-

Posts

109 -

Joined

-

Last visited

-

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Canute reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Ondras71 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Ondras71 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Siggi52 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Siggi52 reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Archi reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Archi reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

mtaylor reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

mtaylor reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

druxey reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

druxey reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

GrandpaPhil reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

GrandpaPhil reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

Jsk reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

Jsk reacted to a post in a topic:

17th-Century Speeljacht by 0Seahorse - FINISHED - scale 1/50 - CARD

-

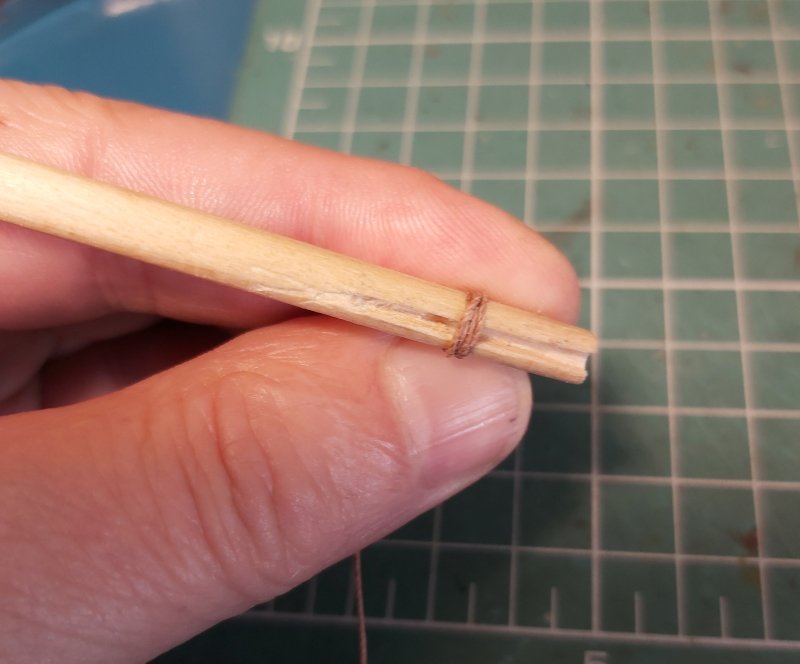

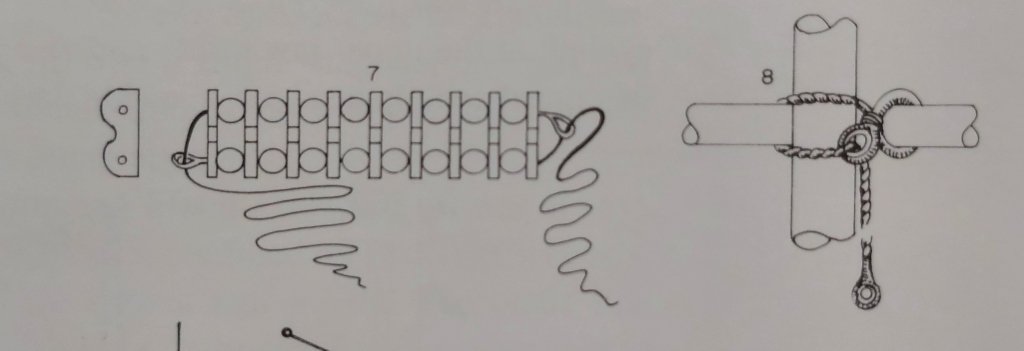

The moment has finally come, "finally", because I made two sails all week long and made a total of 12 of them. Each time something went wrong (stains), I made a mistake (wrong course of the warp and weft), after the third attempt it turned out that I drew the template wrong, the fourth one had stains again, etc. But finally the model is finished. All in all, with such simple rigging there is not much to describe, so maybe I will share an idea (found on YT and simplified) for a different way of making coils of ropes hung on belaying pins. There are, of course, several methods for making and hanging coils, and one of them involves tying them in such a way that there is a single loop at the top and only this loop is attached to the belaying pin. The original video is here: How to make coils. Taking into account that the scale is smaller, I used a 6mm round dowel in which I quickly cut a groove. 1. I braided dowel 4 times 2. I passed one loop 3. I put the second loop into the first loop 4. I tightened everything together 5. the size of the loop can be adjusted with the free end of the rope I don't know how this method will work at 1:100, but at 1:50 it's certainly a good idea. And now a few pictures: Greetings Tomek

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

-

@ccoyle Chris, I am preparing instructions and typesetting for the printing house. If I finish this week, next week... we have two holidays and half of Poland takes additional holidays to have... 9 days off. But the work will certainly go to the printing house next week. It would be safe to say by mid-May. Tomek

