-

Posts

3,317 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

Can you please remind me what your lower deck port opening width and height are in MM? I’m assuming that the white framing are the port lid stops, and that you will plank up to and around these? Also, what is the distance between openings in MMs?

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

In fact, I didn’t catch it in post #428, but your layout there actually shows 17 piercings, including the bow chase port. Should be 16 in total.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

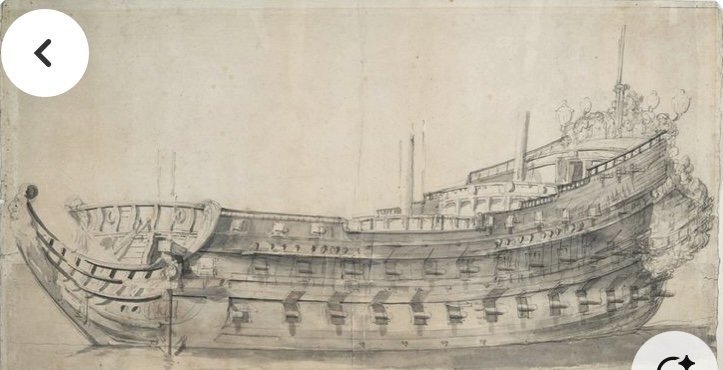

As far as creating a more compressed impression between gun decks, I think you are succeeding, there. What has me confused about your layout is that you show 16 lower deck piercings (red squares), but the forward chase port is in the position of a broadside gun - too far aft, in other words. This has implications for the layout of all gun decks above.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

I’m going to let this sit as well. Gotta really focus, and I’m not quite where I want to be.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Before you start cutting, might you want to be sure of the stagger pattern for your middle deck guns, and where that will all map out for the upper main deck guns?

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Voila! And, I also agree that going back to 9MM ports will be appropriate.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Try increasing the spacing between ports 2 - 15 to 22 MM, this will be just under .875 imperial, or 7 scale feet at 1:96. Your current spacing looks a little crowded, and the space between the bow chase port and the next gun aft is too large. You are trying to impose 1671 dimensional parameters on a kit based off of 1693 dimensional parameters. It doesn’t have to “be” exactly right. It just has to look right.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

At scale, if you end up in the vicinity of 6.5 - 7’ between ports, then that’s where you want to be.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

