-

Posts

356 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Walter Biles

-

-

He released it and laid it on the floor, and it held it's shape. I think it would have done more, but he didn't want to chance damage to it because he was putting it on a boat.

- druxey and thibaultron

-

2

2

-

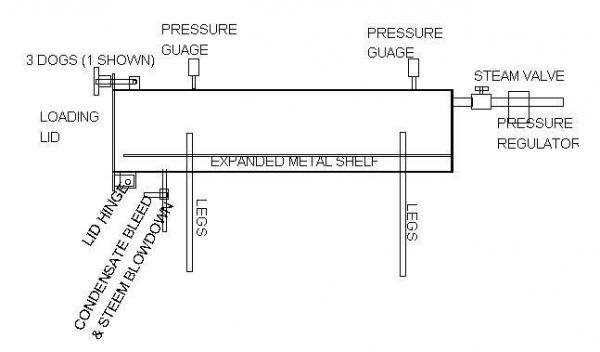

This illustration comes from the steam tank that we used for preparing planks for bending at the Severn River Repair Center when I was in the Navy.

The steam was regulated to about 30psi. There was a shelf of expanded metal all the way through the steamer to hold the planks up out of the condensate.

The valve on the upper right of the picture was opened after loading the lumber into the opening hatch on the left end and it was dogged down fully. The steam was allowed to enter the tank with the bleed valve at the left bottom open for a few minutes, then it was closed for a bit.

After about 5 minutes when the steam pressure was up to it's setting, the condensate valve would be cracked enough open to allow the condensate to dribble. This allowed the steam to keep entering the tank, It was watched to make sure it did not let the steam to blow out. Once it was stable, we would leave the wood in it for about an hour, and at that time, the steam was shut off.

Then the condensate valve could be opened all the way to let the pressure off. Once the pressure was down, and the steam had stopped blowing out, the dogs would be cracked and backed off carefully.

One of the sand crabs(civilian shipwrights) showed me a piece of oak that I had helped him put in that was about 1"x2"x8' and I asked him how much bend could it take. He showed me by tying a loose overhand knot in it with about a foot of the plank sticking out each side of the knot. He then straightened it out, and used it on the boat he was working on.

The pressure of the steam drove the moisture into the wood in just a little while. When the steam was down, ie. not available, they tied some weight to the timber and attached a line to it and dropped it in the basin overnight. That was not as effective as the steam, and it would not bend to the same degree without damage.

I thought that some of you might find this interesting.

- druxey, thibaultron, Mark P and 9 others

-

12

12

-

That really looks neat, Bob. I like it!

-

Ed,

You made that transition look so much simpler than I thought it could be. I love it!! Walt

-

Wow,

Those look like "grab yer partner and do-se-do" floor widths. Yep I'm here too.

Walt

-

Michael, A Happy new year to you also!

Row, Happy new year to you and all my best wishes.

Patric, Happy new years and best wishes.

Mark, I know you'll be by, and a Happy new years and best wishes to you and Janet. I'll be praying for you both.

It is not at the admiral's prompting, It is just that since she is back home I need to get some of the things done for both our betterment, and now is the best time while she can be home for a while to get in her ideas about how she would like to see things change. I have been too neglectful of getting on the stick and getting it done.

Bob, You and the admiral both doing okay? I hope you both have a Happy and healthier new year this year !!!

-

Well, this work has been stalled for some time this past year, and I am in the midst of moving everything to make room where it is needed, which means I am going to fabricate some extra storage places before what must stay, can stay. I am also trying to catch up with putting something besides a sheet in my wife's bedroom window and a lot of other things so we can entertain friends without having to move many things to my outer work shop, tying it up all the time. So for the next few months at least, I will be too busy to be back on here for boat building. I may pop in once in a while to say hi, but not much else. I hope that when I get done, I will have a more organized home, hobby room, and work shop, so I will be able to move around and do things without the all- in- a- clutter that has prevailed since I was forced into retirement. So I wish you all well, and hope that I can get done sooner rather than later. I'll try to keep up with viewing some builds. I really want to keep up with EdT's Young America, and Mike's Maria and whatever else he takes on. And Popeyes multi ship fleet, and Rich's Constitution, and Bob's new build I just know he'll get started soon, if he hasn't already, and I cant think right now but I know there are 3 or 4 more. Everybody keep up the good work,

:D

:D

Walt Biles

-

-

Rich,

I was doing some catchup on your log. I really like your rigging line dispenser on page 99 post 1471. That is really a great idea, Would you mind if I use it? I might make some modifications to it to fit my needs, but that is a great way to avoid the lines from becoming all scrambled up, and I see it would lend itself to labeling the line positions for size and content.

