-

Posts

32 -

Joined

Profile Information

-

Gender

Male

-

Location

Toronto, Canada

-

Interests

Wood Ship Modelling

Recent Profile Visitors

-

Y.T. reacted to a post in a topic:

Admitting some kits are now beyond me.

Y.T. reacted to a post in a topic:

Admitting some kits are now beyond me.

-

kgstakes reacted to a post in a topic:

Pretty cool tool: drilling positioner

kgstakes reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Y.T. reacted to a post in a topic:

Pretty cool tool: drilling positioner

Y.T. reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Ryland Craze reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

Ryland Craze reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

-

Ryland Craze reacted to a post in a topic:

Pretty cool tool: drilling positioner

Ryland Craze reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Nirvana reacted to a post in a topic:

Pretty cool tool: drilling positioner

Nirvana reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

-

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

I have unpleasant experience with DSPIAE tool maker. IMHO their tools are bad but made to look as expensive quality tools. I have their circle cutter. All hex head adjustment screws are made of material so soft that their hex indent gets broken first time I tried to have them adjusted with hex key. -

Y.T. reacted to a post in a topic:

Pretty cool tool: drilling positioner

Y.T. reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

robert952 reacted to a post in a topic:

Pretty cool tool: drilling positioner

robert952 reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

robert952 reacted to a post in a topic:

Pretty cool tool: drilling positioner

robert952 reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Y.T. reacted to a post in a topic:

A flag from Trafalgar flown by HMS Spartiate

Y.T. reacted to a post in a topic:

A flag from Trafalgar flown by HMS Spartiate

-

Y.T. started following Rope serving machine , HMS Falken - little sister of HMS Wasa , HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship and 4 others

-

Well. Wasa had sunk on its own. Design problems. What about Falken? Again problems with design? What was the reason for it to sink?

-

Y.T. reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

Y.T. reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

Y.T. reacted to a post in a topic:

Mobile Phone Repair Clamps

Y.T. reacted to a post in a topic:

Mobile Phone Repair Clamps

-

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

I tried my old jewelers draw plate today. I easily drew my 3.87 mm wood dowel into 3.5 mm and 1.78 bamboo toothpick into 1.5 mm. These are the sizes required for the tool in question. -

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

thibaultron reacted to a post in a topic:

Pretty cool tool: drilling positioner

-

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

I am sure you'd enjoy making it but your expenses will be 10 times the purchase price of $25 US. -

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

I had not much success using a dowel plate on wood. I found no way to draw it through holes. It beaks if drawn or pushed through. May be I need to know some technics? How to draw the wood through the holes? -

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

Here it is for a third of a price. https://www.aliexpress.com/item/1005009136471457.html?spm=a2g0o.detail.pcDetailTopMoreOtherSeller.1.7a1eFTQvFTQv0U&gps-id=pcDetailTopMoreOtherSeller&scm=1007.40050.354490.0&scm_id=1007.40050.354490.0&scm-url=1007.40050.354490.0&pvid=27f490df-9fae-4fba-9710-2122afaa99e6&_t=gps-id:pcDetailTopMoreOtherSeller,scm-url:1007.40050.354490.0,pvid:27f490df-9fae-4fba-9710-2122afaa99e6,tpp_buckets:668%232846%238113%231998&pdp_ext_f={"order"%3A"250"%2C"eval"%3A"1"%2C"sceneId"%3A"30050"}&pdp_npi=4%40dis!CAD!54.57!34.38!!!39.24!24.72!%402101ec1a17501082161951638ecee0!12000048045620437!rec!CA!4223898072!X&utparam-url=scene%3ApcDetailTopMoreOtherSeller|query_from%3A#nav-description -

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

But still very hard to resist the temptation. -

Pretty cool tool: drilling positioner

Y.T. replied to CPDDET's topic in Modeling tools and Workshop Equipment

This is cool tool. I would be especially interested in axial center drilling. Thinking over it I can see that to have a good centered hole I must use very accurately dimensioned round dowel stock. I measured my so called 4 mm dowels and they are all 3.87 mm. I have to put it into a groove marked as 4 mm DIA. The drilled hole will not be at axial center. I am afraid it will be very noticeable by the eye. -

This photo is just a support of my advocacy for shiny ropes. At the end ship model is always an artistic representation of a real ship.

