-

Posts

1,362 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

As always, you've come back with far more material than I expected, Jon. Thank you so much for your efforts. The photos and plans will be very helpful during my construction. 🙏 -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks, Greg. A modeler wrote in his build log that he couldn’t use the laser‑cut cap provided in the kit because it wasn’t the correct size, and that he had to make it from scratch. If that’s true, when the time comes you can also easily make the cap using this method. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you very much for the photos, Jon. They are wonderful and very helpful to me. Do you have a photo in your archive showing how the flying jibboom is connected to the cap? Thanks again. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Spent about two hours today on the bowsprit cap. Rather than fussing with an angled square hole, I just built it up from two pieces and glued them together. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Don't worry Peter, I might have gone a bit overboard 😁 With the gratings in place, tying the Gammoning knot won’t be easy, and wrapping it around the bowsprit will be tricky too. It could also make the bumkins installation a bit of a headache. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg. I deliberately held off installing the gratings at the bow until now, just to make it easier to secure the gammoning. Without the gratings in place, tying it wasn’t difficult at all. I’d recommend you do the same, it saves a lot of trouble. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I’m back at the shipyard, continuing from where I left off. I’ve mounted the bowsprit in place and secured the gammoning. As mentioned earlier, I decided to use rope instead of chain. After that, I glued the steps onto the bowsprit. Finally, I prepared the fore stays and connected them to the hearts on the bowsprit. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

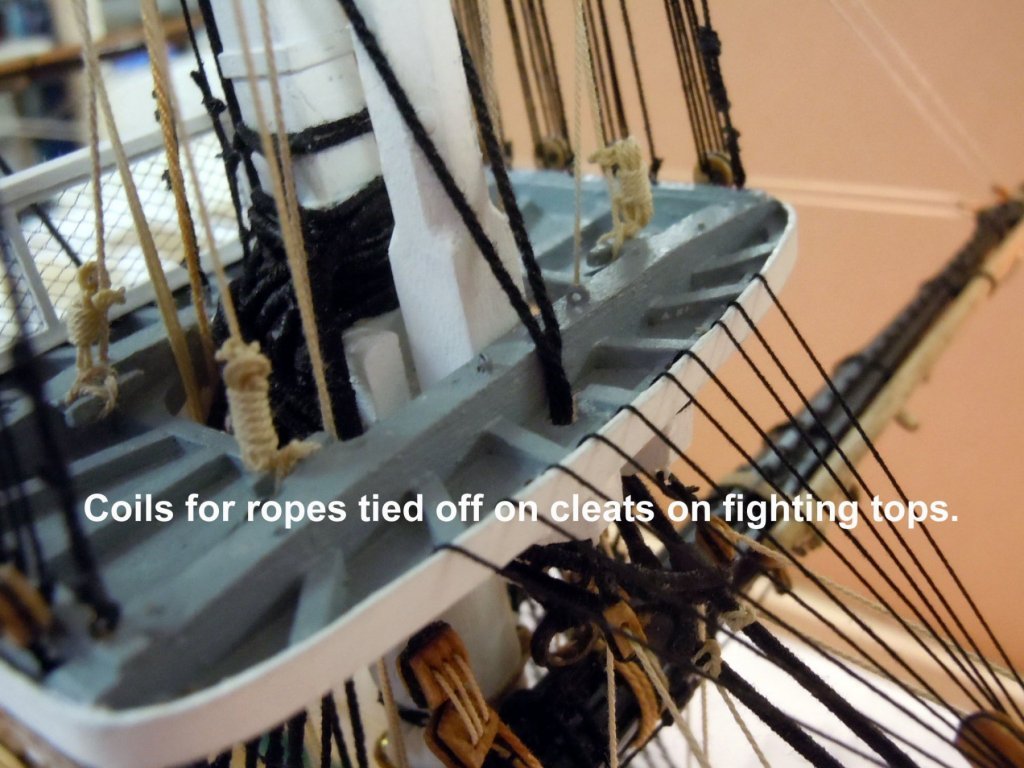

Hi Peter. Now that only the masts, spars, and rigging remain, there aren't many options left. Since you won't be bringing any machinery, it seems you won't have much opportunity for woodworking. You can complete the dead eyes and eyebolts on the fighting tops, and prepare the bobstay and shroud collars on the bowsprit. If you're unhappy with the shape of the blocks that come with the kit, you can shape them with files and sandpaper, you can strop the blocks as you said or you can just do R&R as the woodartist suggested. -

These are very thin and fragile. I'll make the stanchions for the railing from square brass rods if I can find. If not, I'll settle for round brass rods. They won't be noticeable because I'll paint them all white. Brass stanchions are a suitable material for your overall concept. You could consider using them on the railings as well.

