-

Posts

1,061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

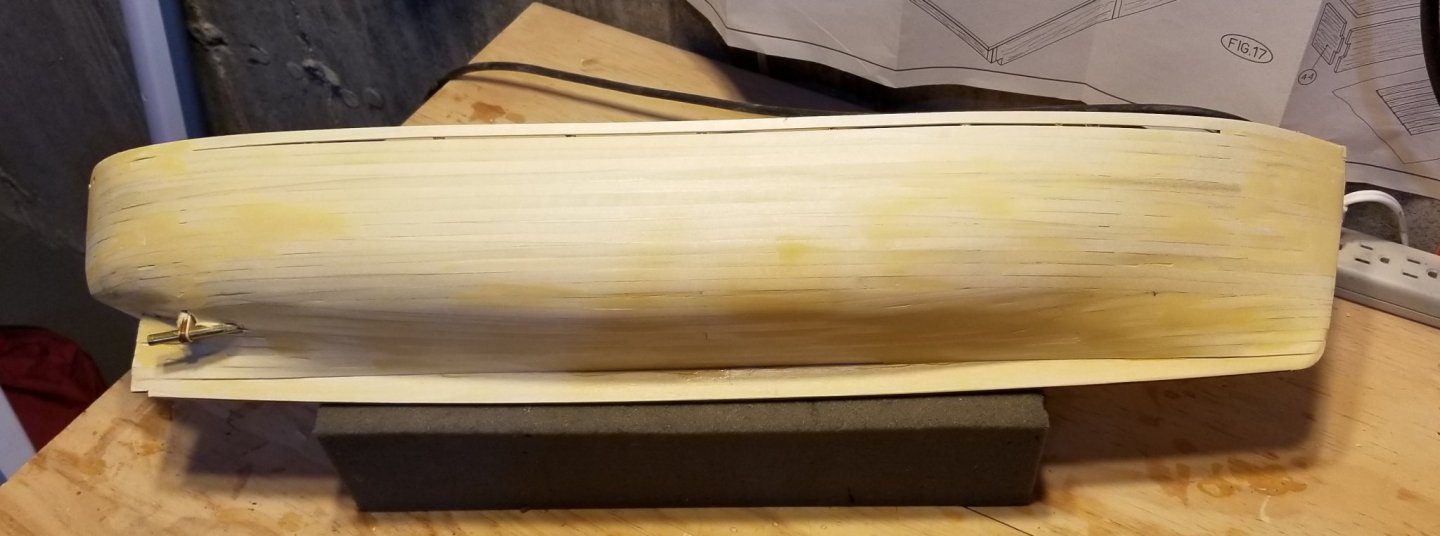

After a couple of weeks away, I have finally finished the first planking. What you see is wood filled, sanded and varnished. Next is second planking, which is the same wood since this hull will be painted. Regards, David

-

Cornish Pirate: As I mentioned in my post, Ages of Sail in California, from whom I bought the kit, always honors shortages and did for me. I know that Mantua UK has a physical shop in Windsor. Since you are in the UK, I wonder if they were the seller of your kit, and if so, you could contact them to make up the shortage. My log might serve as support that the kit is under-supplied. One thing to do is not go by the 2,400 count, but instead measure your "empty" area and calculate what you really need -- might trim the cost if you have to pay. But if https://www.mantuamodel.co.uk/ is where you bought it, they should honor it and make it good. Even if you didn't buy it from them, here's what they say on their website: "Mantua Model UK Ltd was formed in 1997 as part of the Mantua Model group of Italy, one of the largest model manufacturers in the world. Mantua Model manufacture all types of boat, ship, aircraft and car kits, and are renowned for their wooden model ship kits." So according to them, they are part of Mother Mantua -- and therefore I would think they should honor the shortage regardless. Good luck! Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

Robert: Instructions are fine. Materials are OK -- the main thing is not to let the mahogany second planking get too dry and brittle. I used a steamer on it for the bends and found that it did get brittle when it dried. You should buy the finishing kit they recommend -- and use it as recommended. I found that I had to mix small batches of the brush-on as it firms up quickly. The whole point of this boat is the look of the mahogany, so it's all in the finishing. One thing I did was to warm the bottles of finishing goo before mixing them, using a box and a light bulb. Also, you should definitely build a box larger than the boat and use it with a light bulb to cure the finish. Temperature is important and my workroom is cold-ish. Finish the smaller pieces of mahogany and then mount them. I tried to keep a good log, so you can see some of what I did in the log. Regards, David

