-

Posts

304 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Schrader

-

I Love it!!!!!!! I want to build one some day

- 81 replies

-

- egyptian

- byblos ship

-

(and 1 more)

Tagged with:

-

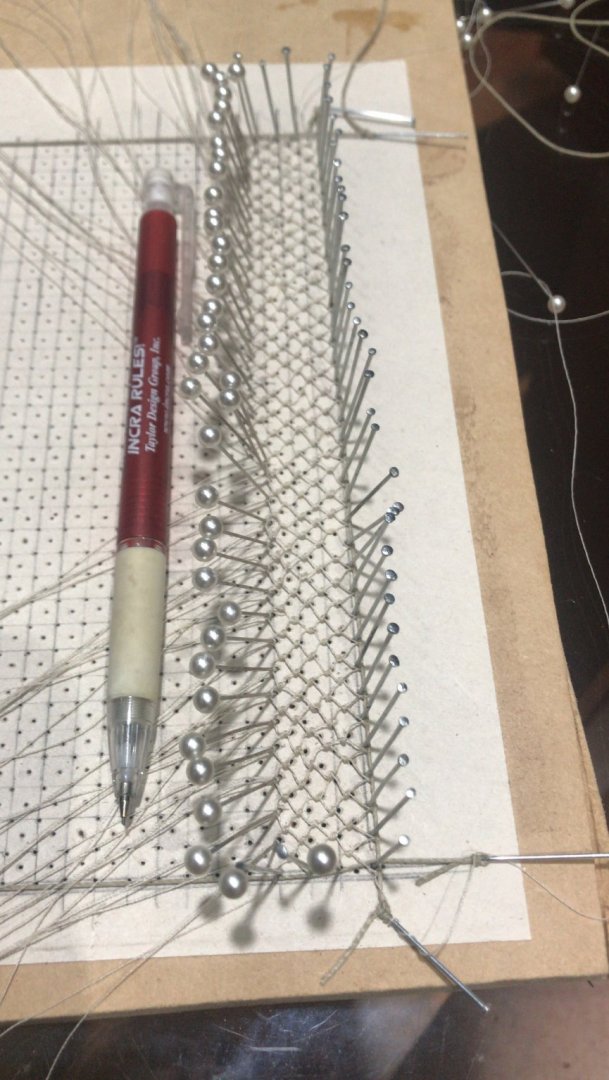

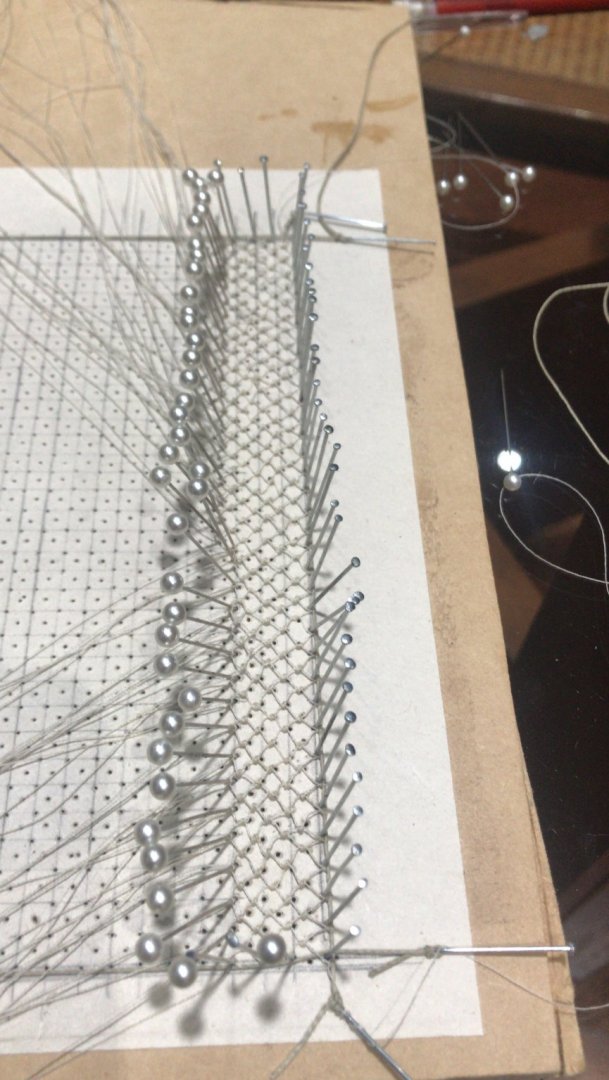

