-

Posts

571 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Timothy Wood

-

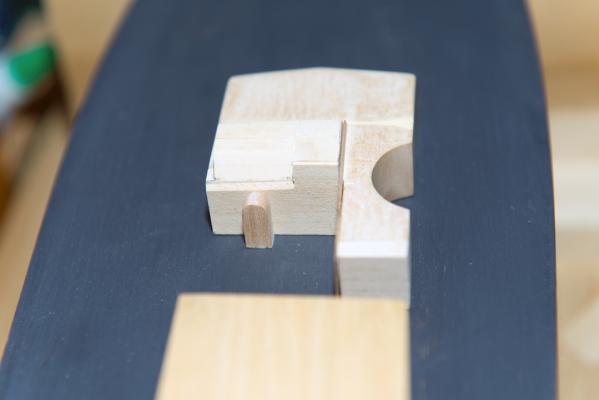

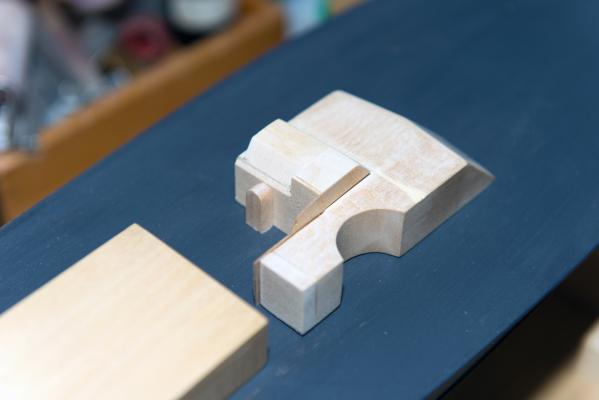

Greetings, I have attached the block to the hull, then I attached a piece of aluminum angle to the block, this bolts to the Wilton Power Arm. The best thing about having a power arm is you can move your work into any position needed. (See photos below). My first step will be to cut the shear into the deck, after that is complete I will start shaping the hull. Cheers, Tim

-

Greetings, I have added a piece of plywood to the aft side if the chart house and added the steering box. Still have to add plywood to the top if the instrument panel and the leading edge of the wind shield. Cheers, Tim

-

Greeting! All the lifts have been glued, the hull is ready to receive a piece of wood the will allow me to attach the hull to my Wilton Power Arm. Using the power arm makes the job of carving the hull much easier than if it was attached to a normal vice. I have added the outline to the backside if the hull. One step I have given myself an option with is the rudder, I can carve it into the hull or add it later as an addition. Cheers, Tim

-

druxey, They are, they are.... I wan't to get started in on the fun ASAP, but I have one more lift to gule...

-

According to the web page September 2010 http://www.sailkarma.com/2010/09/lets-race.html Cheers, Tim

-

I stumbled across this on the net while searching for more information for the Schooner Atlantic. It sure would have been great to be there and see these two square off! 3 masted schooner Creole vs 3 masted schooner Atlantic, this took place at "Les Voiles de Saint Tropez". Cheers, Tim

-

Next two photos show the African Mahogany lifts. I will be using Mahogany from the water line down to the bottom of the keel, this area wont be painted. I intend this area to be natural wood, above the waterline will be painted with the schooners original hull color. Cheers, Tim I hope everyone in the U.S. is having a good Labor Day Weekend!

-

Richard, I believe I'll pull up a chair and watch your build. I did a half hull of her about a month ago. I must say she is a beautiful craft, I look forward to watching your build. Cheers, Tim

- 162 replies

-

Jay, I didn't want to forget about you! If you wan't a sneak preview with half hulls check out my build log from the BlueJacket Kit Endeavour. Tim

-

That's a beautiful area, I took my wife up to Maine shortly after we were married. We went in September to avoid all the summer people from Mass and Conn. I should have remembered from my Navy Days that the state rolls up the sidewalks after Memorial Day weekend! Oh well we had a great time any way and I had a good time showing her my old stomping grounds! Tim

-

Thanks Wayne, I don't want to put anyone to sleep! Where are you at in Maine? I was stationed at NAS Brunswick photo lab from 1983 to 1987.