- 49 replies

-

- dumas

- Chris-Craft

-

(and 2 more)

Tagged with:

-

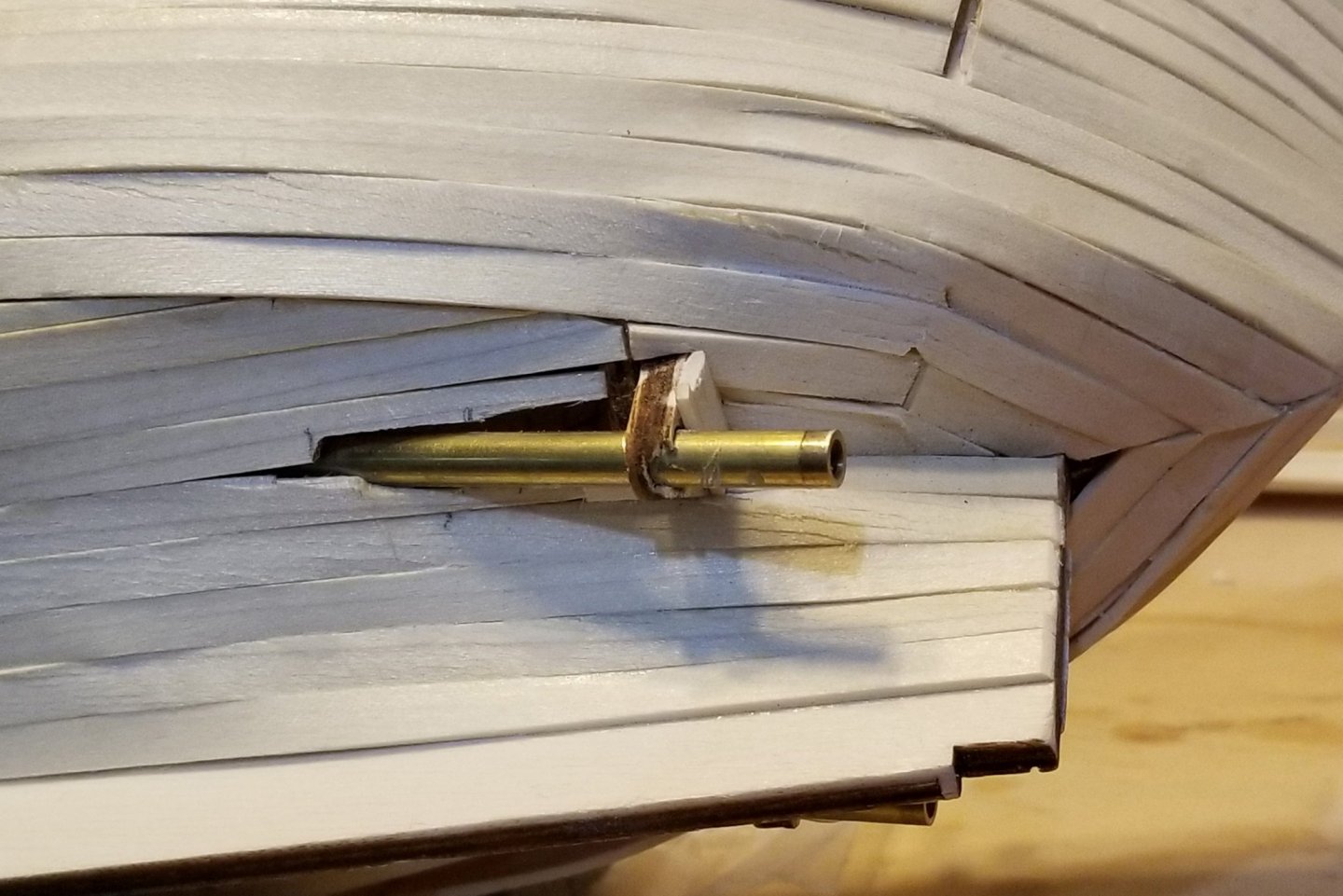

Working the first planking around the prop shafts. It's basically an improvizational act, and what I did was to create a "floor" of short planks on top of which I could mount the first planks under the shaft. What you see in the finished picture will be dressed with a housing over the prop shaft to hide the rough area where it enters the hull. That goes on after the second planking. I am about to go away for a couple of weeks, so won't fill and sand this until I get back. Regards, David