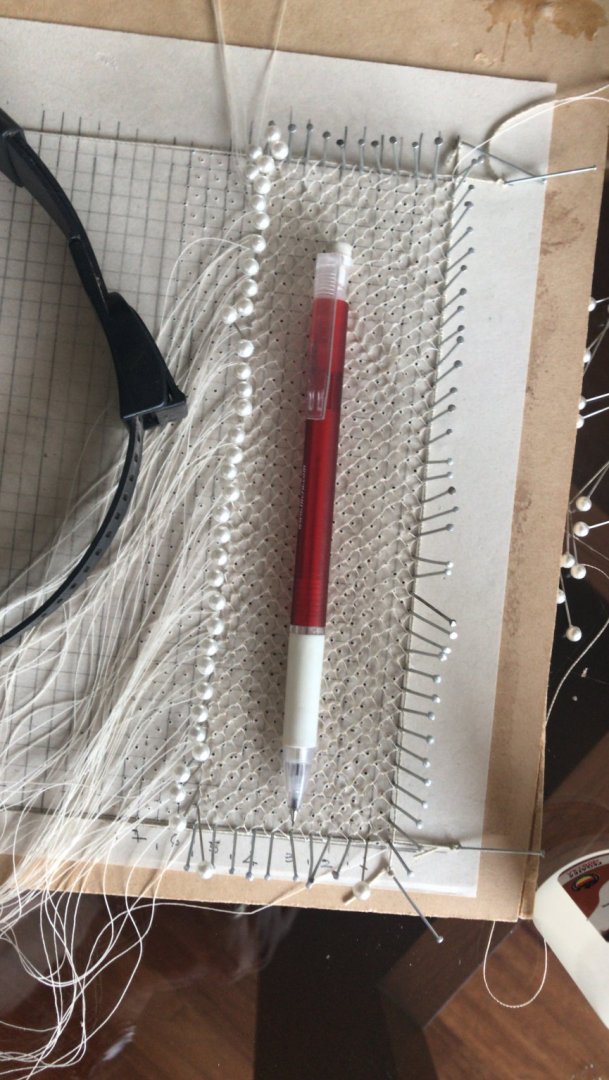

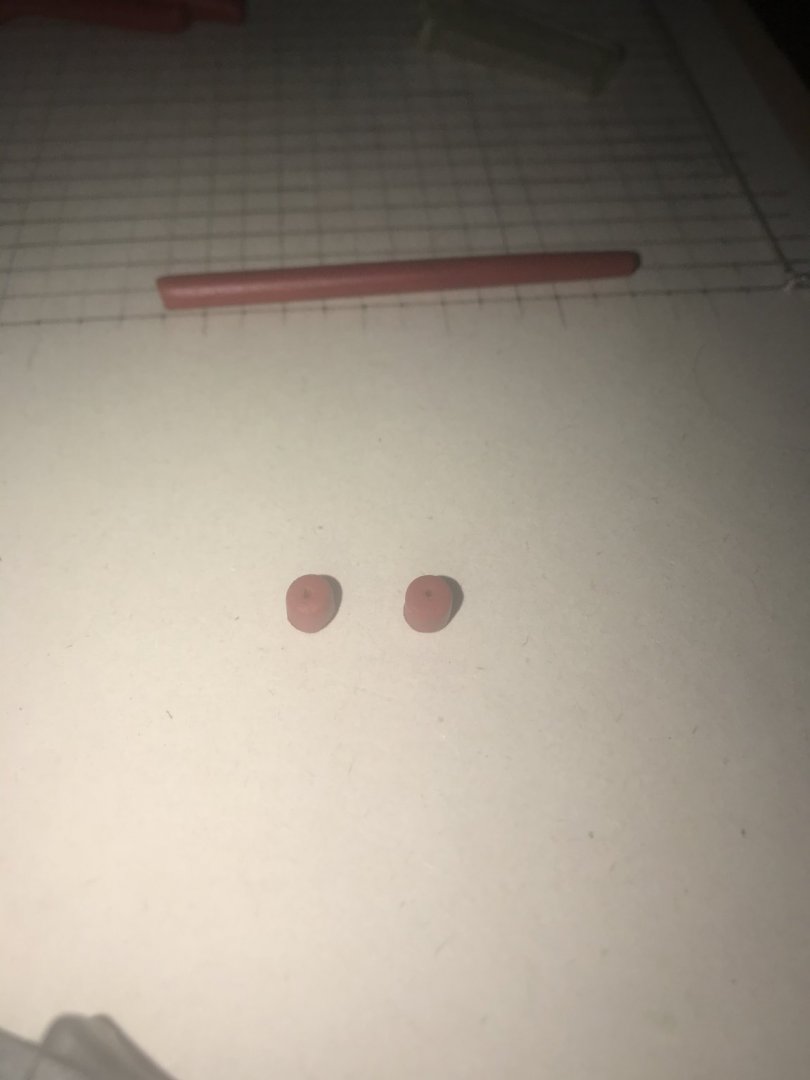

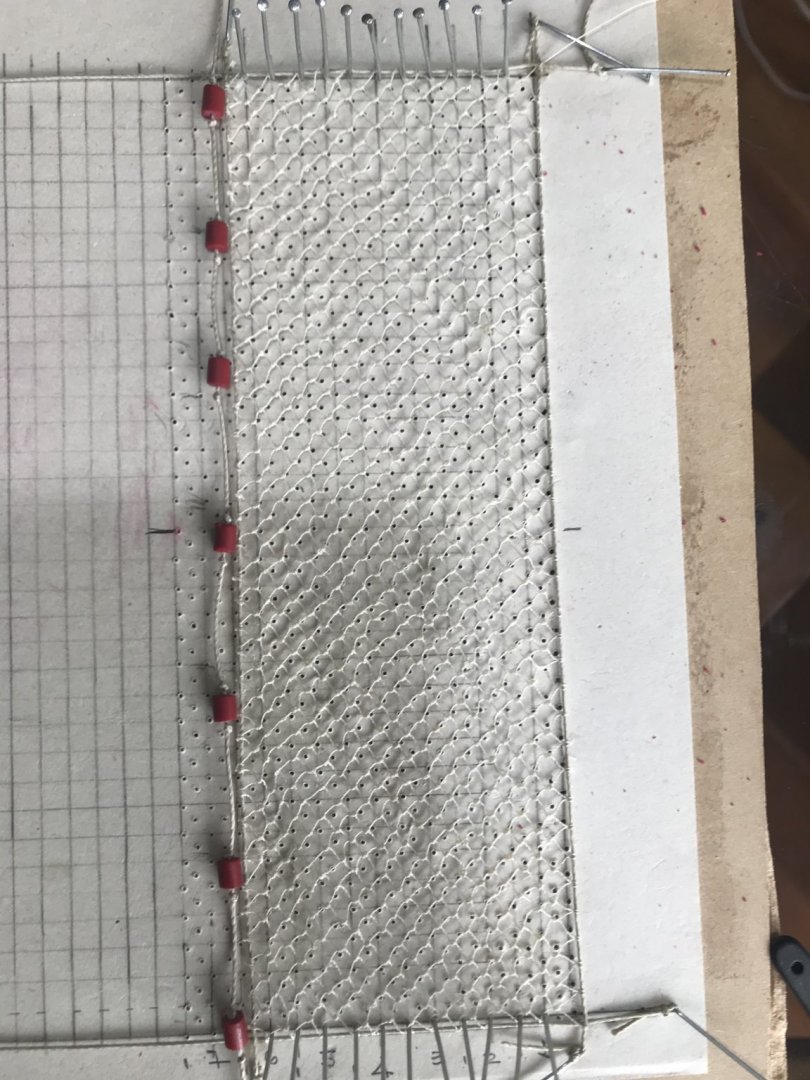

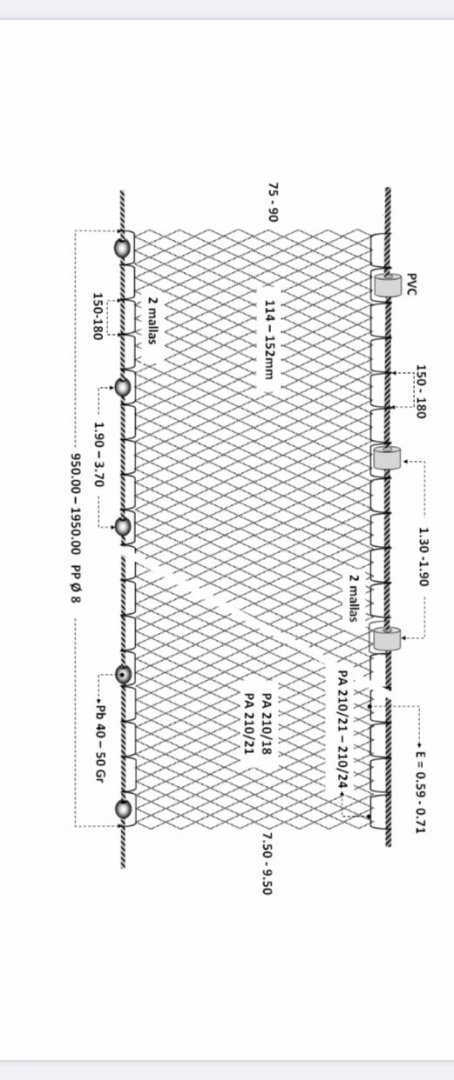

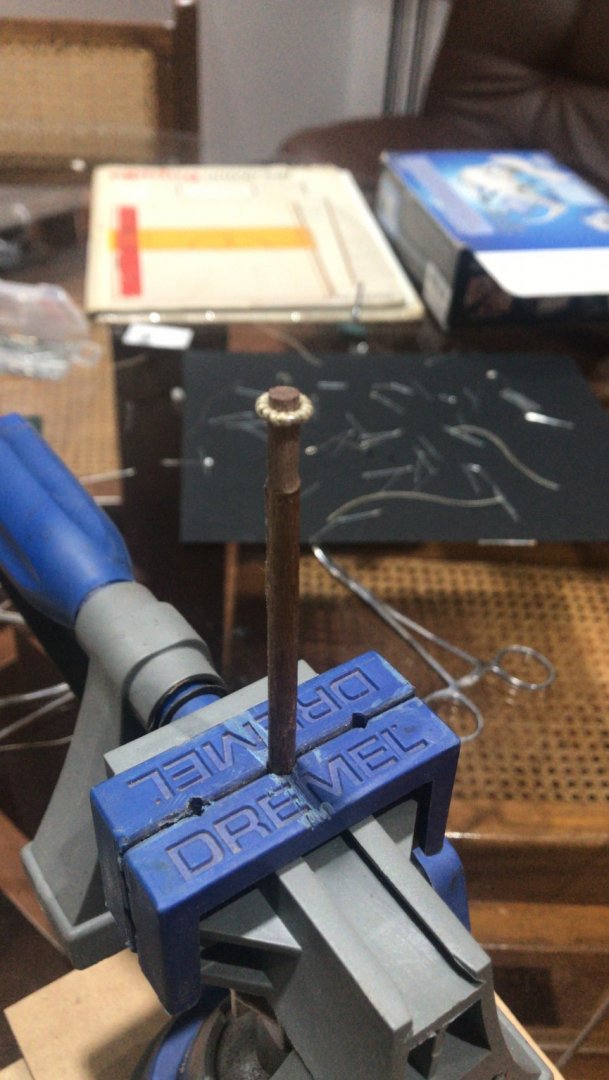

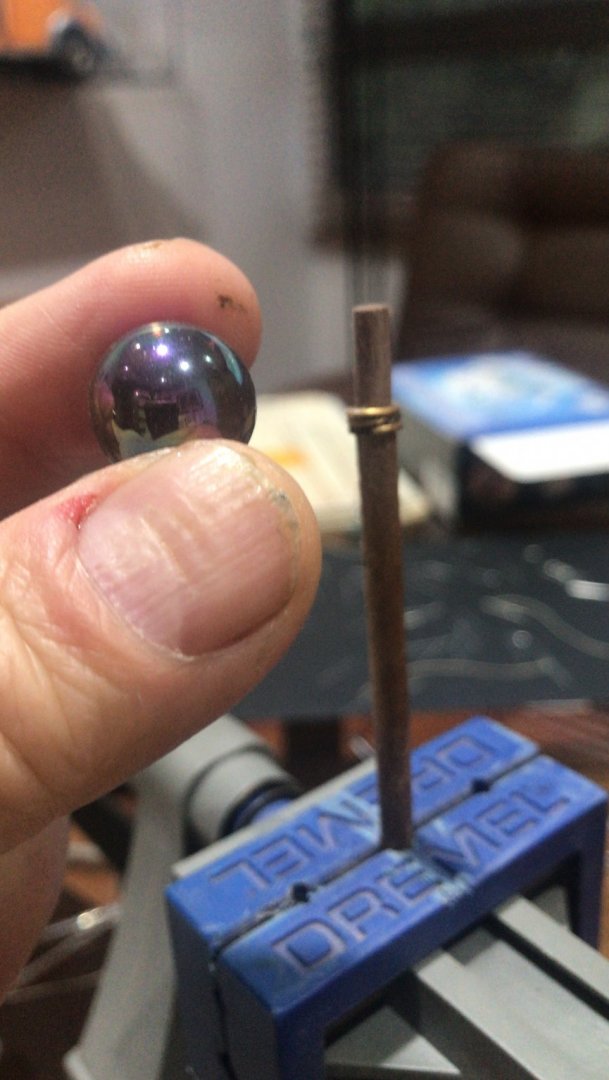

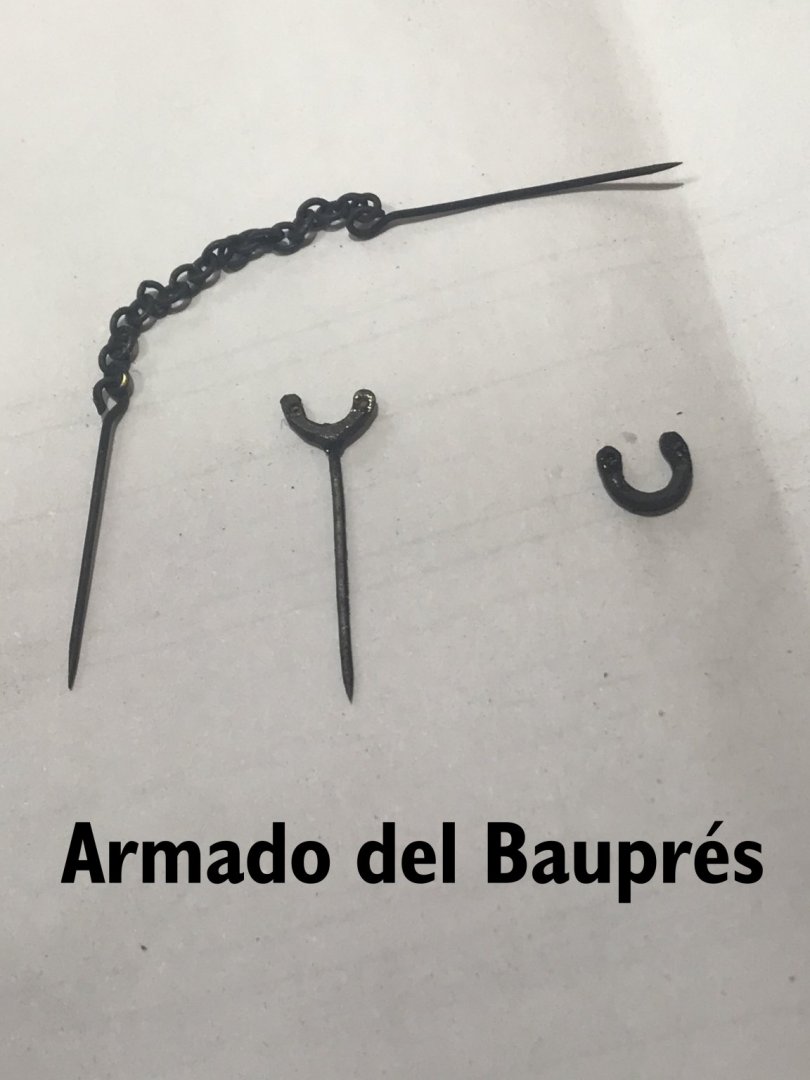