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

-

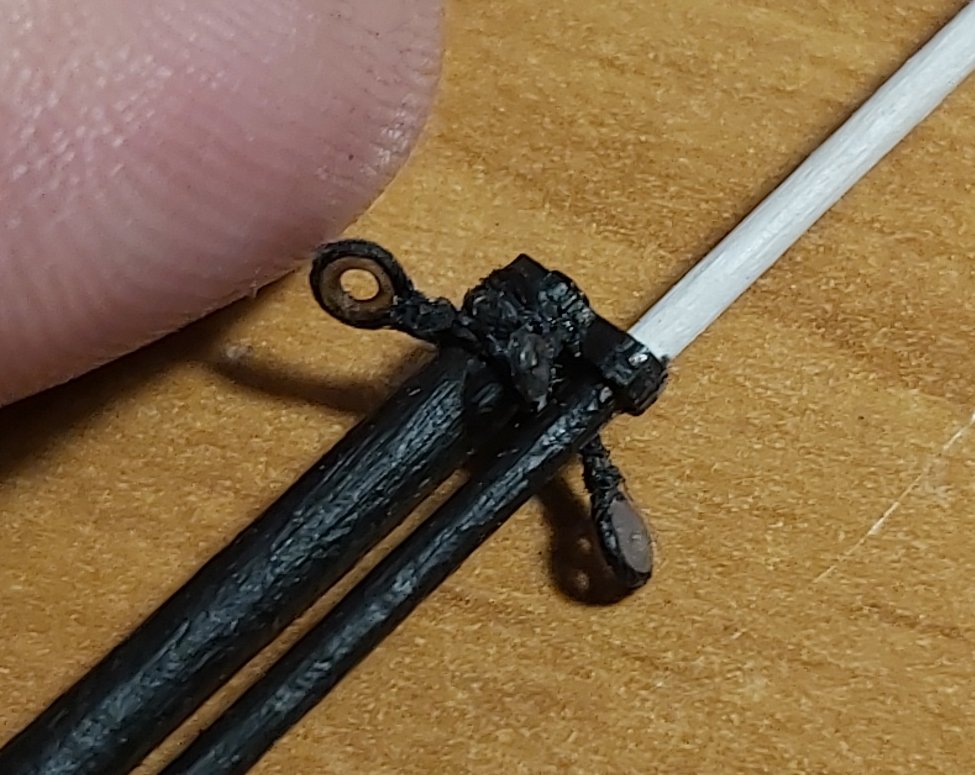

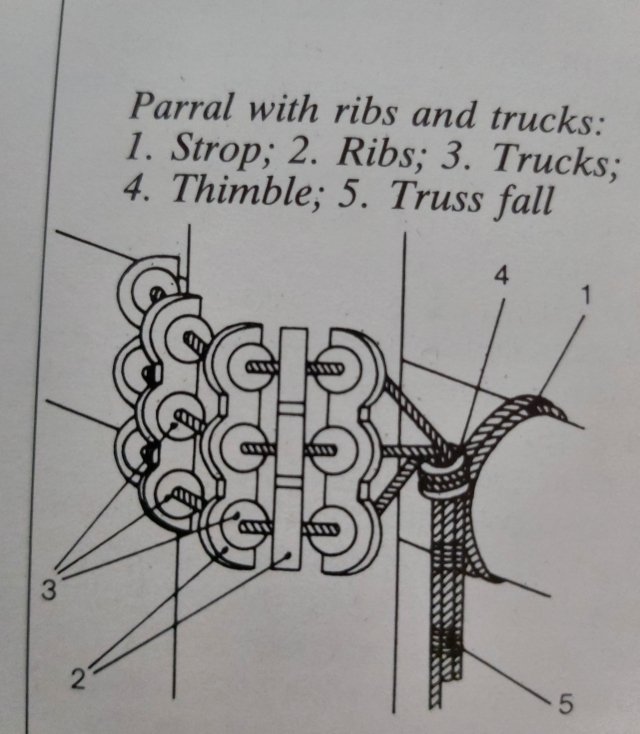

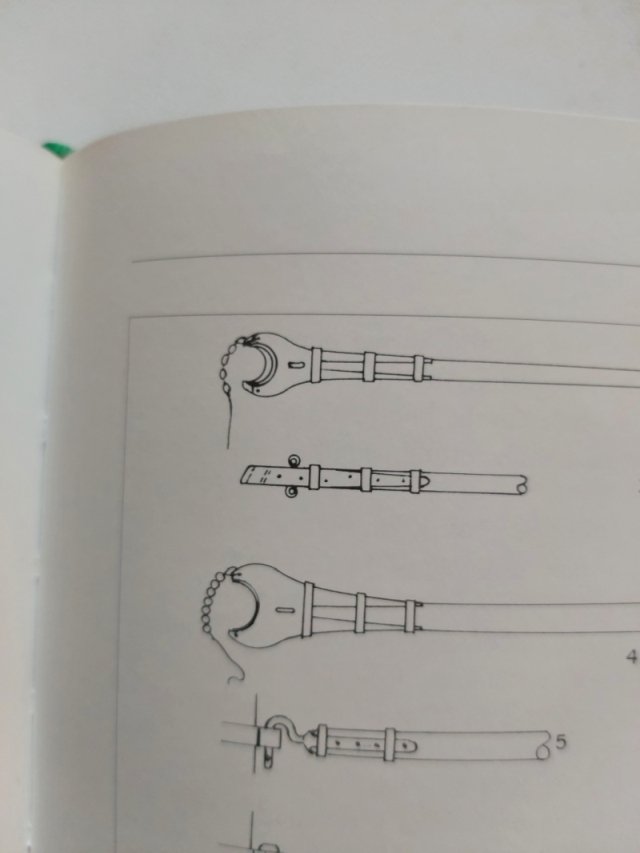

Good job! I tie the thimbles with thread or rope around them, but before seizing, I secure the thread around the thimble with a minimal amount of CA glue, applied with the tip of the needle. As for parrals, I think these beads are called "trucks", at least that's how I read Modefeld's drawings. ("Historic Ship Models" by W. Modfeld) Boom and gaff probably definitely had these "beads". In the case of yards, it could be an ordinary truss pendant (i.e. just a rope). ("The Global Schooner" by K. H. Marquardt) The suggestion to use wire insulation is simply an imitation of these beads, as they are so small that making them by hand without precise tools may be very difficult. Best wishes Tomek

- 34 replies

-

- card

- Revenue Cutter

-

(and 1 more)

Tagged with:

-

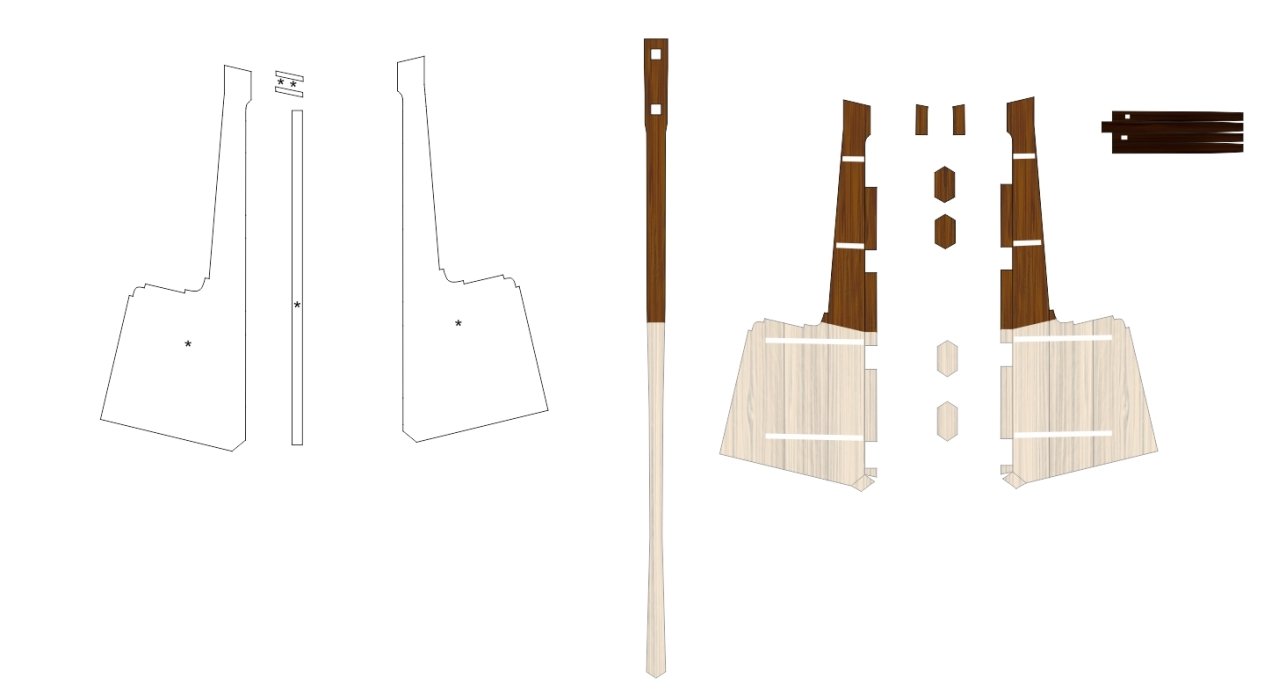

It took a long time to finish the hull, but it can finally be presented. In accordance with period drawings, I applied thick nails (glue and paint) on the wales, and attached two pairs of reinforcements to the stem. All the finishing touches and modest decorations appeared. Initially, I thought about cutting them with a laser, but it would require some plasticizing (e.g. with glue) and painting - which means a lot of work and time. So I cut out several copies by hand with a sharp scalpel and glued them to the sides. The decorative ends of the railings are simple bottomless "boxes" that I used to mask the ends of the edges of the railing. In the stern part there are belaying pins printed in resin , a bench and a rod on which the sheet of the second sail moved. And a few little things at the stern. All decorations are "conventional", i.e. you can make others according to your own intuition and skills. Leeboards, characteristic for coastal units that moved in shallow waters, according to the plans, had semi-circular indentations - after gluing such a part, I gently cut out these indentations with a scalpel, corrected them with a file and covered the whole thing with strips. They were hung with an eye on a hook coming from the side. They were lifted by ropes, which is clearly visible in the photos. A few more words about the rudder blade, which unfortunately I don't have any photos of. A simplified version would consist of layers of cardboard and that's it. Usually, however, the rudder blade was thicker at the front edge and thinner at the rear. That's what I did: the side layers of 0.5 mm cardboard are glued together at the back, and an additional narrow strip of cardboard is glued between at the front. This can be seen on the masking strips. The front edge (where hinges are) was not perpendicular, but ended at an angle - the glued side parts in the color have appropriate protrusions at the front, which, glued together, create a triangular ending. The recesses for the hinge axles are, of course, masked with another small strips. The thicker upper part of the stern blade, where the tiller is mounted, was created by appropriate shaping and simply gluing thicker cardboard between. For imaginative modelers, instead of the missing photos, I am posting a scan of the parts. And that's all. Regards Tomek

