-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Garward

-

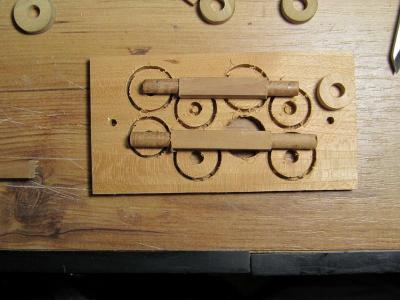

Continuation Considering the gun sizes, I decided to try to make brackets for fastening of pins demountable. Brackets I bent from a steel strip 1,2 mm thick, elements of their fastening I made of brass. I made this knot completely, but bent brackets weren't pleasant, replaced them slightly modified cast Alexey Baranov's production (replacement I will show a bit later). Brackets were tried on to an experimental gun carriage from a pear, made in the course of preparation for construction, it is yet that gun carriage which will be used in this model.

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

Continuation Axes are made of a pink pear, cylindrical parts with a diameter of 6 mm are made by means of a mill for round preparations http://modelshipworld.com/index.php?/topic/434-manufacturing-of-round-preparations-for-a-booms-and-thin-yards/. Bandages 2,5 mm wide with an internal diameter of 5 mm for the ends of axes are turned from a brass bar.

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

Hi, Phil, thanks for the comment!

-

Thanks, Michael!

-

Hi, Bob, many thanks for an assessment!

-

Hi, Mark, thanks for the comment!

-

Thanks, Pat! I am glad that MSW again works and we have opportunity to communicate with colleagues .

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

Hi, Ron! The best way of construction of various adaptations! At first search of improvised materials is carried out, and then already there are ideas on their application. I too often arrive thus .

-

Hi, Frank, process of construction of your model successfully moves ahead!

- 389 replies

-

- supply

- caldercraft

-

(and 1 more)

Tagged with:

-

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

Trunk machining Trunk after machining Washing (2-3 minutes) in a hot solution of lemon acid Blackening in 20 % a solution of selenious acid Trunk after Blackening Trunk after machining by a brass brush.

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

Hi, Wacko Joe, thanks for an assessment! The building berth really turned out quite convenient, I use it with pleasure and is happy that in due time didn't buy the ready design which is available on sale .

-

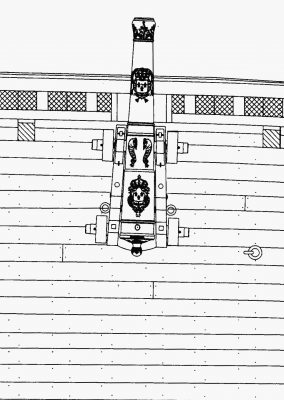

Wooden details - a gun carriage (except axes and aim wedges), frames, preparation of boards for a covering are made on a milling cutter with CNC.

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

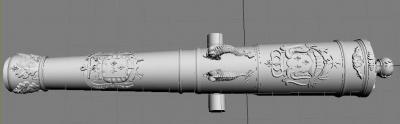

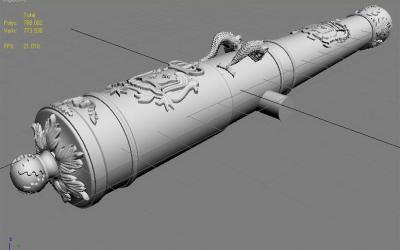

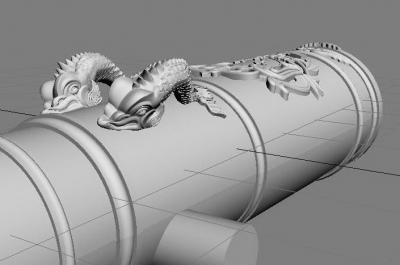

3D model of a trunk of a bronze gun and external type of gun trunks right after molding - so-called "fir-tree" (a photo from Alexey Baranov's workshop).

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

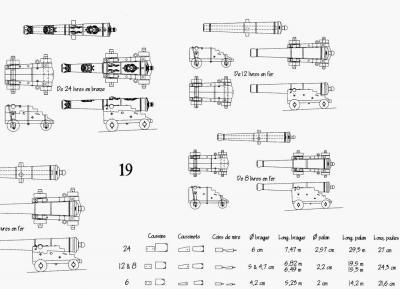

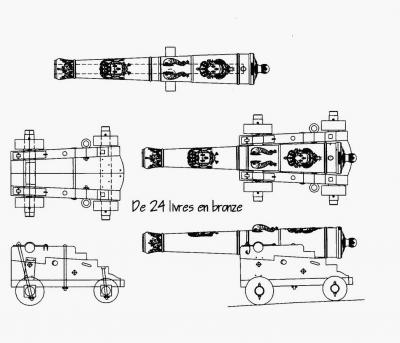

The gun model represents as a matter of fact battle stations, consisting of a bronze gun with some accessories and board and deck fragments. The model is made in M 1:24 under drawings of monography Le Fleuron (G. Delacroix), the trunk of work of Alexey Baranov, the basic wooden details - a gun carriage (except axes and aim wedges), frames, preparation of boards for a covering are made on a milling cutter with CNC our Polish colleague Mirek. I also have tried to consider experience of the French and Italian colleagues http://5500.forumactif.org/f28-le-fleur...-delacroix http://5500.forumactif.org/f17-artillerie on creation of similar models. At once I want to tell that this the first mine, but not a unique variant of construction of an battle stations, with use of the mentioned details, such variants with various degree of detailed elaboration there is a set and everyone modeller can choose a variant to the taste. Drawings of a 24-pound bronze gun from the monograph

- 111 replies

-

- le fleuron

- cannon

-

(and 1 more)

Tagged with:

-

-

-

-

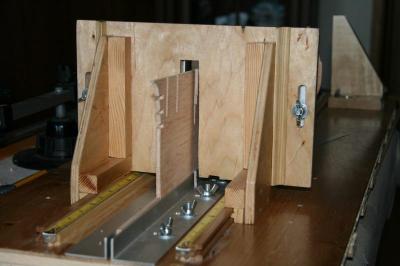

The building berth is developed for construction of type-setting hull in length to 1 metre (for example, kits of type Montanes, Victory, Superb, Vangard, Astrolabe, etc.). The design allows to fix reliably and precisely keel and bulkheads in the course of assemblage of the hull, its covering and installation on the hull of details. The building berth consists of the basis (the laminated parquet board 1000х380х14mm) on which are established: - Directing for fixing keel (an aluminium corner 40х20х2 mm) with cuts for bulkheads (cuts are made under concrete model, in this hull Montanes-OcCre); - Figured directing on which in the course of installation of bulkheads the carriage (plywood of 10 mm, figured laths) with a dural plate regulated on height , located at right angle to keel (for installation and fixing of bulkheads moves lengthways keel); - Lateral racks (a board 20mm) with moving possibility lengthways keel and it is perpendicular to it (for hull fixing); - Parallel clips (an oak 20mm). Depending on a stage of construction of the hull those or other details of a building berth are applied.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.