-

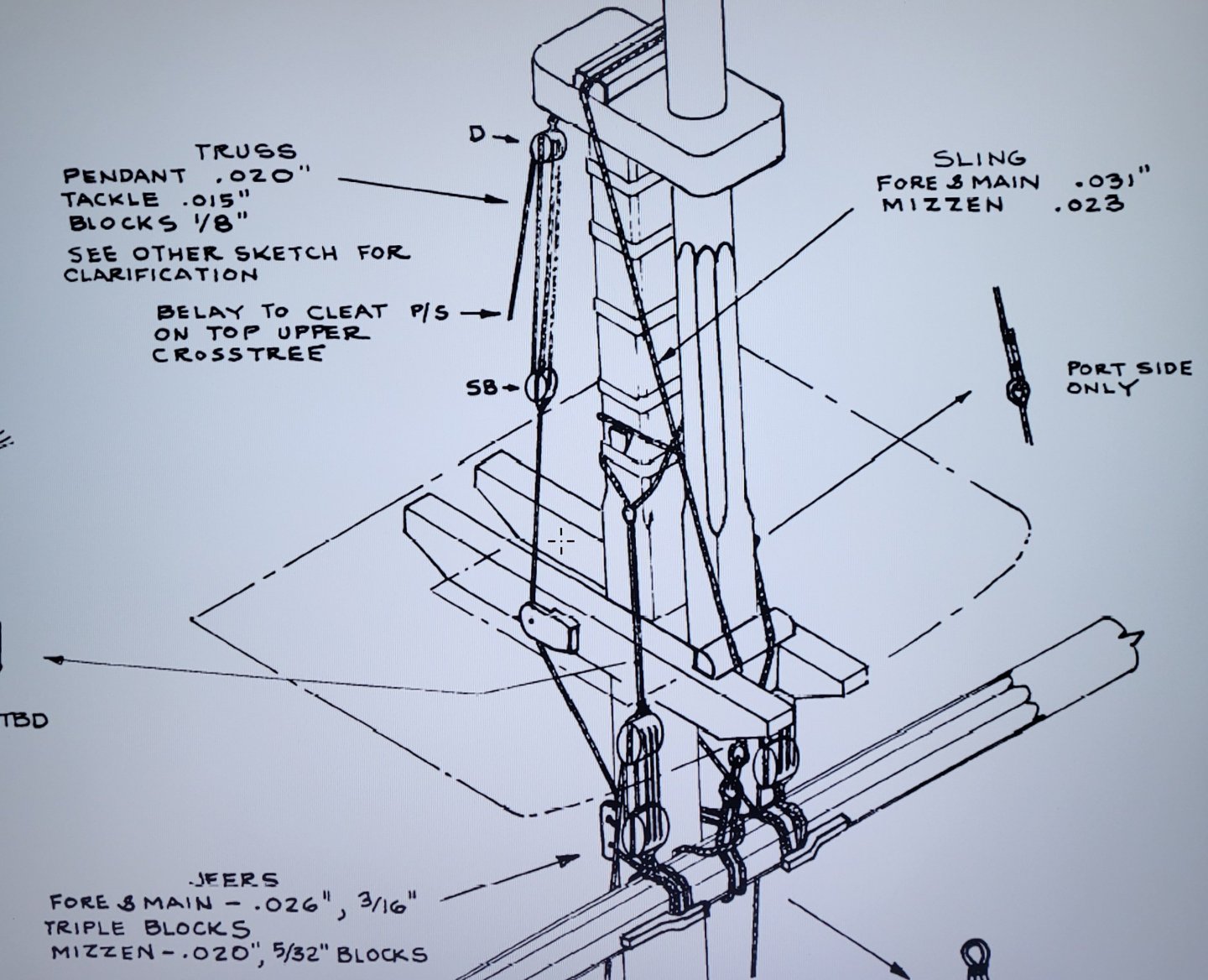

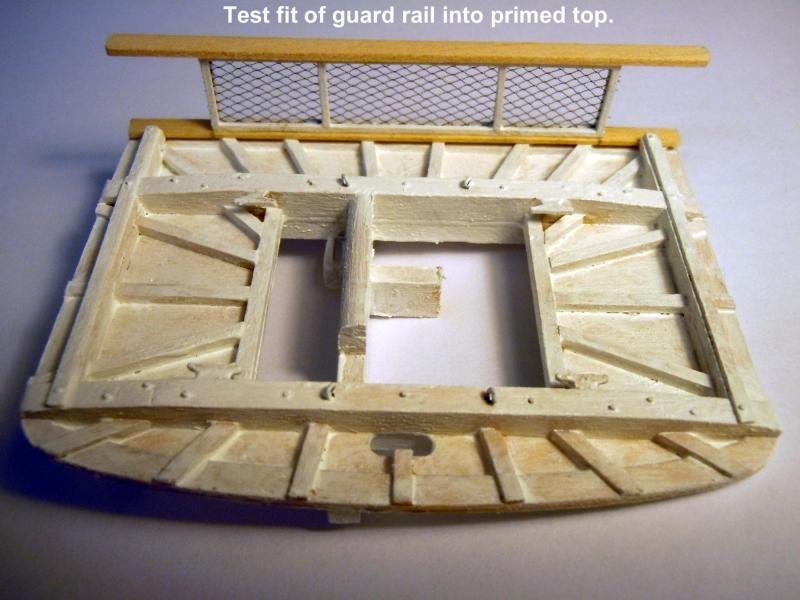

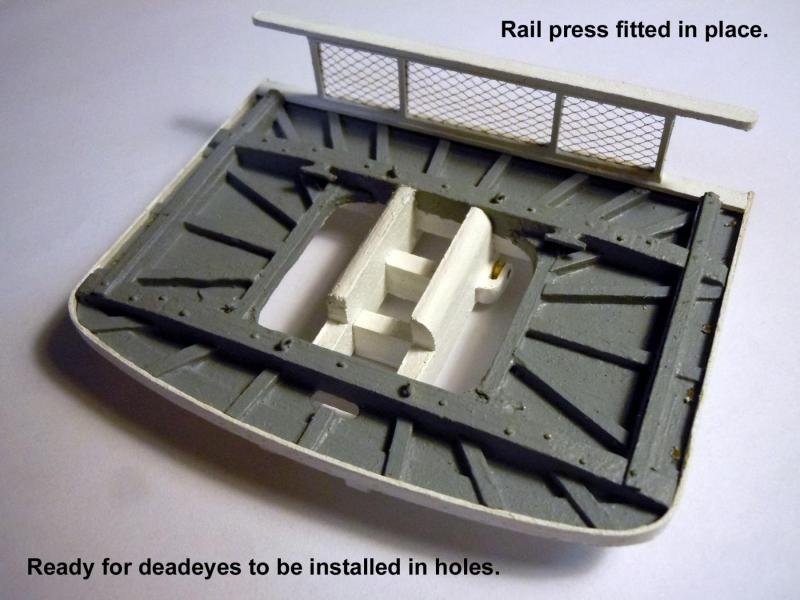

I apologize if I caused any confusion. Actually, I'm following Xken's concept, and my fighting tops will also have that trailing edge, but I'll mount them last, along with the guard rail, after the rigging is finished because I don't want it to prevent me from reaching the fighting top while I'm rigging. I took these photos from Xken's log.

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon. My daughter and grandkids are coming to stay with us for the next two weeks. I probably won’t be able to work on the ship during that period, but I’ll keep checking in on the forum. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

