-

Posts

5,497 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by rwiederrich

-

-

-

-

Today I ascribed the forecastle and main house deck and installed windows....

-

Daear Rob,

from my work on 1/700 ships in boxes I learned the hard lesson that gypsum is going to give its water into the air for/after very long years! So this "water" of a closed bottle or showcase will show "dew" inside. And later you'll get mold or serpula fungus! But the model's wood will have "labored" long time before you can see these or other signs. This is why ships are bottled in coloured window putty. I like your sea in action and authentic colours very much. And so I want to give you my bitter know-how - before you enclose your showbox -due to the wonderful work you are doing.

HTH.

Thanks HTH for your fine comments and advice. The dental stone is not in a box of wood it is sitting on top of foam and the wood is wrapped around the foam..not the dental stone. Yes gypsum will evaporate water for a time till it is totally void of moisture. It should not cause moisture condensation and or collection....since it will also not be encased in a glass case.

Thanks so much for your fine comments and concerns..and for looking in.

Rob

-

You have a very interesting and resourceful approach Rob. I'm enjoying reading about your techniques and sources. Thank you for sharing them with us.

I've strayed from the purist approach....and have learned from experiences that anything can be re-engineered for my purposes. I'm after the overall appearance not the method of how I achieved it. Some would say that the build is as important as the final product....but I gather, that since these are but models and mixing all manner of media to achieve my goals will not result in the little ship's sinking...I delve head long into it. Plus..I'm generally lazy..so if I can utilize a method, material, technique that saves time and money....I'm all over it. I want a fine final product and I don't care if I have to use Dental alginate in its construction. When it's all said and done..the viewer will never know.

Thanks for looking and commenting.

Rob

-

Most folks build from scratch..using typical plank on frame or full solid hull construction. I, as is my custom, try to use pre-engineered hulls and then rework them and build them up with wood. Revell has a good hull in the Cutty Sark model and it doesn't take much to rework it into an American clipper hull....especially if the below water line is not going to be an issue(under water).

I use black or brown India Ink diluted in pure Isopropynal alcohol. The I paint it on the surface I want weathered and it seeps into the cracks and when the alcohol, evaporates it leaves the staining. It works fast and I use this method on all my builds in some level of dilution. Then I go back over and dry brush cerium oxide powder(2 micron)(Extremely fine) over the entire surface to add highlights and additional weathering that simulates sun bleaching and wear.

As far as the board and lattice or board and batton work on the forecastle and deck house...I make most things. but I do have a stock of this is many scales pre-made. It is for building scale N,HO model railroad buildings. It can be found at most quality railroad building suppliers. I think Micro Mark sells it as well as Model Expo.

Again...I will use any source for materials to build my ships.....and sometimes Model railroad supplies work best.

Thanks for asking and looking in on my build log.

Rob

-

your turbulent ocean waves are excellent. I haven't seen a sea like that modelled before.

Thanks Brian...I wanted a rich full *BIG* sea to set my clipper Donald McKay in. I am not a master at making water as some are...but I did the best I could with a medium I'm quite familiar with.

Again thanks.

Rob

-

-

Bill...I always begin with a Revell CS hull and make the necessary mods to create the hull I need. I prefer to use existing engineered hulls...then I make the mods to them for my own purposes......and there is ample after marked CS hulls to modify. My Glory of the Seas and Ferreira are also modified resin hulls.

Check those build logs out to see what I did there.

Thanks for looking in. I'll get lots done tomorrow...with pics to follow.

Rob

-

Speedy and good looking work there sir.

Michael

Thanks..I tend to be pretty fast.....I have and use lots of wood so I tend to redo stuff if it isn't correct. I built the Glory of the Seas hull in about 2 weeks time....and since I have my techniques down...I hope it goes even faster.

