-

Posts

1,076 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

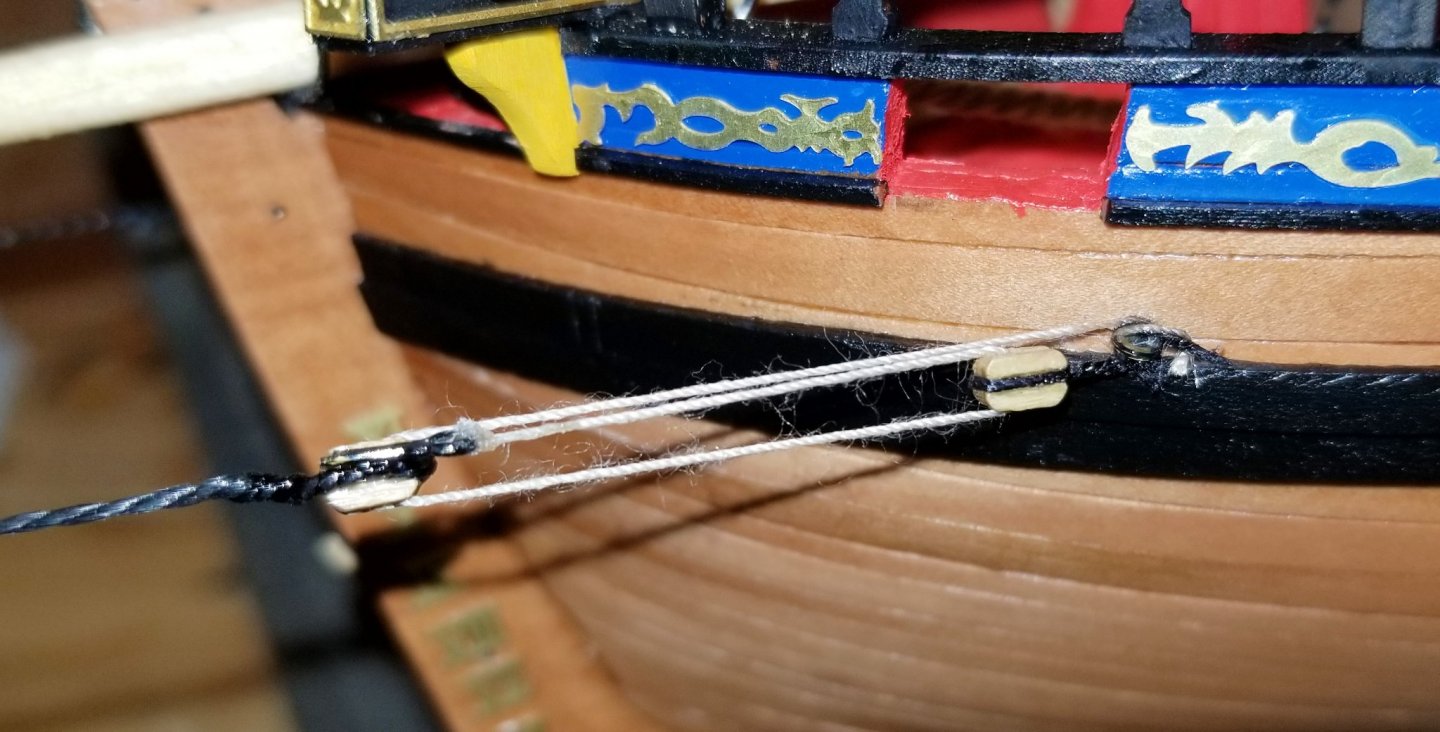

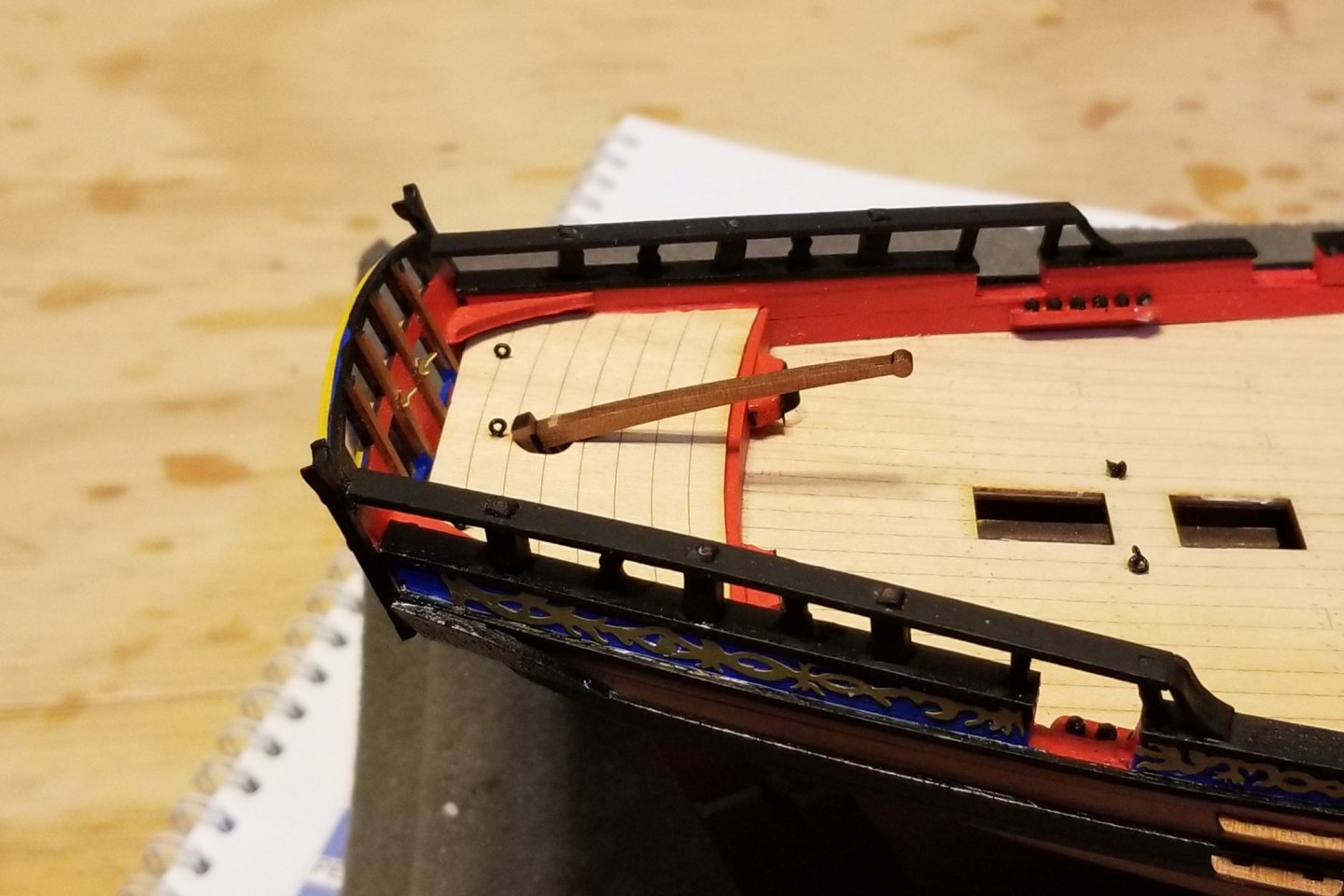

Installed the bowsprit and side rigging for it. The stays on each side of the bowsprit are the same thread that was specified for the shrouds. When it's under tension, it twists. So if you rig the blocks loose all the way (the way you'd do with a deadeye) and then tighten them, the block on the stay spins and the rigging between the blocks twists -- bad look. The way I solved it was to attach the thin thread to the eyebolt on the block attached to the stay, pass it through the block at the hull only, and then tension it. That causes the stay block to twist, and if you hold the twist there and then finish rigging the thin thread back through the block on the stay, the rigging aligns when you re-tension it and looks as you see in the picture. But it took some work to figure out a solution. Regards, David