-

I use a steamer when I'm planking, which gives these basswood planks a lot of flex. I had too much bulge at the stern, so to adjust it I did the following as shown in the picture: Used a rotary cutter to make a shallow "V" so that I could bend the whole structure down Installed the next plank, steamed the "V" area, and then used reinforcing ribs behind to attach the "V" area to that next plank Installed a short length of planking behind the "V" to hold the wood filler I'll need. Then all of this will be sanded down and filled with wood filler to smooth it out. Fortunately, it's the first layer which is more forgiving. I think I'll follow the "run of the planks" on the second layer vs. steaming to bend them. Regards, David

-

Klaasvg: If you look above to the picture from Puctored, it shows the shape of the bow with the original uncorrected frames. At the end of this log or in my gallery pictures of the Titanic, you'll see my bow and can decide if the difference is worth it to you. If it is, then if you go backwards in time from the post I referenced above, near to the beginning of this log, you'll see how I used laminated strips to correct the frames. I suspect you could try that on the frames you have mounted -- but looking at Puctored's picture above, I doubt that it would be worth it. I'd just go ahead and use the frames you have. It's certainly NOT critical. You may need to soak the first layer planks to get them to bend at the point where it narrows. Regards, David

-

Klaasvg: Not sure from here, but it looks like you need to taper your bulkheads a bit more. Use a sanding block or sandpaper on a block of wood -- or you can use a Dremel rotary sanding drum if you take it carefully and check. When I do mine, I take a piece of planking and lay it flat at the center of the boat (no glue), then bend it around to see how it lies, and then take the bulkheads down on gradually increasing angles, checking my work with the dry plank as I go until it aligns and there is a good flat fit with the angled bulkheads. Hope this helps. Regards, David

-

Klaasvg: OK, I looked back in my Titanic log and remembered how this ship is planked, and I think we've been miscommunicating. The section of the manual you are referring to deals with the FIRST layer of planking. For those, when I needed to taper, I used a planking vise. Marked the start and end of the cut and then put it in the vise that way and ran a knife along the vise. If you don't have a vise but you do have a steel ruler, you can use that and run the Stanley knife along the ruler -- you just have to keep it from slipping, which is harder on long cuts. Clamping the ruler onto the strip can help. The scissors part refers to the second layer, which really isn't a "layer' but is strips cut out of the large piece of thin board. You paste the template onto the board (I used Gorilla spray rubber cement), and then use sharp office or kitchen shears to cut the strips out. To see my first planking, go back to my October 20, 2018 entry in this log, and then follow from there to see how the second layer strips go on. Regards, David

-

Rick: I don't think so -- but what might have helped is if I had started at the king plank and worked outward, vs. the other way. But that would have required some heavier work at the edges of the deck, and some real planning to get the starting angles right. Regards, David

-

Deck planking now finished. For those of you following the "alignment" saga on port & starboard sides, I have some close ups. At the bow, I was only able to maintain it (barely) by using stealers, and you can see them in the close-up. At the stern, it's aligned at the very stern -- but that will be covered. Moving toward midships, the alignment falls off and I couldn't maintain it. The issue is the angle at which the basswood planks hit the centerline. That angle determines the width of the butted edge, and if the angle coming in on the second side you plank is slightly different (which is almost inevitable, I think), you can't maintain alignment. Ah well, I'm happy with the end result. Regards, David

-

Started the deck planking. Nice pattern of alternating wide basswood and narrow walnut, with curve following the line of the boat. Will look nice when sanded and finished. The rough spot at the stern will fortunately be covered. Now the trick will be to get the other side lined up exactly with this one where it butts at the center line. Regards, David

