-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

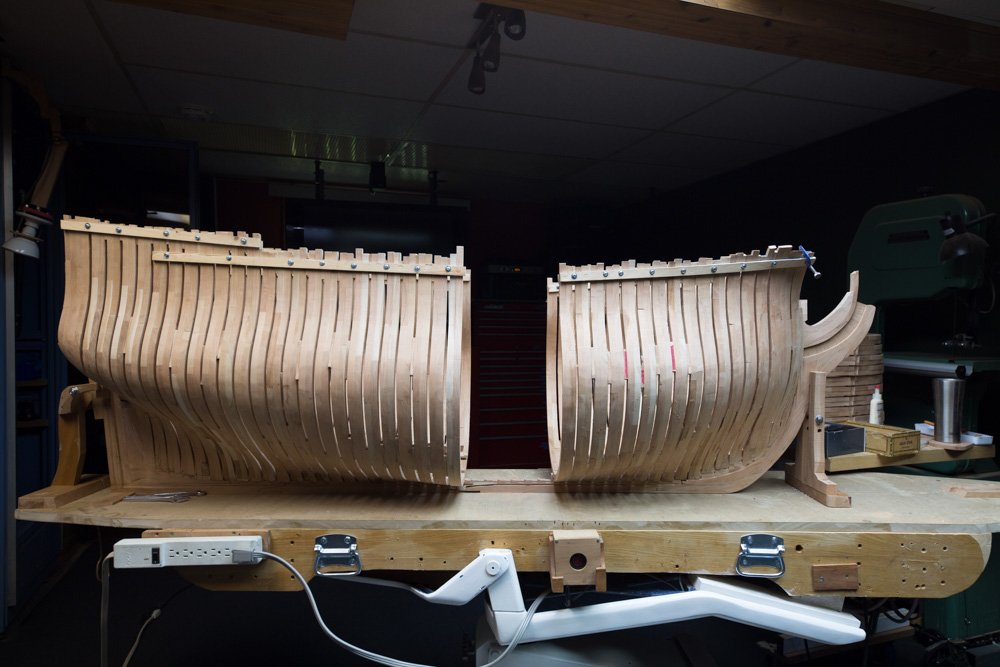

I did correct the spacers thickness on 1 section of about 20 frames. I could fit the last spacer, but strength must be use, and this would be an error, not to correct it, because this induce strength could bend some frames. Roughly 1 spacer .215’’/ 20 frames : about .010’’ less : .215’’- .01 ‘’: .205’’ the new thickness. For 60 frames, 60 times glue thickness changes the overall thickness. It is very difficult to do 60 frames with their components to exactly the same thickness at 001’’ close. Theoretical and practical thickness of the entire sandwich are different. On 8 feet long, overall thickness was 1 spacer too thick , glue thickness is at least partially responsible and I am for the rest and even more. Even if I could be precise at .001'', I would still have to subtract 60 frames, double thickness + 1 spacer: 60 X 3: 180 glue thickness probably at least .180''

-

There is no good or bad answers in choosing cutter or rotary tool, it remains a personal choice a matter of preferences. Which ones will produce cleaner edges, gives more nerve to the work? Only knife or both? Here is an example of rotary work : https://modelshipworld.com/index.php?/topic/15340-74-guns-ship-by-gaetan-bordeleau-124/&page=9

- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

Roter Löwe 1597 by Ondras71

Gaetan Bordeleau replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

I built this kit some 30 years ago with this book: Risse von Schiffen des 16. und 17. Jahrhunderts -

Neko, you built miniature cutters and you show us that you will have the necessary skill to produce nice carvings. Sculpture is an art you can learn, but you need to have basics talents. I would say that the most important tool would be the proportions. The last ones I did were for the Fleuron which also appeared in this forum. If I could suggest 1 helping hint for carving, it would be to try rotary burrs and for the smallest ones, dental burrs. There is a learning curves in using tools. In carving, we begin with knives but a knife is harder to control than a rotary burr. You need to exercise strength and control his dosage. With rotary burs... you need no strength to control it, the tool has the power and you concentrate all your talent on the carving.

- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

Hi noel_colledge, The previous 74 guns 1/24 weighed 130 pounds. To move it, you need wheel as big as you can, the bigger, the easier, and I also a lifting table with a cylinder. Good morning Carabrente, When things are done correctly fillers inserts easily without pressure. Fillers are all the same thickness at 95% and some are thicker. The idea is the same as a pressure cooker, you need a valve to release pressure or else it will explode. The best things as others clearly well demonstrated is to a have a spacer not glued at every 4 to 6 frames.

-

Impressive results and very nice drawings, Marc. How far will go with this model, will you do all the carving?

- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

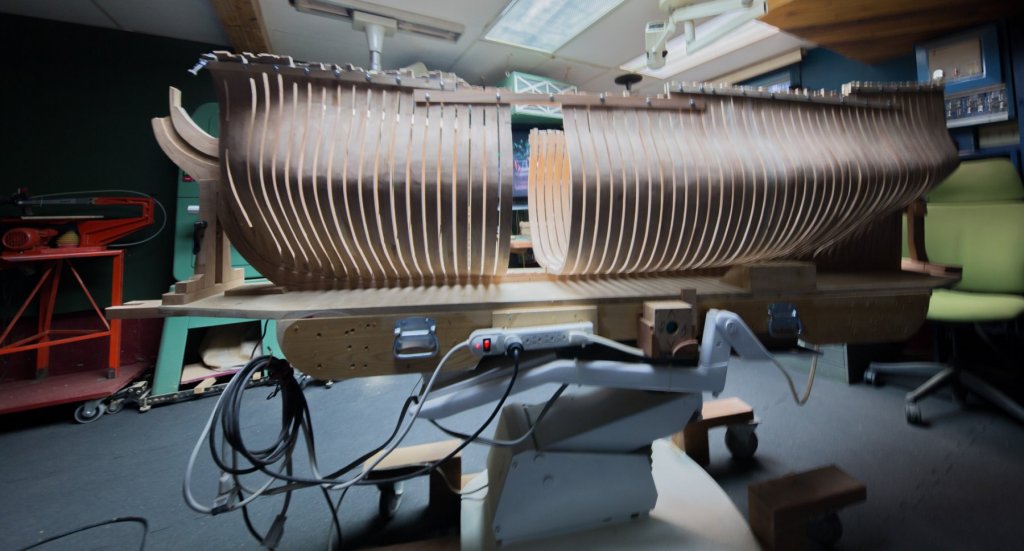

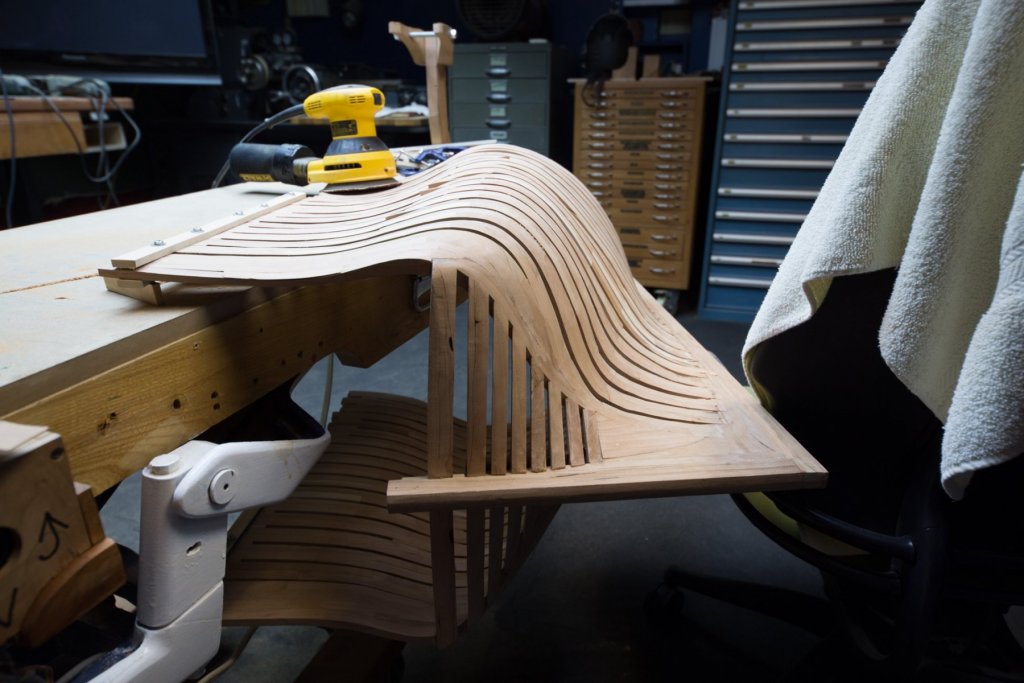

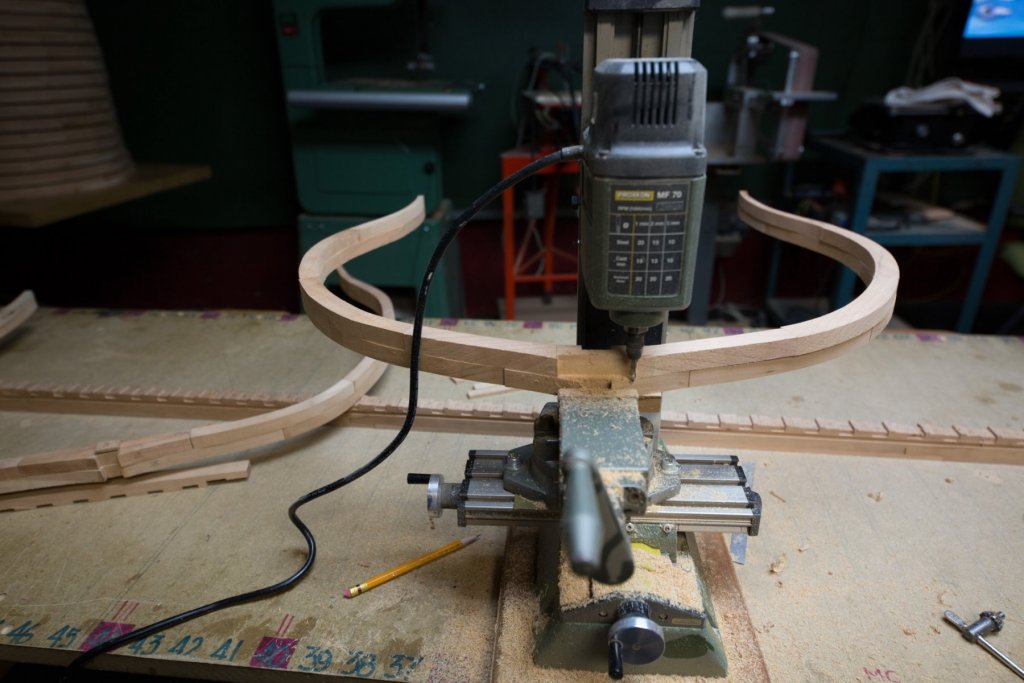

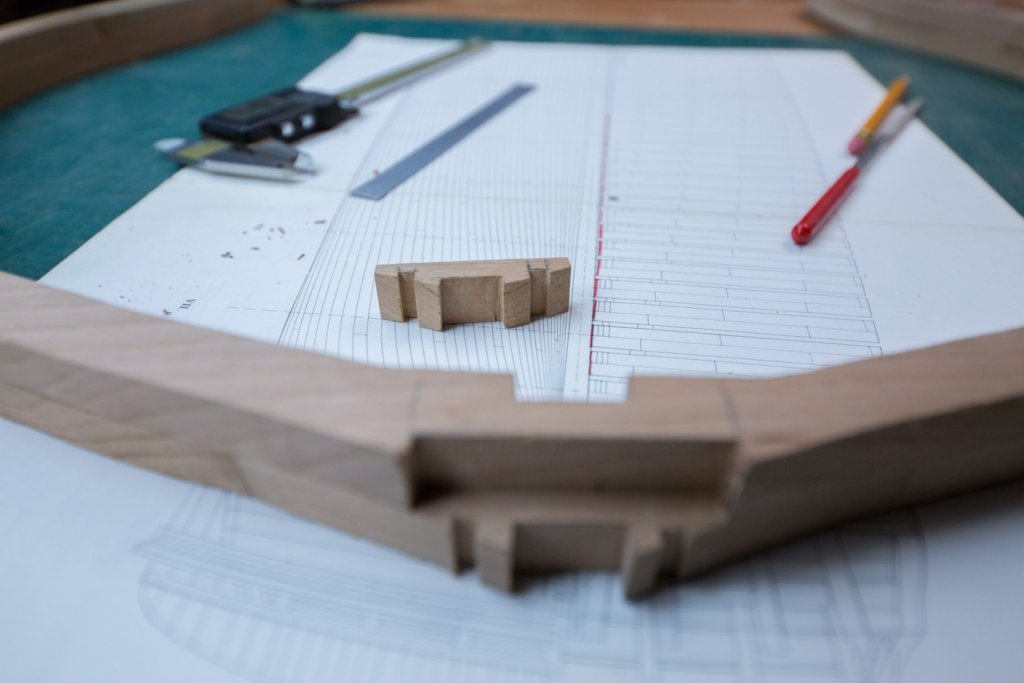