-

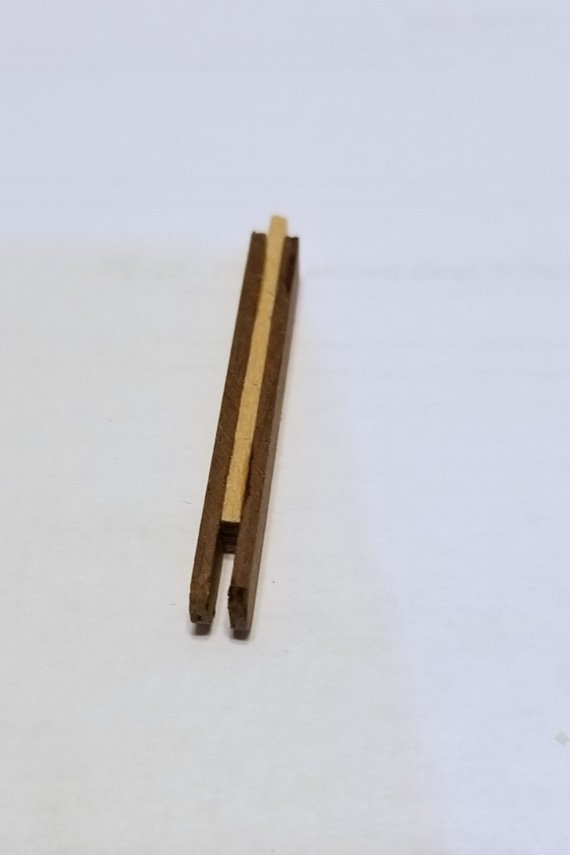

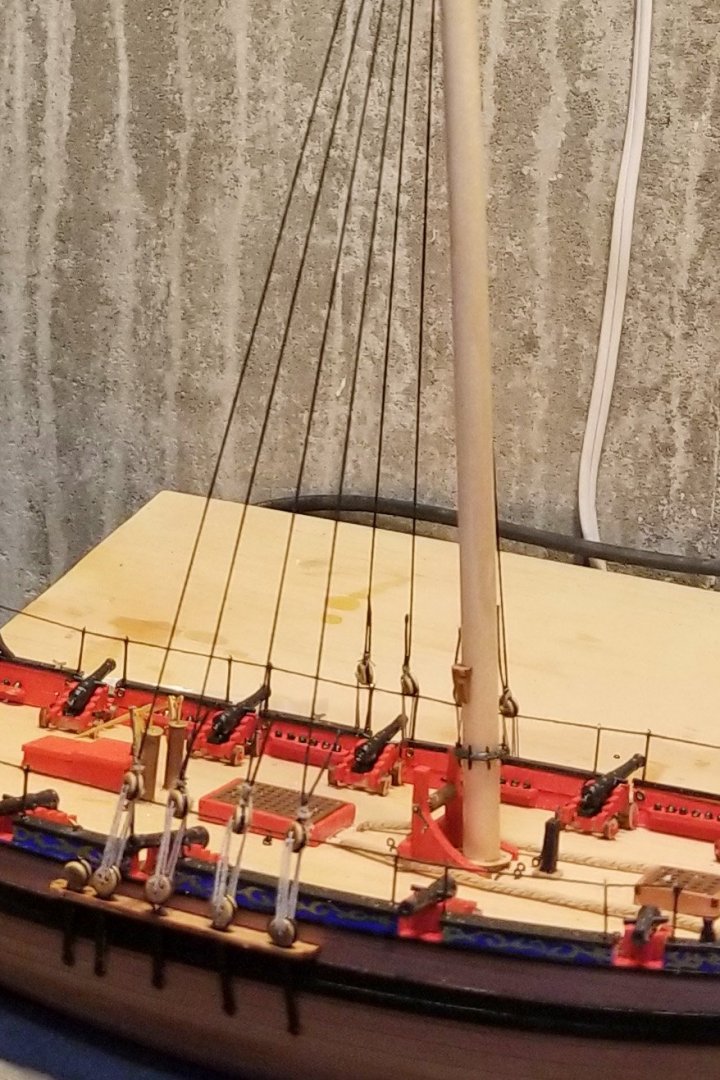

Remaining two shrouds rigged on each side -- they don't get ratlines. Also installed the shroud cleats. I haven't seen anything like these on other ships I've built, and I think they are kind of cool. The manual says paint them black, but as with the hull-mounted cleats, I left them unpainted and I think they will show better this way. Nothing is actually rigged to them in the finished model. Regards, David