-

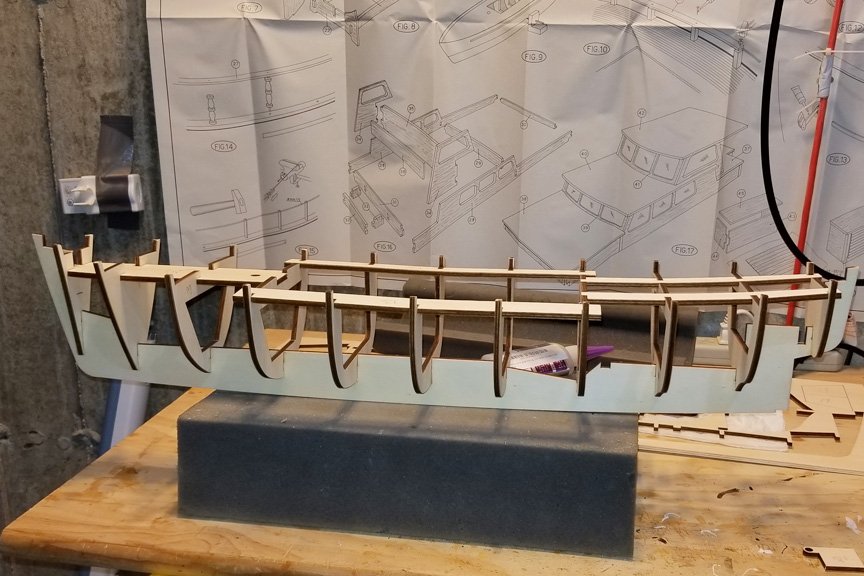

Here's the hull frame. Goes together nicely and a good fit all around. The frames and keel are plywood -- I prefer MDF (Amati uses it) as it's more rigid. Regards, David

