-

Posts

2,556 -

Joined

-

Last visited

-

JeffT reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

JeffT reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

JeffT reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

JeffT reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

-

CoastieGeorge reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

CoastieGeorge reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

-

JeffT reacted to a post in a topic:

HMS Victory By Mort Stoll by a Caldercraft Kit Embellished to show Lower Decks

JeffT reacted to a post in a topic:

HMS Victory By Mort Stoll by a Caldercraft Kit Embellished to show Lower Decks

-

JeffT reacted to a post in a topic:

Spam in member message section?

JeffT reacted to a post in a topic:

Spam in member message section?

-

JeffT reacted to a post in a topic:

Spam in member message section?

JeffT reacted to a post in a topic:

Spam in member message section?

-

JeffT reacted to a post in a topic:

Spam in member message section?

JeffT reacted to a post in a topic:

Spam in member message section?

-

Freebird reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

Freebird reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

-

HMS Victory: Caldercraft or Artesania Latina

JeffT replied to darkening's topic in Wood ship model kits

I'm working on the AL Anatomy version. There are no written instructions (video only) and no full size plans with this version. I did see that the closed hull version does have instructions but no words. I don't know if it has full size plans. You can look at the instructions on the AL website. Caldercraft does have instructions but not much for pictures; they are also available for download on the jotika website; but there are plenty of build logs to look at. As someone else mentioned, the CC is huge compared to the AL. -

Nearshore reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

Nearshore reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

-

Kevin reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

Kevin reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

-

Russ2025 reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

Russ2025 reacted to a post in a topic:

HMS Victory Anatomy Version by JeffT - Artesania Latina - 1/84

-

Its been a while but I haven't been totally idle. I finished all the Orlop deck fittings except stanchions and glued in place. I'm glad that I built the cabin sections in separate parts as it would have been too difficult to properly position them in one piece. There are a boat load of stanchions to make for this deck so it will take a while. Most of them require shaping as well. Pictures of the current situation:

-

Kevin reacted to a post in a topic:

San Bartolome 1584 by Kevin - Ships of Pavel Nikitin - 1/48 - Jan 2026

Kevin reacted to a post in a topic:

