-

Posts

996 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mbp521

-

I still think it’s impressive that you harvest and mill your own wood on property, then turn out beautiful work. -Brian

- 393 replies

-

Timber-framed outdoor kitchen - Cathead - 1:1 scale

mbp521 replied to Cathead's topic in Non-ship/categorised builds

Absolutely beautiful Eric, thanks for sharing your adventure of the build. Time to now go and enjoy the fruits of your labor. Looking forward to what you cook up next in the kitchen. -Brian -

Barncave Shipyard by mbp521 - Scale 1:1

mbp521 replied to mbp521's topic in Non-ship/categorised builds

Beautiful door Javlin! I love the smell and look of cedar and I have an over abundance of it on my property that I could harvest and make one like that out of (and would love to), unfortunately I just don't have the tools to mill it it. Definitely don't have to worry about the termites with that door though. -Brian -

Barncave Shipyard by mbp521 - Scale 1:1

mbp521 replied to mbp521's topic in Non-ship/categorised builds

Javlin, I am starting to have an issue with the way that I built the door. With the cooler temperature and lower humidity in the room and the heat and high humidity outside, the door is starting to warp a bit and not closing properly at the bottom. I have been looking up different ways to to somehow latch the door at the top and bottom to hold it evenly in the jamb, but most store bought methods are pretty expensive, so I've been trying to come up with a DIY method. Still working on that. Mike, I haven't posted updates yet, but I have a 42" 4k TV mounted above my work station area and a mini fridge is in the works. Won't be long and the only reason I'll need to go into the house is to shower every now and then. 😁 -Brian -

Roger, another great question. When researching the City Class boats all the references that I found referred to a painted band as an identifier for which boat it was. Not once did I run across anything that stated whether or not the band was painted directly on the stack, or a separate band. I never even gave any thought to the fact that the heat could burn the paint off, also the boats very rarely had any down time and had to be ready to go in a moments notice, so the boilers were constantly stoked. I did go back and review some of the old photos that I had from my research and from what I can tell, it looks like the bands were painted directly on the stacks. Nothing that I can see shows that the stacks were any wider where the bands are that would indicate they were double walled in this area, and unfortunately neither of the stacks of the Cairo were recovered (they were knocked down by one of the other boats on patrol with her that fateful day to hide her location) and they may have rusted away over the 100 years she sat on the bottom of the river. So my guess is that they had some good paint that held up to the heat, or they kept a good supply of paint on board for touch ups. -Brian

- 393 replies

-

I think you may be on to something here. It’s is a strong possibility that this could be where the stairs are/were located. The walled area you circled seems like the typical construction of the day to surround stairwells and would be a prime location for them. From past experience of staring at old black and white photos it’s sometimes hard to get a good perspective of where details are located. I find my brain tends to put things that are not there in places where I think they should be. -Brian

- 393 replies

-

No model is ever complete without a sampling of blood, sweat and tears. One down, two to go. 😁 Could it be possible that the stairs were just forward of the engine room and run perpendicular to the center line of the boat and come up to the boiler deck, just under the covered area of the boiler deck structure? Just a thought. It wouldn’t be the most ideal place but given the diminutive size of this boat, there’s not much room anywhere else. -Brian

- 393 replies

-

Looking good John! I definitely remember those tight bends on the Texas deck being quite the pain, but you did a great job using household materials to get them nice and clean. A cheaper alternative to silkspan, as Yves suggested, is regular tissue paper and ModgePodge. I used this method on my Cairo for the deck structure roofs. I painted the ModgePodge on the wood, then laid down the tissue paper strips, overlapping them just slightly. With each strip I painted on a thin line of ModgePodge at the seams and let it stick out a bit to simulate the tar seeping from under the tarpaper. The results were very convincing since the ModgePodge leaves a little bit more of a shinier finish than the tissue paper when painted. I can’t take credit for the method I used though, I borrowed it from @kurtvd19 who had suggested it on my Chaperon build. -Brian

- 157 replies

-

- chaperon

- Model Shipways

-

(and 1 more)

Tagged with:

-

Timber-framed outdoor kitchen - Cathead - 1:1 scale

mbp521 replied to Cathead's topic in Non-ship/categorised builds

No complaints here. Post all the food pics you want. Everything looks delicious! And you had me at pickled beets. One of my all time favorites! -Brian -

Nice work Eric. Having the guards the same length as the depth of your clips is a happy accident. Almost as if you planned it that way. 😁 I’ve used both methods of decking, each with their own advantages and disadvantages. Building the superstructure over the planks is less cutting and give you nice clean lines, but you have to make sure that your planks are laid out evenly so they balance out on each side. Using the guides gives you a chance to have the superstructure wall locations in place before planking so you balance everything out ahead of time, it’s just a little more labor intensive. Personally I think putting the guides down first is the way to go. -Brian

