-

Posts

32 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Vermont, USA

-

Interests

I do a lot of wood working in my home shop. I have built an Adirondack guide boat from scratch and lots of furniture. I plan to build the foochow from scratch and maybe make the parts on my DIY CNC router.

Contact Methods

-

Yahoo

stevensturgis@yahoo.com

Recent Profile Visitors

-

LHS reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

LHS reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

LHS reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

LHS reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

Pete Jaquith reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

Pete Jaquith reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

JerseyCity Frankie reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

JerseyCity Frankie reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

xken reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

xken reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

cristikc reacted to a post in a topic:

Flying Fish by steven sturgis - Model Shipways - 1/96 - American Clipper Ship

-

I've put a hold on the clamps for now. The nails didn't thread deep enough to hold the strain on the clamps so they stripped out. Ill have to redesign them. Im still working on the sail design but was told to get out of the dinning room for Easter (Admiral's orders). I was losing my patients with them any way. Lots of test pieces and no clear answer yet. The planking is continuing on the Flying Fish slowly but i think it looks good. Boy i leave the room to work on the ship and Misty takes control of my chair. The snow is starting to melt in the north east. Good thing to I was getting cabin fever. With the sun staying up longer it will be harder not to go out side . This may slow down the build a little.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

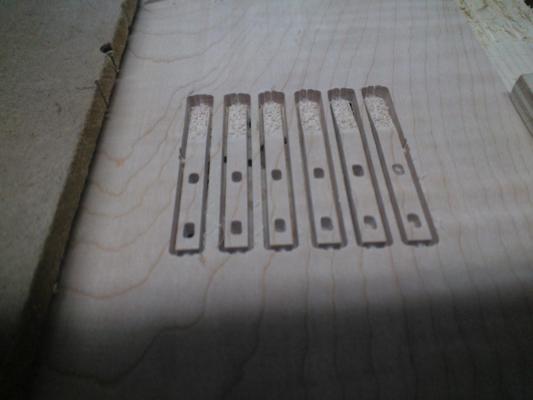

-

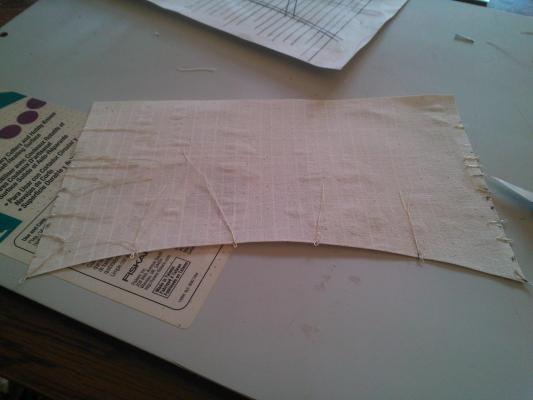

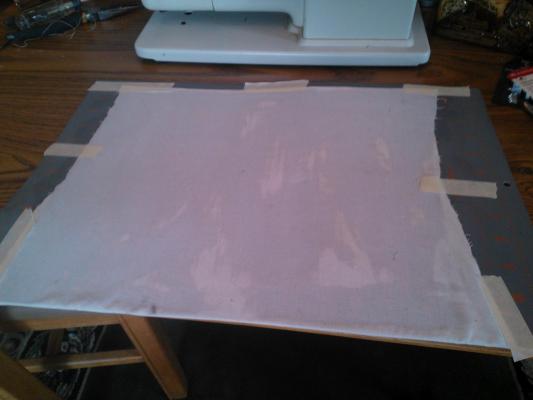

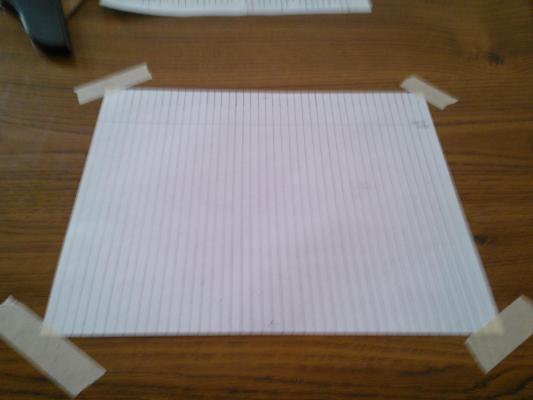

Well I've been prototyping my sails with the input from my sail making forum. I ordered silkspan and muslin to try out. The silkspan although nice and light did not stiffen as well with the GAC 400. The silkspan shrunk and took out the curve of the sail. I drew lines for the seams on the muslin with a white pen before coating it with GAC 400. The pen marks come out light but darken with the stiffener to a nice shade. I draped the cloth on a cut out of a piece of cardboard to set the shape. I made the cloth wider all the way around as it seamed to get a better shape to the sail this way. I plan to add strips for the hem and bands after it sets. I added the stiffener to a piece of cloth before cutting up the strips. This aides in cutting small strips. I will add the reef points before gluing the strips on the edges to help hold them in place. I am it tn the process of making some small wooden screw clamps from maple. The maple fingers where cut out on my CNC. I used # 6 finish nail for the threaded rod sections. They have to be threaded half way across from both ends with a right and left thread. I made the barrels with a 3/16 piece of brass threaded for left and right barrells. You need two each for a clamp. Make sure you put the barrels on each side opposite it counterpart I broke my milling bit because i was stupid so the assemblies will have to wait. Keep the barrels in tack as long as possible because they are easier to handle for threading.This clamp can put a lot of pressure to bear on a small spot be careful. These are a bit more complicated then just threading one side but are much more useful in the long run.