San Bartolome 1584 by Kevin - Ships of Pavel Nikitin - 1/48 - Jan 2026

-

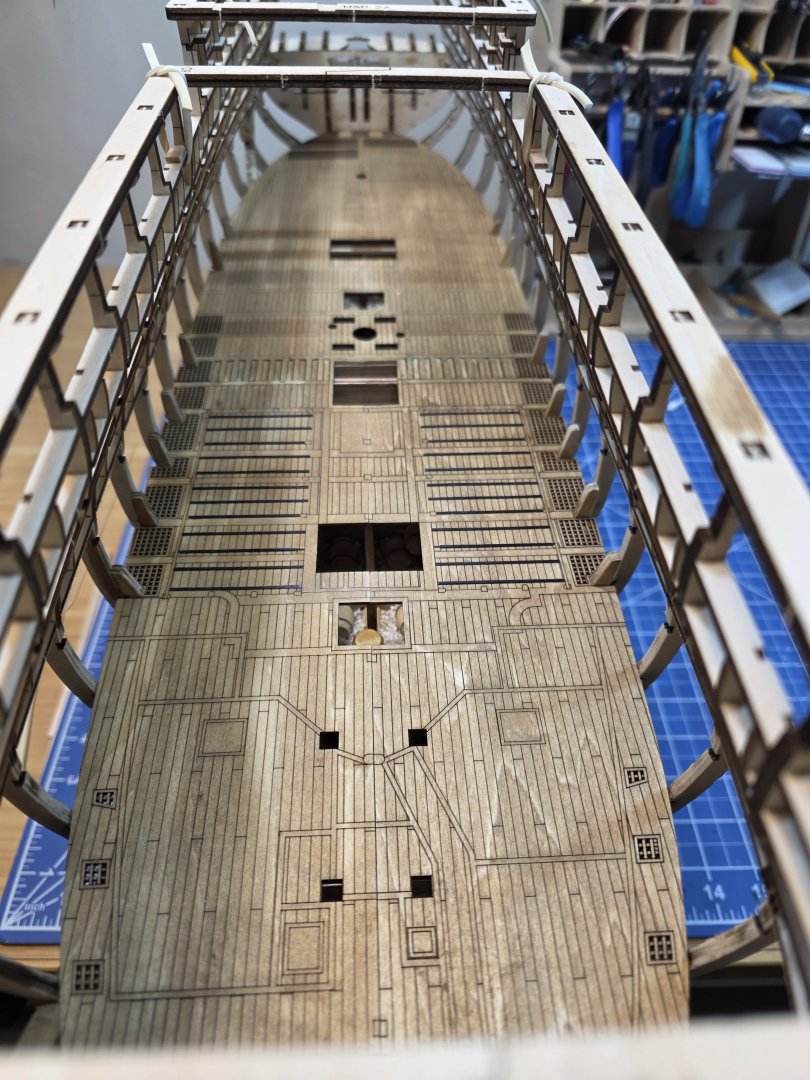

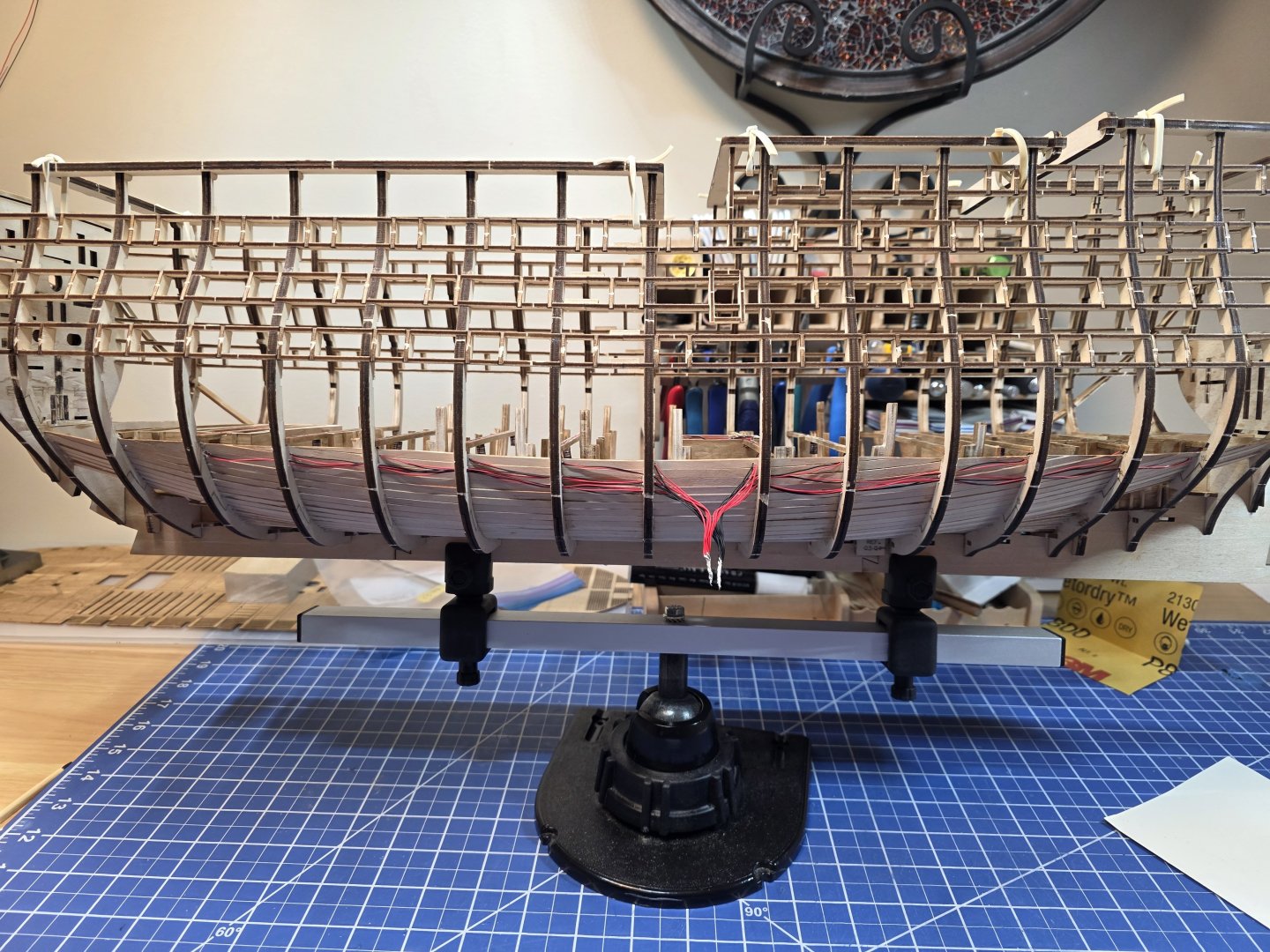

Pressing on with video 10. The orlop deck pieces are installed. The sections/openings all align with each other rather well and with the hold below. Quick mast check shows good alignment for the mast holes and other mounting areas below. I wasn't thrilled with the way the fore and aft sections come together. These little tabs were very fragile. I think I broke at least half a dozen of these during the dry fit. It also took quite a bit of tweaking to get the fore and aft sections to fit together. I ended up gluing some strips to the bottom of the forward deck sections so that the aft sections had something they could be glued to. Otherwise, there was no way to keep them together. Even with that, they just don't go together very well and there are gaps and they don't really align well. The result is not a good look but it is what it is. Other than that, the deck look good. Courtesy hold with LEDs lit pictures.