6 months of work and the last one, sanding only. Vibrations transfer to the frames while sanding, especially with the orbital sander. One way to avoid this is to insert spacers between each frames. This way, each frame does not resonate as when we pinch a violin cord but all the frames become a whole unit and vibrations disperses in the whole assembly.

-

On the pictures, we see the control plank for perpendicularity in 2 ways. Others are sanding setups for all the curves. The main 2 ways to assemble frames to the keel use a jig to align the frames between them: - a plank supports the frame contour. Frames are assembled upside down as Hahn did or reverse. -Frames alignment can also be done another way; with just a baguette to align frames. This baguette moves the same way as the assembly goes. The other part of this assembly is the frame sanding. Again, there are 2 ways to do the sanding : the easy way and the hard way. When a jig is used to support frames, most of the sanding will be done after gluing all the frames and after taking the frames out of the mold. This method is much more restrictive because the accessibility to all the frame parts is restricted when it is in the mold. The other method has the advantage of ease of maneuverability in all the ways you need. Sanding is much more easy, at least for a model at 1/24 scale. Part which need to be sanded can easily be position. Also another very important part : height adjusting table. Working at the good height is often the difference between holding a heavy part easily or with much difficulty.

-

Hi Karl, Chris is right: with the practice of the first one, the result of the second one will be a masterpiece.

-

ancre Le Fleuron 1729 by rekon54 - 1:24

Gaetan Bordeleau replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Welcome back Giorgio! -