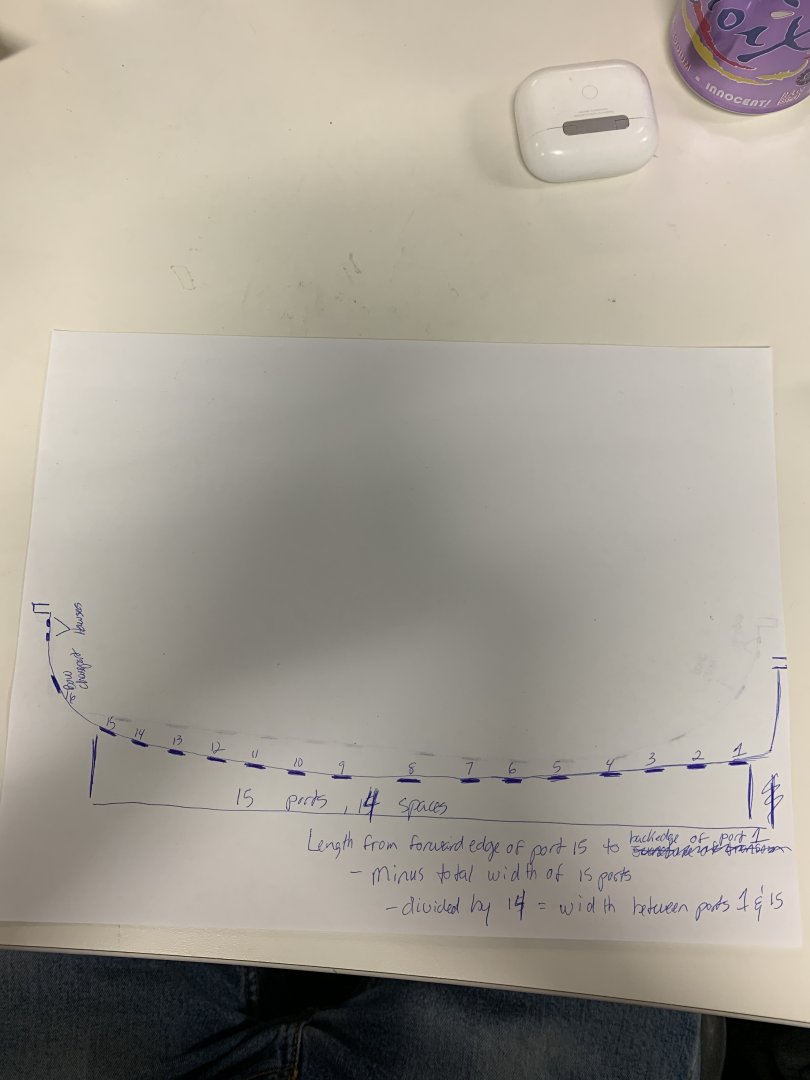

I think you measure along the outside of the hull. As you say, establish the position of port #’s 2 and 16, and then calculate even spacing for the guns in-between. A straight linear measurement of the deck length is not particularly useful, here. Here is a poor drawing illustrating the calculation. Port numbering not so important, here. You get the idea:

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Definitely 3 aft sheer steps are appropriate.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

It’s a very small detail, Eric, but in your schematic of the proposed forward bulwark, where you show the lowered placement of the three round f’ocsle ports, I will make the following suggestion: Even though the open space will be negligible, you should not fill the gap between the top third of the round port and the underside of the caprail.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

My only real issue with pronounced pitch on the poop royal deck is that this is one deck that makes sense for the open chicken coops to reside on. However, you could always stilt the legs of the coops so that they are on the level.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Generally speaking, Eric, your rise over run looks almost about right to me; maybe a little extreme though. I’m afraid this won’t be terribly scientific, on my part, but I would be inclined to nudge the termination points of the pair of lower main wales, down another 1/8”+. That way, you’ll have a better connection to the upper transom moulding that we discussed, above the stern chase ports. Honestly, I don’t think you were too far off on your previous iteration: As for the poop deck, which is carrying guns, it would not have any kind of pronounced forward pitch. The poop royal deck, though, may have had some pitch simply to increase headroom in these birthing cabins. Is that what is happening on the poop decks of these Dutch two-deckers: Hard to say, but it seems so. Or, what about this Dutch-built Frenchie, Le Neptune: Here’s a Puget drawing of a third-rate: I’m on the fence on this one, although Michel Saunier seems to have made a definitive choice on this question: photos, courtesy of Marc Yeu.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Michael, thank you so much for the kind words!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Alright, so I was wrong about SR 1693; her length between perpendiculars was actually 170’ FF. This amounts to an increase of 5.5’ FF, or 5.863’ Imperial.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

SR1’s keel length was 142 French feet, which is longer than the English and Imperial foot by 1.066. That is one factor. The other is that the Heller Kit is based on the dimensions of SR 1693, which I don’t remember exactly, but I think measured 172 French feet between perpendiculars - which is the measurement from the forward most face of the stem to the furthest aft rake of the stern post.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Because this plastic is so thick, my preferred method for cutting openings is to neatly scribe the opening; drill a series of tightly spaced holes within that opening, using a Dremel; cut through the perforations with a stiff box knife; and then square to my lines with files.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

It’s super tedious, Eric, but you’ll want to thoroughly level any wales or ornamental footprints, otherwise there is a good chance they will telegraph through your thin styrene planking.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Hello Wefalck, With the busyness of the holidays, I somehow missed this update to the log. I’m just seeing this now. My apologies for such a late reply. I hear what you are saying about the fretwork panels, and ordinarily, I would agree with you. The problem, I have found is with the material, itself. Fretting out styrene - especially such small parts - is very difficult to do without introducing un-intended deformities to the perimeter of the parts; the material is just too flexy. This is why, I like to leave it in-sheet while I fret it. That way, I am much less likely to break these fragile pieces, as I did with the trailbord, when I first tried doing this the more conventional way. For assembly of these breast rails, I will place the central panels first - the belfry and the name plaque for the QD - which are bracketed by their stanchions to either side, and then I will build the breastworks out from the center. I have already glued the peripheral breast panels to their corresponding outboard stanchions. This way, I can bevel the stanchion knee bases to the port/strbrd camber of the deck, while ensuring that the top edges of each panel align in a fair arc. The beauty of this approach is that I will have firmly established stanchion head locations to accurately pierce the breast work caprails. Or, at least, that is my theory 😜 Happy New Year to All! Best, M