Walt Biles

-

Rich,

I have the plans out for my kit. Page 2 has the side view of the rigging of the whole ship, The cross trees are a little circle with the rigging to each on each mast with the #s 274-277 going up the formast. On page 3, the #s are marked to the top view of each cross tree, with the for/aft view just below each one. That should give you a clue how to find the rest. I highlighted around each cross tree # on both plans for quicker Identification. My kit is a long way off yet until I get more experience reading plans and working with kits. The only boats I have done are self drawn plans, and scratch built. Funny, but that way I seem to know just where to look for my parts, go figure! I started with scratch and am working toward using kits and plans. I never was one to go the normal way on things.

Have fun!

Great job so far!

Walt Biles

Walt Biles -

-

About your planking pulling away from the framing. Did you sand most of the char from the lazer cuts off the edges of your frames. Often that can impede the glue from holding by the charcoal from the lazer giving a carbon that releases from the wood and glue. A good sanding until you get most of it off before glueing can help the hold of the parts. I found that to be the case with some kit tools that I did earlier. Nice job so far. I like it.

Walter Biles

-

Marsalv,

How are the knots on the ratlines tied and how are they secured at each end. So far I have not obtained any books on rigging, and have always wondered how they can keep the cross lines from slipping down. Yours look fantastic, but I can not tell from the pictures enlarged. Do you have any recommendations on books for references on rigging?

Walter Biles

-

Jerry,

I have a suggestion. Make the edges of the hatch taper in towards the middle of the hatch by maybe 5-10 degrees, and put the gasket material between the lower and upper taper so when the screw comes down, it will pinch it as the taper closes up on it. I think you might get a better seal out of it, IMHO.

Walter Biles

-

-

Thank you, Popeye and Michael.

Walter

-

I filled up with wood putty to the rib surfaces, sanded, and put on 3 more 1/8 x1/2" planks. I am at the radius curve going down the hull. I decided since I could not get in to find the foam, I would just fill the space. After sanding the fill to where I was above the water line, I have started planking beyond onto the lower hull. I am satisfied. The fill should help me when I get down into the convex curve of the hull.

Walt Biles

-

I too am building a tow tug for recovery. I figure if my lines for boom control get fouled, I better have something with hook and tow capacity so I can exert enough force to get it unstuck, and with enough power/speed to drag a capsized boat back against the wind and drag. I fully intend that even if it fully fills the hull, that it will not sink. The same with the tug. The tug won't have to sail like a tug as long as it can do the job I need it to do. I live out where some good sized cow ponds are the most likely to be where it will be sailing, and I need to be prepared. I hope I'm not being paranoid. I just figure-- Be READY.

Walt Biles

-

-

Hi, Bob,

Lettie is sure beautiful! I have been watching the build. Which of the Chapelle books was the one for rigging you mentioned you kept in hand? I now have 3 of his but have not really set down to read them yet. My most recent was The Search for Speed under Sail. That has some awesome drawings foldouts.

My Admiral is finally back home this past month.

Walt

-

-

Popeye,

Well, maybe, if I do all of them. I usually just work on just what strikes me most when I'm ready for something else to work on. I've been thinking about that since '69 also, but I never had the time to actually measure out spacings and dimensions while I was at the boat yard. Drawing the Meridea to scale only took a little over an hour. I had to get up to chow before they closed the doors. The ones I am most likely to start of those listed, would be the Galilee boat once I finish Meridea.

I looked at all of the kits I was given, and I wouldn't feel comfortable with AL and I am not thrilled with the Constructo kits, not to say I won't get to them one of these days, but I've been thinking more about my interests while I was in the navy, than most other things.

I knew that railway was on its late life even then, but if I could even build a model for a reminder for others, It would please me. When I was there, they only used it for the smaller stuff, rated boat.

Walt

-

Thanks for the likes and responses, everyone.

Popeye, If she works out, I may use her form to do a mould for a fiberglass hull. That way I could also use the top of her to do the same and return her to her original shape around the edge of the deck and shorten her cabin to original. Then I would have a real model of the original. Maybe, some day, if I live so long. I have some other things I'd like to build, first. I have been thinking about doing a marine railway that they used to have at the navy yard. I could make it operational. I used to help get the boats out of the water as part of the division function.

Too bad that wouldn't qualify for a build log here, although it would be nautical related. I have offered the academy museum to do one for them if they can help me get the dimensions and plans. Otherwise I would have to do a lot of it from my memory, and my training in bridge work in Sea Bee school which would probably not fit their criteria.

Walt

-

How long is your Titanic model and what material is it I saw in the picture a way back there? I had thought about building one of those for RC once. I never found the right size.

Walt Biles

PLANKING STEAM TANK

in Building, Framing, Planking and plating a ships hull and deck

Posted · Edited by Walter Biles

After hearing so many asking about bending wood,I get to thinking, if the pressure cooker was big enough around, I think it might work to just bow the pieces around the outer sides of the cooker and give them a pressure cooking for awhile, say 30 minutes. I think the jar rack plate for the bottom could be used to keep the wood from getting soaked too much in water.

My wife's is a 16qt. I think I will try that next time I bend. I checked, it's okay.