-

Posts

5,518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Wonderful work...love it. I finished the Great Republic. Keep up the good work. I'll be working on the Glory of the Seas now..... Rob

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Thanks Greg..I appreciate that. Now I can shift my focus to the Glory of the Seas and finish her up as well. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks so very much Paul....she is a pride of my clipper fleet. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Bob..it was your wonderful encouragement and correction that aided the effort. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Pat..it was a great time and your encouragement was a treasure. Now get to the Victoria....mmmm Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Keith it has been a pleasure. Rob(thanks for the comments)

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Steve.....What an adventure. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

I'm getting close to finishing her...just a few more lines on the head gear and some flags. I found this print of her. she was amazing. Rob(Hope to get her in her case soon)

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Indeed, skysails and their masts were the easiest additions...adding Howes and Forbes rig to the lower topsails(Newly added sail), would have been a bit more work, but what made sail work easier for the crew. Double topgallants came along even later. If practice was equal across the board....the Red Jacket probably was originally fitted out with mains, topsails, topgallant and royals. It was the clipper hull that made the most impact in the new design.....the rig followed along after. Rob

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

How Realistic Can One Make Sails?

rwiederrich replied to Julie Mo's topic in Masting, rigging and sails

If you have any questions just ask Gabe........ Glad I could be help...and follow my build log of the Great Republic and you can see pics of the process....... Rob -

The painting I saw is very similar to the first image of the book cover..... Like most early clippers they didn't have lower topsails or skysails....not until the mid 50's did many get overhauled. Rob

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 64 replies

-

I was hoping to find some progress this morning....but I know full well these *Lady's* can't be rushed and I know excruciatingly well about time availability. I myself am only hours of work away from completing my own GR build, but *things* always come up...I have to install a privacy fence this weekend...so there goes my *hours* of dedication to my own build...... Love your work and am looking forward to your next post. Rob

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Yes it has. Time availability means the world. I built my 1/96 Cutty Sark on its *ways* depicting her rudder repair...in just over 3 months. The entire thing. Because I had nearly unlimited time to dedicate to it...almost 8 hours a day...and if one is ambitious and tenacious...it is possible. Here, with the Great Republic...she was made totally by scratch...just a set of plans and a start date. I'll try to really focus on getting the spanker rigging finished up...because there is still some sail rigging to tend to and the national flag to mount. NOT TO MENTION....I have a few more details to finish up on the head gear with the addition of some stays. Apart from that..she is about ready to be put in her case. All this really means is that as I finish her up..the Glory of the Seas is waiting..and she will be hauled out on the work bench and I will begin again on her rigging and yarding. IT NEVER ENDS. Then we'll be over at that log. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

My son and wife just today said when are you going to fill that empty case.....? Not, before the model is finished I said..... Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

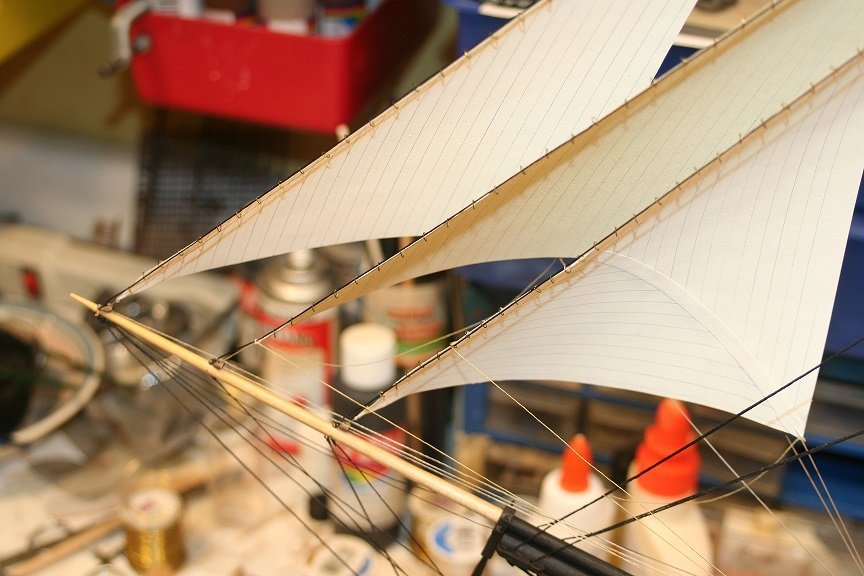

How Realistic Can One Make Sails?

rwiederrich replied to Julie Mo's topic in Masting, rigging and sails

The jibs and stay sails sheets are thin stainless wire painted to mimic rope -

How Realistic Can One Make Sails?

rwiederrich replied to Julie Mo's topic in Masting, rigging and sails

-

How Realistic Can One Make Sails?

rwiederrich replied to Julie Mo's topic in Masting, rigging and sails

I used a cake fondant roller to smooth and roll the leading edges to give them weight and a good billow. Paper is vary forgiving Rob -

How Realistic Can One Make Sails?

rwiederrich replied to Julie Mo's topic in Masting, rigging and sails

As some know...I use plain copy paper to make sails and they work pretty well, and look very convincing too..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.