Rob

-

-

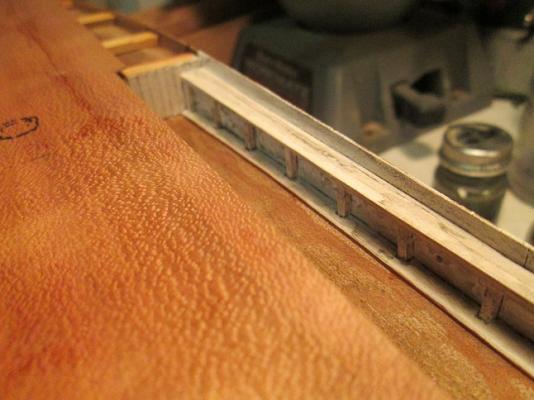

The monkey rail will be added after the the forecastle deck is laid. The main rails and waterways went in smoothly

Rob

-

- mtaylor, EricWilliamMarshall, Archi and 2 others

-

5

5

-

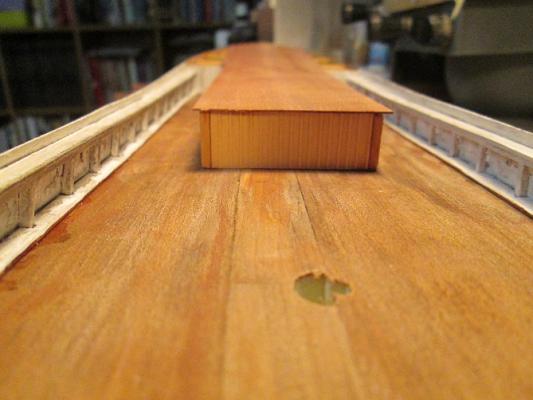

Now that the build up is finished...I'm going to lay out the main cabin and prepare for the decking that will extend from the forecastle to and over, forming the roof of the deck house. a single gang way will proceed from this to the poop deck. I'll finish off the forecastle front and doors at that time.

Before all that I will install the bulworks timbers and the waterways..

Rob

-

- avsjerome2003, gjdale, augie and 2 others

-

5

5

-

-

One note on the mods...I had to remove lots of rail detail along the hull to accommodate the new wood bulwork extensions..plus the McKay has a different stern so I also had to remove material there as well to make room for the wood additions. Today I will do more work and take some pics of the corrections.

Rob

-

Super job Ed...super job.

Rob

-

-

-

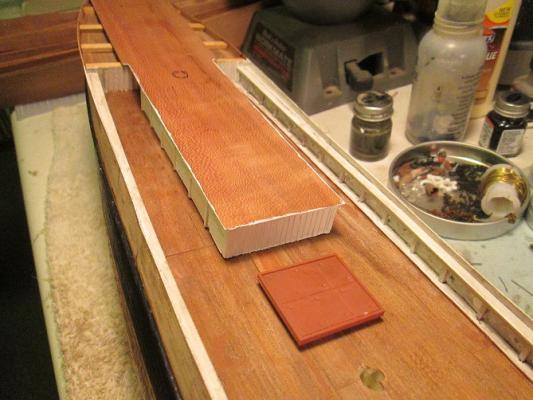

Today I began the mods to the CS hull. I had to remove the monkey rail and remove the cheeks and relocate the Howes hole and be prepping for its new location. I then decked the main deck between the poop and forecastle. Next was laying in the new bullworks.....which is quite taller then the CS.

Loads still to do....I'll finish up the starboard side and then steam the stern to bend it around the rounded stern.

So we begin the Donald McKay build.

Rob

-

Looks like steam drills and drivers are being employed.....were those utilized during the 1850's?

Great image by the way.

Rob

-

- gjdale, EricWilliamMarshall, Piet and 9 others

-

12

12

-

Amazing build...thanks.

Rob

Donald McKay 1855 by rwiederrich - medium clipper

in - Build logs for subjects built 1851 - 1900

Posted

Lastly I added the rail and monkey rail......still needs sanding and I need to add the aft monkey rail around the stren.

Rob