-

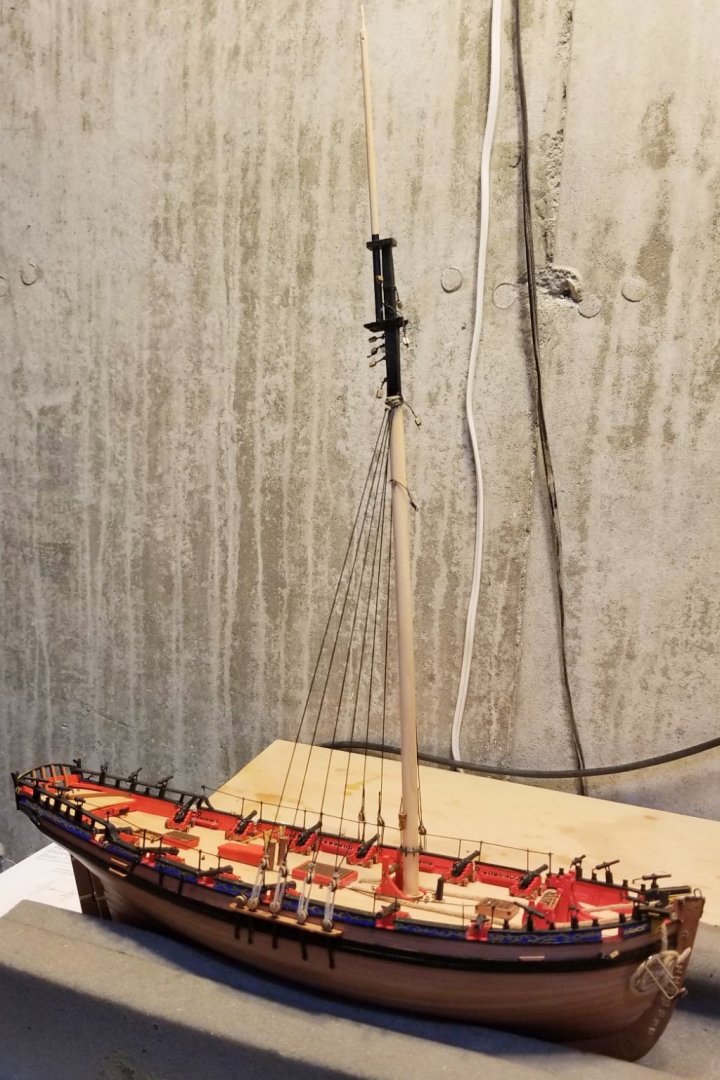

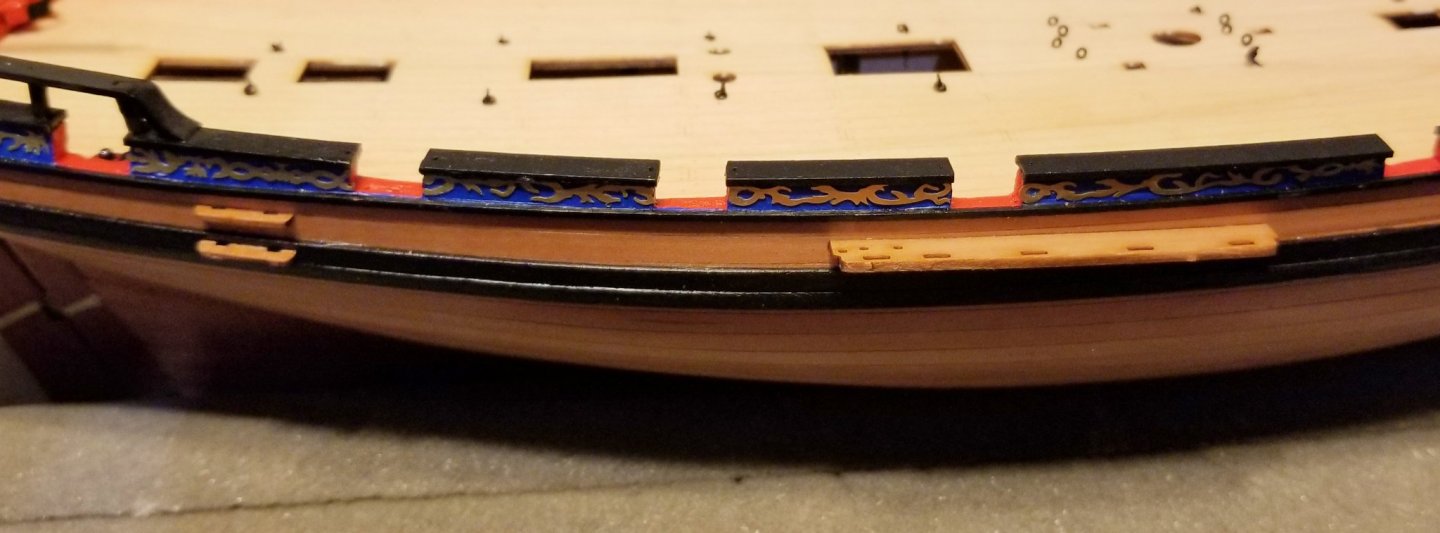

I have now completed work on the hull. Added: Deadeyes on channels Cannons Stanchions and railing Anchor cable Some side rigging The manual says to wait to rig the anchors until the other rigging is complete (makes sense), but I installed the anchor cable across the deck and through the hawse because it would be tough to get at after the mast rigging is up. You can see the excess at the bow held with paper clips for later attachment to the anchors. Next step is the mast and yards. Regards, David

-

Hello, Brian. I can't recall - but I would only have done so if they supplied balsa and called for it in the instructions. I use a steamer to take tension off the planks for bends like the ones you are referring to. Good luck - it's a nice little kit. Regards, David