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

walnut has a specific grain to it. You need to look for the direction that it will lay. Also if you try to bend it or add stress from not forming to hull it will crack. If you stream it and get it to form to the hull you should be able to hold it in place with out claps. Then it will not have stress built in as you cut your gun ports. I believe it would be better if you cut the planks around the gun ports as you plank.

-

I've been doing some research on ships my ancestor captained and sail design with different materials in another forum. I would like to build one of these ships. The work on the flying Fish is continuing. I made some progress on the planking today. I also have been doing some mock ups of the display case I will build. I can't make up my mined on the style. I also ordered some tap and die to make some neat clamps I found in another forum. There like the wood screw clamps I use in my shop but very small. I will put up photos and instructions when I get the parts in and build them. I also like the display that was done on this model. It looks like the ship is under sail at sea. Ship in waves disply http://modelshipworld.com/index.php/topic/152-le-superbe-by-blue-ensign-heller-plastic-built-as-le-praetorian-after-boudriot/ sails http://modelshipworld.com/index.php/topic/9979-your-best-sail-cloth-and-technique/ reserch on ships http://modelshipworld.com/index.php/topic/9958-i-need-help-in-finding-these-ships-in-plan-form-elizaulyssescarolineatahualpa/

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

I believe its just a different brand butt lets let the experts handle that question. -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Thank you all this is good stuff. I hope I can still get silk span I would like to try it out. -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

I like the look of the silkspan and the layering of the cloth details. What weight silkspan do you use? -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Good stuff. I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way? -

Your best sail cloth and technique

steven sturgis replied to steven sturgis's topic in Masting, rigging and sails

Thank you twintrow. I did look at that but some one needs to go back and up date the links. About 80% don't work any more. I was going for full rigged full sails. Can you do that in paper? 1/8 scale Im sure this is old hat to the expert modelers but passing on that knowledge is needed by the next generation of builders -

Very nice sail work.This will help me on the Flying Fish. (what a tangled web we weave).

- 126 replies

-

- le superbe

- heller

-

(and 2 more)

Tagged with:

-

Hi every one. I have been looking for the best sail cloth for my Flying Fish build. I would like to get a lot of suggestions that I can look at. Please include where the cloth can be bought. Do you change the color with dyes? do you age the cloth some how? How do you add detail to the sails? All sail makers are welcome to post their designs I know a lot of you don't put on sail because it covers the rigging so anyone that does would be a great asset to the topic. Looking forward to seeing your tricks and designs.

-

Cutty Sark by Keith B

steven sturgis replied to Keith B's topic in - Build logs for subjects built 1851 - 1900

The copper looks good I cant wait to do it on the Flying Fish -

I am looking to build a ship from scratch. I Am a descendant of William F Sturgis of barnstable Massachusetts. He was the captain of many ships and I would like to build one of them. I have been looking around the internet and can't find the ships. I think I want to build the Atahualpa but need to find one of these in plan form. I hope some one with experience in researching ships could guide me on where to find these ships. Eliza,Ulysses,Caroline,Atahualpa http://modelshipworld.com/index.php/topic/9958-i-need-help-in-finding-these-ships-in-plan-form-elizaulyssescarolineatahualpa/

- 34 replies

-

- flying fish

- model shipways

-

(and 1 more)

Tagged with:

-

I have looked at this and found nothing that would help. I think all try writing to the sturgis library.

- 2 replies

-

- ship researching

- plans

-

(and 2 more)

Tagged with:

-

I am looking to build a ship from scratch. I Am a descendant of William F Sturgis of barnstable Massachusetts. He was the captain of many ships and I would like to build one of them. I have been looking around the internet and can't find the ships. I think I want to build the Atahualpa but need to find one of these in plan form. I hope some one with experience in researching ships could guide me on where to find these ships. William F. Sturgis (February 25, 1782 – October 21, 1863) was a Boston merchant in the China trade, the California hide trade and the Maritime Fur Trade. Eliza,Ulysses,Caroline,Atahualpa all are merchants I think around 1800 In 1809, his ship the Atahualpa, owned by Theodore Lyman http://en.wikipedia.org/wiki/William_F._Sturgis

- 2 replies

-

- ship researching

- plans

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.