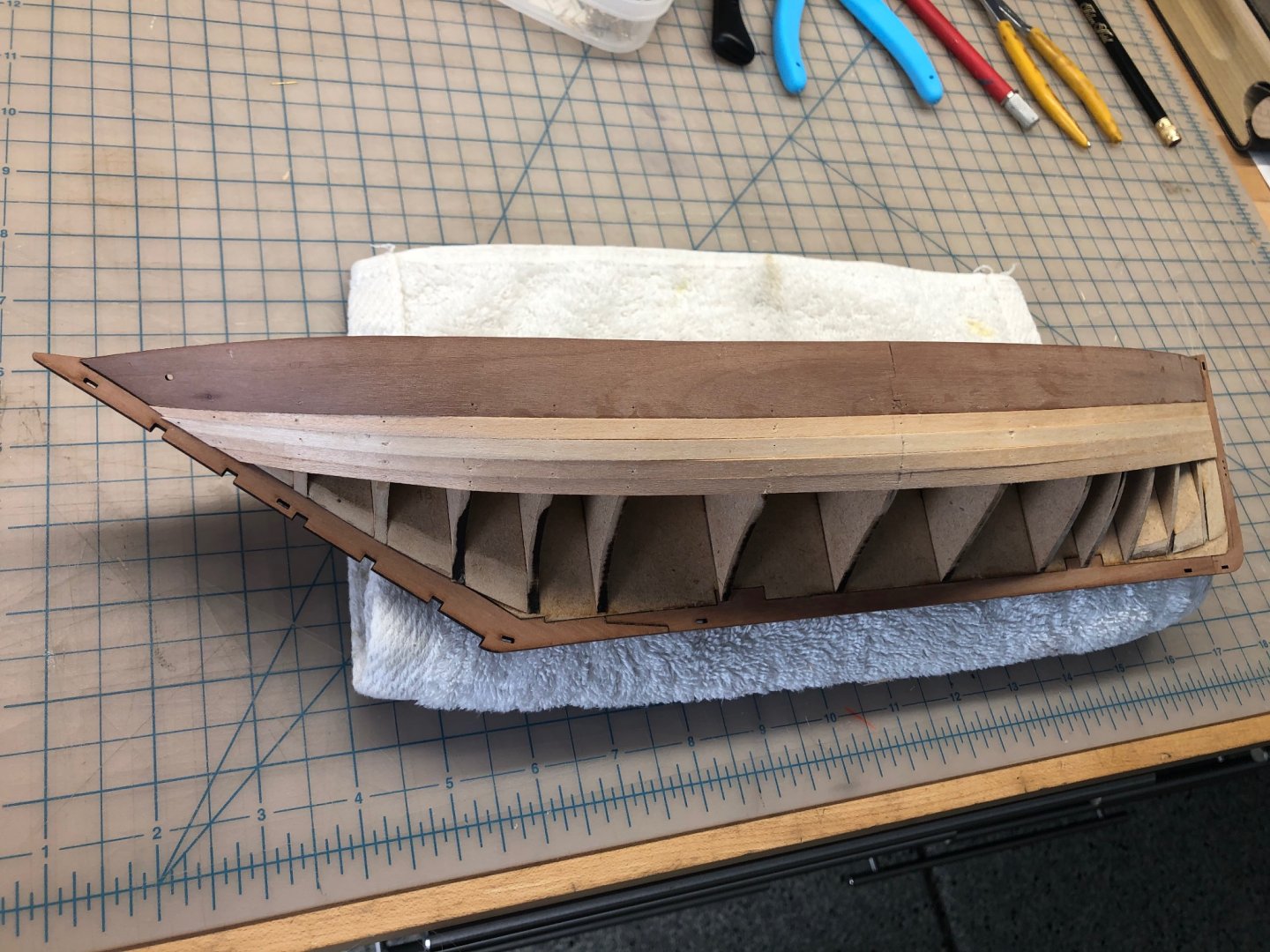

One last detail in this report: At Blue Ensign’s suggestion, I’m taking special care to make sure the first planking at the stem is trimmed down and sanded thin enough to allow the second planking to seat properly in the stem rabbets. The rabbets are formed by side pieces of pearwood which sandwich the stem, as well as the keel and rudder post. Those will be added next. Here I’m checking the fit of one of the stem side pieces. It seems that I’m in pretty good shape here with the ends of the first planks... perhaps a bit of fine tuning to go.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

