-

Posts

1,735 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by flying_dutchman2

-

Jack, Thank you very much for the information. So, it looks like I need more items to do the one decal? The stuff I got from DecalGear is not enough? Adding decals is presently an art with add-ons. In the old days it was luke warm water, place decal and I used hairspray as bonder and cover. (I know I sound like an old man). I found the website from Microscale and will probably order the 4 items Jack mentions. Then I should be set, I hope. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

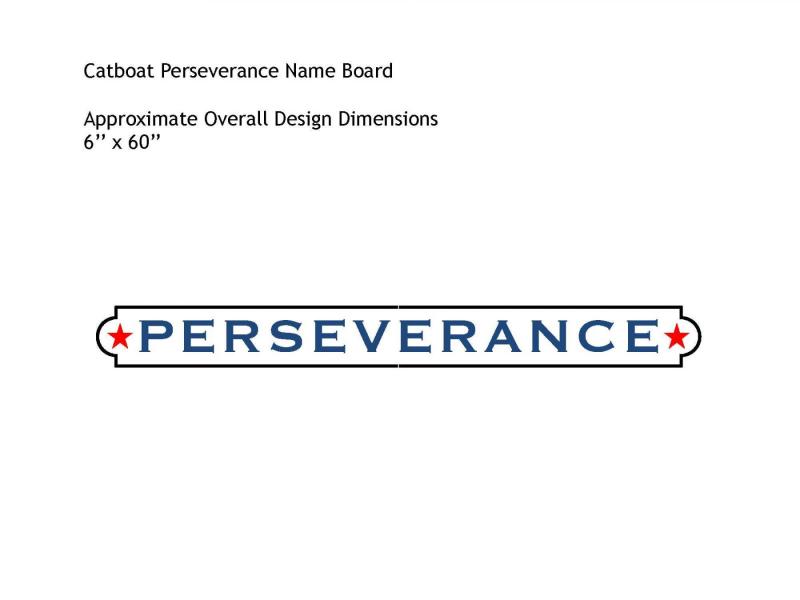

Good Morning. I have several questions: 1. - My brother-in-law mentions in an email that the name board with the word 'perseverance' goes on the 'aft combing'. I am assuming in the picture below where I have the word Perseverance, is the aft combing. Is this correct? Question for Jack and Popeye. 2. - I got the Decal-Gear (CD, decal paper & Bounder) in my possession and I have the following question. Will the decal adhere to painted wood? Will the decal adhere to a thin sheet of wood veneer? My plan is to create a name board from 1/64 Baltic Birch ply-wood and put the decal on that with the bonding material. I appreciate everyone's input. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Kees, The details on this boat of yours are amazing. You're thinking of everything that belongs on this boat. Excellent job. Marcus

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Nils, Caught up with your built...... WOW amazing details and as Cog said 'crisp'. He is right on that one. One word, AWESOME Marcus

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

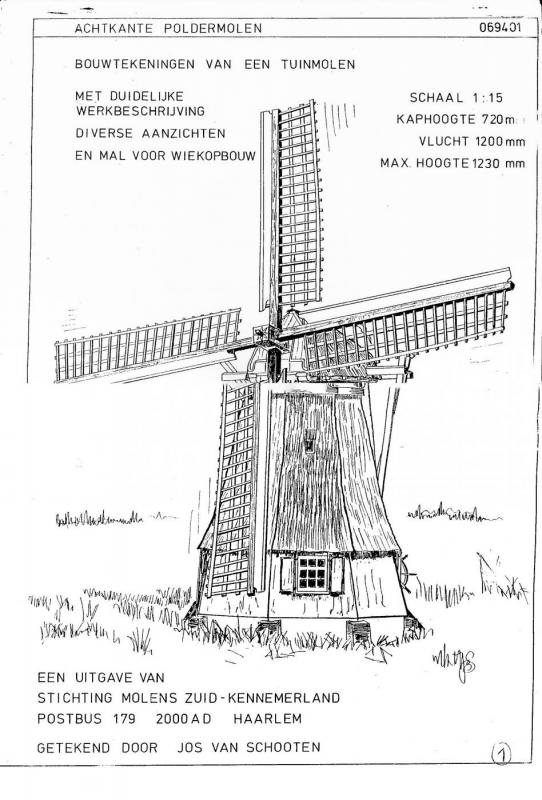

Carl; Below is a scan (A3 format) from the windmill with information. There are 23 pgs. of plans and 1page of materials and 17 pages of how to build it. The plans are to scale so trace, glue on wood and cut out. The scan is in Dutch and describes the measurements of the mill and scale, as well as the address where it was printed, the architect and what it all includes. I know this is a bit off-topic but wind mills have sails as well. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