-

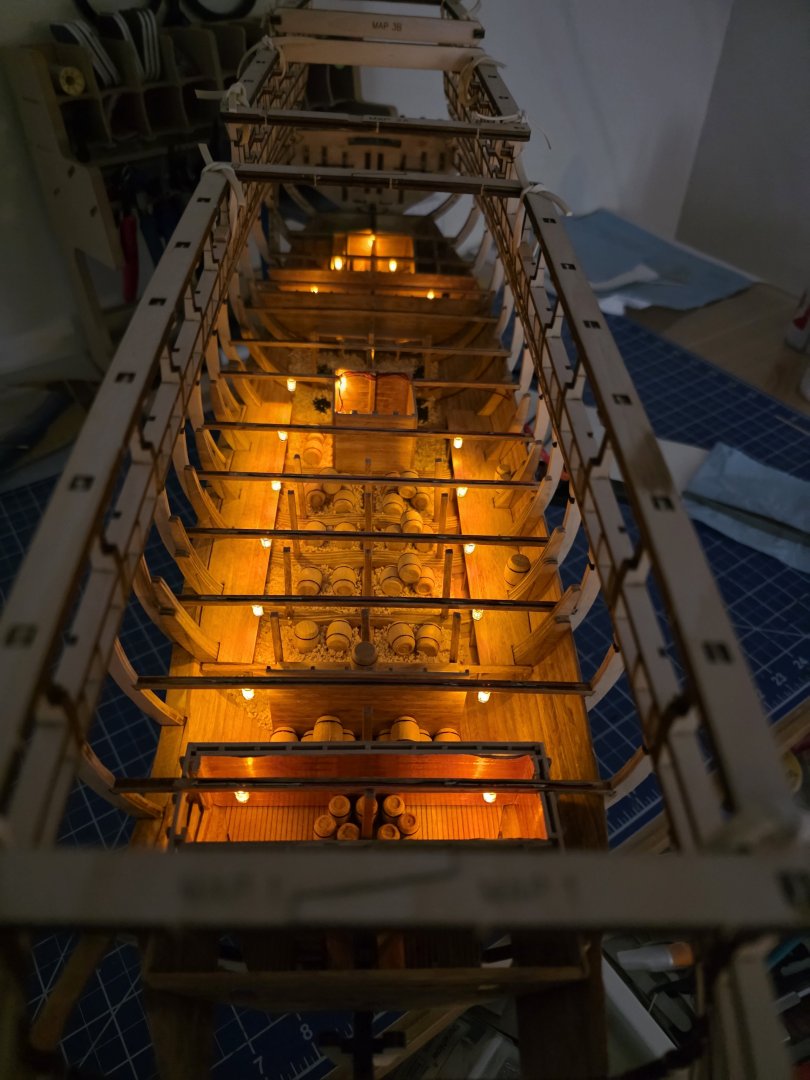

Finally got all the LEDs done in the hold. Took a little while but its not a race I guess. I had a few redos along the way as I wasn't satisfied with the result. Still need to paint a few exposed wires inside to finish up and in the end, no one will know the wires are there. I am now complete through video 9. I think this is a much cleaner result in the end with a lot less wires to deal with. I was hesitant to do this at first, but now that's it done I'm happy that I did. The LEDs really add life to the model. You can see my take on the flour bags here as well. I had to move a few barrels around (second set up from the bottom of the picture) as there are a couple parts that extend down into that area of the hold from the orlop deck. This isn't addressed until video 11. A good set of plans would have been useful in making that known much sooner.