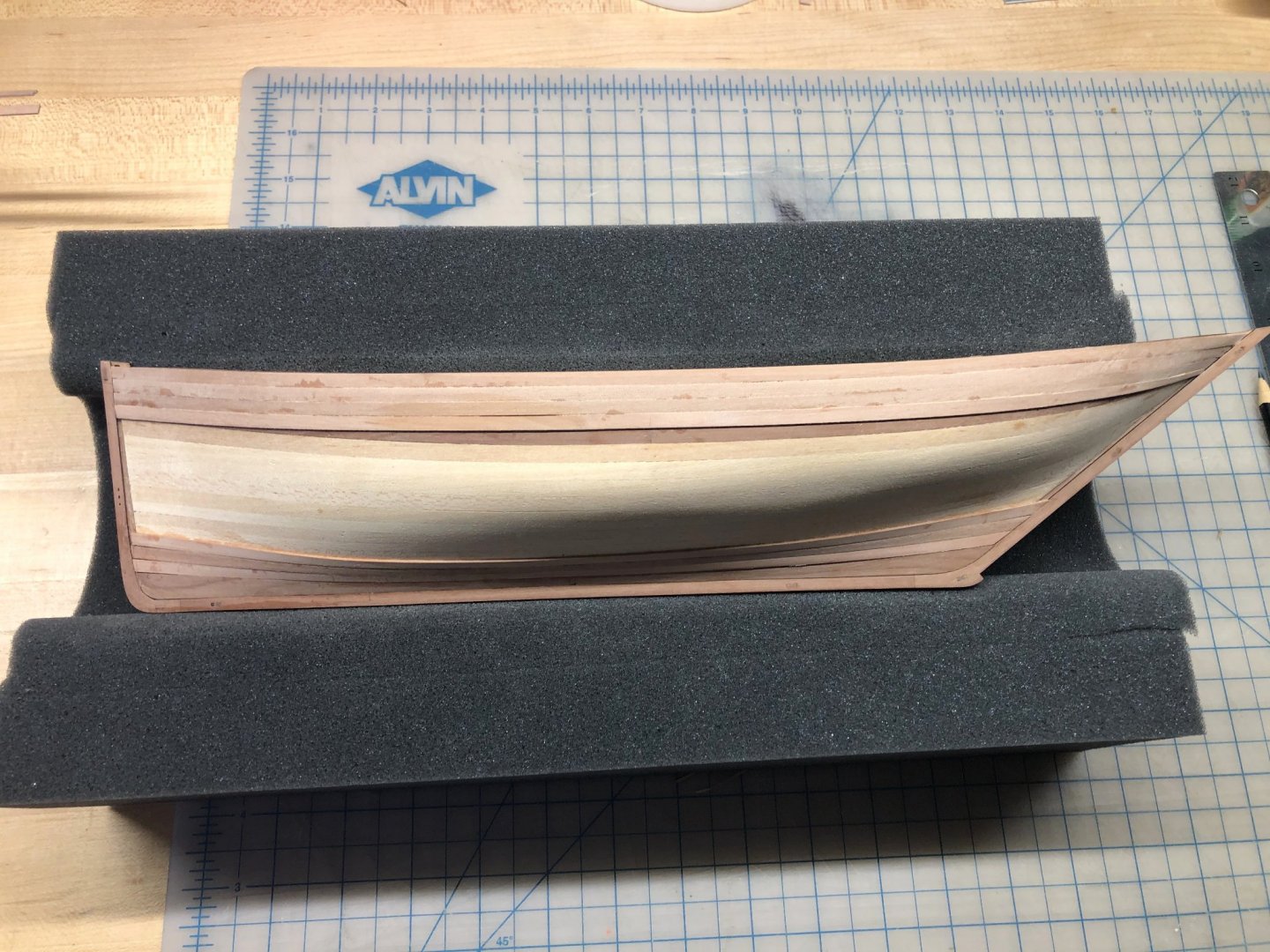

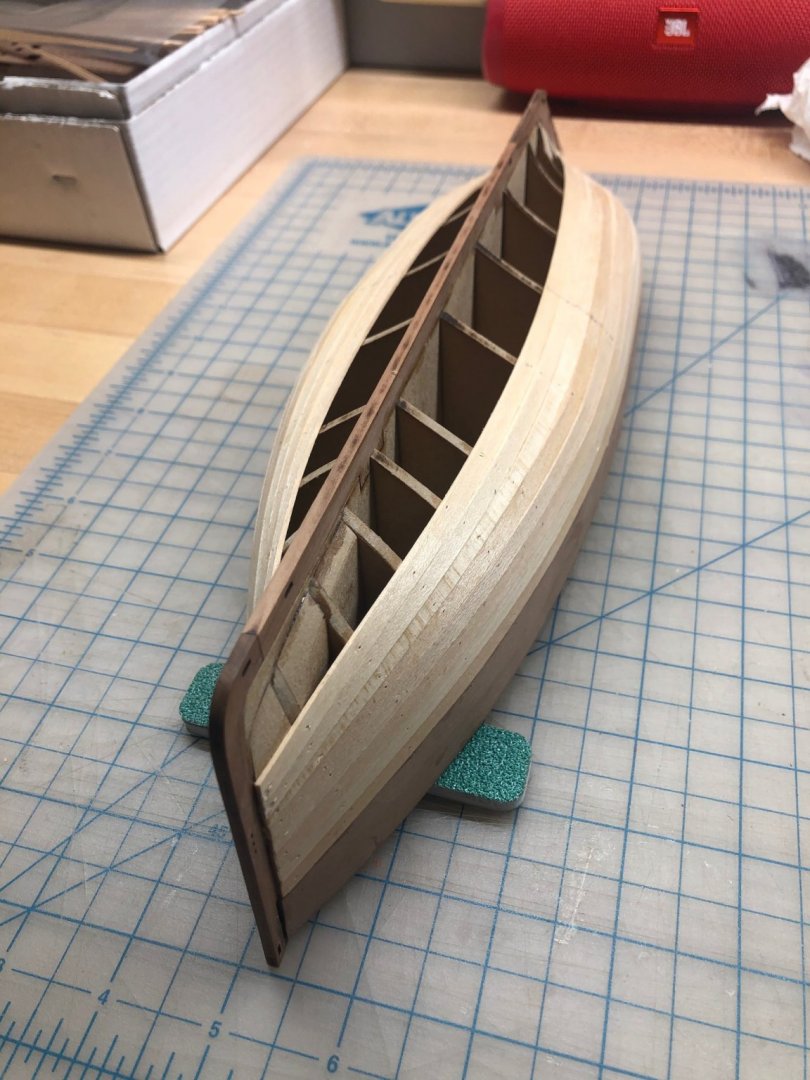

A few more photos of the sanded hull. I have to say again how pretty I think the shape of the Zulu is, and the planking here really shows it off. I’m kind of sad I have to cover up this all this work, but again, it’s all about the journey. The consolation is that, with some luck, it will have another layer that will be even prettier.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