- 393 replies

-

Another casualty of giving into peer pressure. 😁 Truth be told, I think it was the right decision. Blame or no blame. But if it turns out we were right, you have to invite us all over for smoked salmon. 😁 -Brian

- 393 replies

-

Timber-framed outdoor kitchen - Cathead - 1:1 scale

mbp521 replied to Cathead's topic in Non-ship/categorised builds

Looking good. It won’t be long now. I’m guessing that the process of curing the concrete and stucco will also season the inside as well. Also, there are very few things that compare to the flavor of smoked meats. 😁 -Brian -

I’m thinking you’re on the right path. You’ll have more cuts to make, but in the end you’ll also save a lot of wood. Since you are also milling your own wood, it’s more time saved. Plus, the gaps will never be seen. -Brian

- 393 replies

-

Barncave Shipyard by mbp521 - Scale 1:1

mbp521 replied to mbp521's topic in Non-ship/categorised builds

Thank you Brad! The Dillon has been collecting dust since I got the Hornady a couple of years ago. I need to get off my duff and sell it. My bench isn’t quite as heavy as yours, but with the 4x4 & 2x4 construction it’s pushing 300 lbs. It sure was fun trying to move it in to place by myself and I don’t plan on moving it again anytime soon. -Brian -

Barncave Shipyard by mbp521 - Scale 1:1

mbp521 replied to mbp521's topic in Non-ship/categorised builds

Thank you all for the kind words! No DM’s yet Eric. 😁 While it has been fun planning and building my shipyard, it’s not something I’m ready to do again for a while (that is unless the misses decides she wants a room as well). This project has seriously got me jonesing to get back to working on shipbuilding. Shouldn’t be too much longer. -Brian -

Barncave Shipyard by mbp521 - Scale 1:1

mbp521 replied to mbp521's topic in Non-ship/categorised builds

Hello everyone, it's been a while since I last updated my progress on the shipyard but I managed to find some time to get an update in. Day 25 I was able to get most of the cabinets painted up and finally started work on the benchtops. I forgot to take pictures of the painting, but who really wants to watch paint dry anyway? Started off with my workstation area, just a simple corner desk that will hold my monitors and other assorted computer accessories. This section will be a few inches lower than the rest of the bench, for ergonomic reasons. I've found it hard to spend 8-10 hours a day at work on a 36" desktop. All of the bracing up, painted and ready for the tops to be installed. Corner top installed. More of the benchtops cut and installed. Day 26 My original plan for the benchtop was to build it out of MDF, paint it black, then print out a bunch of old ship pictures and plans and glue then to the benchtop, then coat the whole thing in clear epoxy resin. That was until I found out that the price of MDF has just gotten stupid expensive. So I did some re-thinking and decided to go with some OSB and matte black Formica. This cut the benchtop cost in half. Prepping the first piece of Formica for gluing. and the first section is in. Moving along with the Formica. Day 27 With the Formica all installed it was time to trim the edges of the benchtop out. I went the cheap method with this and used 2x4's to make the trim. I ripped the 2x4's and rounded them on both sides to give a nice bullnose edge that is easy on the forearms. Again I forgot to take pictures of the ripping an rounding process, but here is the first piece going in. Day 28 With the trim work in it was time to start moving a few things in. I had to clear off my current adjustable workbench so that I could get it painted up and the top modified to where it will work in my new shipyard. The benchtop edging was given a coat of stain and varnish and I moved my organizers in. Day 29 I had a few short upper cabinets left over that I couldn't figure out what to do with, when it finally hit me. The would provide great overhead storage for my reloading powders and primers. They would be high enough to keep the grandkids from getting into them and still be accessible to my reloading bench. Had planned on installing a piece of 1" flat steel on the wall in this area and use magnets to hold my building plans on. Instead I installed a piece of steel angle iron to help support the uppers and also function as magnetic plan holder. Finally I started moving my stash in. I left this corner open for the sole purpose of storing my future builds. And I moved my reloading bench in as well. There will be additional shelves above the bench mounted to the stringers that are currently on the wall. Just need to get those built. I'm going to also make a few modifications to this bench to help hide some of the clutter, but that will come later on. I've got my adjustable workbench out of the house and is currently waiting on paint and some trim. I'll have photos of that project on my next update. Just a few more items on my to-do list and the room should be ready to start creating some sawdust again. Thank you all for stopping by. -Brian -

USS Cairo by Zetec - FINISHED - 1/50 scale

mbp521 replied to Zetec's topic in - Build logs for subjects built 1851 - 1900

Beautiful work John! Definitely a different approach to building the top, off the hull. Do you plan on making the top open to view the inside gun deck? -Brian -