-

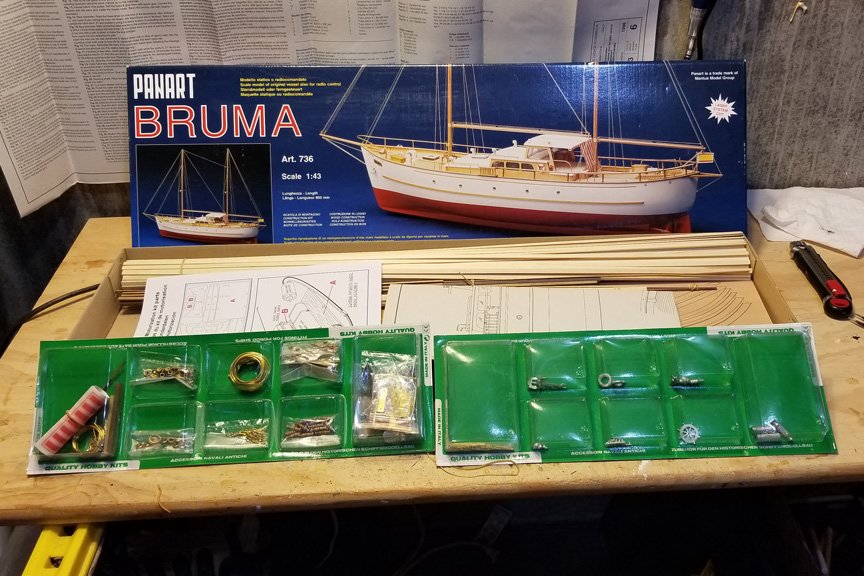

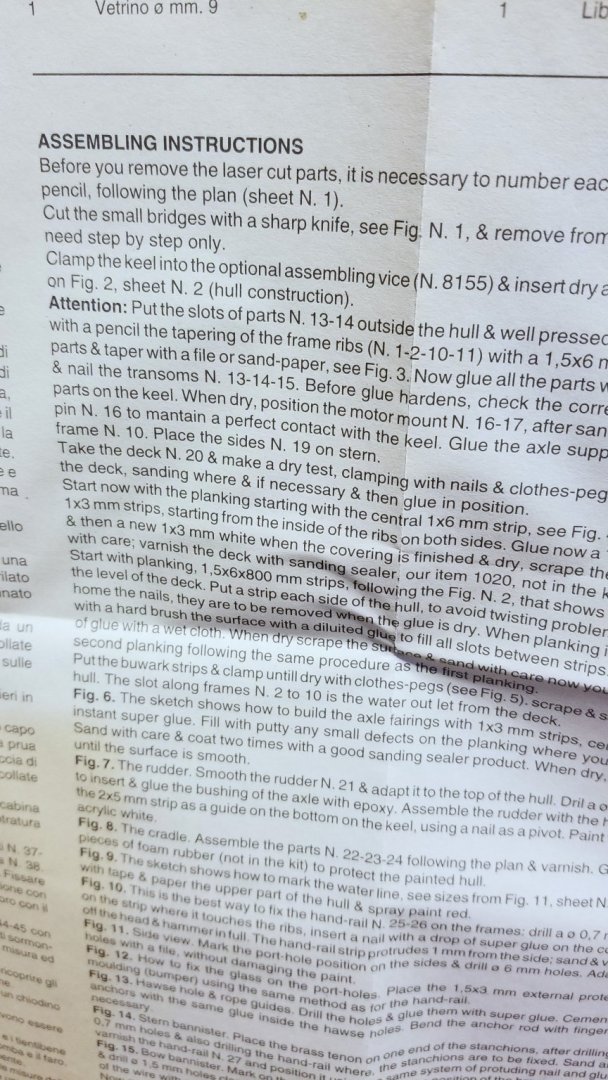

I'm starting the Bruma, which I chose to give me something hopefully less complex and long than the Cutty Sark. Here are some "What's In the Box" Pics. It's wood, laser cut sheets, some fittings, and plan sheets. The instructions are printed on the back of one of the plan sheets (in several languages). The English instructions are about one column length, including the parts list. What I'm going to do is scan them so I can print them out and still be able to use the other side of the plan sheet. Regards, David

-

Henrik: Thanks very much. Up next, I'll be building the Mantua Bruma, which I picked to give me a bit of a complexity break. Then after that, the Kolderstok Batavia, which I picked because of its beautiful painted colors. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

COMPLETED! A set of completion photos are in the gallery at https://modelshipworld.com/gallery/album/2021-cutty-sark-by-drobinson02199-mantuasergal-scale-178/ I enjoyed this -- my longest build at about 7 months. As I noted above, I'm generally happy with the kit, but would caution others about multiple parts shortages -- copper plates, certain blocks. I got around it with spares from my stash. I was also disappointed with the flag, which is printed on one side only. So I didn't use it. But other than that, it's a nice kit. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

Bender: I've been happy with this kit, although it's not without its drawbacks. The wood and materials quality is fine. My major complaint is that there have been items where Mantua didn't supply enough in the kit -- more than one case. The biggest issue was copper plates, so be sure to get matching spares from whoever you get the kit from. I'd say 300-400 extra, which Ages of Sail sent me gratis. For other items (some blocks, chain) fortunately I have a leftovers stock from other builds that has backed me up. I would also say that the plan sheets are sometimes ambiguous and I had to study them carefully to figure out where something should go. I haven't looked at other models or build logs of other Cutty Sark models so I don't have a basis of comparison. But I've built two Amati rigged ships (Revenge and Fly), and while the Amati quality is better, I have no complaints about this kit. It has a nice natural wood coloration at the deck level. There is no sail plan included, but you can buy one from the National Maritime Museum (I bought the deck and rigging plans and didn't find them of much value to me). Here's a link to the sail plan https://shop.rmg.co.uk/collections/cutty-sark-gifts/products/cutty-sark-sail-plan-50-x-70cm Interestingly, when I was in college (1960s) my roommate built the plastic model, and I thought it looked nice for a plastic one. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

The yard lifts are all done now (see picture). The other picture shows the first piece of rigging on the foremast lower yard. I'm now going to get into the yard braces, and I have looked at the rigging diagram and concluded that the best sequence for braces to preserve ease of access for rigging is: Do the top three yard braces on the main mast next. Then do all of the yard braces on the mizzen. Then the top two yard braces on the foremast. Then rig the inner brace on the main mast lower yard (matches the one I've done on the foremast lower shown below) Then rig the three lower yard braces on the foremast Finally, rig the three lower yard braces on the main mast. If I do it that way, I hopefully will minimize contortionist activity getting "inside" rigging already installed. Getting close to the end now. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