-

I figure it's time I put a little work in on the Elco, I guess I've been spending too much time on the Atlantic half hull. I managed to get the remainder of the spray shields cut and they are now ready to be sized and glued into place. Cheers, Tim

-

The photos below show the first three lifts glued and the fourth lift with glue applied and finally clamped to the top three lifts. Rather time consuming, but well worth it in the end. Cheers, Tim

-

Elia, I totaly agree! I have the BlueJacket solid hull hit of her on my "Wish Lost".... I have to get much better at sticks and strings before I atempt anything like that kit! A beautiful shil to say the least! Cheers, Tim

-

Last night I was able to get the first two lifts glued together, I'm working from the deck downward. I use standard wood glue on the lifts, then clamp them for 24 hours. Cheers, Tim

-

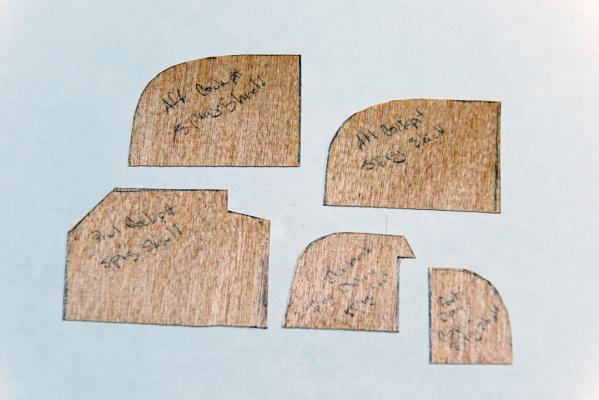

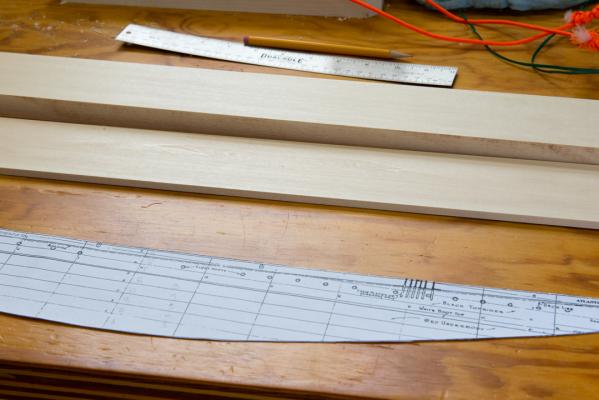

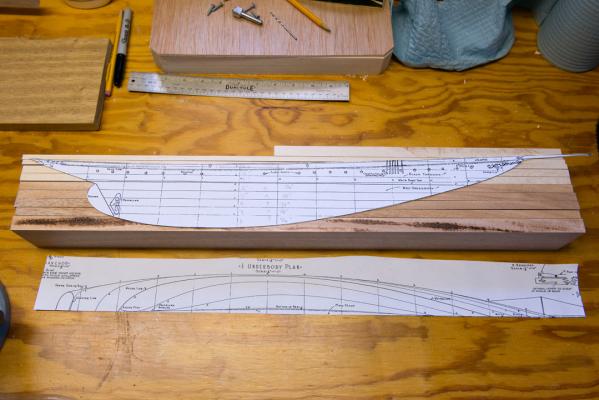

Greetings, We have had great weather the last few days which gave me a chance to get outside and plane my wood. After I did my basic planing and cutting to size I still needed to plane each lift to the correct thickness. This last photo is of all the lifts at their correct thickness with the profile drawing of the Atlantic placed on top for size. My next step will be to cut each lift to the basic hull shape at it's corresponding position in the hull. Cheers, Tim

-

Jay, I had not heard that, I sure hope someone picks them up. They are really good to work with! Tim

-

Thanks Bob, I agree the lines are beautiful, I envy Jay (above), for having the kit possibly one day I'll have to add to my build list! Cheers, Tim

-

Adam, Great repair job on the keel. A couple months back after returning from a model club meeting, my Elco PT Boat did a nose dive out the truck door onto the driveway and ended up exactly in the middle underneath the truck (Murphy's Law). I was almost sick to my stomach. As it turned out it wasn't as bad as I first thought. The fix only set me back a couple of days. As always, keep those photos rolling in! Tim

- 97 replies

-

- Willie L Bennett

- SkipJack

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.