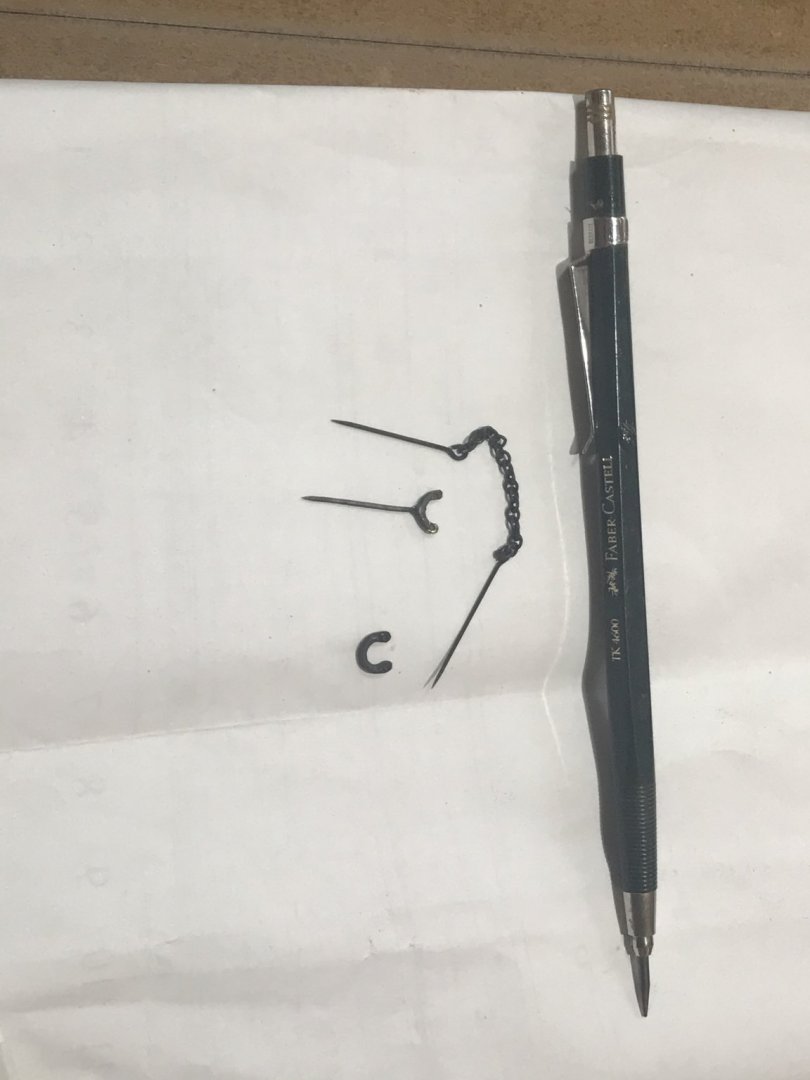

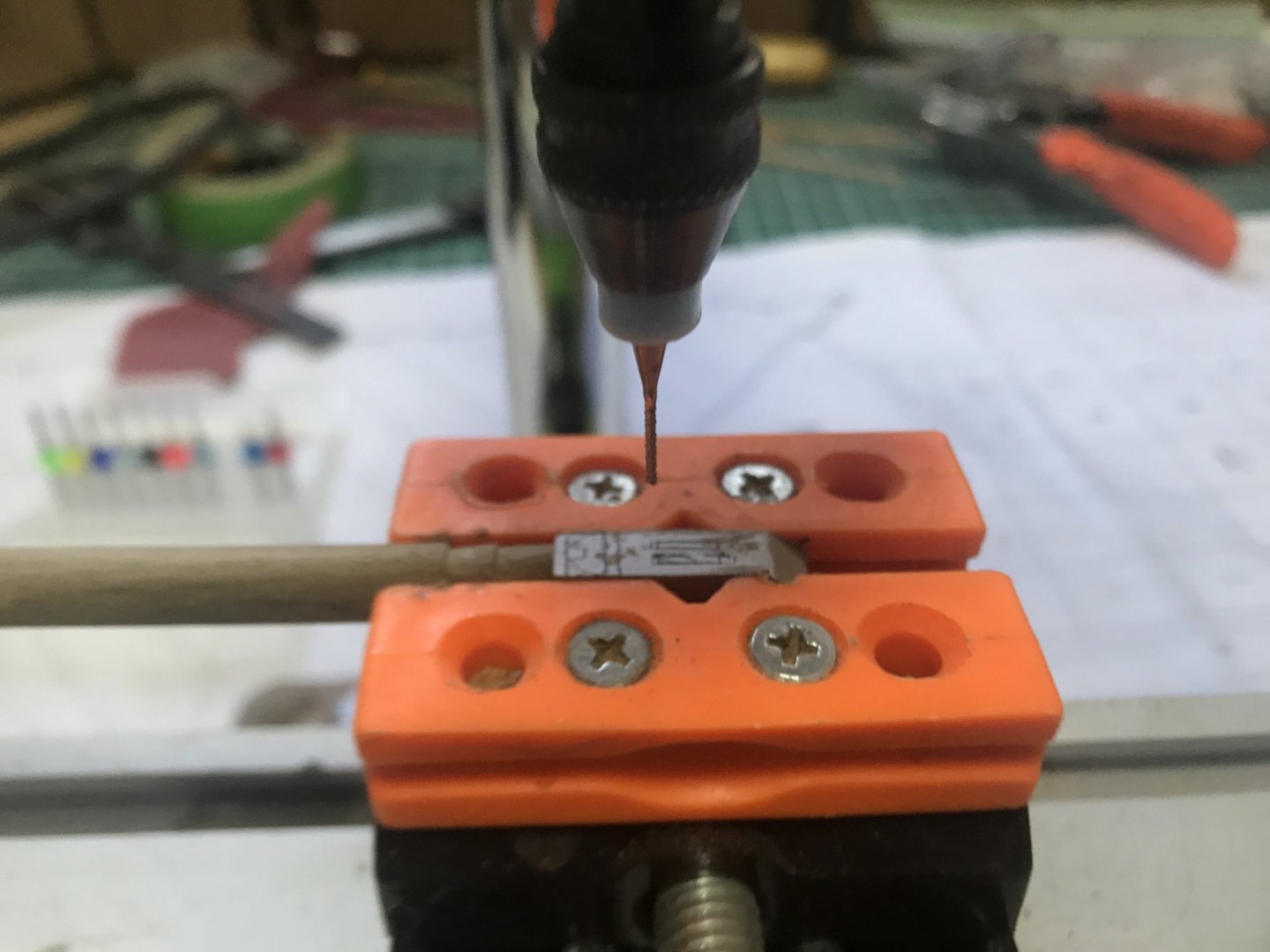

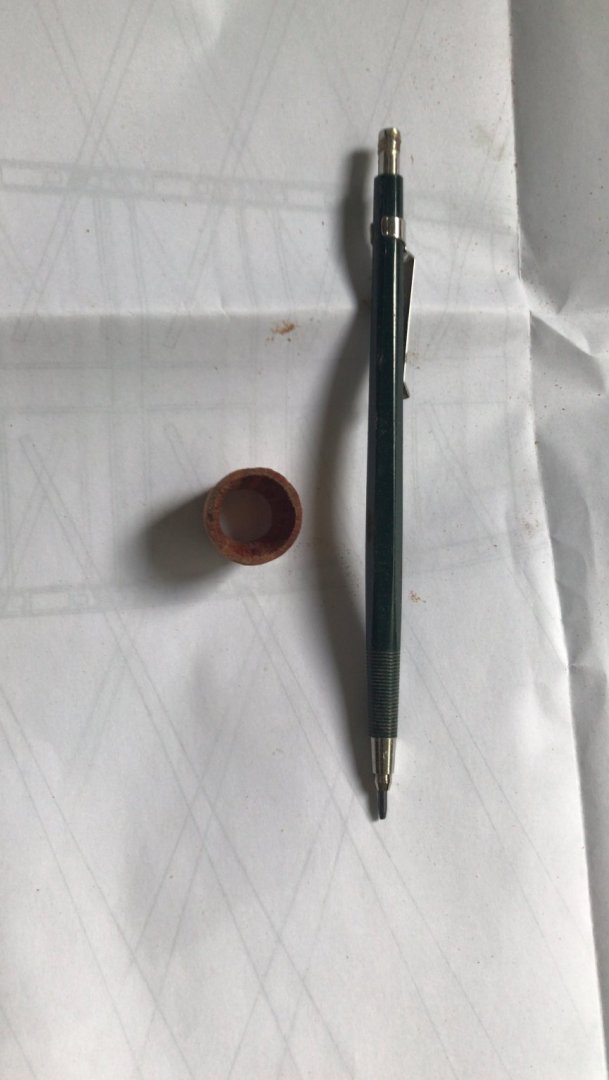

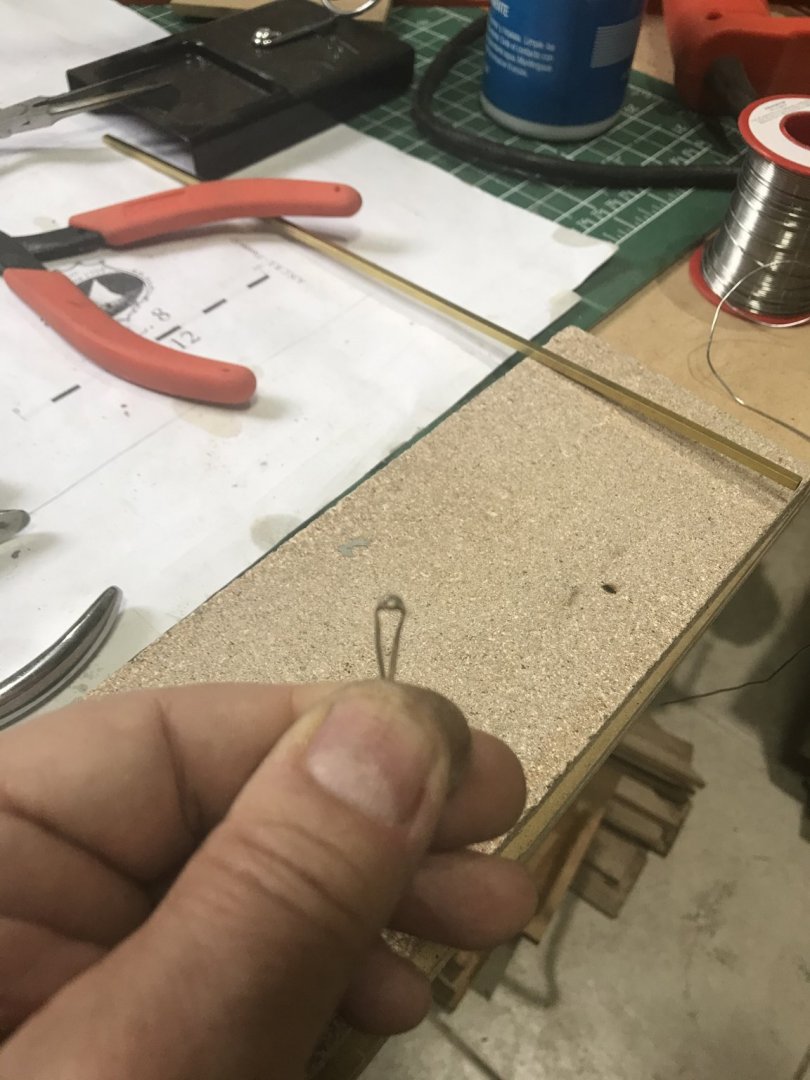

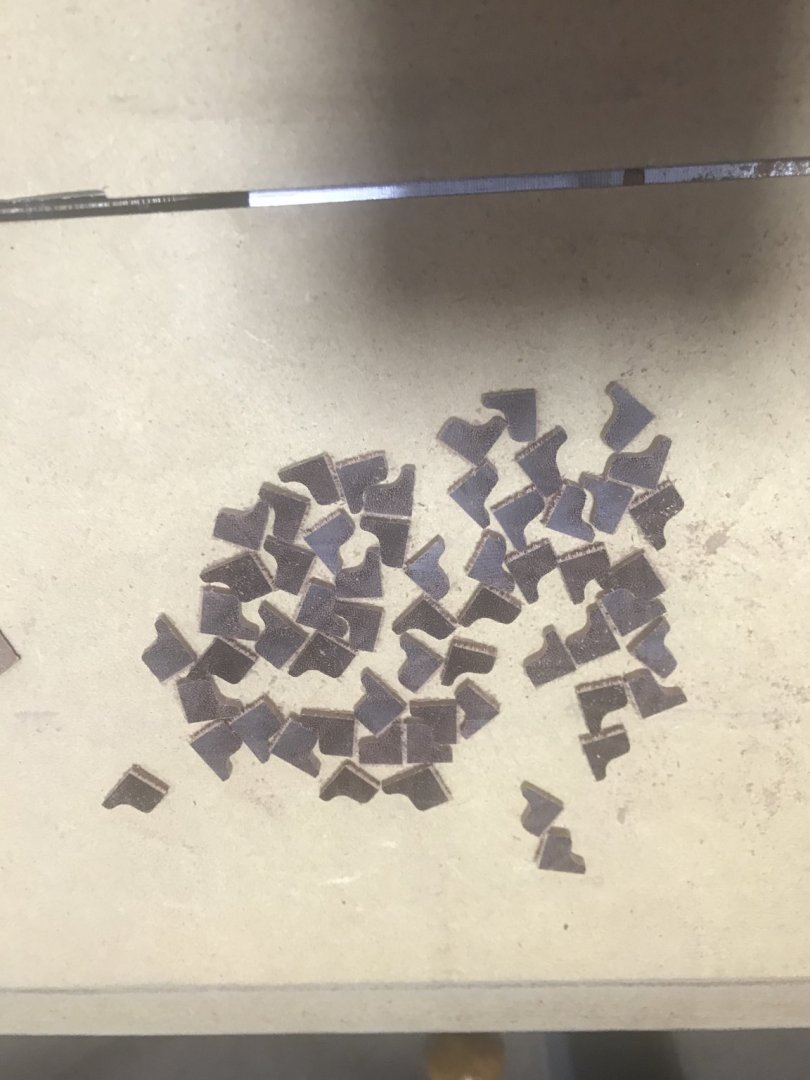

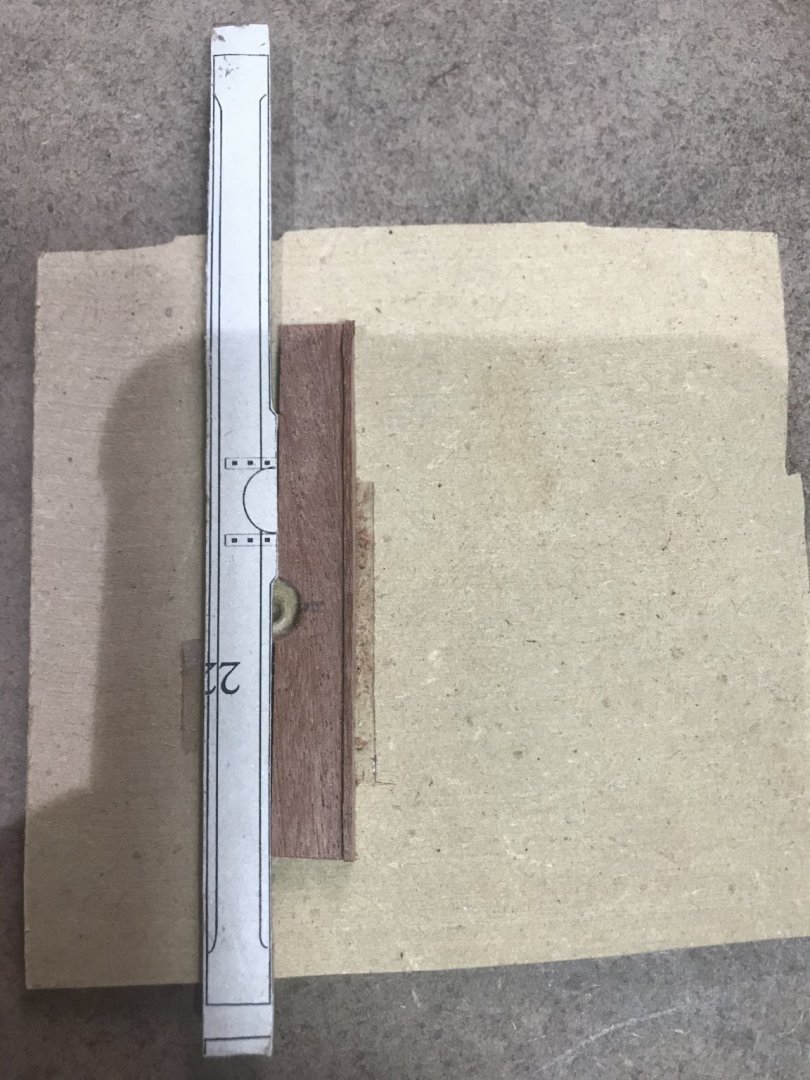

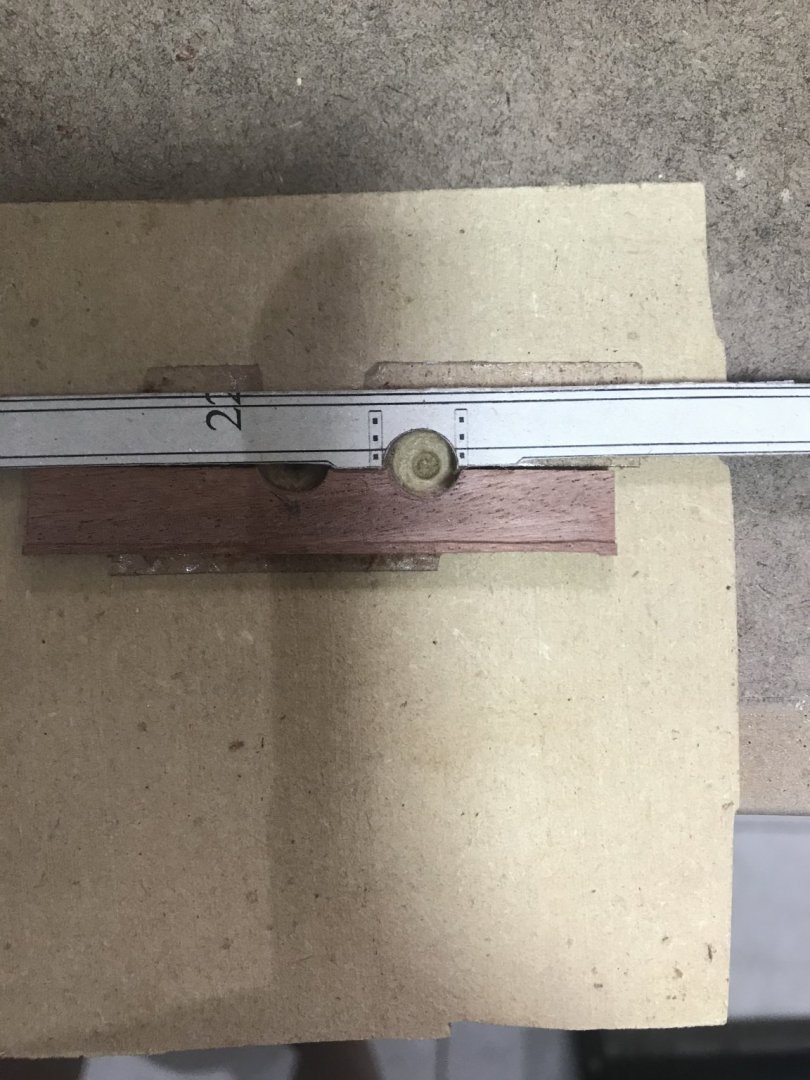

Anchor grapnel....... This piece has some difficulty since we have to weld 8 pieces in a little space. Producing heat that will pump out those pieces that are already welded. So I decided to make a “mold” where all pieces can be “secured” ....... Two pieces of wood with 5 holes.... 1 for the central piece an 4 for the hooks. One 2 mm wire heated in one of its ends...... Smashed..... Its hole.... A little tube in the other end and hooks in 1 mm wire.... All pieces in the “mold”. Secured an welded...... So far... so good... Tips..... And blued.....It is done