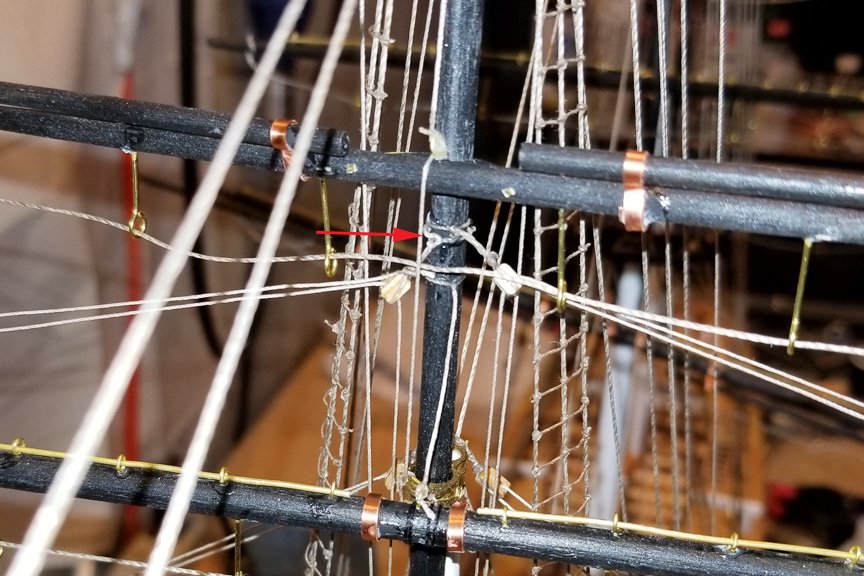

I'm in the process of rigging all of the yard lifts -- the ones that run from the mast to the tip of the yard (because all of the yards also have simple vertical lifts as well). The bottom two yards are attached to the mast by a hinge, so they can take the upward force of the lifts. But the other yards slide up and down, so without doing something it wouldn't be possible to tension the yard lifts to get each yard to be horizontally lined up. Solution was to install a small vertical yard downpull starting with the third yard on the foremast. Pictures attached show the first three foremast yards with the lifts rigged, and the small vertical downpull (marked with an arrow) that I used on the third yard up to create something for the yard lifts to pull against. I'll be installing the lifts on all the yards on all the masts before turning to the other running rigging. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

Mike: Your experience with Amati on parts is different from mine -- on all my Amati kits I have had a lot of leftovers in terms of wood, blocks, rope, etc. Now my Mantua Cutty Sark is a different story -- I have had to dip into my "stash" lots of times. Regards, David

-

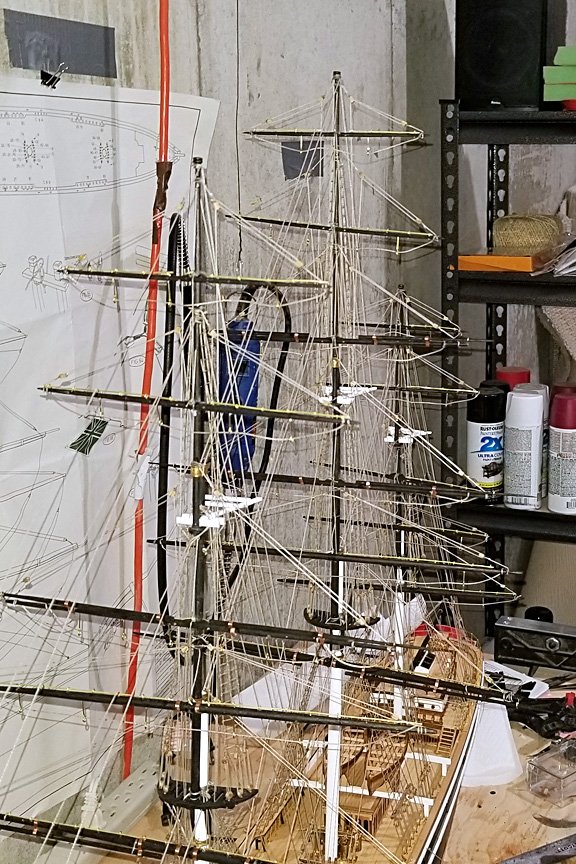

I've now hung all the yards (all 19 of them!) and have begun rigging with the three spars on the main and mizzen. All shown below. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

Mike: I'm glad the log was helpful to you. I really enjoyed this kit -- and in fact have enjoyed everything I've built from Amati. The quality is really first class in their kits. On the Titanic box, it says "museum quality", and if you don't mess it up, that's what you get. I have seen some members refer to the group of those who have built a Swan class ship (either Pegasus or Fly). Maybe we can be the start of the group that has built the Titanic.

-

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.