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

-

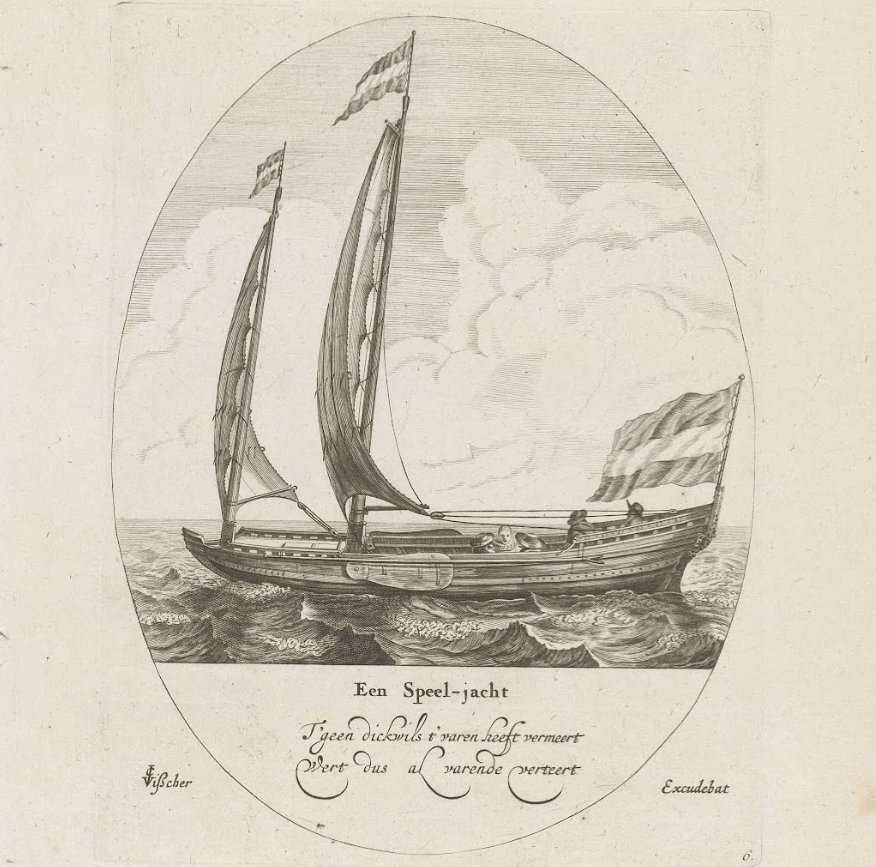

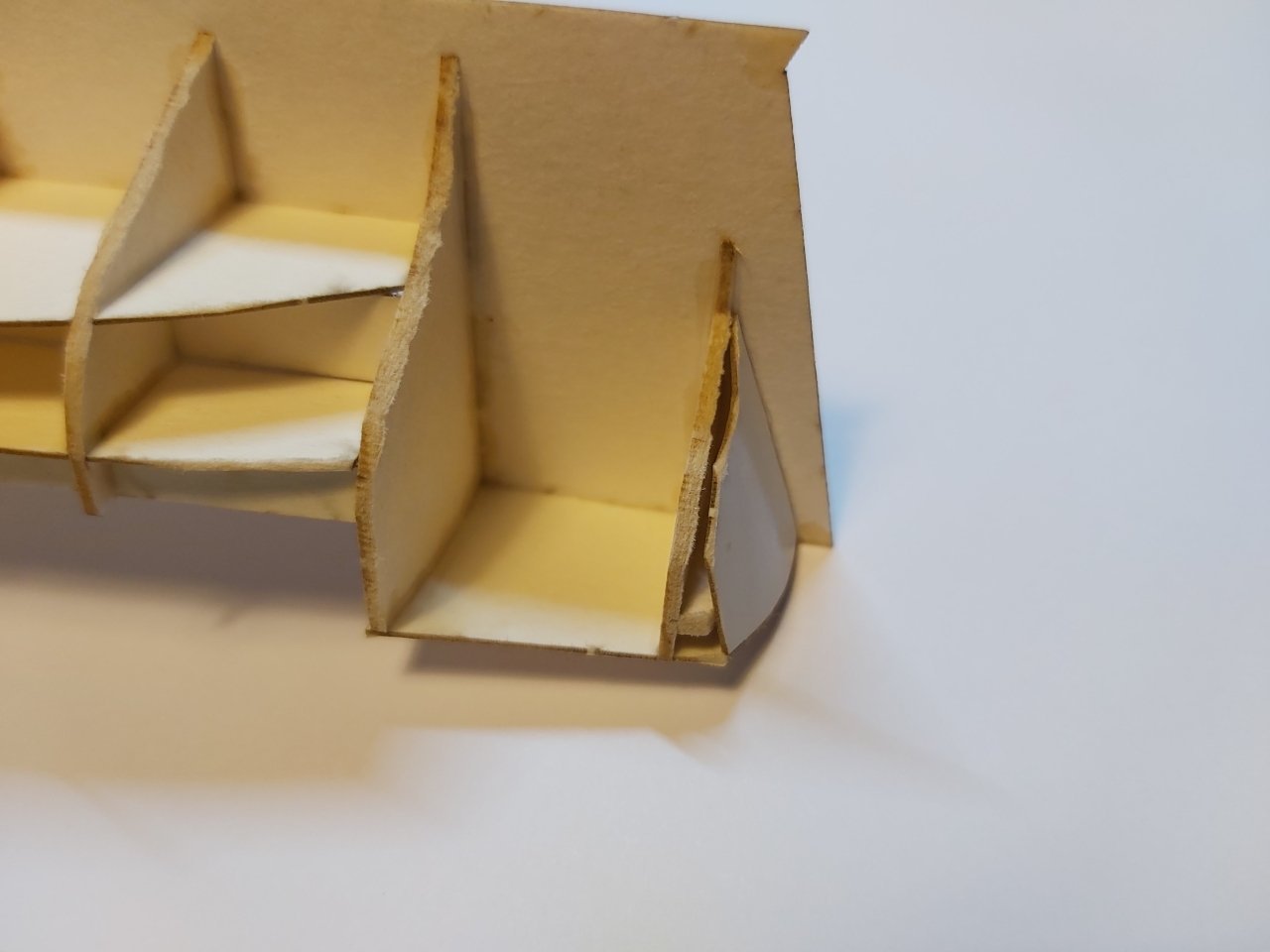

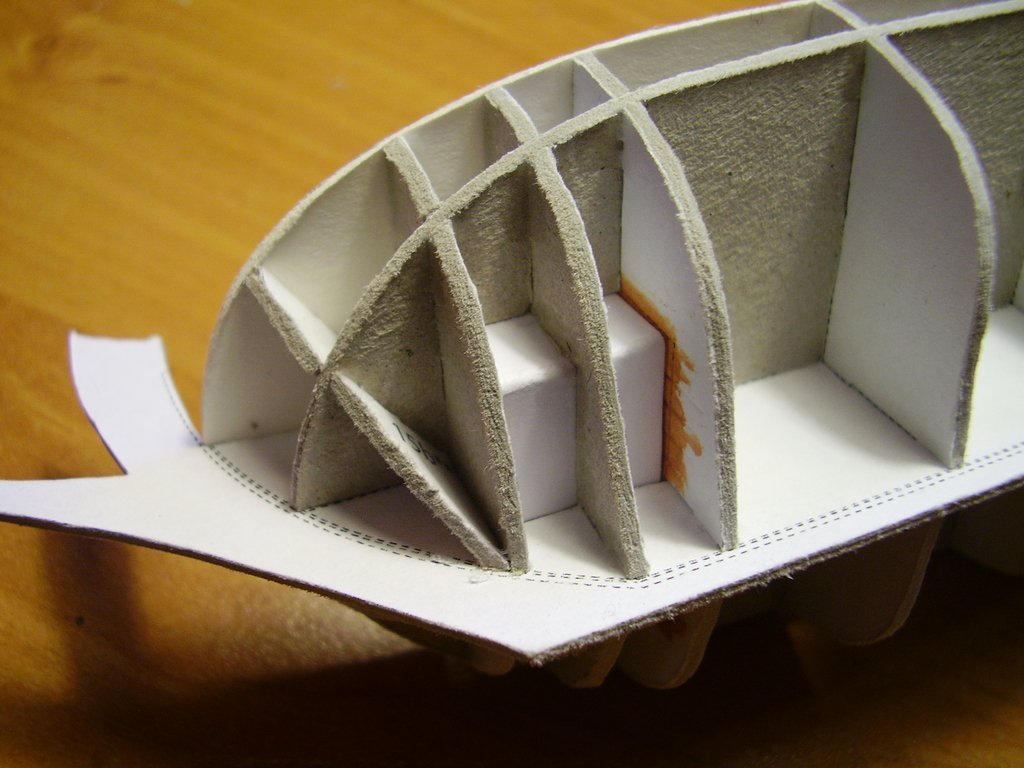

Hello colleagues Many modeler friends said to me that it would be nice to assemble a cardboard sailing ship, but rigging is generally too difficult. Therefore, a few years ago I asked Ab Hoving for an idea for a simple model with the simplest possible rigging, and I didn't have to wait long (2-3 hours) when a precise and immediately three-dimensional design of a "recreational yacht" appeared on my computer. ", i.e. "Speeljacht". This design is very similar to the commercially available plans drawn by Cor Emke. [url]https://www.modelbouwtekeningen.nl/nvm-1006017-speeljacht-volgens-nicolaas-witsen-167.html[/url] Recreation on the water was probably not an invention of the Dutch, because in the tomb of Tutankhamun an image of the pharaoh fishing on the Nile was found, which can be considered entertainment on the water. However, until the 17th century, sailing ships of various types fulfilled basically only commercial and war functions or were used for work, such as fishing. It was only when the trade in Asia enabled merchants to build great fortunes that yachts for entertainment appeared. Maybe it was then that "yachting" appeared as a way of spending time with family, friends or for business purposes. Not only did people relax by sailing for pleasure, but such expeditions were accompanied by delicious feasts, including plenty of drinks. Nicolaes Witsen even mentions a "beer house" under the aft deck. In addition to romantic trips, owning such a yacht meant prestige and/or wealth - a bit like modern billionaires and oligarchs. The decorations were chic, but not flashy. The Netherlands was a Calvinist country, so one had to be modest. There was usually a family coat of arms on the stern. A similar model was developed in wood by Kalderstock. And for the inquisitive and curious: the Clean2Anywhere Foundation has been experimentally recycling plastic for several years, building replicas of small historical yachts from it, including this speel yacht. Link to one of the videos where you can see the construction of a speel yacht: [url]https://www.youtube.com/watch?v=eqrIHFulcZU&t=3s[/url] And how is my construction going? So quick and easy that I didn't take many photos, especially obvious stages like frame frames,... ...or "first - false planking" The retouched cardboard edges of decks has always "disgusted" me, so I experimented a bit and glued narrow strips on the visible edges, imitating the face of the boards. The stripe is 0.7 mm, my hand trembled a bit and it didn't turn out perfect, but I think it's a very good idea for the future. Since masking the edges like this has a future, I went ahead and played with the edges of the planks at the stern. There is also something to complain about, but that's my fault - I liked the idea itself. A large number of visible frames required tedious gluing and retouching, and initially I planned to glue them to the hull first and then continue covering them with the planks. Fortunately, before I started