-

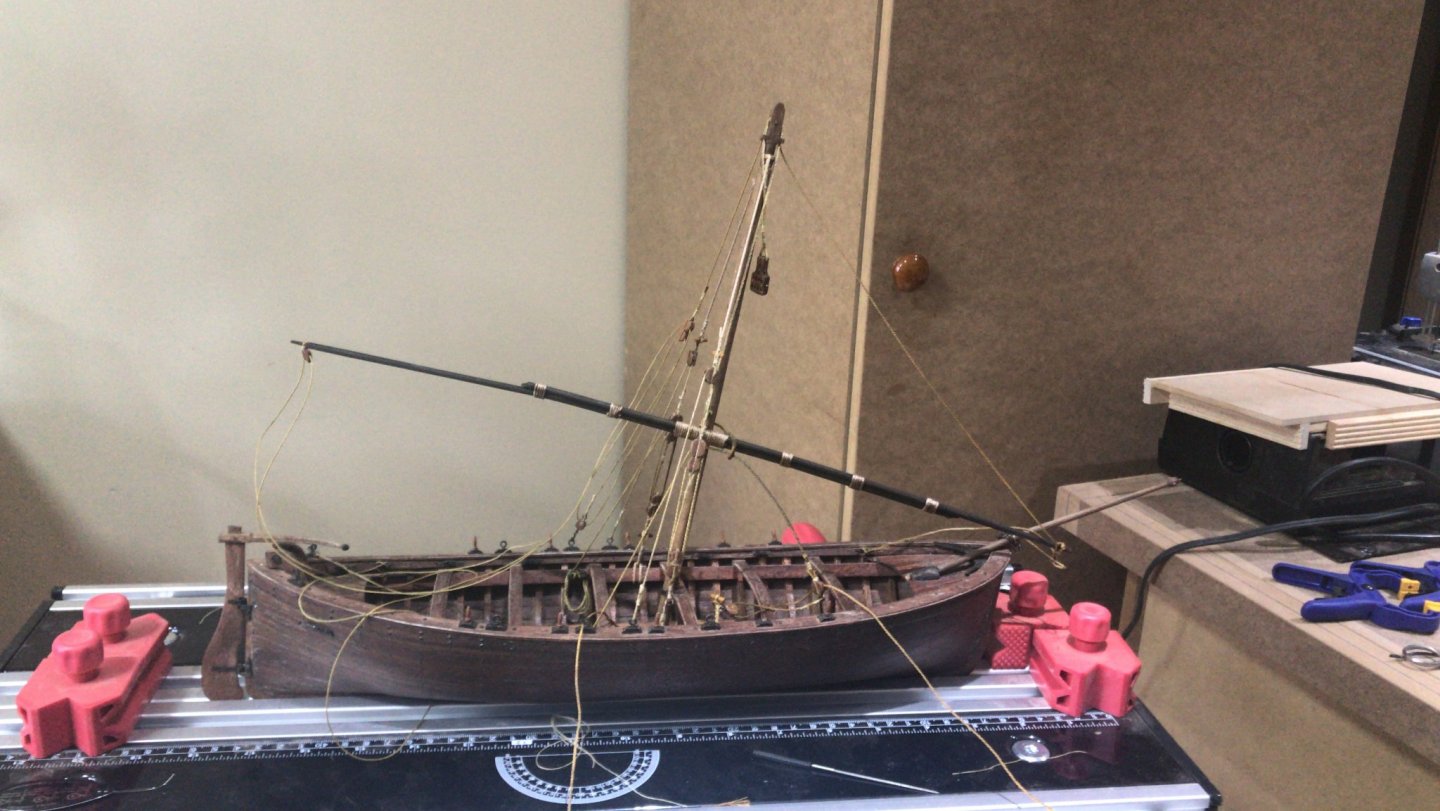

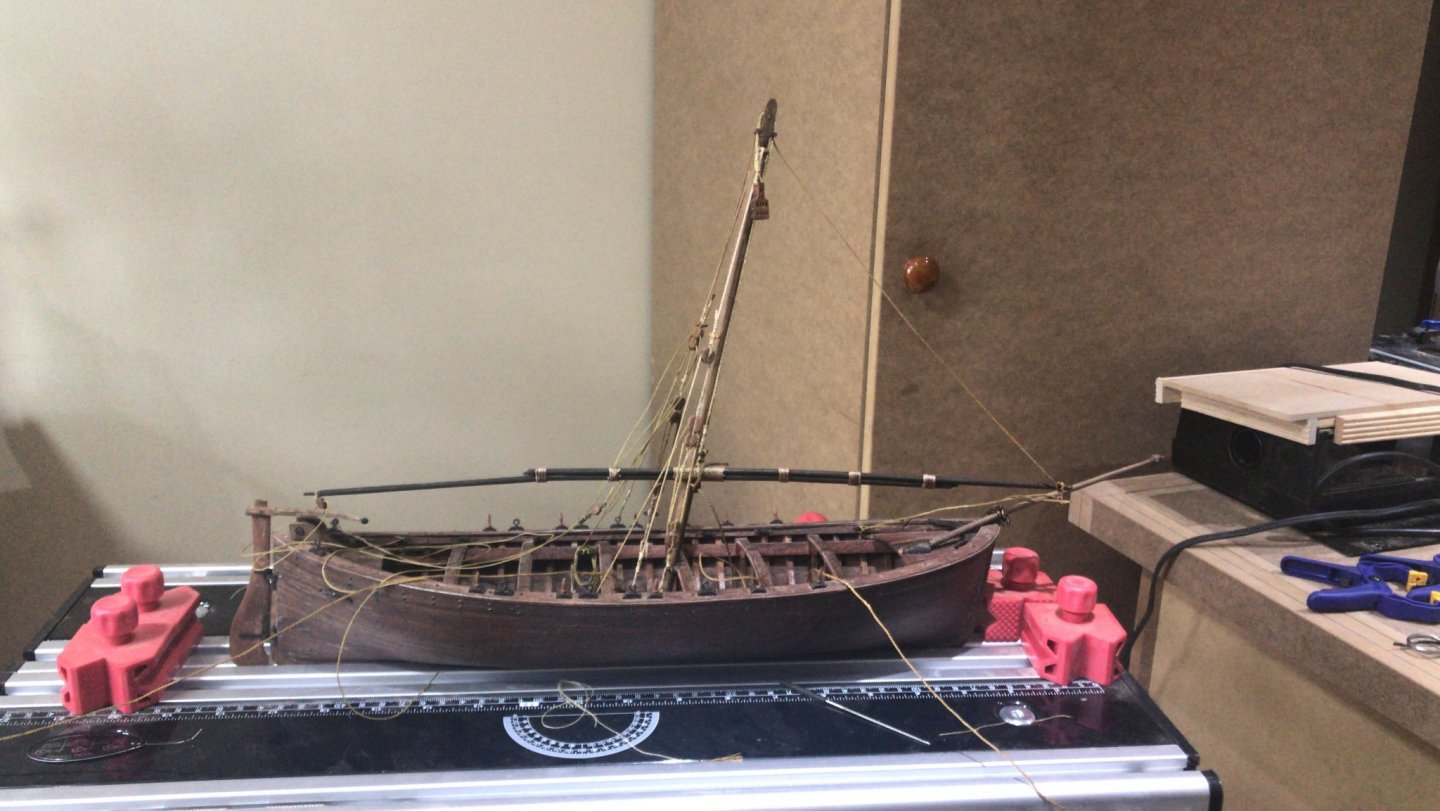

Tim Very.... very..... nice work. So educational. You took your time to explain every step. Thanks a lot nothing to compare with mine. At the present I followed your advice I’m posting a log about my present work. The St Caterina. thanks again this my final result in my longboat