I have salvaged a lot of computer parts over the years and the heat sinks are another form of paper weights. What is left is one decal "Perseverance" on the name board and I need to make a burgee. Once completed I will send email and pictures to my sister & brother-in-law mentioning about a display case from Bluejacket. Once the case without the Plexiglas gets send to me I will get the Plexiglas, install in the case, put it all together and pack it for shipping. The will tell me where I need to send it to. Then on to working on the Utrecht. But I was reading a thesis from a person at Leiden University about the history of Dutch pleasure yachts. In here she mentioned a Pleasure yacht (Plezier jacht) from the 17th century. The NVM which is the Dutch Society of Model builders has plans of such a boat. ................Delima......... Then last but not least, when my dad retired from the Dutch Foreign Service he volunteered as an administrator/touristhelper for the Dutch Windmill Society. Just before he left he gave me plans from a windmill (Polder Molen 1600). It stands about 4 ft high and it is a do-able project. Depending how much detail you want to add to the mill, you can make it work and if you get a round grinding stone you can even mill grains. Oh yes, my wife gave me the Micro-Mark table saw for Christmas and with it a list of items she wants me to build. Our birdfeeder is falling apart so she wants me to take the measurements and re-make it. Lots of options. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

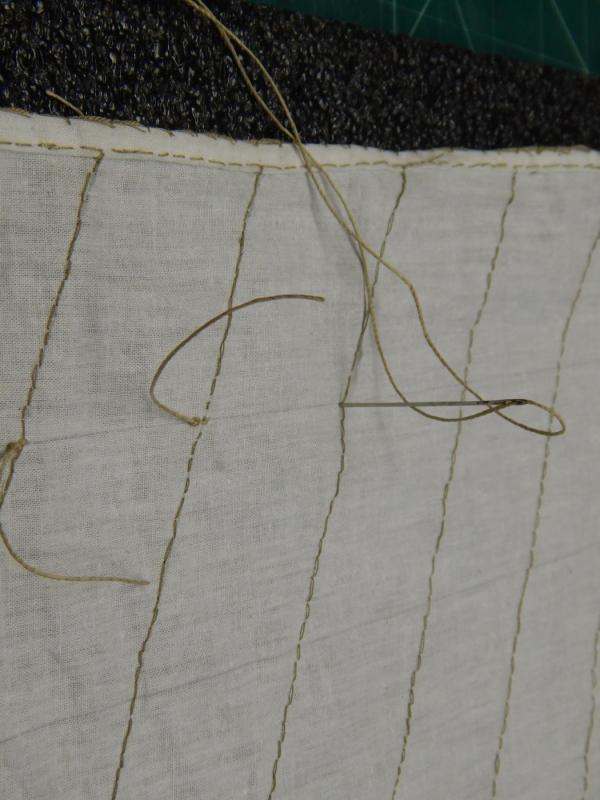

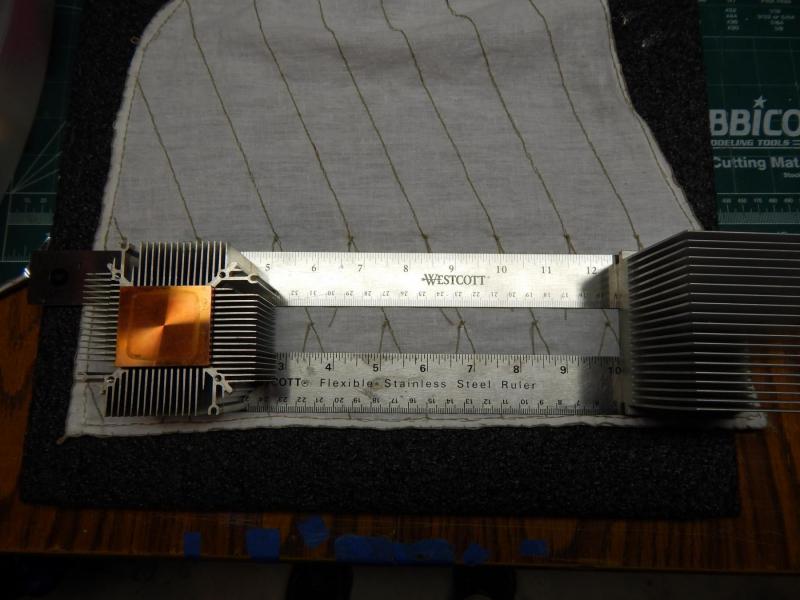

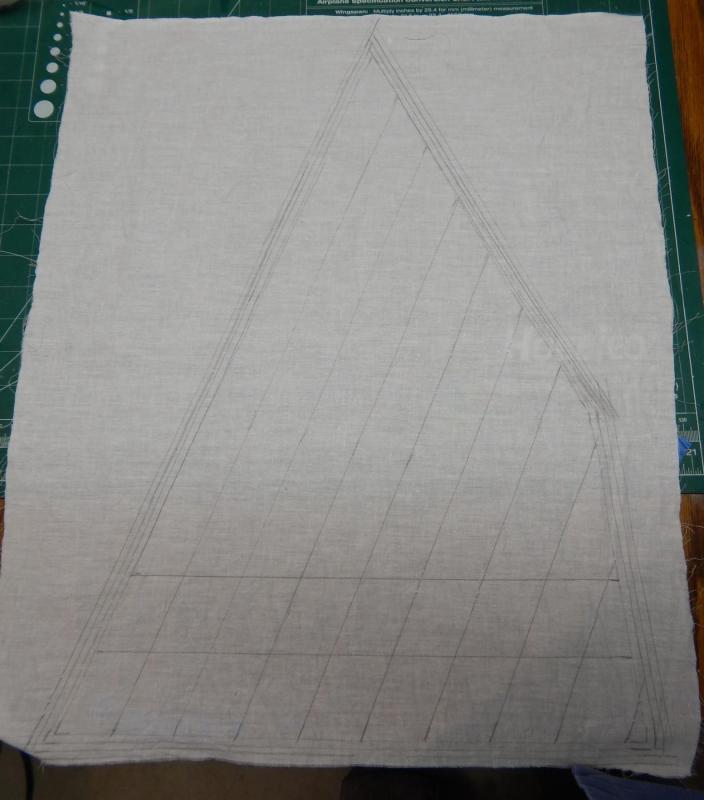

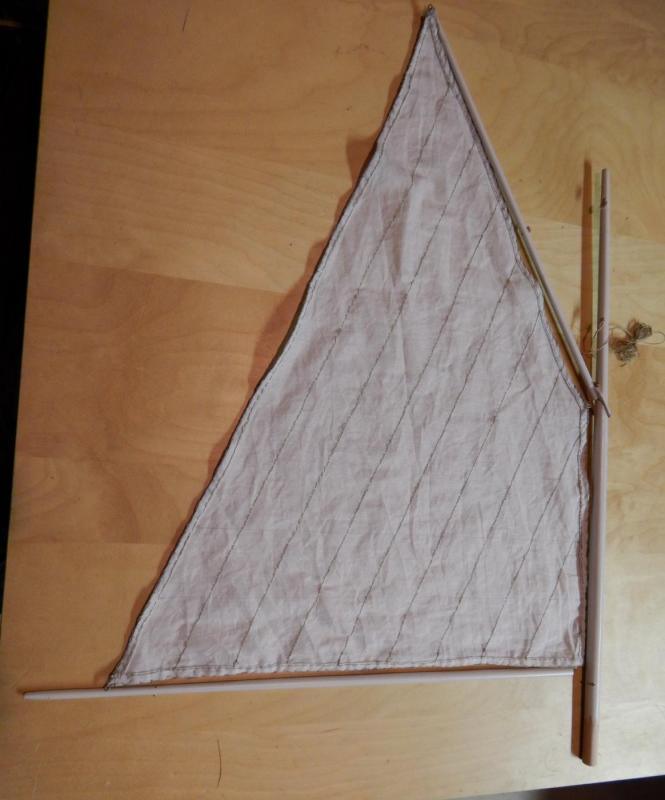

I went to the decal site and purchased the CD, paper and bonder. Will get it this week. The rigging is loosely added to the mast, boom and gaff. Nothing is permanent. The little blocks is to make sure that the mast is at a 90 degree angle to the deck Sewing the reef lines into the sail. After all the lines are installed, they are moistened with diluted white Elmer's glue and straightened out with clamps. The sail is pinned to the foam and the clamps which are attached to the lines keep the lines straight until the glue dries. Some reef lines refuse to straighten out so by laying the sail flat on the foam, a ruler for each reef line row is weighted down by computer heat sinks (Hey Gary, another material procurement) Attached all corners of the sail with string to there designated area so it will be easier for me to attach the sail to the mast hoops, boom and gaff.3 Almost done.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

