-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Garward

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hi, Randy, many thanks for the comment! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hello, kiwiron, I is glad that you like the Montanes model! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Many thanks for the comment! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hi, Carl, many thanks for an assessment of my work! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hi, Nigel Thanks for an assessment of my efforts on improvement of this kit! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks, Wayne! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

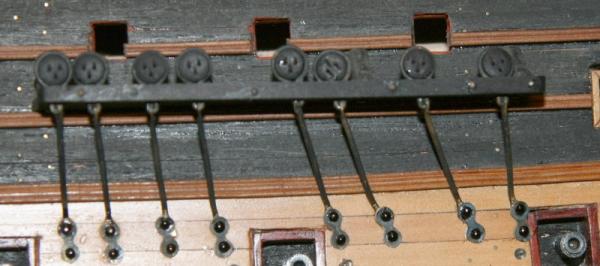

General view of established deadeye and chains of a foremast, mainmast and mizzen-mast (the left board). -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

General view of the hull (the left board) around a mizzen-mast with the established bottom deadeye and chains. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Hi, Keith, thanks for an assessment! -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

CA vs. Wood glue

Garward replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Each type and grade of glue have the appointment and many of them are suitable for wood pasting. What do you mean by the term "wood glue"? -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

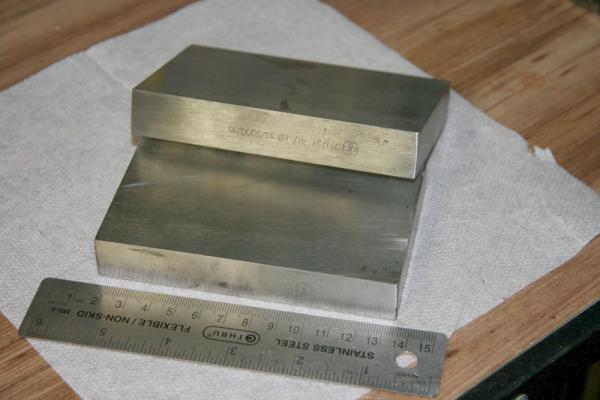

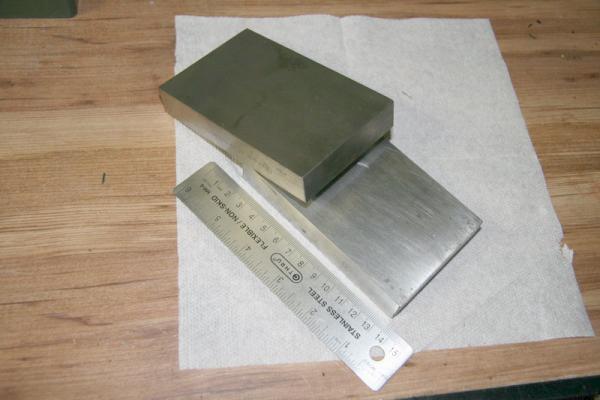

Hi, Carl, I too found them not in any place, I was lucky: at institute where I work, devices for hardness measurement are used -

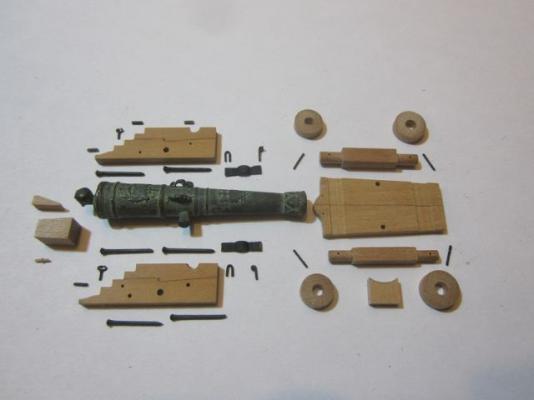

Octahedral preparations and yards become by the sizes specified on drawings. The method of production of octahedral preparations applied by me allows to supervise their size (for example, side width) with an accuracy of 0,1 mm.

-

Manufacturing of laths of an octahedral profile

Garward replied to Garward's topic in Modeling tools and Workshop Equipment

As a result the yard with an octahedron in the middle turns out. It is easy to make similar profiles and in other places of a yard. -

Manufacturing of laths of an octahedral profile

Garward replied to Garward's topic in Modeling tools and Workshop Equipment

-

Here still information: octagon portion of a yard can be done on the lathe of such preparations http://modelshipworld.com/index.php?/topic/1734-manufacturing-of-laths-of-an-octahedral-profile/

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

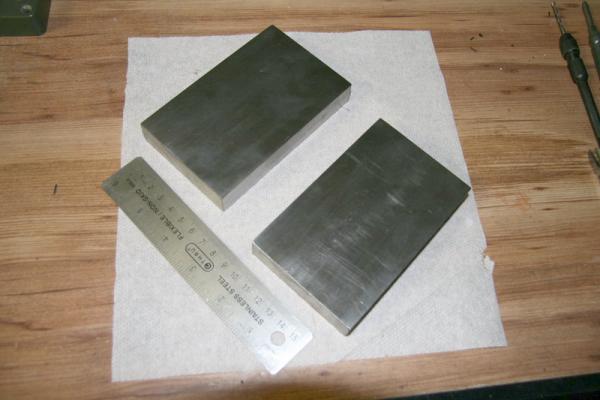

As assembly plates, and also anvils, etc. measures of hardness for Brinell (НВ), applied to calibration (checking) of devices well are suitable for measurement of hardness of metal: steel tiles of the set hardness with one polished (non-working) and one polished plainly - parallel surfaces. After the working polished surface is used (it is covered with very superficial prints of balls), measures become unsuitable to application for the intended purpose and jump out scrap metal. Some such used measures with a hardness about 400 НВ (for steel very high hardness) and well ground non-working surface, I "lifted" literally from a floor and I use for construction of models (see, for example, photo on the previous page). Possible sources of measures of hardness - all industries where devices are applied to measurement of hardness of metal: various laboratories of mechanical tests of metals other. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

This model shows Montanes in the state since 1805, when its bottom covered with copper plates. From 1794 to 1805 years Montanes in the bottom of the copper plates was not.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.