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

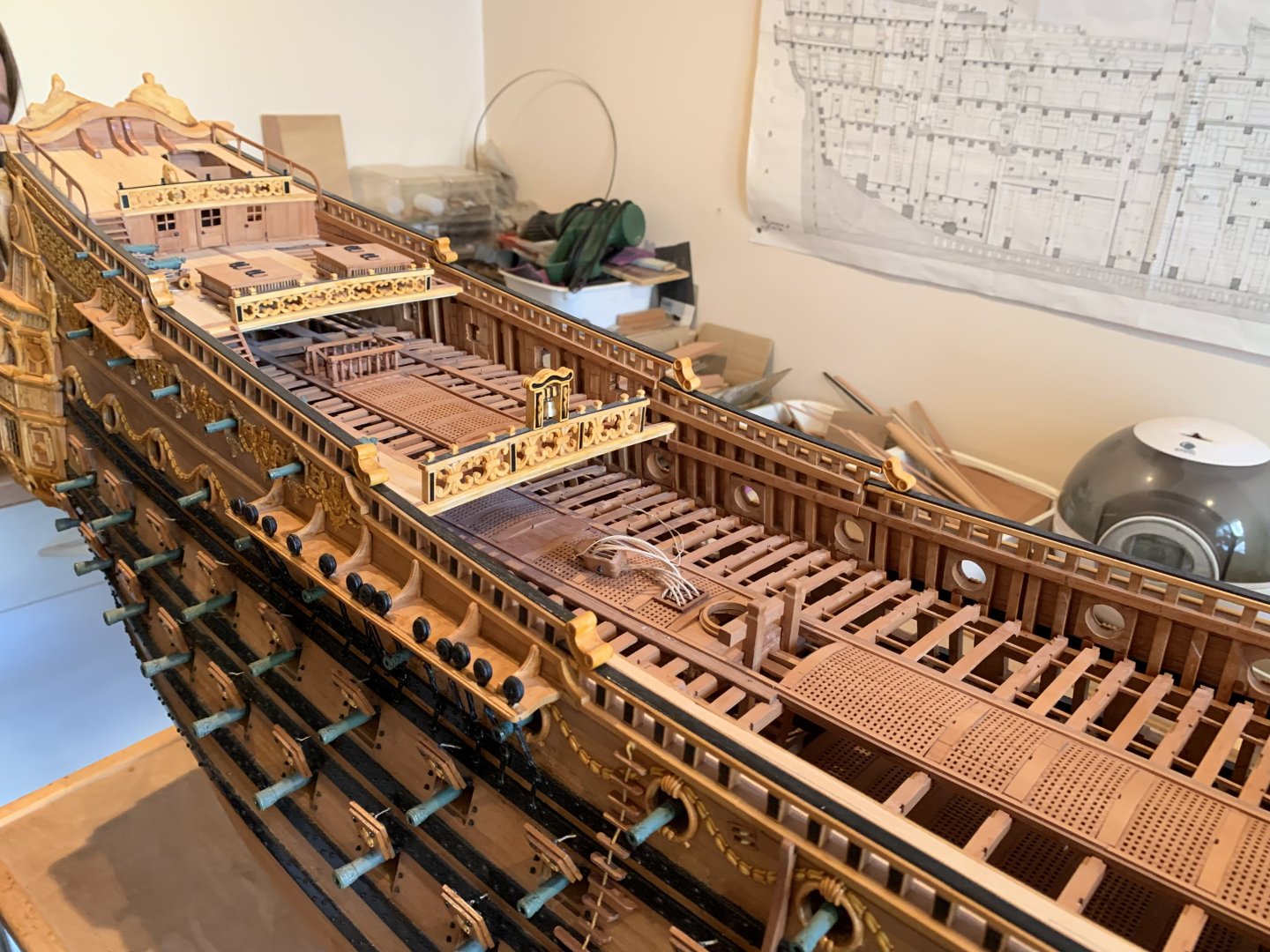

Heller’s SR looks amazing in sheer, but you just can’t focus too much on her underwater shapes. When you minimize the visibility of the lower hull, you vastly improve the credibility of the kit as a scale model.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

The other issue with a lower hull build-out is that the entire midship to bow, along the maximum breadth is just all wrong.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

-

Personally, Eric, I would not even consider building out, or expanding the lower hull. It could be done, but you would need to figure out the rising line of the floors and make pattern guides that faired into the maximum breadth line. The number of difficulties in doing this without CAD are numerous, and getting one small thing wrong, or working from an erroneous assumption could compromise the whole project. Not worth it, IMO. Conversely, it is not too difficult to place the un-cut hull into a waterline sea. As for the QG entry doors, there would definitely have been an actual door there, opening inboard. Seaways can get awful rough, and a ship’s capacity to pump out water would be quickly overwhelmed, if she were taking water in through these large openings.

- 452 replies

-

- soleil royal

- Heller

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.