-

Posts

6,634 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

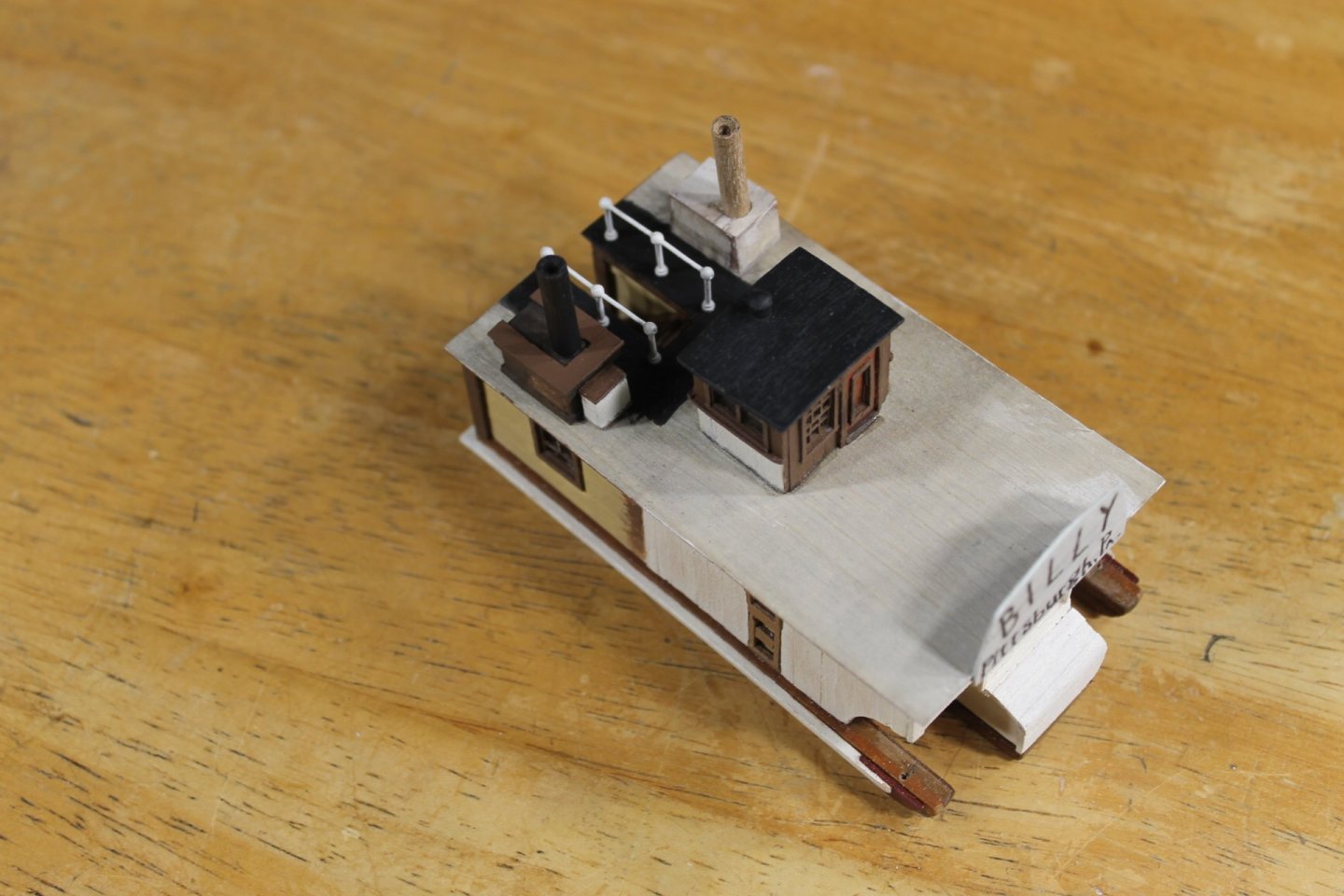

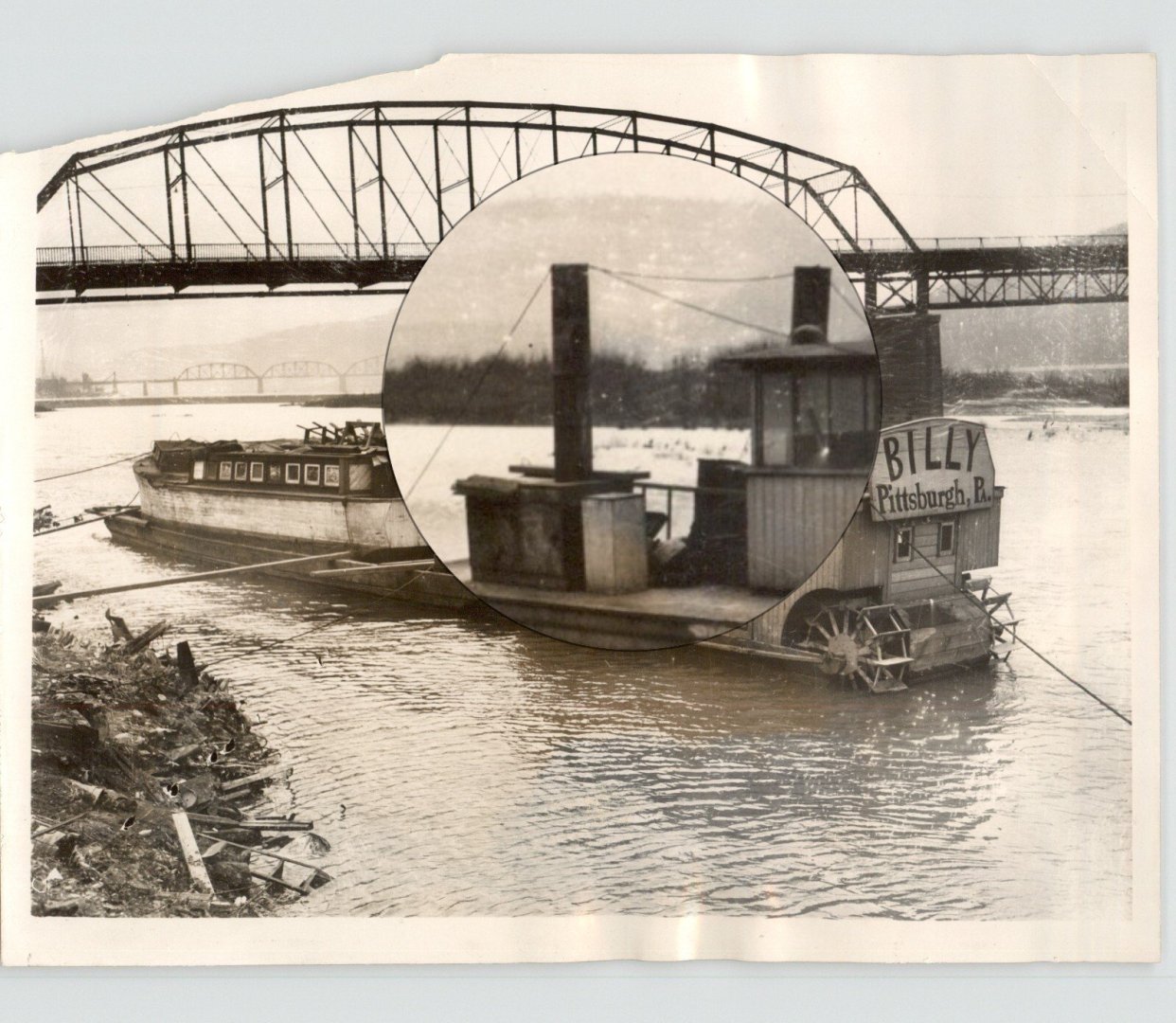