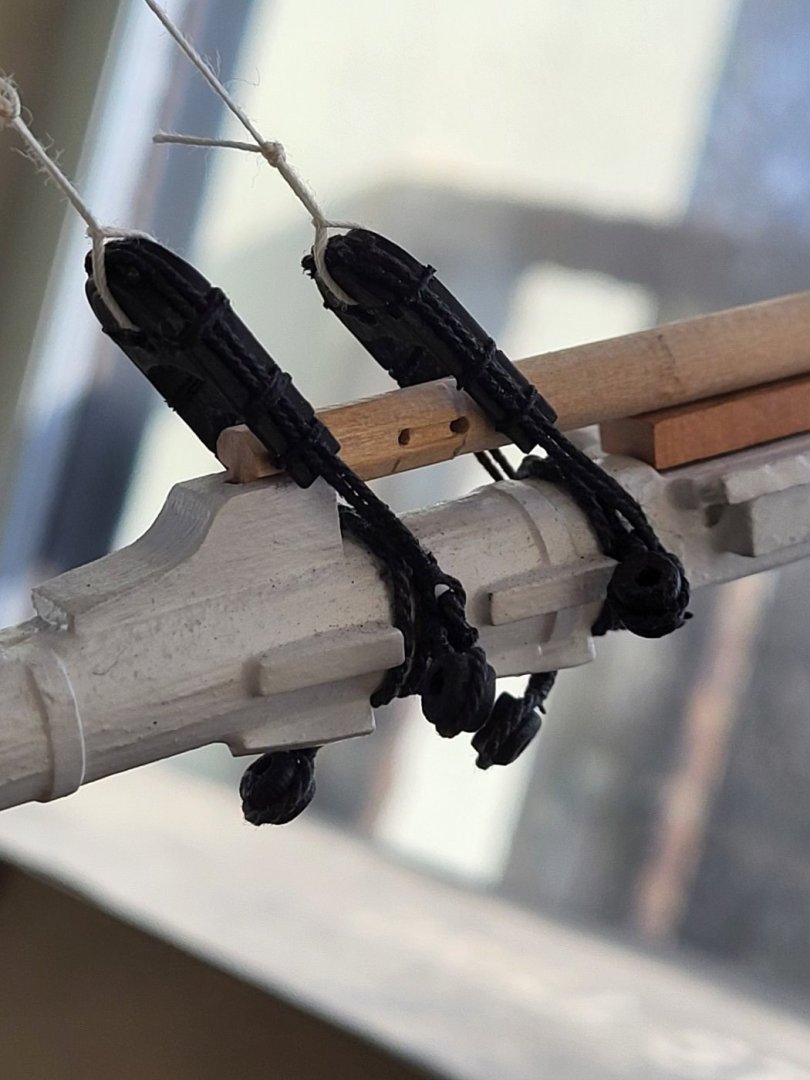

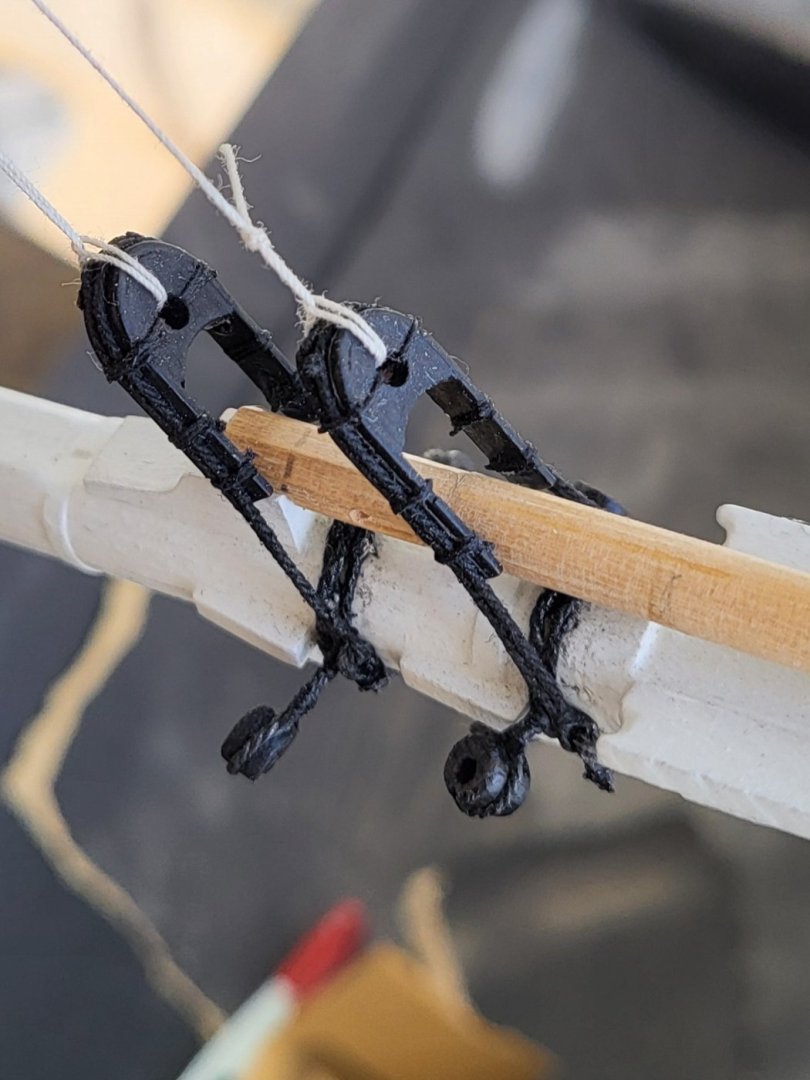

Today I rigged the bobstay collars, shroud collars, and fore stay hearts on the bowsprit. The white ropes are temporary. By the way, Greg was right; when I looked at the photos more closely, I noticed that the hearts were black everywhere, so I painted them black too. Actually, the insides are supposed to be white, but since I'm not very good at painting, I painted them all black. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon! I couldn't sleep last night thinking about how to prevent these from breaking, but I finally found a solution. I would be grateful if you could provide the source link. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

