-

Posts

6,705 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

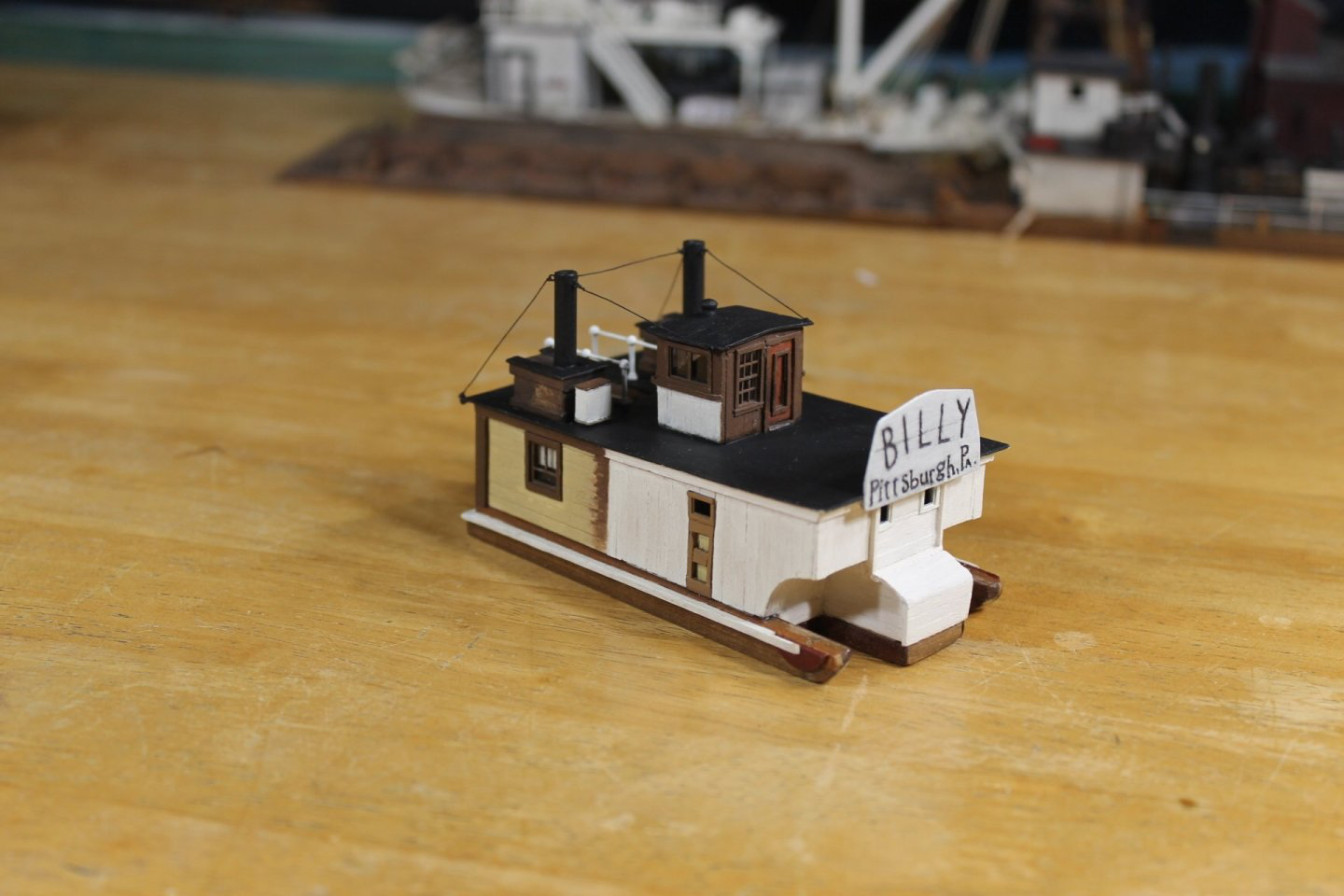

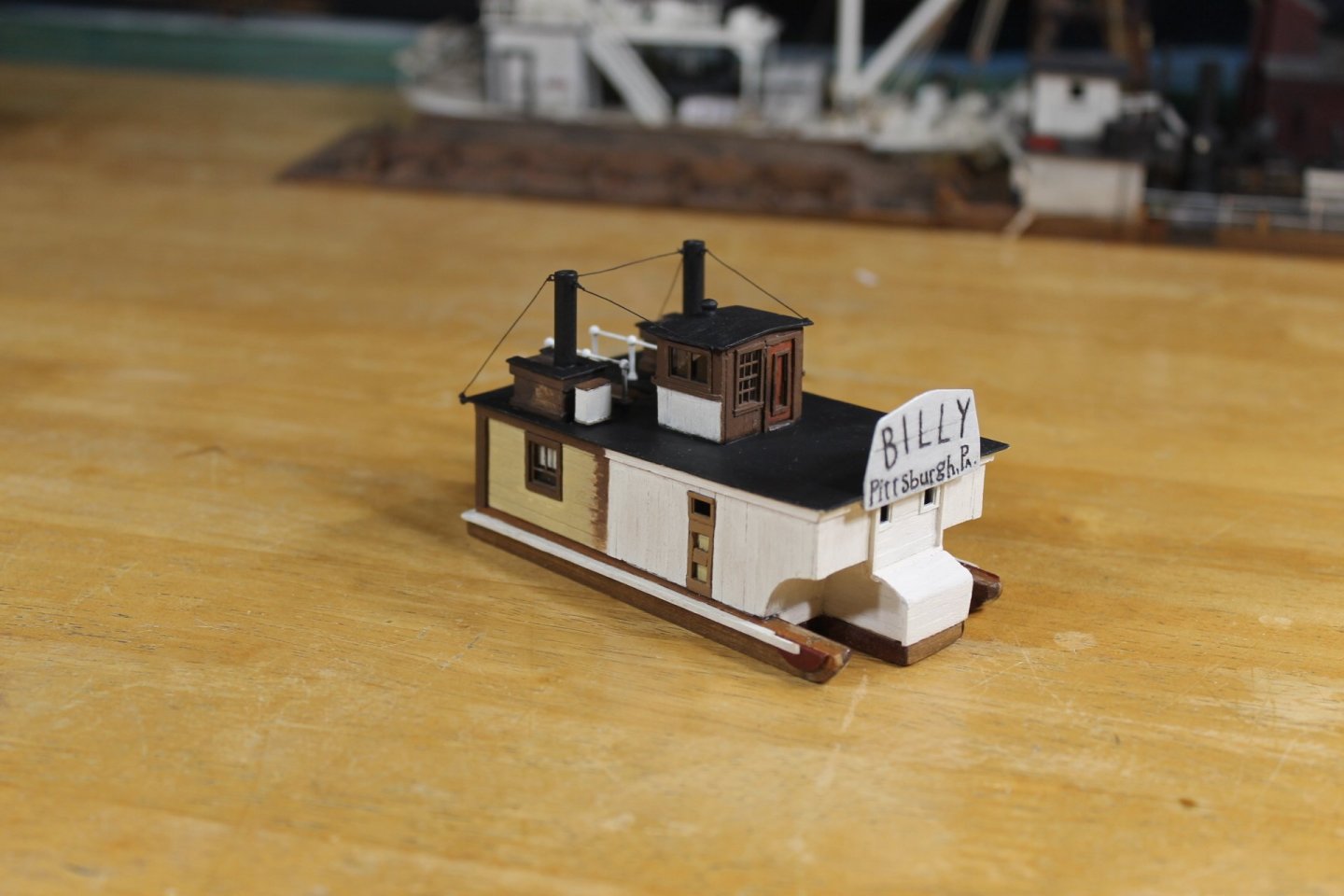

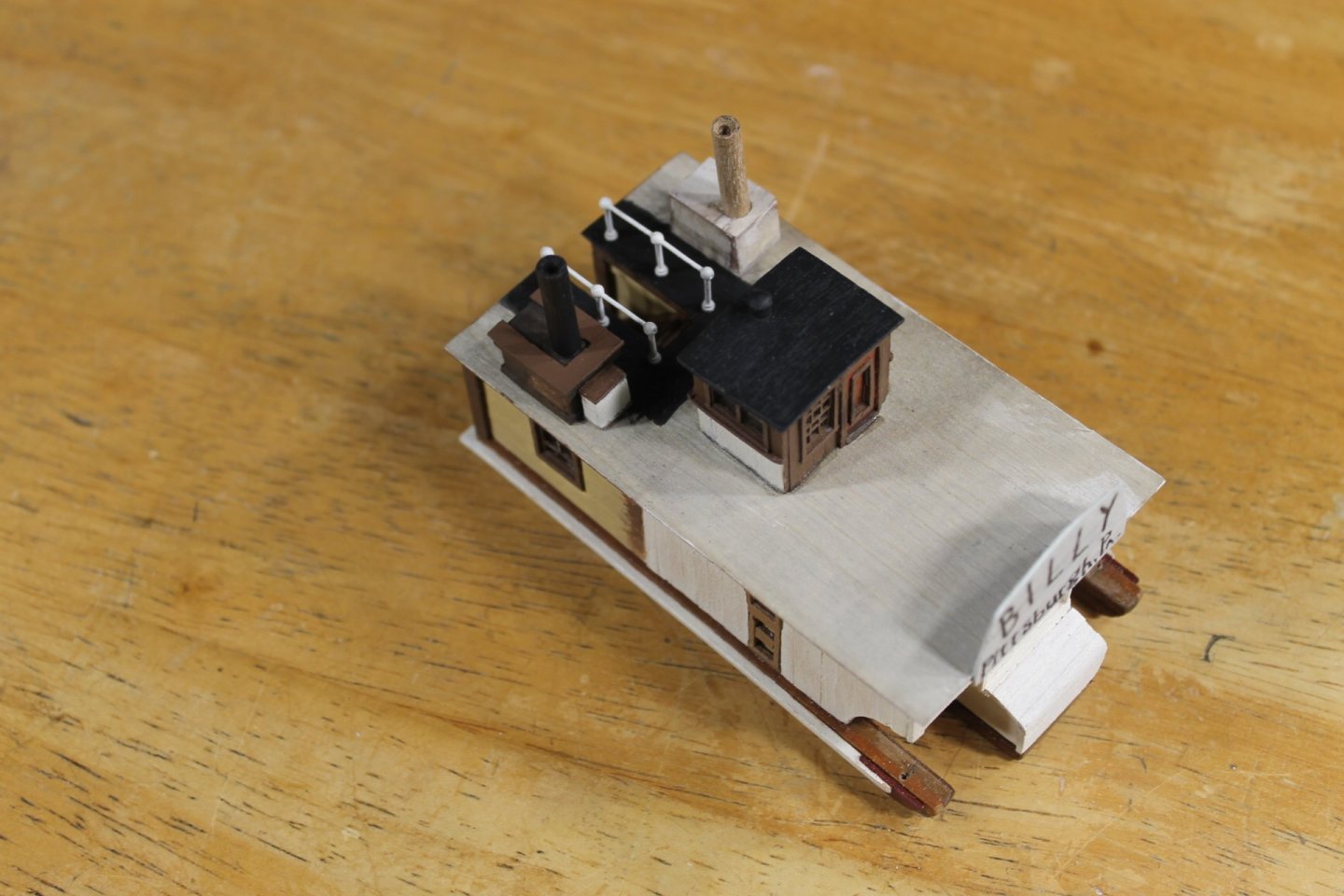

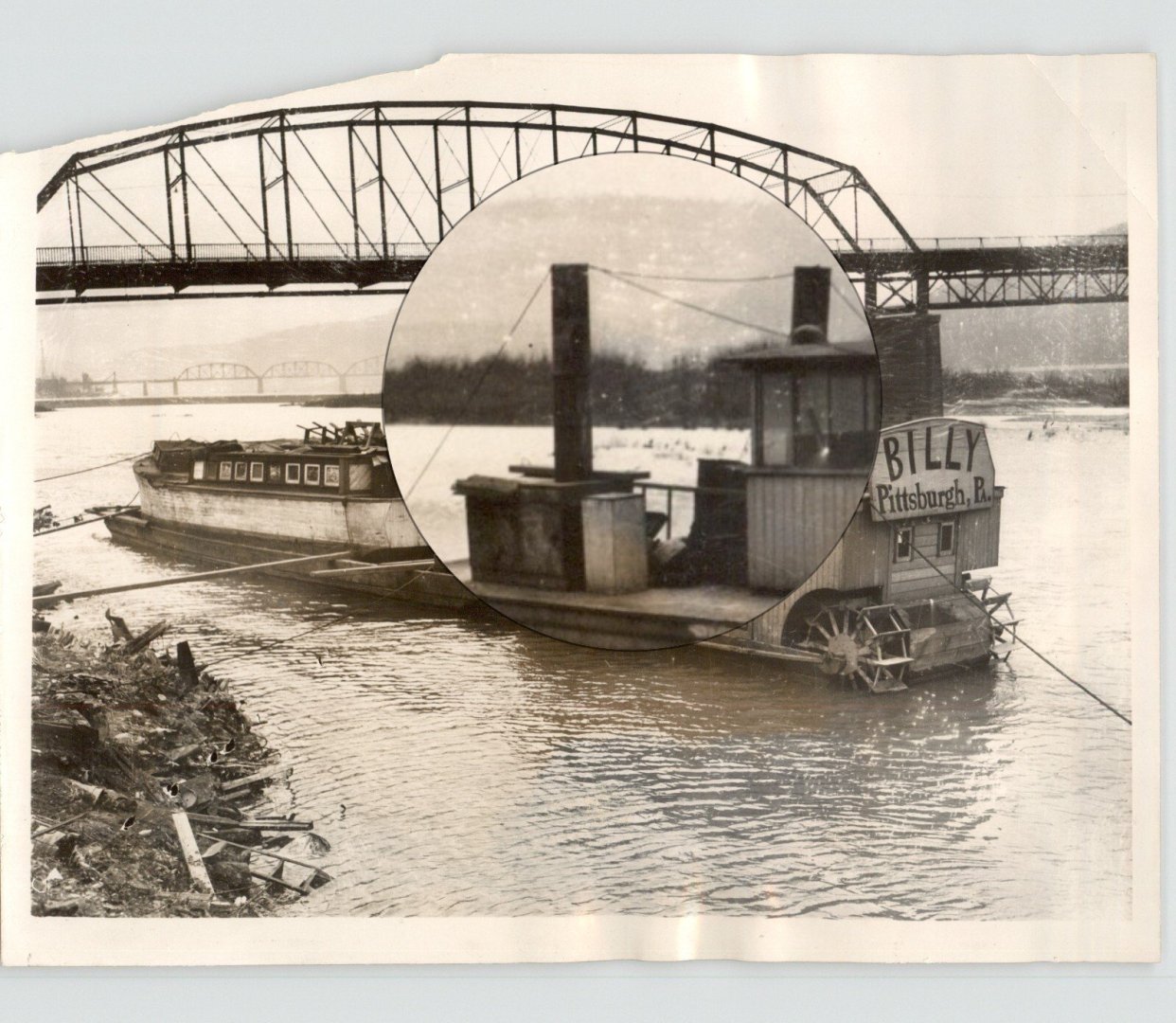

Stays 2.0 are done. You the viewer may not be able to tell the difference but I sure can. I am much more pleased with 2.0 than 1.0. I kept fighting that 32 GA brass wire and kept failing so I dug through Maggie's thread stash and found some silver metallic thread that was the right diameter. This was my first time using metallic thread, what a treat and it turned out to be just the ticket! Most of our models have some weight to them and when running line or wire through eyes the model is heavy enough to add resistance when tying a knot. My biggest problem is Billy doesn't weigh anything. I weighed Billy tonight and as pictured Billy only weighs 0.8 ounce or 24 grams! The metallic thread when looped through an eye and pulled tight will cinch on itself. This allowed me to CA the thread at the eye without issue using just two hands. Stays 1.0 Stays 2.0. All the connections look the same The thread is tight and not wavy. As is off the spool the tread is pretty bright, I gave the thread a very light black wash. Depending on how the light hits the tread the metal in the thread shows differently. It's kind of a cool effect but still might be a little too bright. A second light black wash maybe in order and is not a problem applying. Stays 1.0 Stays 2.0 Stays 1.0 Stays 2.0. I also changed the eye connections from under the eaves to the boiler deck and the wheelhouse roof. Much more sturdy and it looks better, IMHO. Thank you for the likes, comments, and the support. Keith