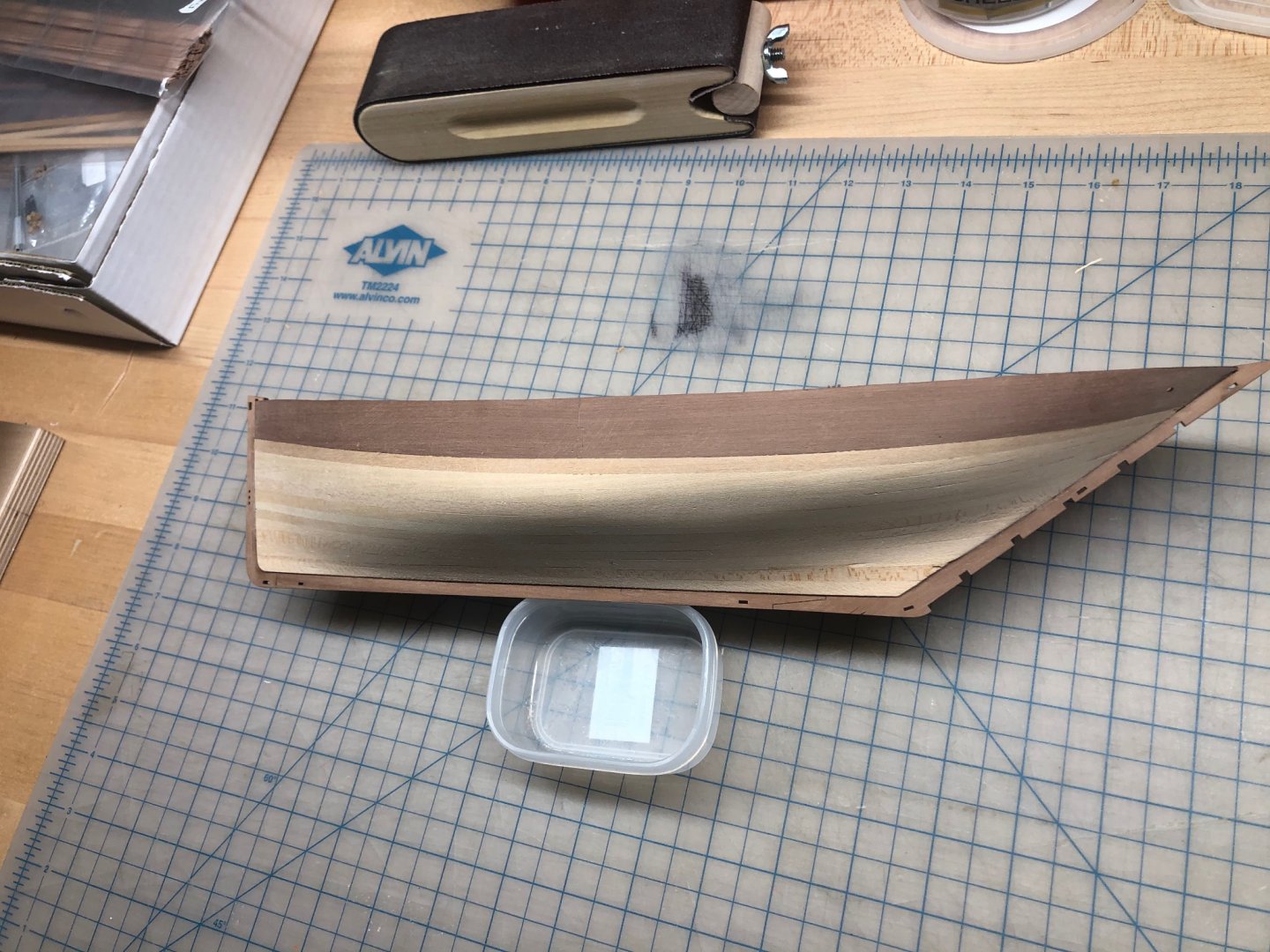

First planking is complete! I’m feeling a little bit proud of myself having groped my way through my first ship planking endeavor. I had to install a few wedge-shaped stealers as the planking approached the garboard, at both bow and stern, as the curvature really changes as you work your way down. But it all came together pretty well. And here is the hull after an initial sanding. I started with a stiff foam sanding stick with 120 grit, and moved on to 220 sandpaper.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

I think this model is really amazing and quite beautiful. The intricate detail is so well engineered and rendered. It’s impressive to me how all of this detail is translated into parts cut from flat sheets. I really love the embellishments on the gunwales, and the way Jim has set them all off with his careful painting. So inspiring. Bravo Chris and Vanguard Models!

- 117 replies

-

- vanguard models

- yacht

-

(and 2 more)

Tagged with:

-

Thanks so much, BE. I so appreciate the advice. Understood...I was thinking that when the first planking is complete, I’d do a final trim of the planks against the posts with a razor blade, and then sand the plank thickness down with a sanding block in those areas. Your model of Muirneag is coming along so beautifully... it’s inspiring to me to have a build by an experienced modeler to check in on! -EKE

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Nice work indeed! That hull has a gorgeous shape, doesn't it? I just love the stern sections. So pretty.

- 261 replies

-

- muirneag

- vanguard models

-

(and 2 more)

Tagged with:

-

I’ve always found that with most things in life that are truly worthwhile, it’s as much about the journey as it is the destination. Thanks Bradley!

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

More planking progress. After work, one or two planks each side. Slow and steady. I’ve found I really enjoy planking, it’s a serene and meditative task.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