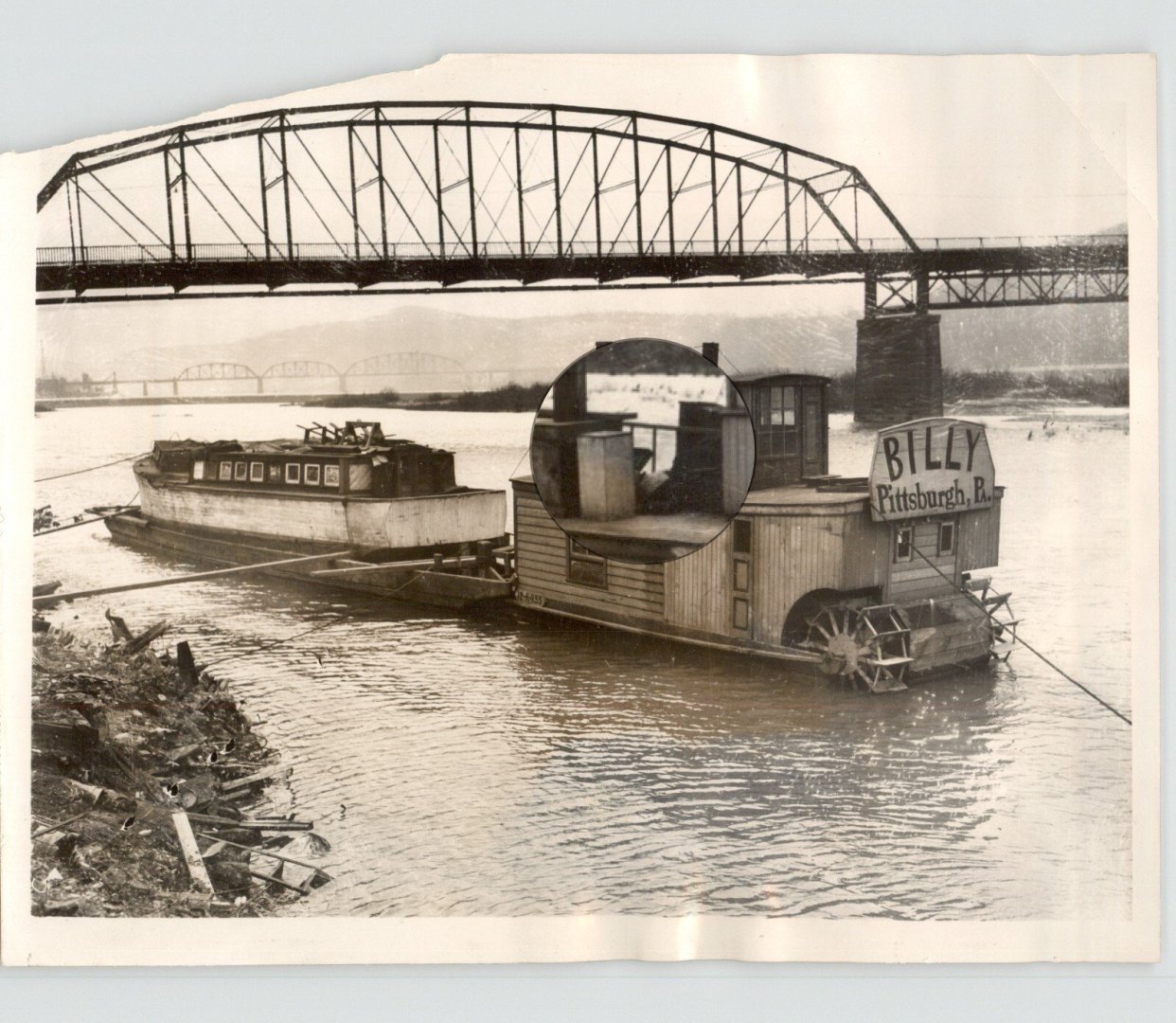

Thank you, John. Delay allows me to make sure I've considered all the possibilities of potential failure and how to avoid failure and what options are available if I do fail. Thank you, Steve. I'm pretty tired of looking at the whorls on my finger tips, once Billy is completed I'll be ready to move back to a larger subject.