CaptainSteve, Jack12477 and Popeye Thank you very much for the information. Jack and Popeye: I checked decalgear.com and for under $20.00 I can have the SureThing Decal Maker: Standard Edition CD, Testors Decal Bonder and some Decal paper............... Did I read that correctly? Looks pretty cool. Thanks, Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

So decal-it is a pc program? Where do you buy the decal paper and the decal bonder? or just give me link and I'll look it up. Thanks a bunch Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

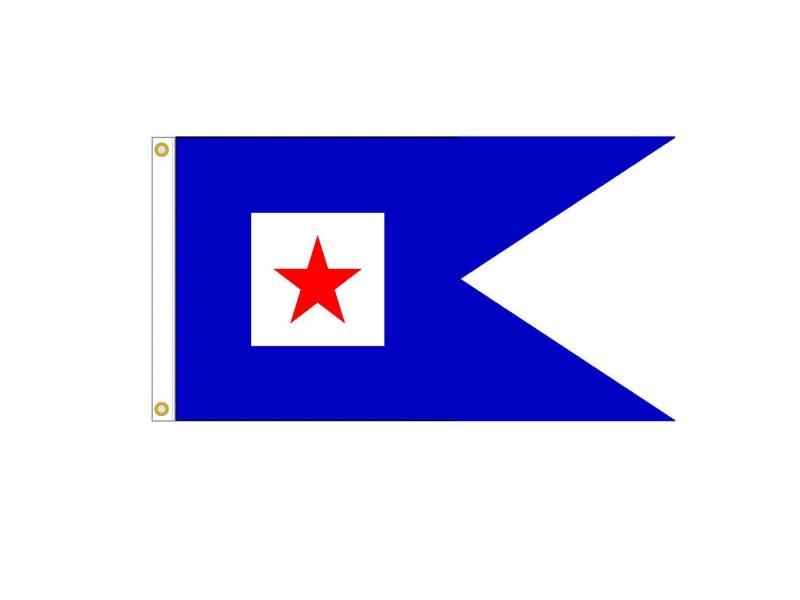

This is something I will do. The flag I will do by a method from Gus Augustin, member of our tri-club and a well known modeler.Post 51 on this page http://modelshipworld.com/index.php/topic/4294-the-first-royal-dutch-yacht-mary-by-marcus-botanicus-finished-mamoli-1646/page-3?hl=yacht mary Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

As of the last post I am ahead. Cleaned up my mistake and learned from it. The boat is pretty much finished and all that is needed is the mast, boom and gaff with the sail. I need to make a burgee (little flag) and the name 'PERSEVERANCE' on a name board. I have no letters so I am thinking (MS Word, required font and printer). Except if anyone has a better idea, I would like to hear about this. Thanks Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Ian; I just magnified your picture and I see how you did this. Thanks

- 86 replies

-

Ian; Presently rigging my cat and I do have a question as I do not understand the description in the plan. Looking at the plan towards the top of the mast there are 3 dots below each other and the description on the plan says, "Topping lift fairlead left side of the mast". I understand that the rope is from the end of the boom and goes up to the mast. What I do not understand is how the rope is attached to the mast. Is it through a hole in the mast? Do you make some kind of eyelet? I cannot make it out from your pictures (post 67, 72, 76). Thank you in advance. Marcus

- 86 replies

-

Thanks. Did 2 light coats of paint and she looks good again. Due to the bitter cold I have both paint can and boat in the warm basement. Then I go outside holding the boat in one hand and spray painting light coats on the boat with the other hand. Run inside before my face freezes off. Let her dry in the garage which is still cold and after about an hour bring paint can and boat back in the basement. Here I will let her dry for 2 to 3 days. I also learned that painting is something that needs to be learned. Eventually I will get the knack of it. Another part of the hobby. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