The boat certainly looks beautiful with the bright wood topsides, and it shows off the lovely pear planking. But the black is certainly more typical of the type.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks so much, Bob! Fortunately, I have all of my new friends here at MSW to lean on. Jim's build log has been a godsend. -E

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

I've been looking at historical precedents on the Zulu, and I'm considering painting the topsides above the boot stripe black. This seems to be the nearly ubiquitous color scheme, almost universally indicative of the type. Here's a few photos I've found: So I think I'm going to try to make her look like this. Will need to do a bit more research to see where the paint actually should stop at the top of the bulwarks. Also need to decide what paint to use... the images of Zulus I've seen suggest a flat or satin finish. I'll be doing a white boot stripe, and the red oxide bottom paint as shown in the photos provided by Chris and James.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks Bradley! "Stealer". That's the word I was looking for. Thanks so much for the information and the image. Very helpful.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Thanks so much Jim! I appreciate the encouragement. I’ve been taking my time and trying to carefully prepare each plank before installation. The stern is tricky, as the curvature is pretty tight there. As mentioned in the manual, there’s a bit of “clinker” type scalloping in the stern area, and this seems unavoidable due to the hull curvature. I’m hoping this will sand out fine. I’m guessing I’ll be needing some short “filler” plank pieces in the aft portion of the hull, since the draft there is deeper, and the first planks installed are well tapered and bend upward pretty dramatically. Isn’t there a name for those kind of “filler” planks? I’ll continue to work with the Amati tool, and I’m sure I’ll get better at using it. It seems that finding the right angle to hold it is important.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