-

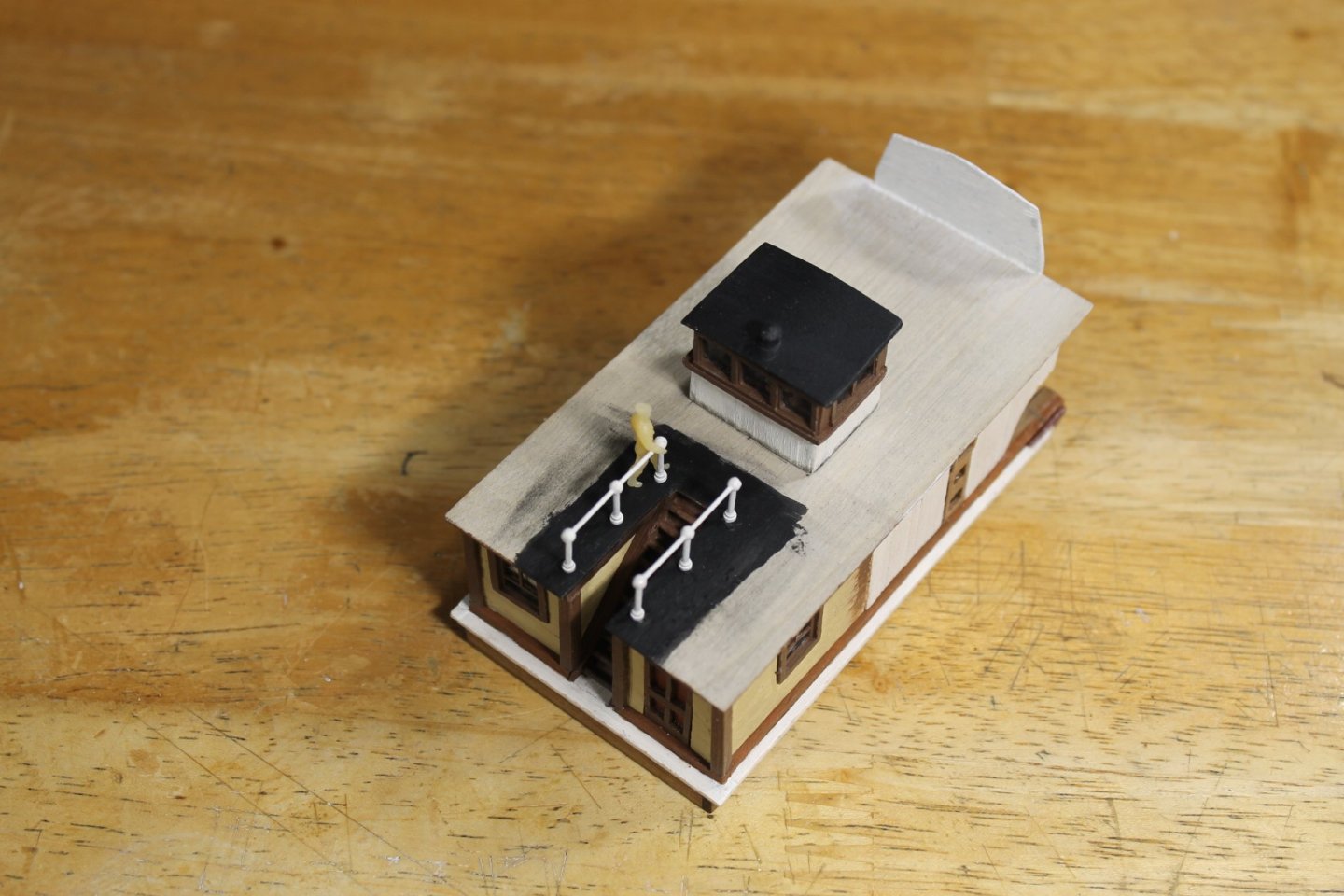

Thank you for the likes and for the comments. I'm calling the boxes that Capt. Engel built for the dummy stacks to sit inside, stack boxes. Pretty stinkin' original, huh? After a couple of months of trying to recreate Engel's work I have a pretty good feel why he did some of the crazy things he did but these stack boxes really puzzle me. The port side one looks unfinished and the starboard side one looks like Elgel ran into something. I'm going to build the starboard side box just like the port side with the dummy stack straight. The boxes are six sided measuring 0.30" x .030" x 0.50". Sorry for the lousy photo. It took 19 pieces to make the finished box not including the stack. With the stack and the three eye pins for the stays each box will consist of 23 pieces.in the assembly. That packing crate aft of the port side box will not be repeated on the starboard side. We'll see what interesting bits I can come up with to add aft of the starboard stack box. I'm leaving railing 2.0 as is, the more I look at it the less it bothers me. I was hoping this post would find me finished with the boiler deck, the next post for sure. That will leave adding three pieces of pipe and the paddle wheels. Billy is getting close to being finished. Thank you for your support and for following along. Keith

-

Welcome to MSW. Glad to have you aboard.

-

Very nice Cutty Sark, Giovi. How long have you been working on her?

-

Giovi, welcome to MSW. Glad to have you aboard.

-

Harvey, in your link to kayaks you've built I don't see any doubles or triples. My wife is 50% Aleut and when we lived in Egegik I became very interested in Aleut culture and history. Kayaks were no longer built by the elders as memory of how to had long faded. I did have the opportunity to witness the building of a traditional dogsled built by a village elder sharing his knowledge. A great photo of doubles. Aleut sea otter hunters resting next to kayaks, gut parkas hanging up to dry, and kayak covers, Unalaska, Alaska, 1896

-

MC, welcome to MSW. Glad to have you aboard.

-

- 56 replies

-

- Steam Cutter

- Harriet Lane

-

(and 1 more)

Tagged with:

-

John, welcome to MSW. Glad to have you aboard.

-

Thank you to everyone for the likes and for your kind comments. I've got stair railings 2.0 done. I made 1.0 from wood and they looked more fence than rail. 2.0 is a bit elaborate for Billy but looking at the press photo the railings are one of the few items that don't look like they came off the bottom of the junk pile. Admittedly 2.0 is much more elaborate than what's pictured but it looks ten times better that 1.0. There very well could be a 3.0, we'll see. I'm holding auditions for someone to portray A. O. Engel. In normal viewing the railings don't poke you in the eye like the photos do. Thank you guys every so much for your support and for being part of the journey. Keith

-

Cutters, Choppers, Guillotines, Slicers

Keith Black replied to MintGum's topic in Modeling tools and Workshop Equipment

I have the RP miter cutter and I'm quite pleased with it. https://umm-usa.com/onlinestore/tools-supplies-cutting-cutr-mitre-cutter-p-11167.html?sort=2a&search_in_description=0&keywords=rp cutter

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.