-

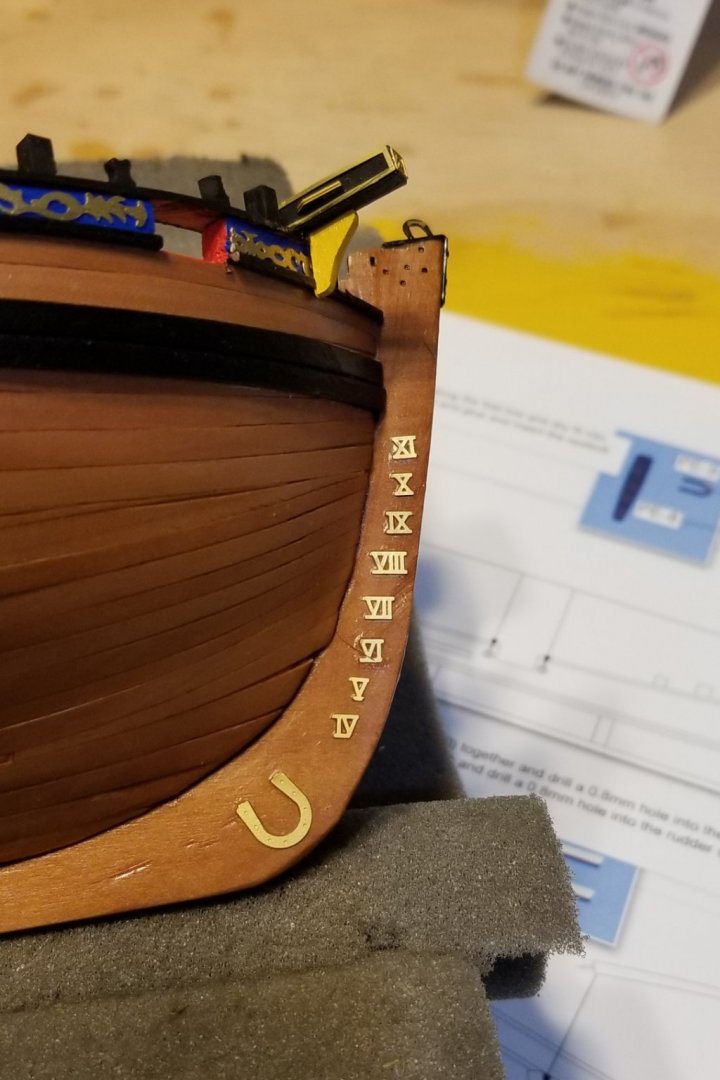

Added the catheads and all of the scrollwork. Some building notes: The hawse hole pieces next to the catheads are cut so that they fit perfectly -- if you fit them backwards from the way the manual says. So I had to sand down the bottom edges to get them to fit properly. The manual says to paint the scrollwork yellow. This is the same treatment (and same instruction) that Chris Watton used on the HMS Fly, which I also built. I love the look of brass, and don't see the point in painting it yellow -- so I left it plain (as I did on the Fly). Regards, David