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

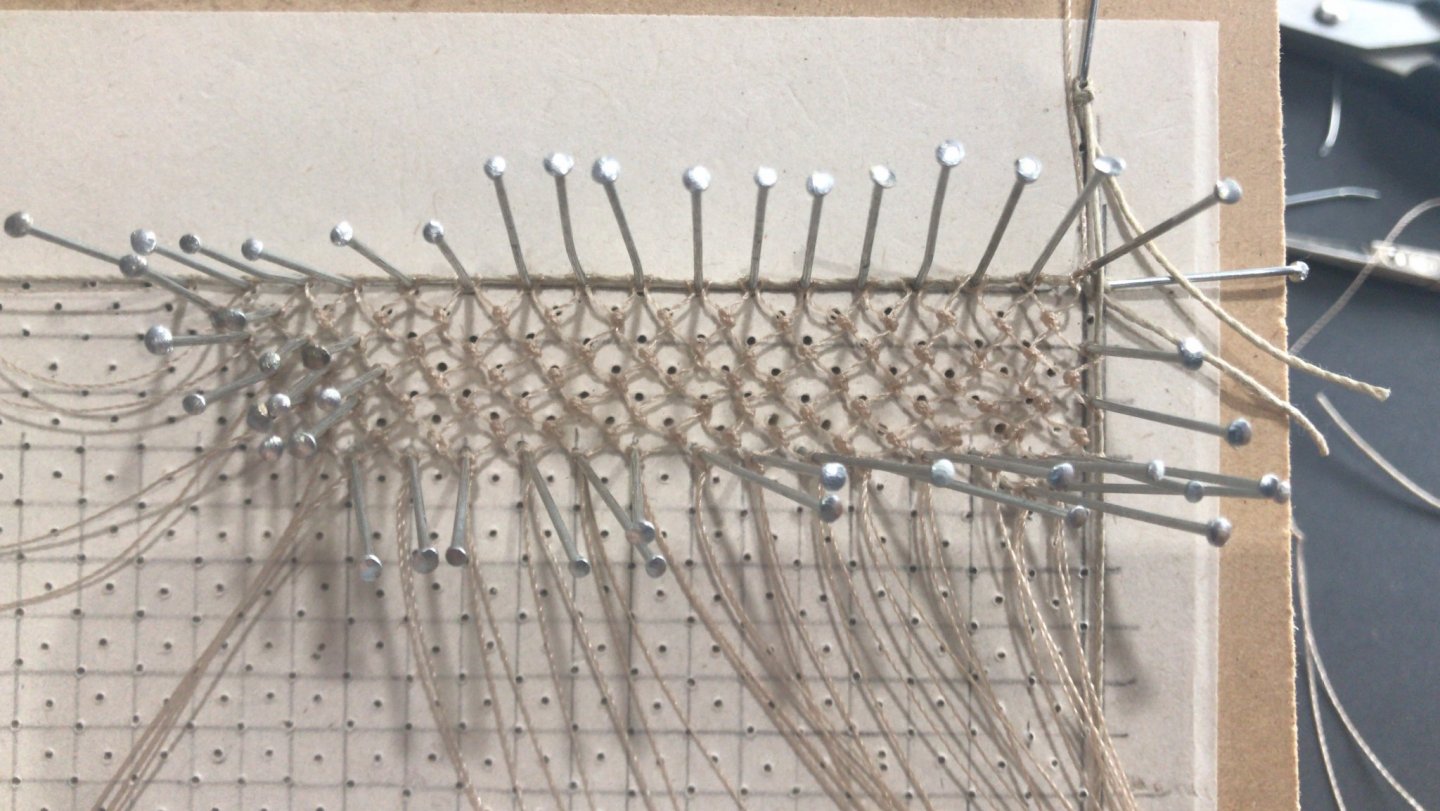

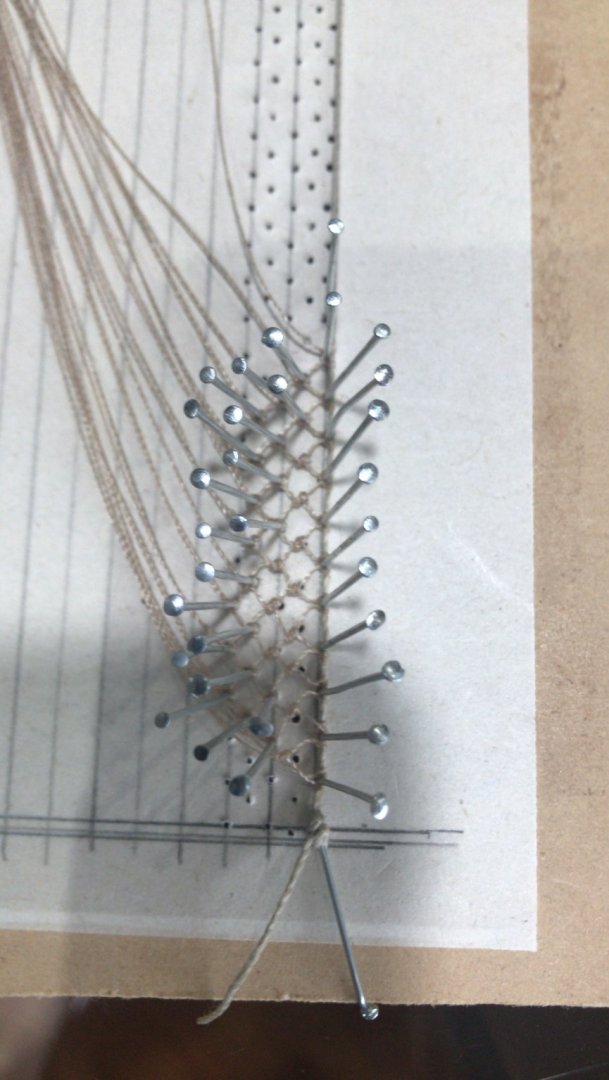

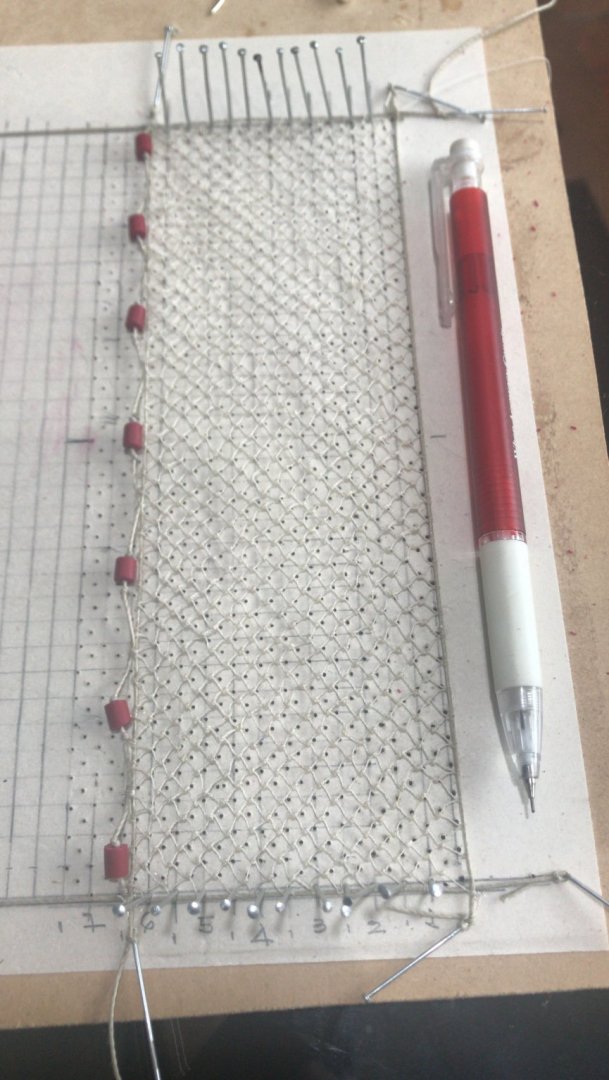

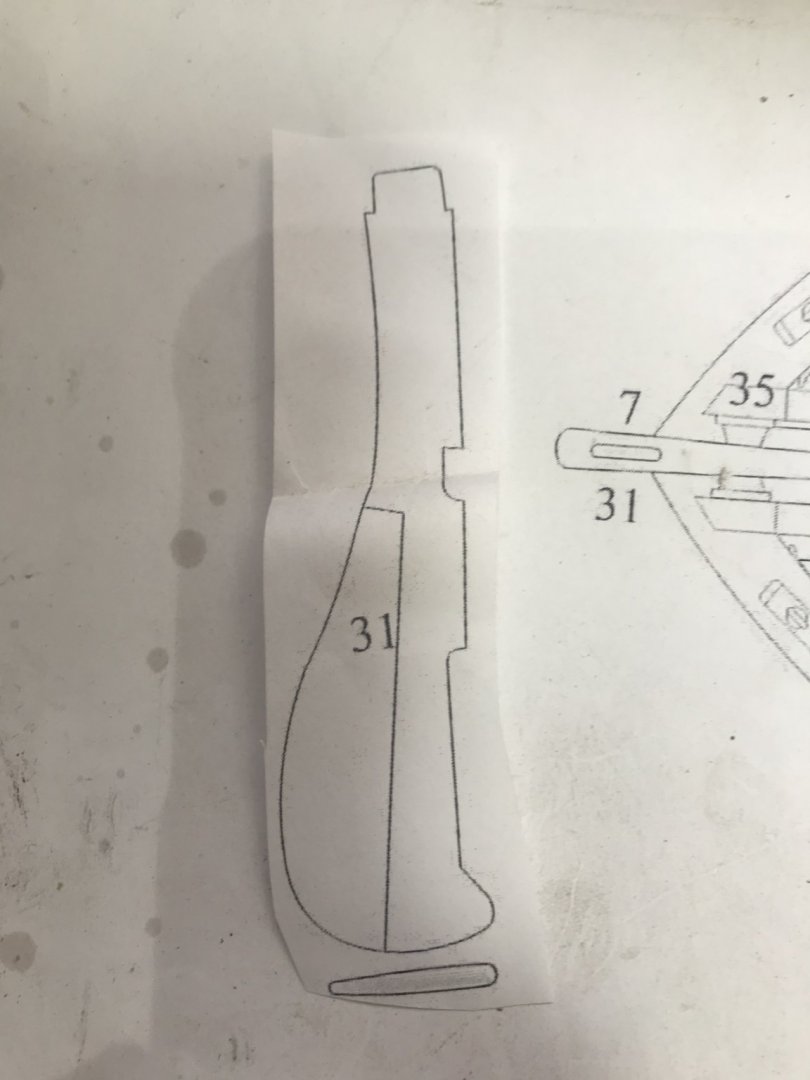

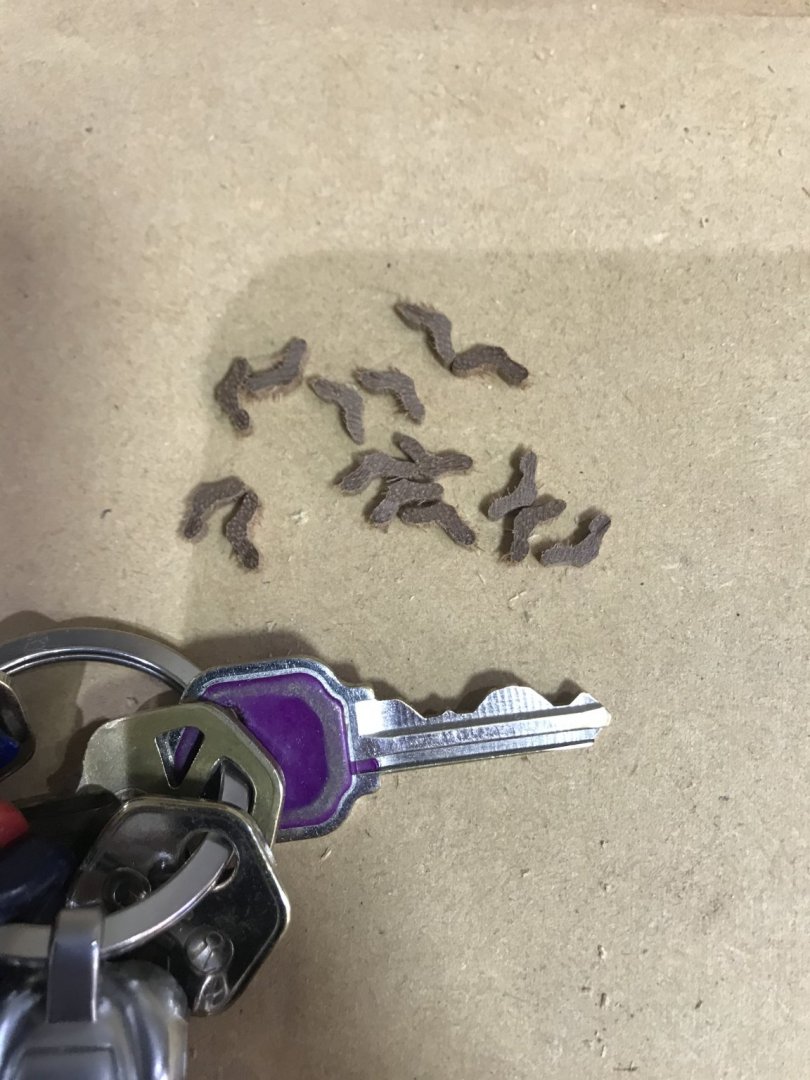

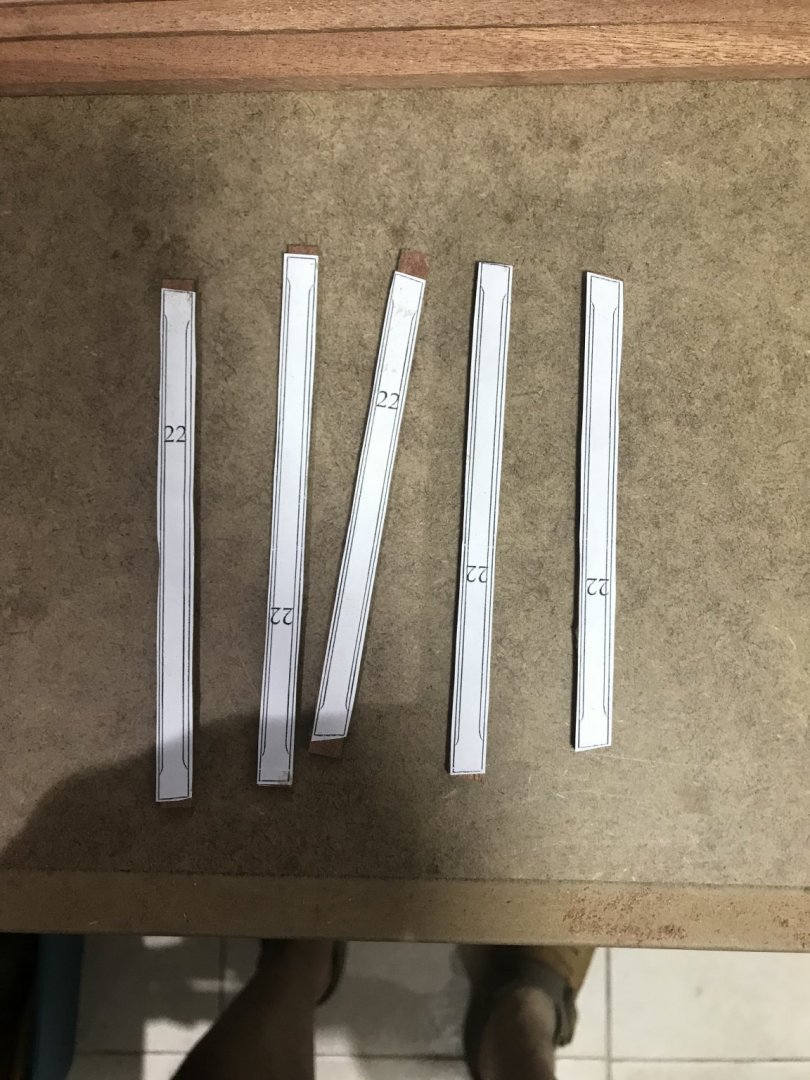

Now is time for the top of the gunwale.......at this time you have to realize that the plans are a “little different” to reality...... then make your hull been your reference, You will realize also that the two sides are not completely identical so..... try your best for make those differences “unnoticeable” Of course... we have to aged them.....For this I took a note about where the oars should work, the ropes will work and I put a little more attention to those sites..... Also I needed to fabricate some cleats..... Then.....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.