-

Posts

6,705 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

removing ca glued rigging

Keith Black replied to Lost and Confused's topic in Masting, rigging and sails

If you don't enjoy tying clove hitches like some folks I know there's the weaving method which I used and like a lot. -

Gareth, welcome to MSW. Love your humor, you'll fit right in. Glad to have you aboard.

-

Mikj, welcome to MSW. Glad to have you aboard.

-

Billy has buckets on the port side! I still need to make the rim frame. I'll choose between thread, wood, or wire depending on which looks the best. The holes are drilled in the outside edges of the buckets and I tested pulling thread through them and that works just fine. I was able to use basswood for the buckets. The two hub assemblies are joined with a 0.088" piece of dowel acting as the outside axel cut to 0.10" length and drilled through the center with a 0.025 drill. An outside axel is necessary because the wheels can not be tipped into place. The wheel has to be placed into position and the inside axel (22 GA wire) run through an eye (pillow block) and then through the wheels outside axel. I wish I could say I made an incredible jig to aid in attaching the buckets to the spokes but nope, fiddly fingertip work as per my usual. The wheel is very raw and needs lots of work before paint. I also need to go ahead and weather the wheel arches because on the wheel is installed reaching in to weather will be impossible. The starboard hubs are assembled and ready for the buckets. I won't be able to get back to serious building till Thursday. Thank you guys for your support and for following along. Keith

-

A neat way to run line to a belay pin is to remove the belay pin, run the line through the belay pin hole, insert the belay pin and then wrap. This makes the line taut and allows the line to be wrapped around the belay pin with ease.

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

I'm sorry you've got to put a stop to her, Bob. Instead of immediately jumping into Vasa why don't you kickback in your easy chair for at least a couple of days and watch TV and take lots of naps.

- 73 replies

-

- Steam Cutter

- Harriet Lane

-

(and 2 more)

Tagged with:

-

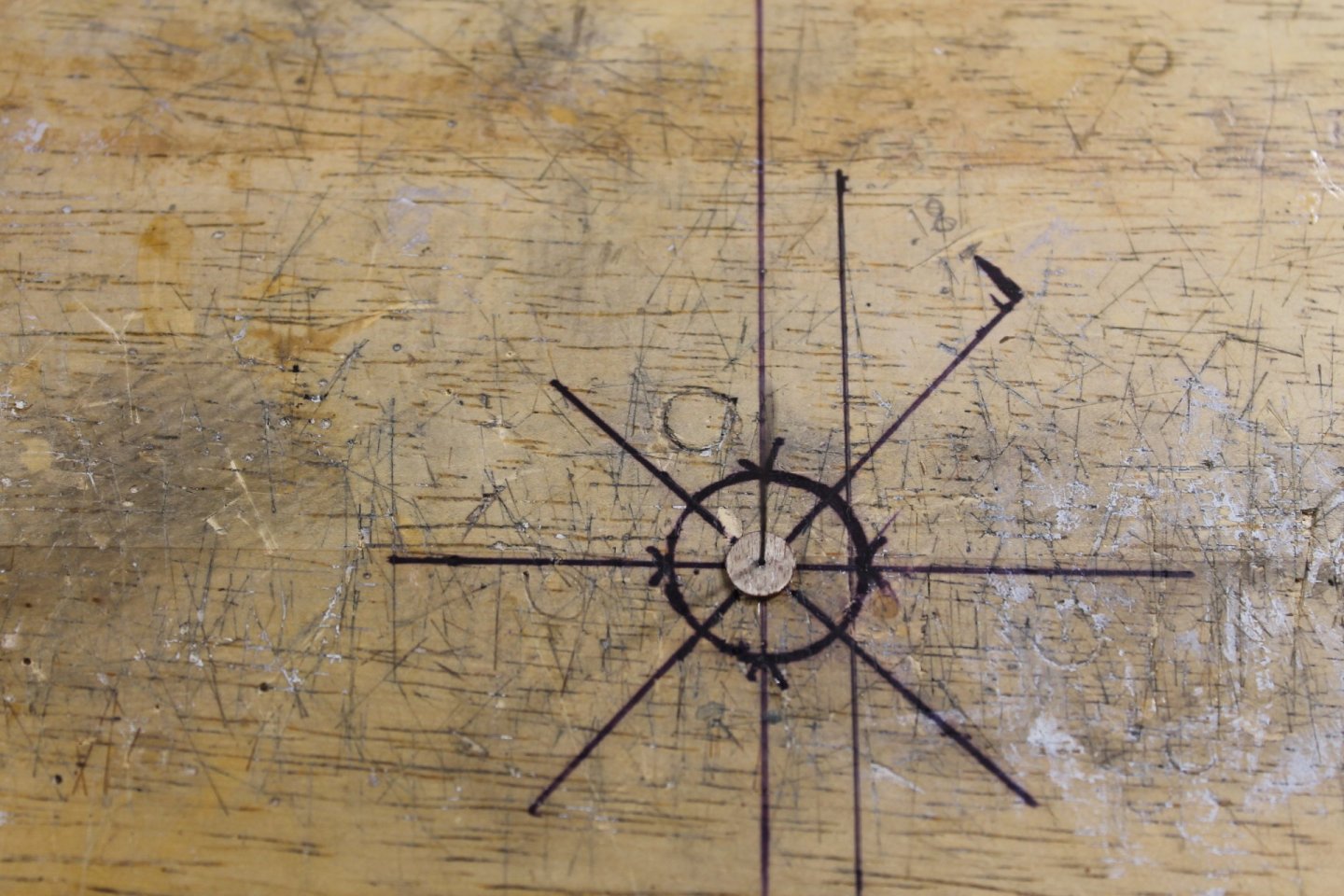

Thank you to everyone for the likes and the comments. The original Billy's wheels were twelve spoked, because of the small amount of gluing area I can only make eight spoke wheels. Using eight spoke wheels on waterline models is easier to fit than twelve spokes so the eight spoke wheels work out well. The hubs are 0.26" in diameter and are cut from 1/64 inch birch ply with a hole punch. As close to the hubs center as possible a hole is drilled. My working templet is drawn on my worktable with the same size hole drilled at the center point. All corresponding work is done in relationship the worktable hole so if the hub hole is a little off center it won't matter other than looks. To the right of the main vertical line is the cutoff line for the spoke lengths. From the worktable hole center tom the cutoff line is 0.35" for a 0.70" total spoke length. The first step is to place a 24 GA piece of wire through the hub into the worktable center hole and then the hub is glued (CA) on one edge to the worktable. All the 0.037" basswood spokes are glued to the hub. The hub and spoke assembly is freed from the worktable and both sides sanded to remove excess CA. The worktable center is scraped clean with an X-Acto chisel blade. The next step is to pin the hub and spoke assembly the the worktable center hole where it rotates freely and the each spoke is rotated into position at the cutoff line and trimmed to length with an X-Acto chisel blade. All spokes cut to length. This completes this part of the process which is pretty easy peasy. Making and attaching the buckets will be the hard part. I think I'll have to make the buckets from the 1/64 inch ply because a hole has to be drilled at each end to make the outside edge brace. The most desirable would be to use 0.10" x 0.037" basswood for the buckets but holes drilled close the edge of basswood have a tendency to breakout even when CA is applied to the edge before drilling. Even though thinner the ply allows holes to be drilled close to the edge without breakout. A little peak at what Billy is gonna look like with wheels with just one hub and spoke assembly in place, very exciting to get to this point. And a look at the dummy stack stays after applying "my" gunmetal acrylic craft paint mixture of silver and wrought iron. I don't know if one can tell if it looks like gunmetal but It doesn't look like Christmas tree lights anymore. Every now and then a sparkle of the silver metallic thread can be seen which looks like when the sun glints off metal. Thank you for your support and for being part of the journey. Keith

-

The Harriet Lane is looking great, Bob but more importantly is your health. Praying for your full recovery.

- 73 replies

-

- Steam Cutter

- Harriet Lane

-

(and 2 more)

Tagged with:

-

Thank you,Keith. I missed pilot Keith's message, I need to go back though your Erebus log. I'd love to do a gun metal wash..........what material/paint would I use? Birchwood Casey would just make look black, I think? I've got some wrought iron craft paint I think I'll whip up a thin wash and test it on some scrape thread. Thank you. Bob. I really like the way the metallic thread resembles stranded cable, I think it looks more so than braided but I can see where it could resemble braided cable as well. Ahh, another use, thanks, Bob.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.