-

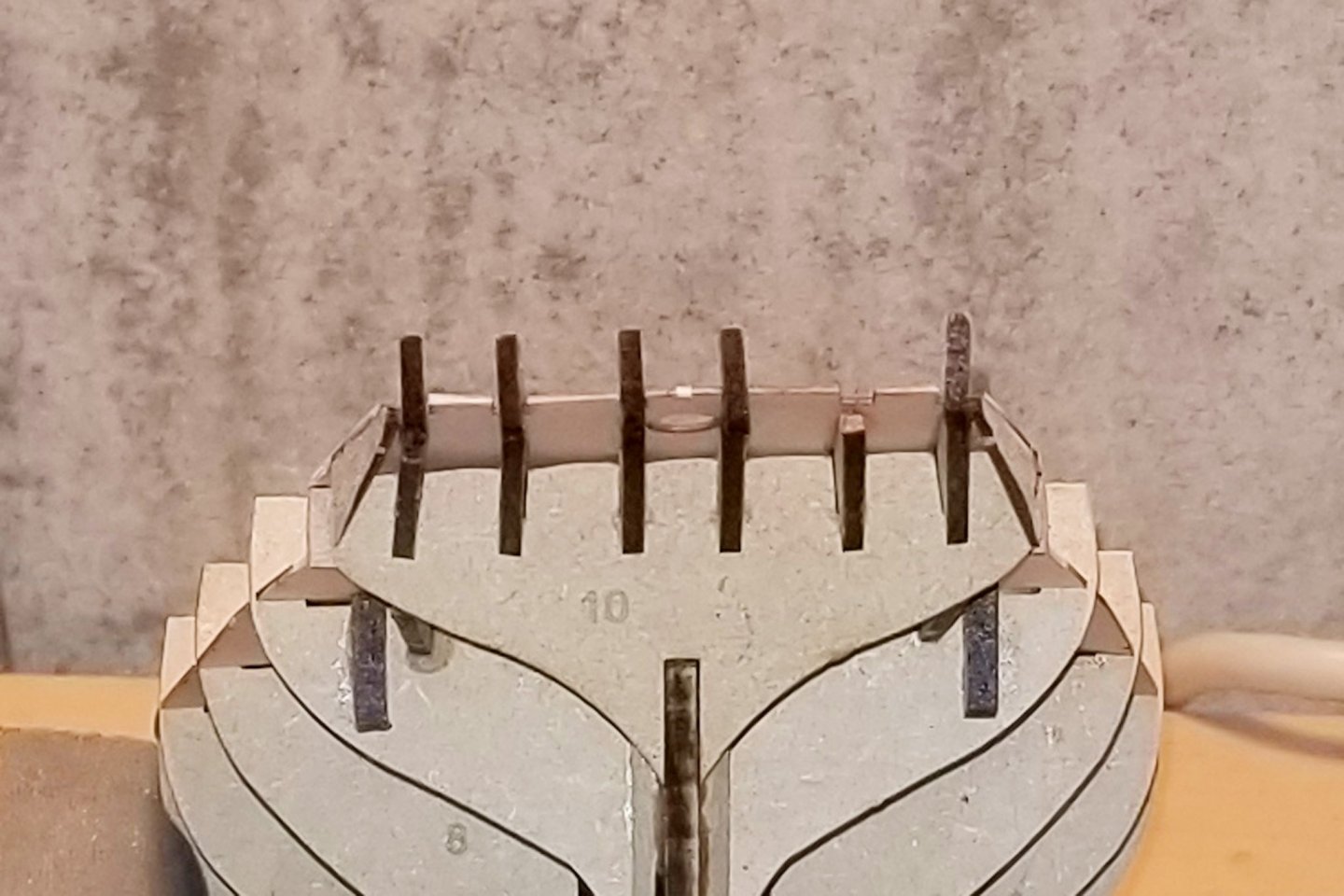

Tree Rail and Timberheads installed and painted. All of the posts have to be sanded down to fit in the slots in the railings. I also found that it's best to install the posts in the top railing one at a time, align the first post and glue it, then trim the rail, then the next post and align that with the slot, glue it to the top, and so on. That way all of the posts align when you finally glue it down to the lower rail. Regards, David

-

Flavia: I left the deck natural and just used clear satin polyurethane varnish. It's a great kit. Enjoy it! Regards, David