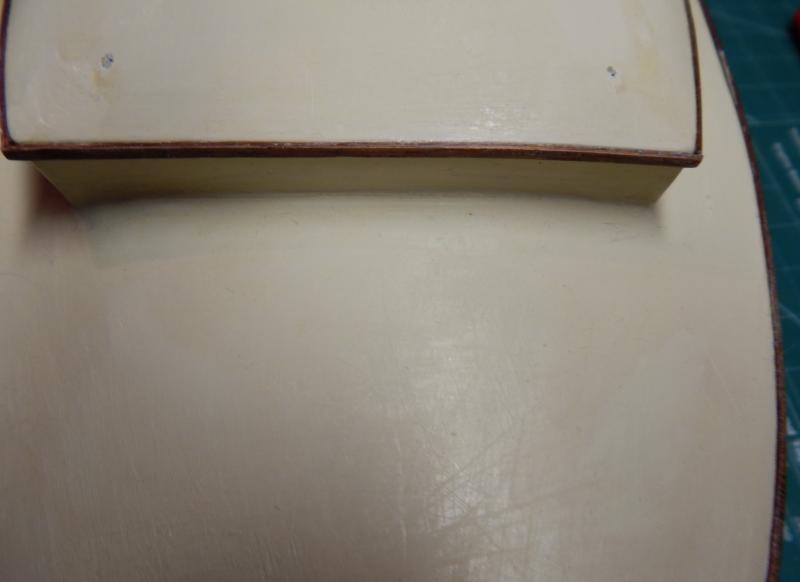

SCREW-UP I put a light coat of polyurethane on the paint and it dried blemished. Then tried the touch ups and that went wrong. So as I mentioned before, stripped the boat of all the trim and hardware and about an hour ago spray painted the first coat. On this picture you can see it good. Ready for painting. What did I learn? Once paint is completed NO polyurethane except the wood work. Redoing the hardware and the trim will be easy as I have done this already. The display stand is ready. The items that still need to be made is a name plate with the word 'perseverance' and a burgee with the Prince Edward Island crest. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Finished mast hoops. Sail marked with light pencil. Sail completed but not attached to mast, boom and gaff. Dry fit. Boomer the cat in the box. Not on the warm mat next to it, no, in the cold box.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

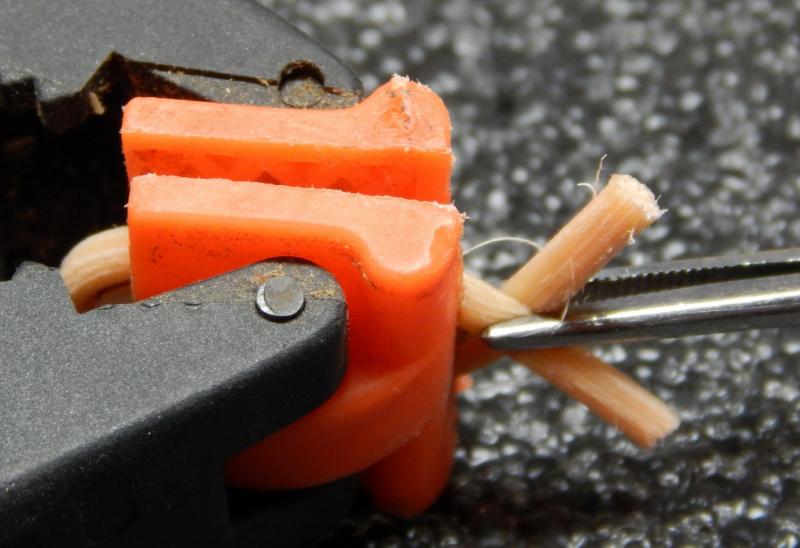

When the trim was all done. Very happy with the results. The cabin windows get trim as well made from the same material as the mast hoops. Used a window cut-out as form. Wrapped the wet canning around the form. Held it in place with a large clamp and the ends that cross over each other with a hemostat.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

I made a colossal mistake @#$Getverderrie%^&* I yelled all the Dutch swear words I knew...........................Didn't trash the boat. I was touching up some paint and a piece of paper towel ended up sticking to the paint. Took it off and left the threads on the deck. Tried to take that off and it left scratch marks. Tried to sand that off and sanded some of the trim and it got worse and worse (Always does) AAARRRRGGGGHHHHHHHHHHHHHHHHH So I stripped the boat of all its trim, and hardware, sanded it down, covered the left over trim with tape and masked the bottom and keel (rust red). Now it is ready for a RE-DO paint job. I did take pictures. Didn't want to as I want to forget this, but it needs to be learned. Runs of in a corner and cries.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

I received the table saw from Micro Mark for Christmas and I am very pleased with it. I am looking for the download of Jeff's (Hobbymill) saw operation pdf guide. Does anyone have it or give me a link to it? I've done some different Google searches but nothing comes up. Mark Taylor suggested that I should look at the blades from Thurston (which I will do). Thank you. Marcus

-

The German Nautical Journal, 'Das Logbuch' has a very detailed article on carving a ship's stern. Even if you don't read German, the detailed pictures are worth a look. Several pictures show what tools are used for the type of carving. If you mouse over the pictures you can click on them to enlarge them. http://www.arbeitskreis-historischer-schiffbau.de/mitglieder/themen/schnitzkurs-1/ Marcus

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.