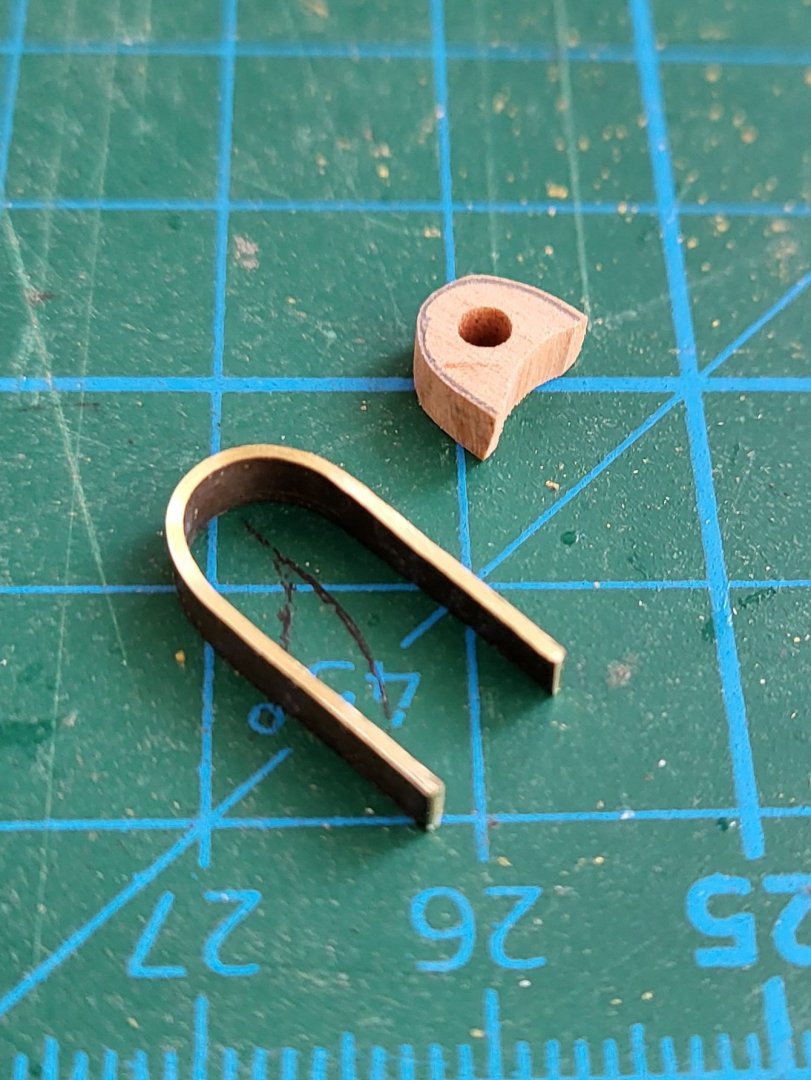

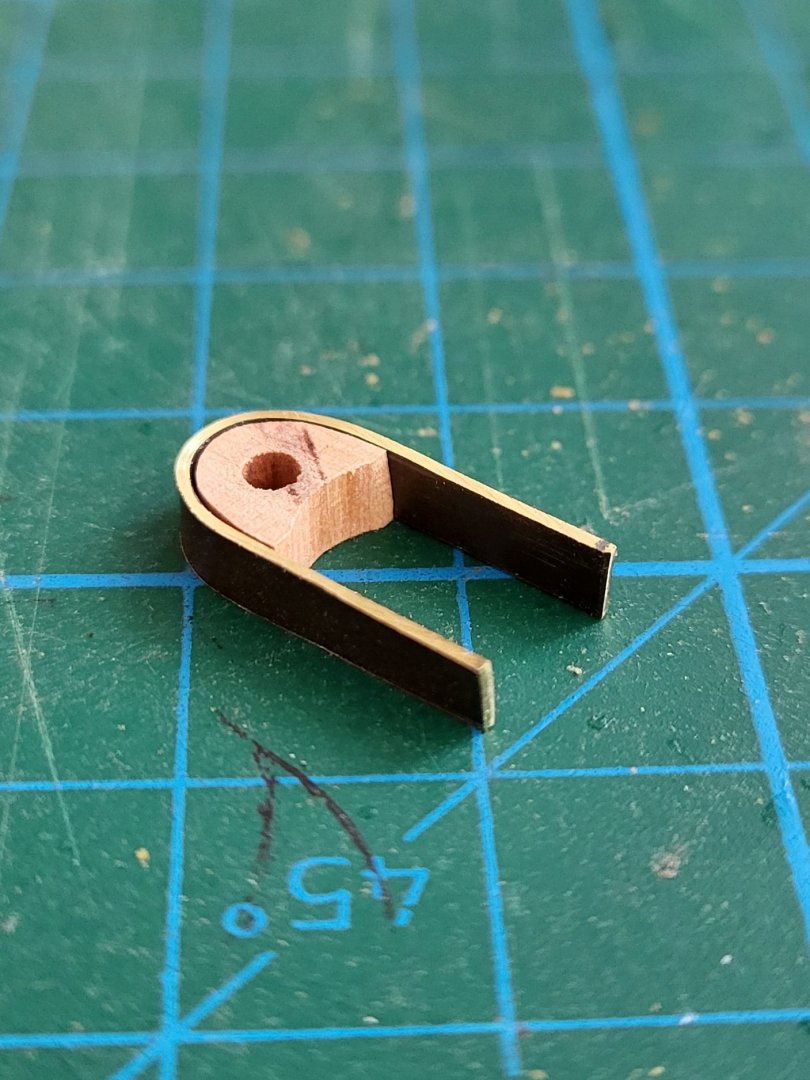

Thank you, Greg! The brass sheet I used is 0.7 mm thick and 3 mm wide. I wrapped the brass strip around a round rod with a 6 mm diameter. As you know, I’m modeling the ship as it appears after the 2015 restoration, and for reference I usually rely on the interior visual tour available on Google Maps. Since the open hearts are shown in white there, I’ll be painting mine white as well. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I’m currently working on the open hearts that connect the fore stays to the bowsprit, using photos of the actual ship as reference. At first, I tried making them entirely out of wood, but the side extensions were so thin that they kept breaking during construction. So I abandoned that approach and came up with a hybrid solution, which turned out really well. This hybrid structure combines brass sheet and wood. Once the open hearts are painted white, the mix of materials is practically invisible—unless you look very closely with a magnifying glass. -

Nice work on the chafing fish, Peter! Just a heads-up—the space between the main mast and the fife rail looks pretty tight in the photo. You’ll need room there for three stays coming off the mizzen mast, which get tied down to the deck with bullseyes. On my build, that gap was really small too, and I had a tough time securing the mizzen stays. Hopefully you haven’t glued the fife rails yet. Also, before you set the masts in place, it’s a good idea to get the eyebolts around them installed first.

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Yes friends, after buying and starting to use the milling machine, I began to enjoy this hobby so much more. Yes, it’s a bit of an expensive investment, but it’s worth every penny. Also, once you own this machine, don’t forget that you won’t be spending tons of money on kits or accessories anymore. In the long run, your money will stay in your pocket. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Jon, Peter, Greg, thank you so much for your kind words. Greg, all of the detail pieces are made from pear wood. I have never used boxwood, as it is both expensive and difficult to source locally. Pear wood offers similar working properties to boxwood while being a more economical and accessible alternative. Bowsprit itself is made from hornbeam wood.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.