-

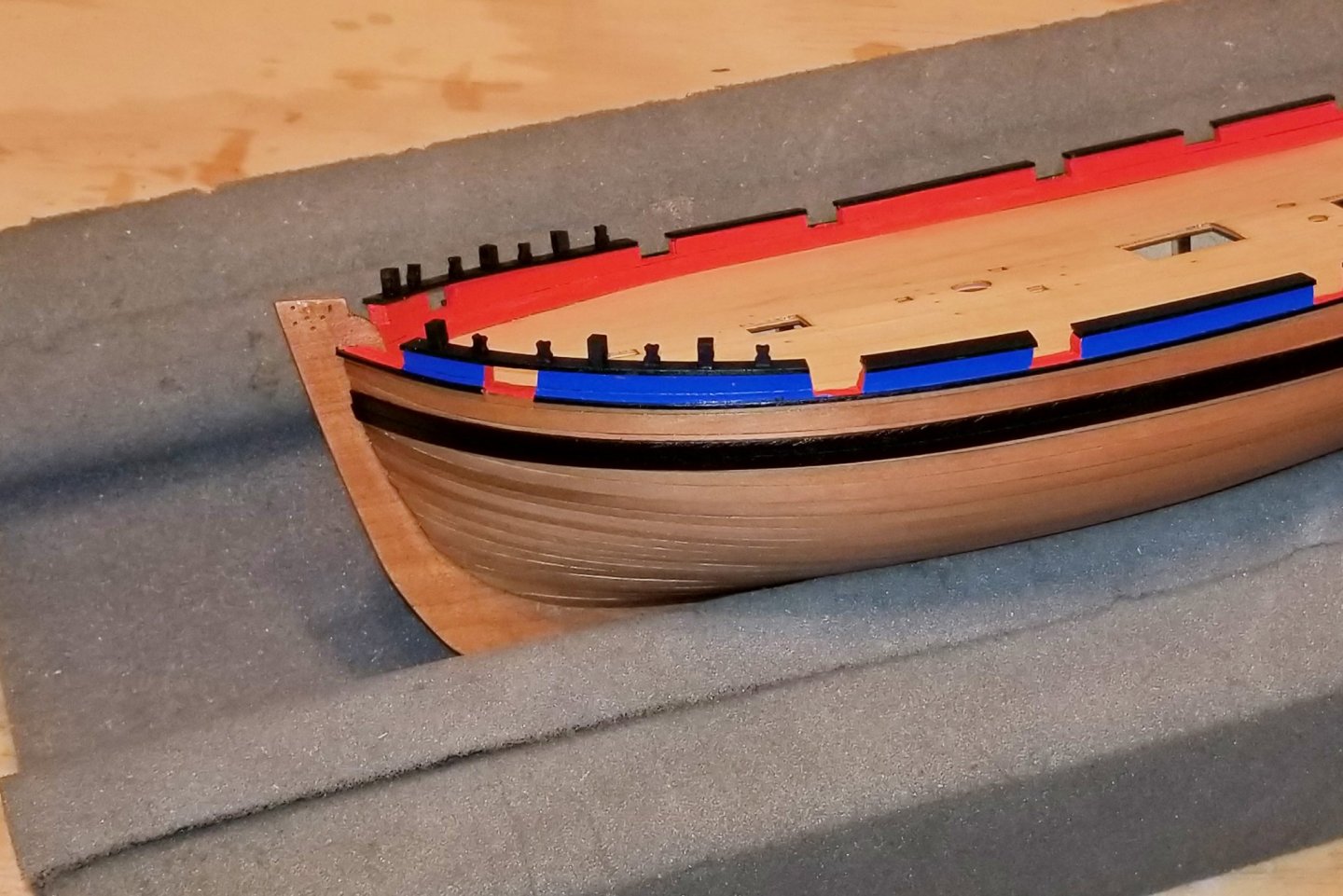

One option when you buy this model is to get a pre-etched deck (so you don't have to plank it), and I took that. In the photos, you can see the deck on the laser-cut sheet, and then mounted on the ship. The manual reads as if you are planking the deck, and it has the side bulwarks planked before deck planking, and then painted red after. When you use the pre-etched deck you really need to plank the bulwarks after you mount it. So you can see that at this point they aren't planked yet. Further, if I paint the side bulwarks after I plank them, I'll need to do a lot of careful masking around a curved bulwark (this is how the manual reads), but what I think I'll do instead is pre-paint the lower planks that run along the deck, which will give a nice finish and obviate the masking.

-

I've filled, sanded and varnished the first planking, and done some work on the stern. The diagonal planks you see at the stern are the pear wood that will be used for the second planking (which is next). As I mentioned earlier, I will probably not paint the hull white as I really like the look of the finished wood. Regards, David

-

Except for the top rail, first planking is done. I experience hull planking as an existential art form. You never quite know what pattern you're going to end up with. This one reflects my continued use of side-bending (with the help of my steamer) until I finally threw in the towel and let the planks run. The result is the most interesting planking pattern I've ended up with to date. Regards, David

-

The upper deck is now mounted. One issue I had is that the rear flanges are very fragile, and before I mounted the deck I set the boat down on its stern and they all snapped off. So I glued them back on, paying attention to the angle, and then glued on the rear deck. One is missing, because I couldn't find it after it snapped off, but I've looked ahead and it won't matter to the build. So that's something to be careful of when building this model. Regards, David

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.