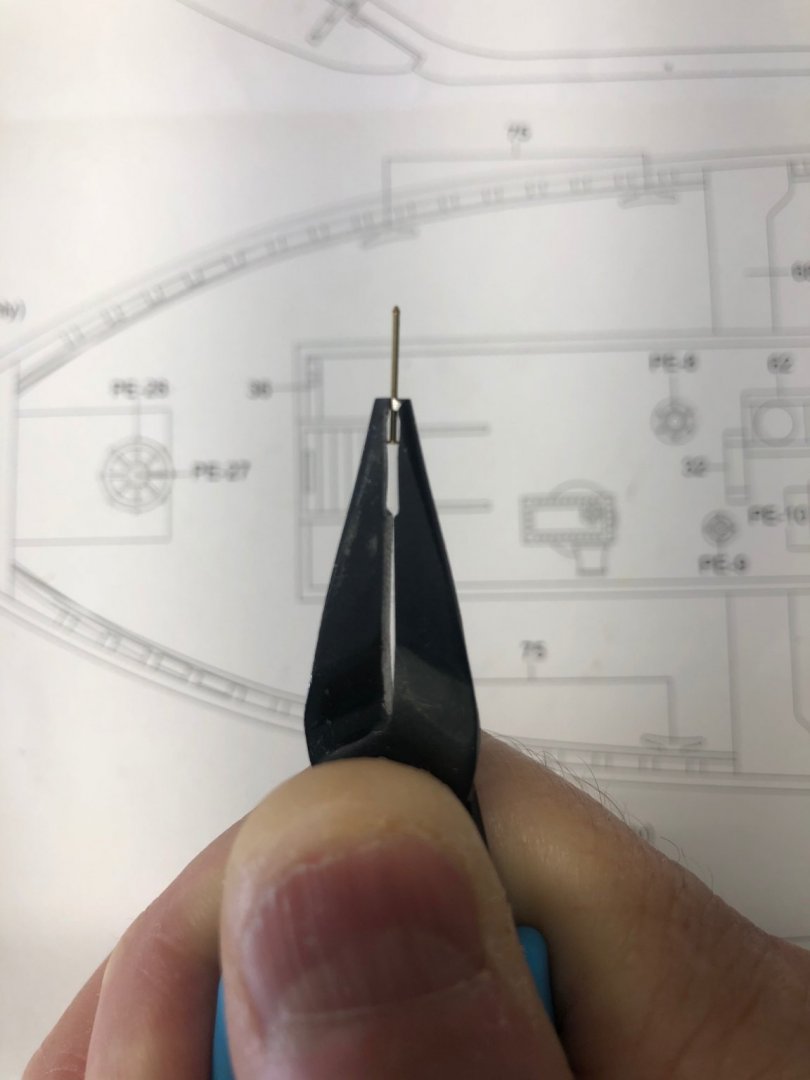

Working on my planking technique. I have tried using the Amati nail driver to pin the planks to the bulkheads, but I find it a bit frustrating. The pins are very tiny, and it’s hard to accurately position them with this tool. Also, it’s very hard to know how far you’ve driven the pin, because you can’t see it while you’re driving it in. So I bought a Pin Insertion Plier from Micro-Mark. I have to say I think that this is a terrific tool. It allows you to place the pin with great precision, both in location and angle. And it allows you to insert the pin exactly as far as you want to, and no farther. Just what the doctor ordered, in my opinion. So I found the good technique was to place the pin with the plier, and then, if I needed to push it all the way home, I can use the Amati tool to do that. Anyone else using the Micro-Mark pin plier? Curious what you all think.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Here’s the start of the first planking. This is the first time I’ve ever done this, so we’re into uncharted territory here. Following the techniques recommended in the building manual. Seems to be going pretty well! I’ve been using white PVA glue, and taking my time carefully tapering the planks and beveling the edges where appropriate.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.