-

Thank you, Jacques. Without the paddle wheels it does look more like a houseboat. Billy was a heck of a lot more colorful than any other sternwheeler I'm aware of. Thank you, Glen. It's not the wire itself, it's the connecting points. I will differently be redoing the stays. Thank you for your support, Keith Thank you, Bob. Even though the Tennessee sits in front of me I've really not paid attention to her in a year and a half. The other night I looked closely at where I left off and I was startled at how much I've forgotten. Bob, short answer to your question is, yes, I'll be going back to work on the Tennessee. Billy has scratched whatever itch I had. Thank you, Keith. We haven't heard from the other Keith, pilot Keith. I think of him from time to time and wonder how he's doing. We seem to lose track of far too many of our MSW family. Gary comes to immediate mind. Thank you very much, Pat. Homemade yes, not so much flimsy, John. I can do better!

-

Alexey, welcome to MSW. Glad to have you aboard.

-

Thank you to everyone for the likes and the comments. I appreciate your support so very much. I said in the last post that the next post would see the boiler deck finished. I lied, I still need to add lumber and metal bits strewn about. John, I'm not procrastinating, honest. Way too much black, I can't wait to get after this with some pastels. With the exception of the paddle wheels the heavy lifting is just about done. I'm not all that pleased with the way the dummy stack stays turned out. I used 32 GA brass wire for the stays and my go to small photo etched eye pins for connecting points. It's all a bit flimsy for my taste so there maybe a stays 2.0 at some point. I've had more revisions with model that any of the previous. Thank you to each of you for following along. Keith

-

Brant, welcome to MSW. Glad to have you aboard.

-

Thank you, John. Delay allows me to make sure I've considered all the possibilities of potential failure and how to avoid failure and what options are available if I do fail. Thank you, Steve. I'm pretty tired of looking at the whorls on my finger tips, once Billy is completed I'll be ready to move back to a larger subject.

-

Thank you for the likes and for the comments. I'm calling the boxes that Capt. Engel built for the dummy stacks to sit inside, stack boxes. Pretty stinkin' original, huh? After a couple of months of trying to recreate Engel's work I have a pretty good feel why he did some of the crazy things he did but these stack boxes really puzzle me. The port side one looks unfinished and the starboard side one looks like Elgel ran into something. I'm going to build the starboard side box just like the port side with the dummy stack straight. The boxes are six sided measuring 0.30" x .030" x 0.50". Sorry for the lousy photo. It took 19 pieces to make the finished box not including the stack. With the stack and the three eye pins for the stays each box will consist of 23 pieces.in the assembly. That packing crate aft of the port side box will not be repeated on the starboard side. We'll see what interesting bits I can come up with to add aft of the starboard stack box. I'm leaving railing 2.0 as is, the more I look at it the less it bothers me. I was hoping this post would find me finished with the boiler deck, the next post for sure. That will leave adding three pieces of pipe and the paddle wheels. Billy is getting close to being finished. Thank you for your support and for following along. Keith

-

Welcome to MSW. Glad to have you aboard.

-

Very nice Cutty Sark, Giovi. How long have you been working on her?

-

Giovi, welcome to MSW. Glad to have you aboard.

-

Harvey, in your link to kayaks you've built I don't see any doubles or triples. My wife is 50% Aleut and when we lived in Egegik I became very interested in Aleut culture and history. Kayaks were no longer built by the elders as memory of how to had long faded. I did have the opportunity to witness the building of a traditional dogsled built by a village elder sharing his knowledge. A great photo of doubles. Aleut sea otter hunters resting next to kayaks, gut parkas hanging up to dry, and kayak covers, Unalaska, Alaska, 1896

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.