exwafoo

Members-

Posts

64 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by exwafoo

-

Have a look at the Proxxon FMZ Precision Vice. It clamps to a table. Got one for my daughter who is doing an art course (special effects) at university and it got the thumbs up from her classmates as well. Al

-

No freebies, but check out the small saws here. I've got some, plus the PE bending tools, and am well pleased with all of them. http://www.radubstore.com/ Al

-

Have to agree with the above. I had not really looked closely at the rest of the pictures and assumed that there was a guard in the pile of bits for self assembly. I don't think the H&S boys would let this in to the country. And the old saying applies 'You gets what you pay for' . Still worth a discussion though. Al

-

Definitely agree about the Byrne's comparison, but it is a lot cheaper. Looks like the body has been made from laser cut ply. Alan

-

Hi All, This popped up whilst browsing. Has anyone seen it before? http://www.banggood.com/DIY-Mini-Table-Saw-Handmade-Woodworking-Model-Saw-With-Ruler-p-959473.html?currency=GBP&utm_source=criteo&utm_medium=cpc&utm_content=all&utm_campaign=electronics-GB Alan

-

Just picked up on this topic. A number of years ago by boy wanted to build and paint some of the Games Workshop figurines and equipment (http://www.games-workshop.com/). The GW stores offer free lessons in this art. I had to stay with him in the shop as he was underage at the time. It was hard not to get involved- and I picked up some good tips and techniques for painting with acrylics - the staff know what they are doing. The techniques transfer across to ship modeling, or any other kind of modeling I suppose. The downside is you would have to buy a box of their models (and some of them are a little different to say the least) to paint in the shop for the lessons, still it was probably worth it for the experience I picked up. Thet also sell books on painting. I think the best tips I could give are: use small amounts of paint, well thinned with acrylic thinners ( a bottle goes a long way) many of these thin coats instead of one thick one use water to clean the brush (keeps the cost down) use a good quality brush Their paints and materials are worth looking at as well - ignore the names, go by the colour. Al

-

Tapering masts, spars and yards

exwafoo replied to bryanc's topic in Modeling tools and Workshop Equipment

There's an article in the attached e-magazine I downloaded a number of years ago. It was free without registration, so I don't think there should be any problems with attaching it, especially as the site has now closed. Its in a 'booklet' format, so you have to go 'page by page. It may be of use Al 001_Journal.pdf -

Proxxon compound table -- Opinions?

exwafoo replied to rtropp's topic in Modeling tools and Workshop Equipment

I have the KT 150 (http://www.proxxon.com/en/catalogues/micromot/english/) to go with the BFB 2000 mill/drill stand. It seems to be a well made and robust piece of kit. Apparently, the bit of backlash can be reduced by replacing the lead nuts with higher tolerance items. I've not had it that long but happy with it. It can also be converted to CNC if the funds allow. Al -

what add ons for a Proxxon mill

exwafoo replied to shihawk's topic in Modeling tools and Workshop Equipment

Proxxon 24256 Step clamps - good solid work holding is essential when milling. Al -

6 in 1 tool kit (multi purpose machine)

exwafoo replied to cristikc's topic in Modeling tools and Workshop Equipment

I got one of these a few years ago. Its a TOY. You will spend more time setting it up than using it. Even aligning the centres when used as a lathe is a nightmare. Even when set up don't expect accuracy, or to be able repeat a cut, the combination of plastic modules, parts and aluminium extruding flexes making it a waste of money. Even the slightest pressure on the tool tip causes it to move. Don't even think of using it on small pieces of brass, or harder. Mine now lives in a box in the garage. I have since started to invest in quality equipment, starting with the Proxxon mill/drill setup with a precision table. I wish I had saved up a bit more and done this in the first place. Sorry for the gloom, however I've had more frustration out of attempting to make the best of a bad job using this kit than anything else I can remember and would not like anyone else to suffer likewise. There are cast aluminium modules available, but its as cheap to buy a small lathe or mill. Al -

I've used a masonry nail for the metal stock, mounted in a piece of dowel for a handle, and with the end ground down (safety specs on) with a Proxxon at a slowish speed and dipping into water regularly to prevent heating and loss of temper. These nails are very hard steel and hold an edge beautifully. They come in different sizes with a box not costing a lot. Cheers Al

-

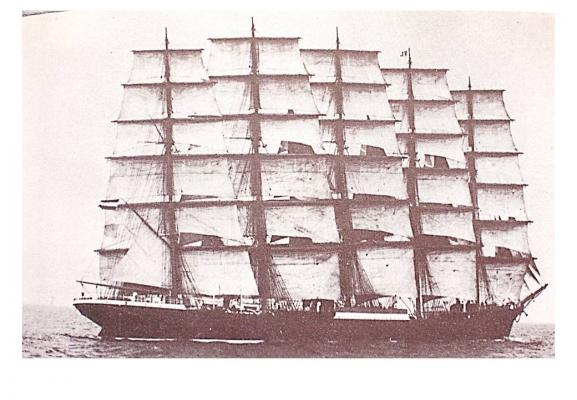

Hi Michael, Following with interest. You probably have lots of photos of Preussen, I've uploaded one I found in Square Rigged Sailing Ships (David R MacGregor, 1980). It may be of use. Cheers Al

-

Deep sea salvage: Finding long lost treasures of the deep

exwafoo replied to Kevin's topic in Nautical/Naval History

I've just about finished a short course on 'Shipwrecks and Submerged Worlds'. This was a 4 week on-line course run by the University of Southampton via the 'Future Learn' organisation owned by the Open University. This was a free course of about 3 hours a week, all you had to do was register. It consisted of short videos and some text reading with lots of links to associated material. It covered Maritime Archaeology as well. I can say that it was/is (I have about an hour to do) a fascinating course. I have done some others as well, up to 8 weeks, 3 hours a week. The web site is https://www.futurelearn.com/ There are a good selection of courses - I should think that this one will be repeated - some of the others were. Worth having a look at. I can vouch for the fact that it is free, there is no annoying advertising and that the courses are quality material presented by professionals in their subject. Al -

I'm (slowly) building a 1/300 brig from Langton Miniatures. Lots of photo-etch (sails, shrouds etc). Having tried to bend some PE sails before using steel rule etc, with varying results, I searched and found the tools at the link. I bought the folding tools. What a difference. I can thoroughly recommend them. I have since bought the PE saws as well. http://www.radubstore.com/index.php?main_page=index&cPath=77_79 Cheers Al

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.