-

My opinion is the rope shine just adds the beauty to the model. Just IMHO.

-

I bought all three. 24 TPI for rougher cuts. I use 32 the most.

-

I recommend this machine. I own it. I use it. It will last. https://www.shipworkshop.com/product-page/sm4-series-serving-machines-wrapping-machines

-

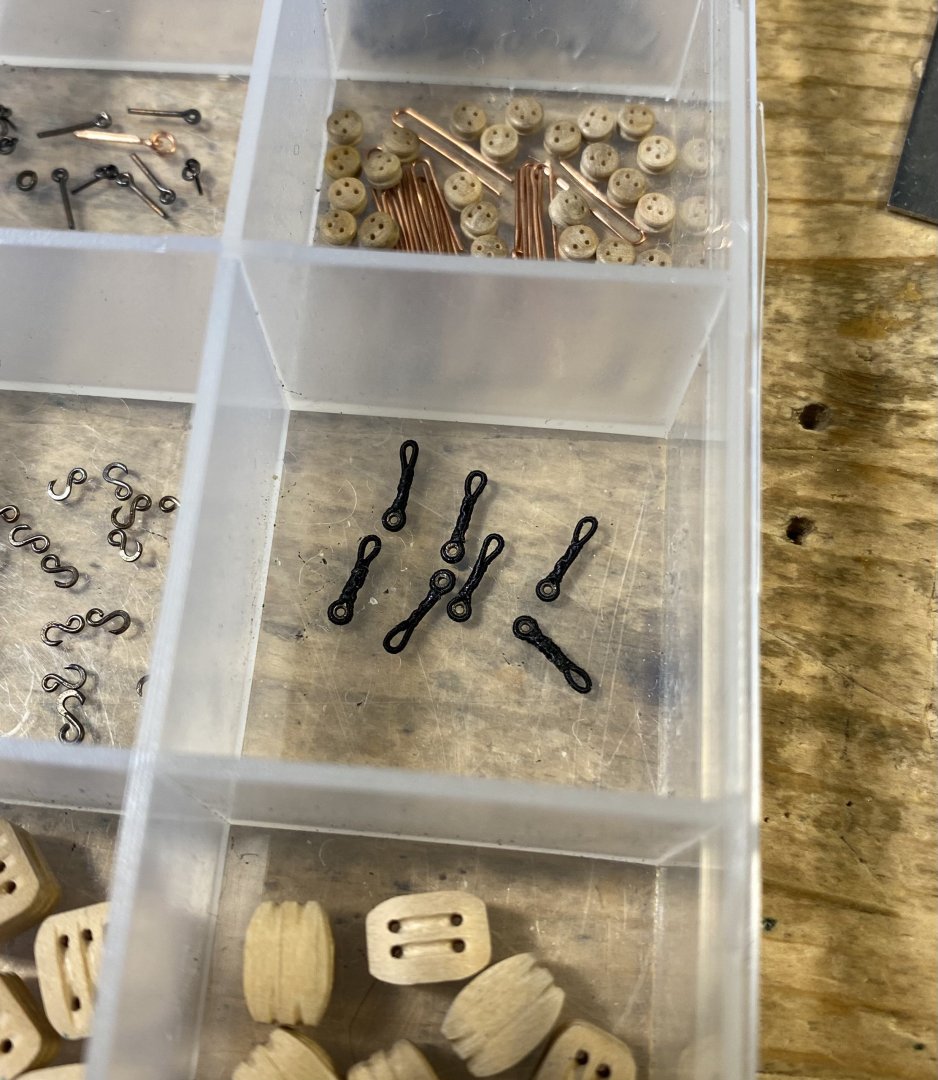

Need help with building a Strap for topgallant shrouds

Y.T. replied to Y.T.'s topic in Masting, rigging and sails

Hi, druxey. We met on this forum before. Nice to hear from you. -

Y.T. reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

Y.T. reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

-

Y.T. reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

Y.T. reacted to a post in a topic:

Need help with building a Strap for topgallant shrouds

-

Need help with building a Strap for topgallant shrouds

Y.T. replied to Y.T.'s topic in Masting, rigging and sails

The first was the worst.now it takes only 15 minutes to make one and each time it gets better and better.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.