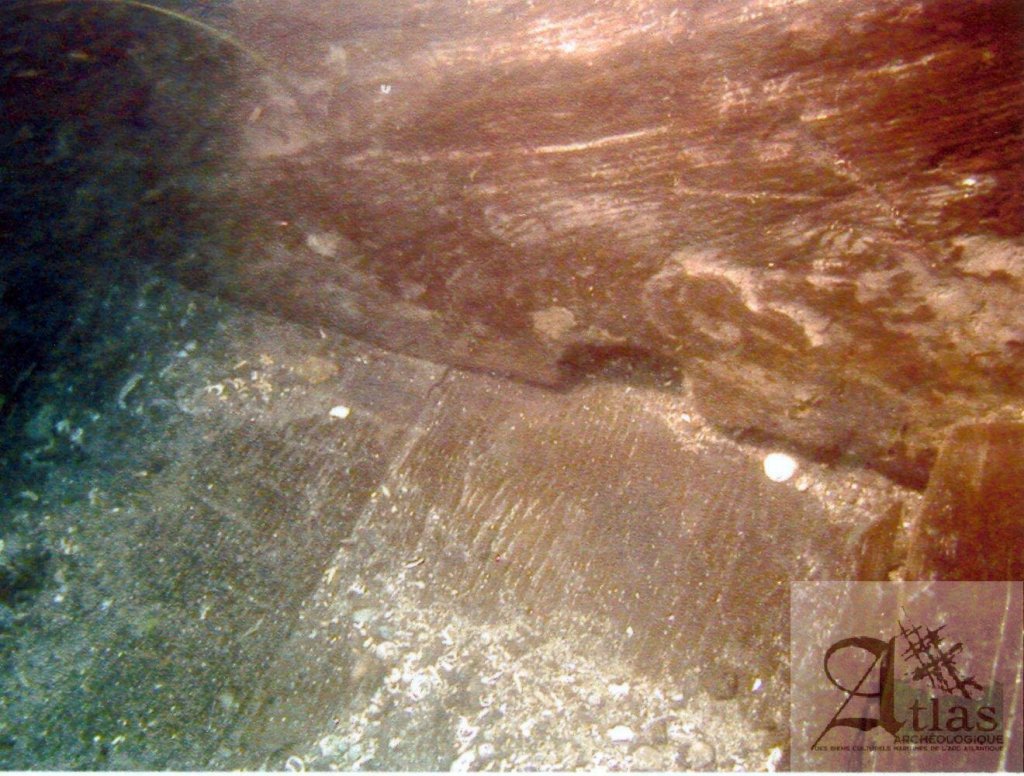

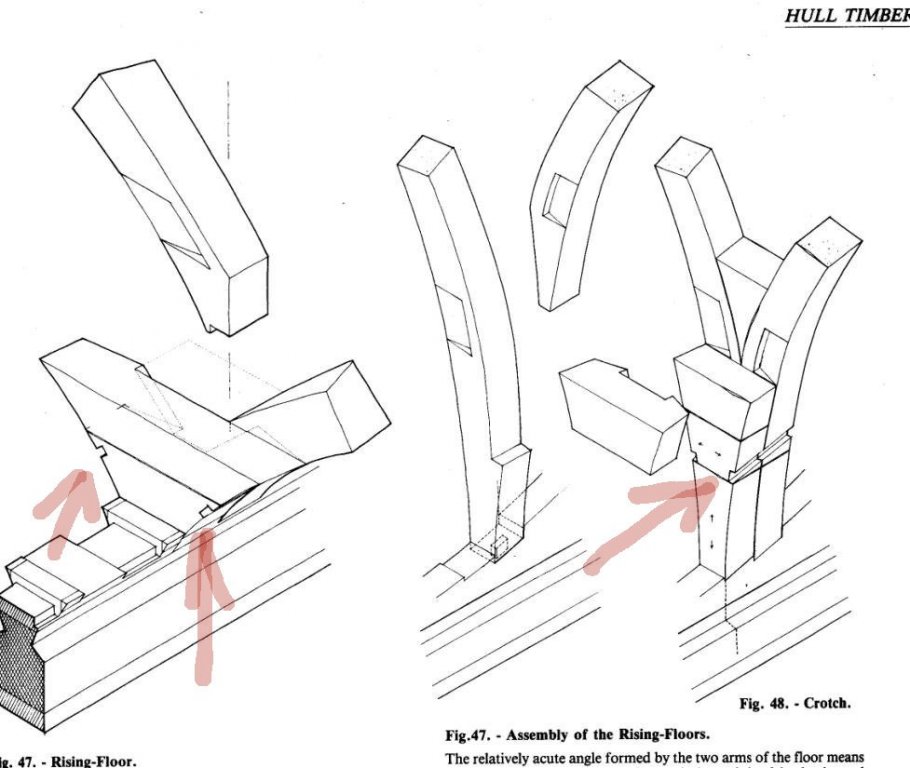

The idea is not to create wooden pocket which could accumulate water and have the wood to rotten. 2 ways to solve the problem: make a hole in the bottom of the pocket, fore and aft ‘’keel’’ would be 100% wood with no air pocket. Naturally, all wood joints are covered with tar. The disadvantage of this last solution, more wood, heavier ship.

-

Many minds together will always be stronger than only one. I think it would be safe to assume that the covered area would be only in the lower part as in picture one. there is something wrong in the second picture. To go through the limber hole channel water must be at least 2-3 feet high before being able to reach the limber hole. Water accumulation in that lower area would probably conduct to rotten wood.

-

Another try on the other side to prevent rotten wood. In the background, the plan showing a notch each side of the keel for the water flow. The notches, I think are drawn on this plan only. This is the kind of reason when a detail is shown on 1 plan only, it can difficult to visualize the other dimensions. This is in this kind of reason why I would like to see a 3D keel included with the drawings.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.