When doing the research on my Cairo, I studied every picture of the City Class boats I could get my hands on as well as a few other boats that would assist me in getting certain details right. One thing in particular that I noticed is that the Brown Water Navy didn’t adhere to many of the more stricter regulations that the Blue Water Navy had in place at the time as far as appearances went. In fact, in some of the photos that I found, the boats were a bit “rough” for Navy standards. My guess would be that since they were on constant patrol and making repairs when they could, this contributed to that “rough” look. With the civilian boats, many were put together on a river bank where there was an abundance of trees for construction, but very little modern construction facilities. They were built on a shoestring budget, operated under the “time is money” category and also had little downtime to keep them looking pristine. One of the draws that fascinates me with the river boats is their “well used, gritty” appearance in just about every photo you can find on them. Especially with the work boats. Personally I think adding this look to a model brings them to a whole different level. -Brian

- 393 replies

-

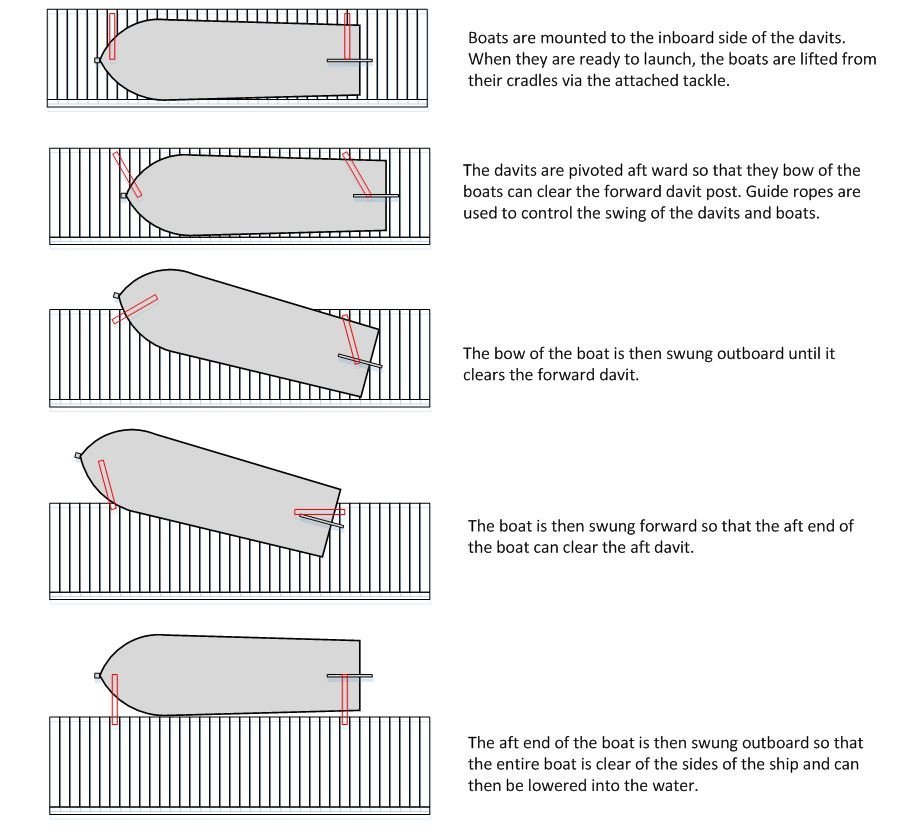

John @Zetec, posed a good question in a PM to me and I figured I would share it here as well, in hopes that it helps future builders of the City Class boats understand how the ships boats were launched. He had asked: "I was looking at the picture of the real boat and the lifeboats on them and how the davits were as they are looking inwards how did they launch the boats I have thought and thought but could not think of a way they done it any ideas." These City Class Ironclads had a unique way of storing and launching their boats, and just by looking at them it can be a bit confusing as to how it was done. I did a lot of research on my build but could never find any info on how it was actually done, but by studying the old photos of these ships I came to get a pretty good idea of how they could have been deployed. I threw together this little drawing that will hopefully help explain how the boats are launched. This may not be exactly how it was done, but given the limited information available it though it was a pretty good stab at their function. If anyone else has a better theory or more info, please feel free to chime in and correct my assumption, it definitely won't hurt my feelings.. -Brian

-

Hello Francis. I sent you a PM with information on the plans. Please consider posting a build log here on MSW, I would love to follow along, as I am sure others would as well. -Brian

-

Timber-framed outdoor kitchen - Cathead - 1:1 scale

mbp521 replied to Cathead's topic in Non-ship/categorised builds

I would be more inclined to use the kit as well instead of DIY, but I have seen videos of DIY people using exercise balls as the form for the dome. They cut a hole in a piece of plywood the size of the dome they want, inflate the ball in the plywood hole around the centerline, wrap the top half of the ball in hardware cloth then form the general shape with concrete. Once the concrete cures, they pop the ball and remove it, then slide the dome off the wood base. The kit version seems to take some of the work out of it. -Brian

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.