-

QUICK-FIND INDEXES to BUILD LOGS FOR KITS

JeffT replied to Dan Vadas's topic in - Index of all kits by brand and subject

Absolutely. -

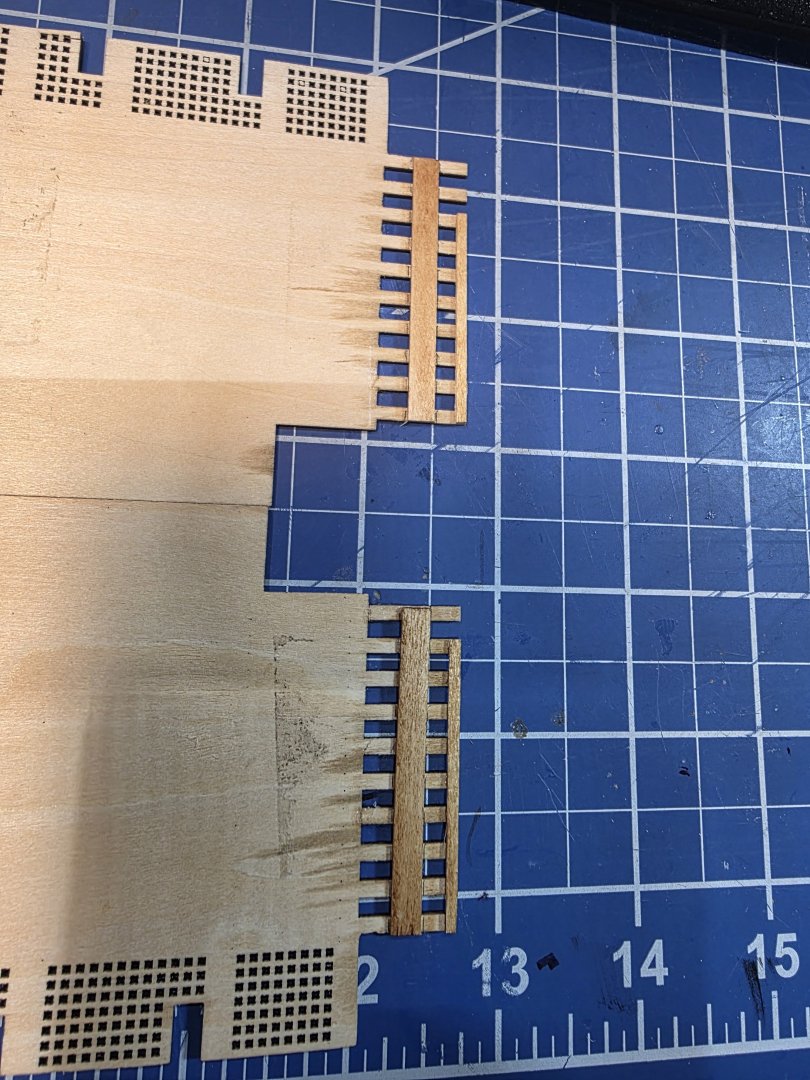

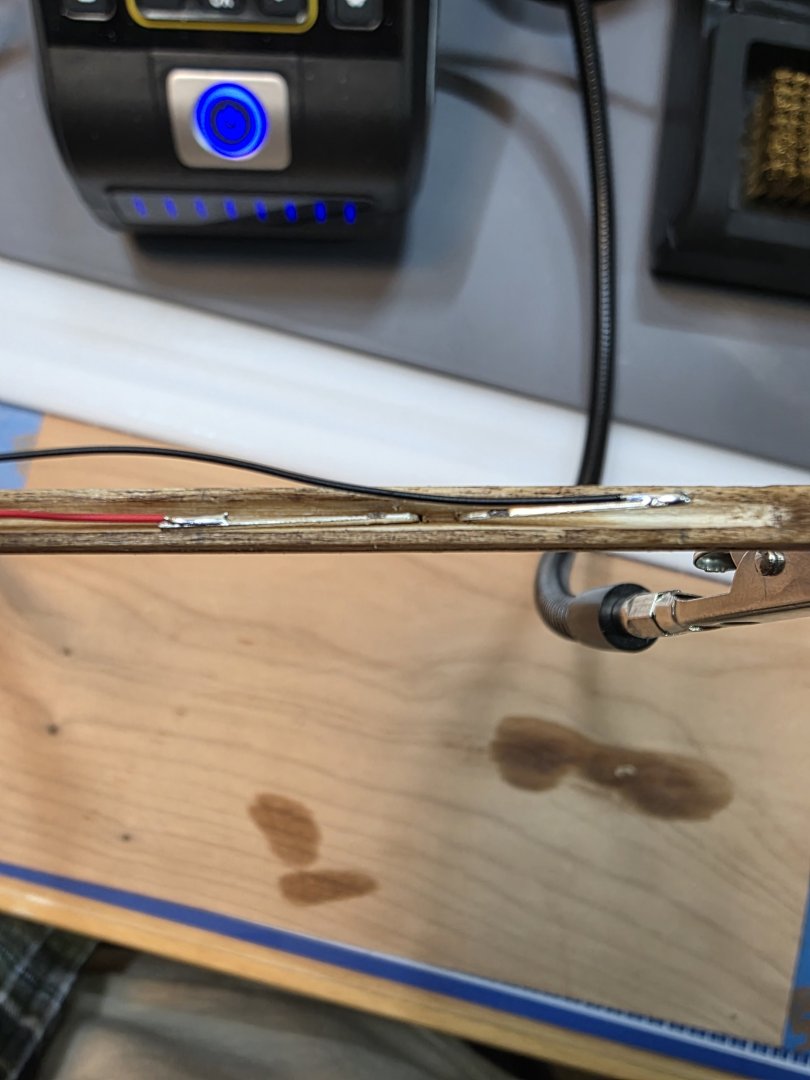

Its been a little while since my last update. I've been watching a lot of videos on soldering and getting a little practice at it. After much thought I have come up with a method of wiring the LEDs that works well for me. I'm using only two wires for each set of bulbs. The AL groove tool doesn't create a groove that is large enough to house the wires and bulb leads, so the groove needs to be widened and deepened. The first thing I do is solder the wires to the starboard LED, trying to solder to the side of the lead. Then, for each wire, I use the soldering iron to burn off some insulation from the wires at the spot where they will be soldered to the second LED bulb. and them solder the wire to the LED. I drill a hole in the bottom of the beam to pass the wires through and then pass the wires through the planking. The location of the wires will make them nearly impossible to see from the open side of the hull and no big holes in the frames. 3 down and a bunch to go. I also stained the deck and added the small strips which are painted black.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.