committing such stupidity, I changed my concept and built this component separately, finally gluing the finished one to the model. In total, in four stages: 2 amidships and 2 aft. The last layer of planks (in color) went very well, and of course the corrections were made on the edges that are covered with wales. This is how it turned out: Modest decorations (as I wrote at the beginning) will only be made of cardboard (no resin), so that the model is fully paper as standard. It was necessary to choose the coat of arms of some noble family. The final choice fell on the van Loon family, also because their "palace" still houses a popular museum.([url]https://www.museumvanloon.nl[/url]) That's it for now, only decorations, leeboards and very simple rigging remain. Regards Tomek

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

-

I don't know exactly how Bumażnoje Modelirowanie currently works. I heard that they print in Poland and the current internet address is probably/maybe/perhaps/not sure https://papermodeling.net/index.php?route=information/information&information_id=4. Many stores in Poland (Orlik, WAK, GPM) have their models, so you can alternatively look here.

-

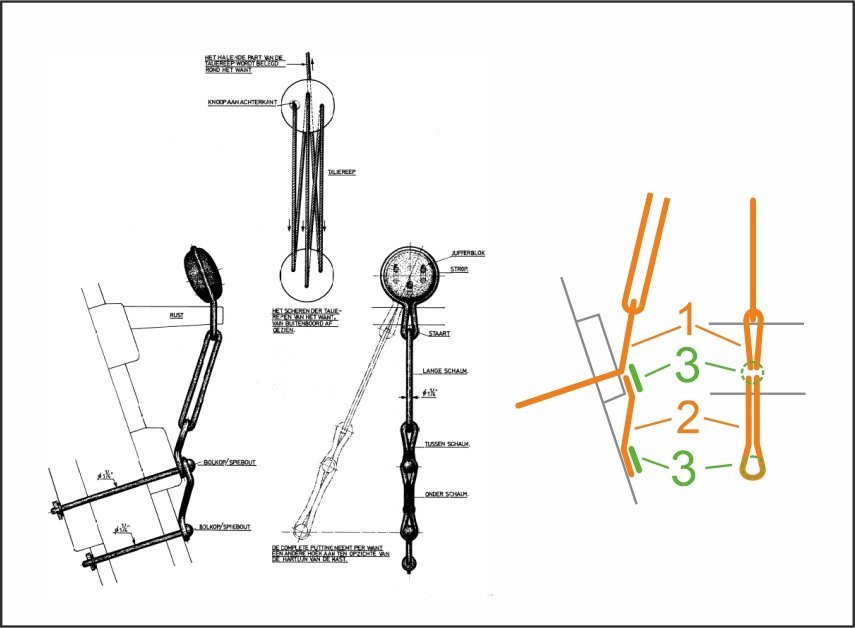

Hello Jeff You perfectly interpreted the markings on the rigging drawings (bloks, cleats, eyebolts). It's exactly as you marked a-b-c. The same applies to attaching blocks to masts. That's exactly what I meant. And you also read the jib boom shift correctly, although of course these all solutions is only my suggestion based on the sources I had at my disposal. Tomek

- 34 replies

-

- card

- Revenue Cutter

-

(and 1 more)

Tagged with:

-

Hello Jeff Somehow I missed the fact that you started building this model and didn't suggest a few important things ahead of time. But I'm glad you reached this stage of construction and "conquered" the hull. In cardboard models of sailing ships, the hull is the most critical element of the structure - you cannot use sandpaper to correct something or to narrow the plank by 0.2 mm. What would certainly make construction easier at the very beginning is grinding the frames at appropriate angles, just like when building from wood. I take this into account in all my designs (this hull was not designed by me, but it always works). Of course, the sanding itself should be gentle. If there is no grinding, subsequent layers (parts) become too short. Below is a photo of the frames of different model polished so that all "transitions" are smooth. If a plank (from the last colored layer) is too short, you can glue them a few centimeters at a time and gradually "stretch" the paper using water-based glue (this type of glue softens the paper and changes its dimensions). Of course, such stretching must be done carefully to ensure just don't tear it apart. I regret that I did not present the construction of the model on this forum, which would be helpful for you. If you need more pictures, there are some presentations on Polish cardboard model forums. I will be watching your build with interest. Tomek

- 34 replies

-

- card

- Revenue Cutter

-

(and 1 more)

Tagged with:

-

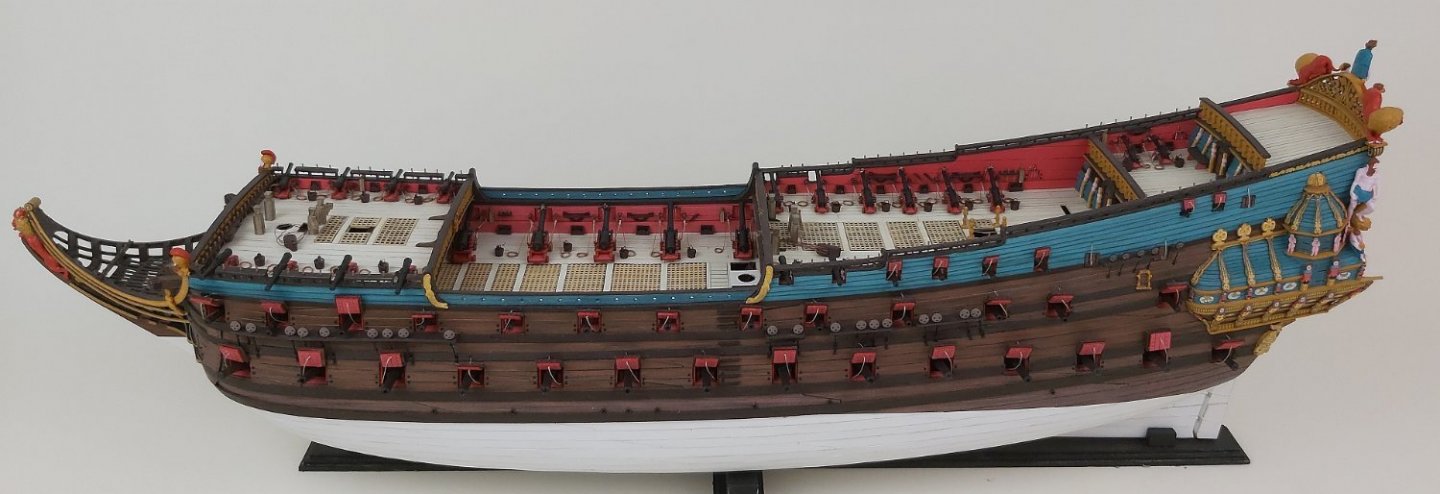

Hi everybody, yes, many months have passed since the last update, but I finally have something to be proud of - last night I raised the last flag and today I can show the completed model of the flagship "De Zeven Provincien". Thanks again to Ab Hoving, who constantly supported me, advised me and cheered me on until the last day of working on the model. Running rigging is so extensive that you can write an essay on what, how, where, what to watch out for, what to ignore, etc. I won't hide the fact that I simplified a few elements or simply "fooled" the human eye. I don't know how many ropes and threads are finally attached to the model. Although it was unlikely that all the sails were set at the same time, I decided as a test (after all, it is a test model) to hang the stay sails to make sure that there were no errors in the instructions or that any of the lines were placed absurdly. I used various sources, but I may have misinterpreted something (especially since some sources were in Dutch). Surprisingly, I found only one error (the designations of ropes 72 and 82 were swapped). I attached the rest of them according to the instructions and it worked. I made the first drawings in the project in the spring of 2017 (my daughter was 10, now 16). A handful of photos, comments and questions are welcome

- 26 replies

-

- Seahorse

- De Zeven Provincien

-

(and 2 more)

Tagged with:

-

Thank you, Chris, for presenting the news. The more precise adrress😉 Seahorse shop. Regards Tomasz Weremko

- 24 replies

-

Hello, I can't believe it's been so long since the last update. I have put up all the masts and I think you can say that the standing rigging is ready. Most components built/rigged as planned. A slight problem arose with the bowsprit mast and the foremast: both leaned back slightly when tensioning the stays, which was not matched by the stiffness of the bowsprit (it moved up a little). I am satisfied with the symmetry: with such a large sailing ship, I managed it almost perfectly. Some time ago, the model, unfinished but secured in the "aquarium", made its first cruise at the Model Show in Nowy Tomyśl. The latest photos of "De Zeven Provincien": Tomek

- 26 replies

-

- Seahorse

- De Zeven Provincien

-

(and 2 more)

Tagged with:

-

0Seahorse reacted to a post in a topic:

An Introduction to Seahorse Kits: Duyfken, Sao Gabriel, Leudo Vinacciere, Armed Virginia Sloop

0Seahorse reacted to a post in a topic:

An Introduction to Seahorse Kits: Duyfken, Sao Gabriel, Leudo Vinacciere, Armed Virginia Sloop

-

Hi everyone, Some time has passed since the last update, but it was not time wasted because I can announce that I have finished working on the hull of "De Zeven Provincien" !!! Hurrah!!!! I made gunport lids (I have a slightly "bent" eye, because a large part of them is slightly twisted in the same direction; similarly with the holes for the ropes lifting these covers, they are all slightly shifted to the left :-))) There was a lot of work on the starboard too, because I did not print the hinges for gunport lids, believing that sticking thin strips would be nicer. I don't know if it's nicer (probably not), but it's definitely more time-consuming. But after dealing with nearly 80 gunport lids, it looked better and better. At the same time, I had to make deadeye attachments because it was getting tight in some places. In fact, I didn't simplify them, I just changed the shape of two lower parts (1 and 2), which I covered with small circles (3). Details in the drawing. Adding various types of riggin equipment to the bulwarks and decks is a normal job and nothing interesting to write about. I helped myself with a 3d printer again and it was a move almost brilliant :-))) I printed 180 belaying pins: delicate, small, nicely contoured shapes. The end result and the time needed for them is incomparable to those made of wire and thickened on top with a drop of thick glue. I am delighted with this solution, especially since I printed in brown resin right away (pigments are not cheap, but the time savings justify the expense) It remains to finish the work on the decorations: the designs of the sculptures were prepared by an external company (I do not have such skills myself) and after minor corrections they were printed and painted. All that's left to do is put a few dozen eyebolts in the decks and set the sloop amidships. Some pictures: Greetings Tomek

- 26 replies

-

- Seahorse

- De Zeven Provincien

-

(and 2 more)

Tagged with:

-

Hi friends I must admit that I am not building the model at a dizzying pace, mainly because of the limited time and more and more details that need to be prepared and thought over. It took me a long time to make various attempts (mostly unsuccessful) to prepare the sculptures on the stern in the form of paper, which would slightly resemble THE SCULPTURES. The external company fulfilled the orders and I have all the sculptures ready for 3D printing, but those made of paper also had to be developed (because it is to be a cardboard model). This is what the first sample printed in resin looks like: Therefore, I couldn't resist and replace the figurehead. Below is the old one of cardboard and the new one printed: In the meantime, I put the rest of the artillery on the decks. There was a lot of it, so I helped myself with ready-made gun barrels and 2mm 3D printed blocks. The print was gray, but the Vallejo primer sticks very tightly and nothing is peeling. Now it's time to glue gunport lids, sculptures and lanterns, and all rigging "devices". Oh, and two more boats. I believe that in June I will start erecting masts 🙂 A few photos of an already armed ship: Best Tomek

- 26 replies

-

- Seahorse

- De Zeven Provincien

-

(and 2 more)

Tagged with:

-

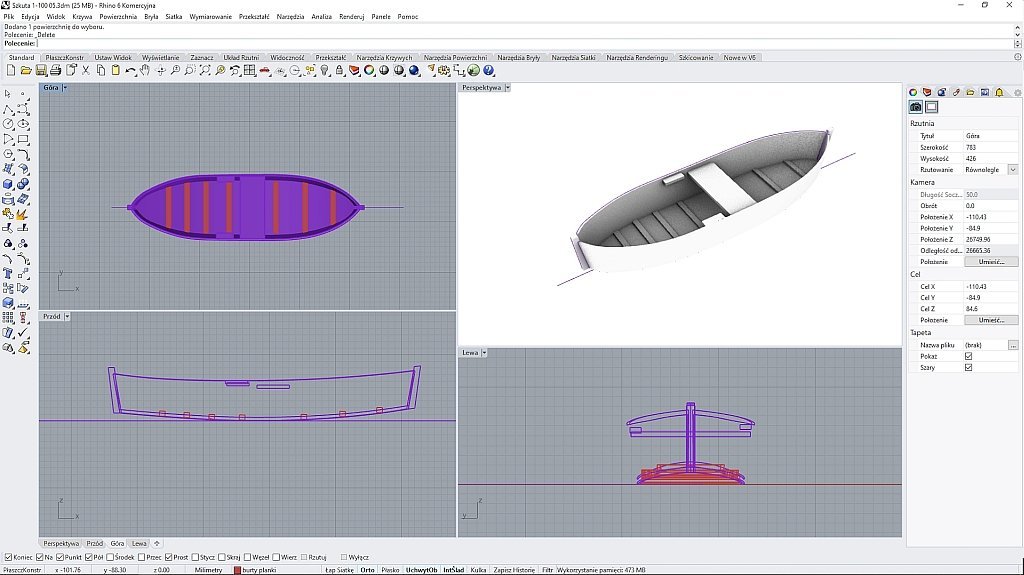

In fact, this boat has sides made of a single board. But I also designed boats with the typical layout of several boards per side. I can only comment on Rhino because I work in this program. One of its functions (probably the most important for me in designing models) is the ability to unfold individual surfaces onto a plane, i.e. to obtain ready-made outlines of parts flat on cardboard (plywood/ wood). The 3D design process itself takes some time, but the surfaces developed later have errors of 0.01mm, so they're perfect. That's why I use Rhino. You can take a look at the SketchUp program (free version available) that some designers use. There are rumored to be plugins on the web that allow the same feature of unfolding a surface to a plane. I haven't explored the topic, so I don't know much about SketchUp.

- 17 replies

-

- Vistula barge

- card

-

(and 1 more)

Tagged with:

-

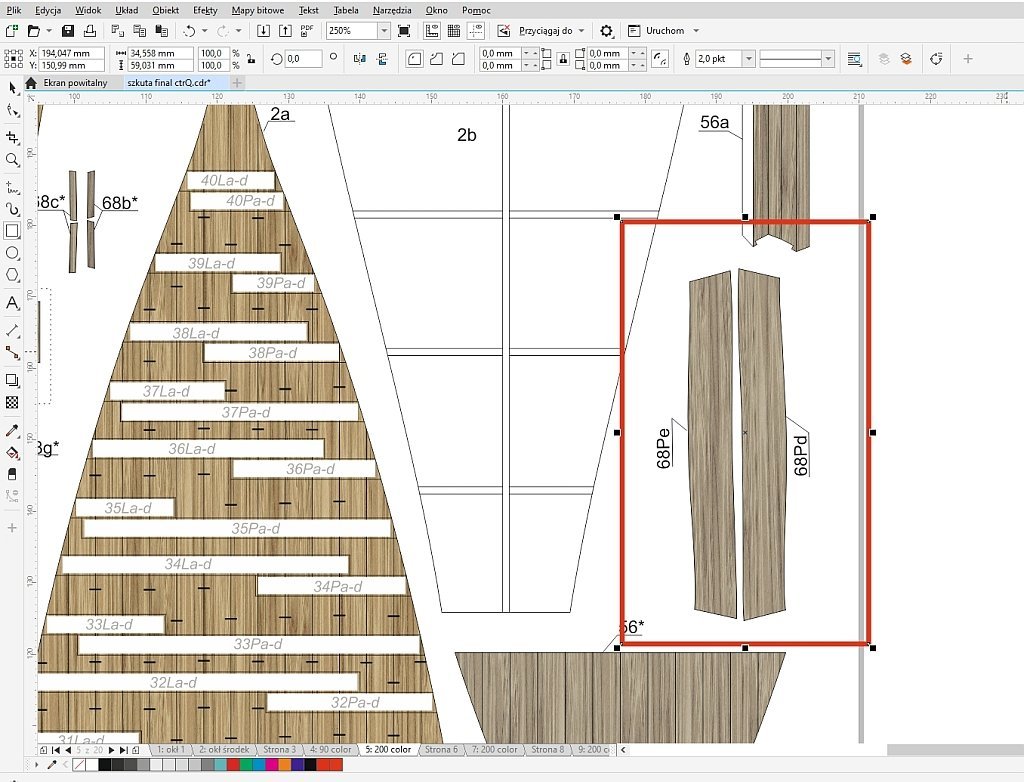

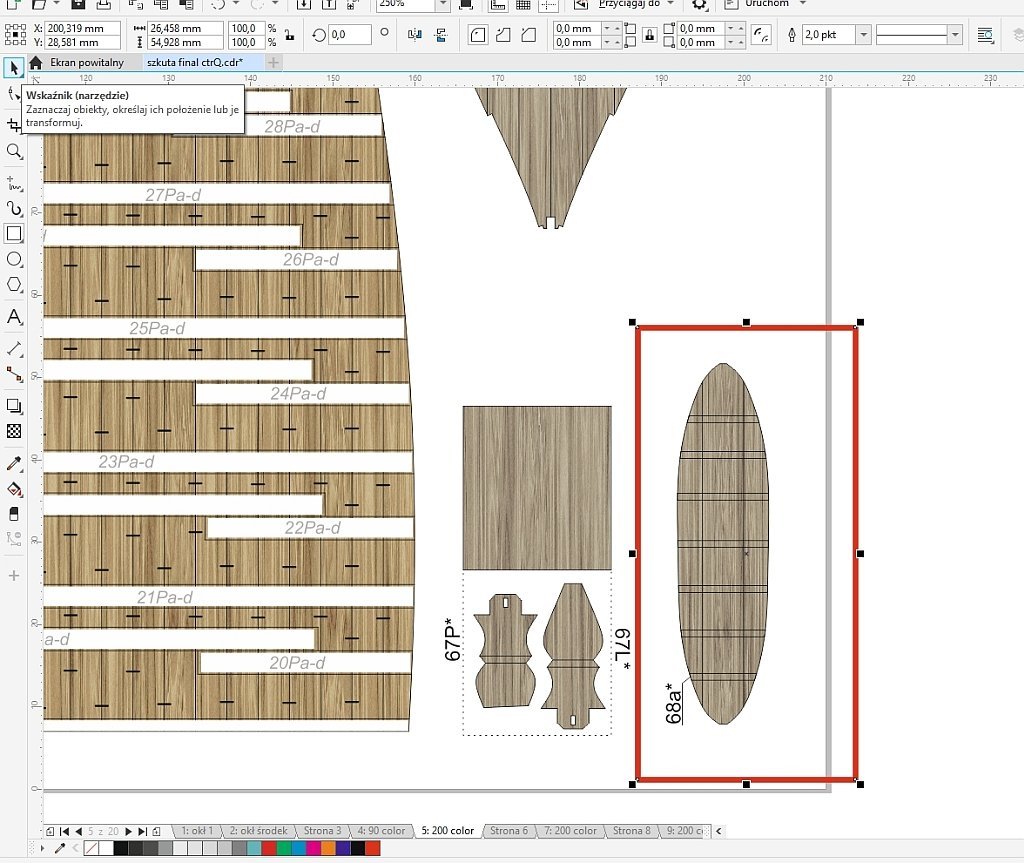

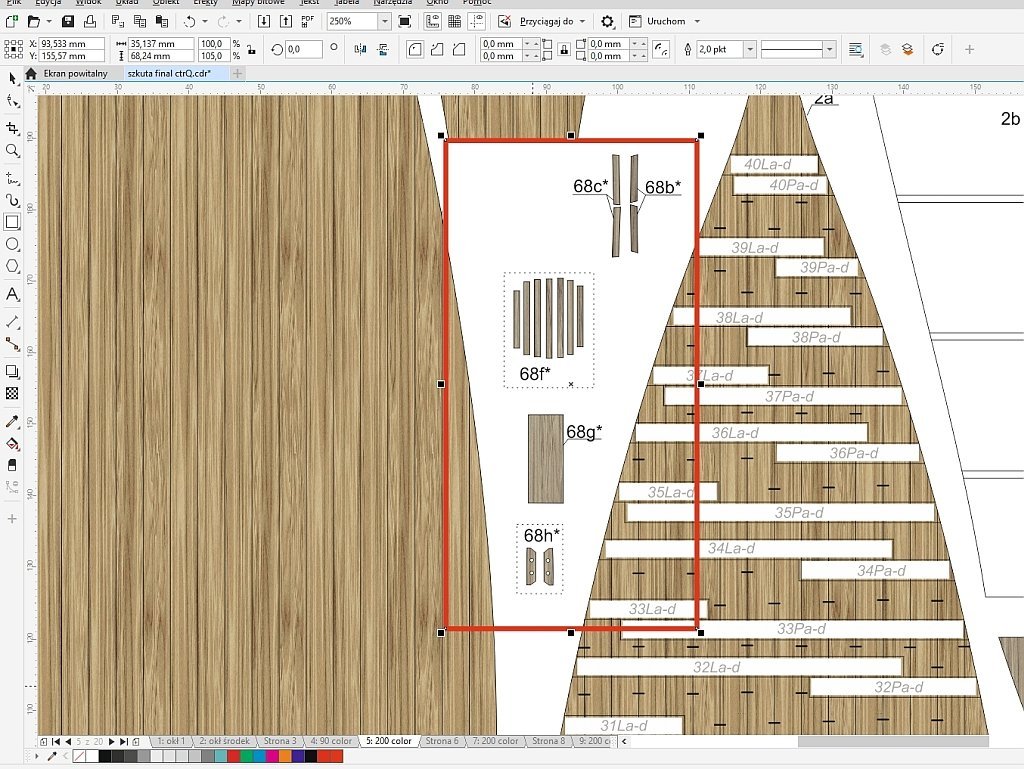

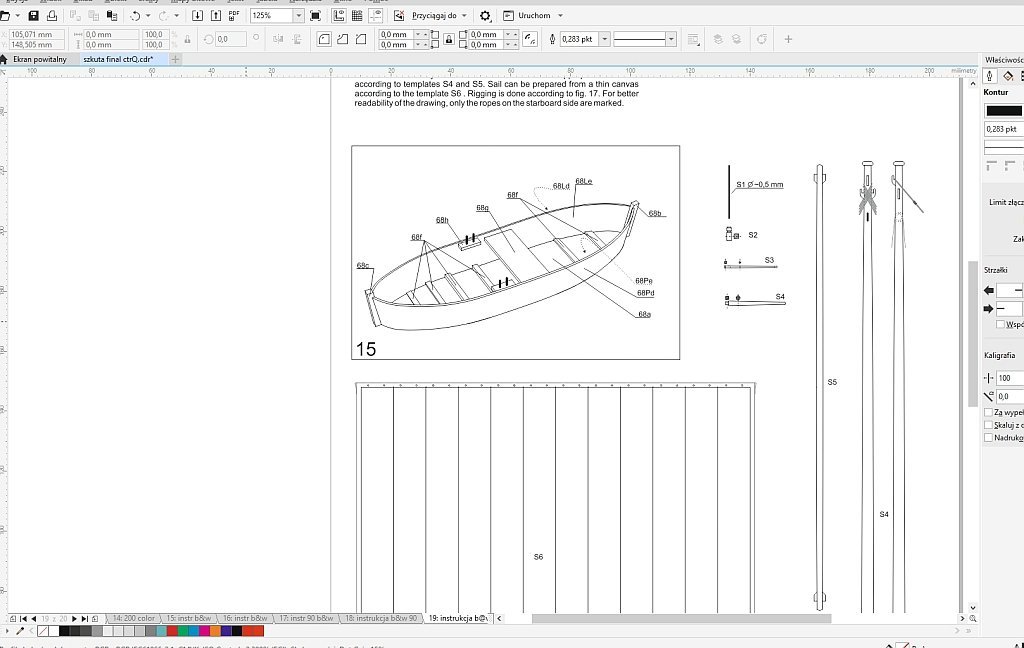

@tkay11 Well, it's rather simple work in paper/cardboard: 1. 3D drawing in Rhinoceros3D... 2. Parts developed in Rhinoceros 3D and colored in CorelDraw + Adobe Illustrator... 3. And a gluing instruction ... I don't know if you expected such an answer. The gluing itself took about 1 hour. White cut edges need to be retouched with the appropriate color, which is obvious in cardboard models. The trick is to choose the right color. Greetings Tomek

- 17 replies

-

- Vistula barge

- card

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.