Mldixon

NRG Member-

Posts

152 -

Joined

-

Last visited

About Mldixon

- Birthday 11/14/1950

Profile Information

-

Gender

Male

Recent Profile Visitors

-

Saburo reacted to a post in a topic:

HMS Winchelsea 1764 by Matt D 1:48

Saburo reacted to a post in a topic:

HMS Winchelsea 1764 by Matt D 1:48

-

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea 1764 by MLDixon

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea 1764 by MLDixon

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Beckmann 1/48

FrankWouts reacted to a post in a topic:

HMS Winchelsea by Beckmann 1/48

-

Rustyj reacted to a post in a topic:

HMS Winchelsea 1764 by MLDixon

Rustyj reacted to a post in a topic:

HMS Winchelsea 1764 by MLDixon

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Mldixon reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

Mldixon reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

Mldixon reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

Mldixon reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

-

Gabek reacted to a post in a topic:

A ship's stove too small to print? (For La Jacinthe)

Gabek reacted to a post in a topic:

A ship's stove too small to print? (For La Jacinthe)

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by CaptMorgan (Steve) - FINISHED - 1:48

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by CaptMorgan (Steve) - FINISHED - 1:48

-

Saburo reacted to a post in a topic:

HMS Winchelsea (1764) 32 gun frigate GROUP PROJECT INFO

Saburo reacted to a post in a topic:

HMS Winchelsea (1764) 32 gun frigate GROUP PROJECT INFO

-

Mldixon reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Mldixon reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764, by Gary B

-

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - FINISHED - 1:48

Mldixon reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - FINISHED - 1:48

-

Mldixon reacted to a post in a topic:

HMS Winchelsea by rafine 1/48

Mldixon reacted to a post in a topic:

HMS Winchelsea by rafine 1/48

-

Rustyj reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Rustyj reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

👍👍good luck Tony, and your welcome. I looked at your build logs, very impressive work...- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

Yes that is the printer I used. The good news is, once you push print you can work on other things. Most printers are going to charge you a lot. Just buy the printer and resin. If you model a lot of parts it pays for itself pretty quickly. And yes it does have a learning curve, but it's not too steep- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

I thought it looked pretty good considering the scale.- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

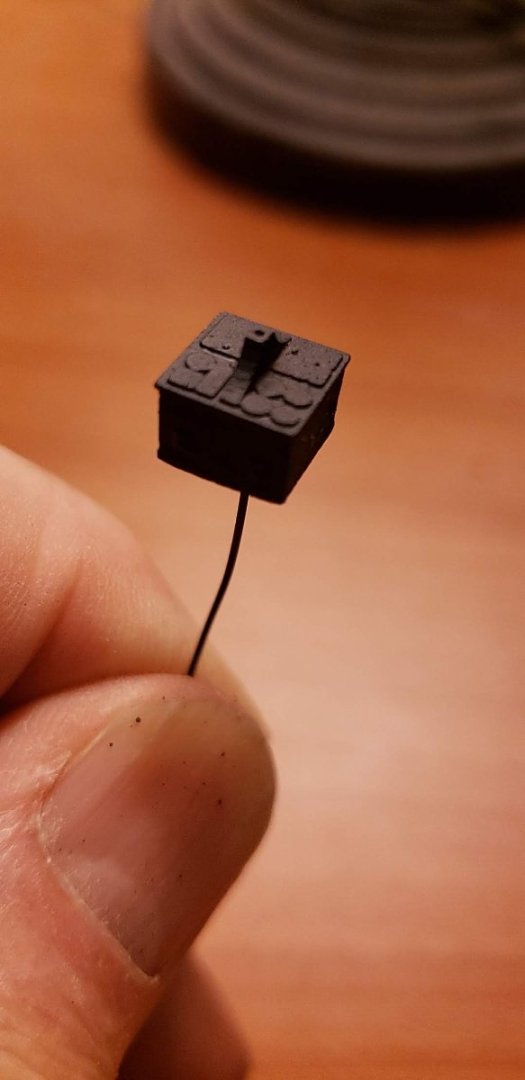

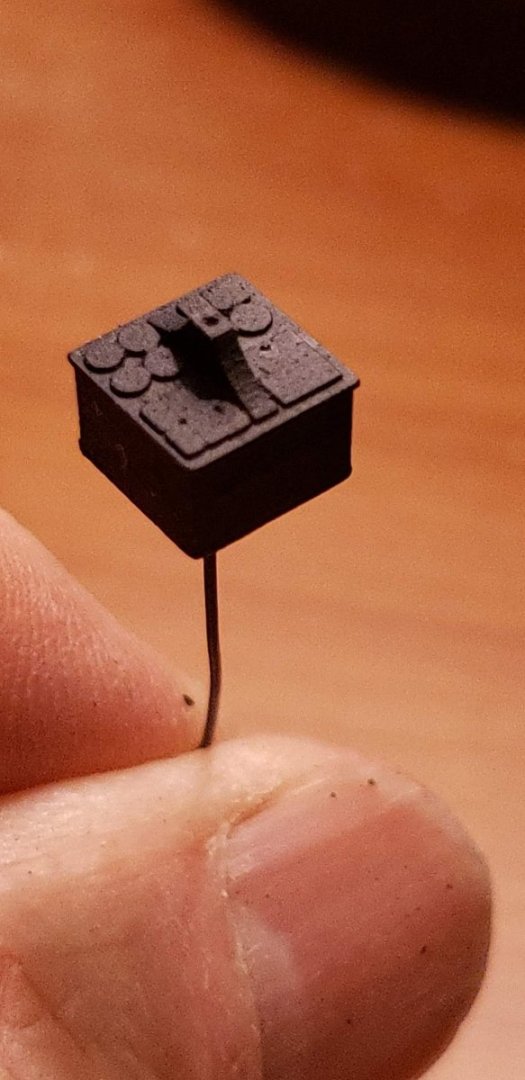

So here are the results of the print of the stove. I primed it in black with an airbrush on about the finest mist i could produce. I did no post cleanup on this, an alcohol wash and blew it off with air compressor. It was a .01mm layer setting and it took 5.5 hrs to print. Cost was 1.5 Cents plus paint, 5 drops. With the naked eye (mine are 73 years old) it appears as a black sugar cube. You will need a magnifier to see any detail at all. And the paint tends to wash out details at this level of printing, so it's got to be very light coats. I'm fairly certain any type of brush on painting would obliterate the details at this size. This was your file as provided. If you exaggerated the details, they would stand out to the naked eye pretty good. I would think the print services are being ultra cautious because of the small size and customer satisfaction. Size verification🔻 Top of stove, Painted to reveal details🔻 Side shot- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

I'll run it this morning.- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

If the advice is to give up, then I'll be happy to give the drawings to anyone who is interested Sure link me to your model stl or obj file and ill give it a whirl on my Anycubic mono and see if it works.- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

A ship's stove too small to print? (For La Jacinthe)

Mldixon replied to tkay11's topic in 3D-Printing and Laser-Cutting.

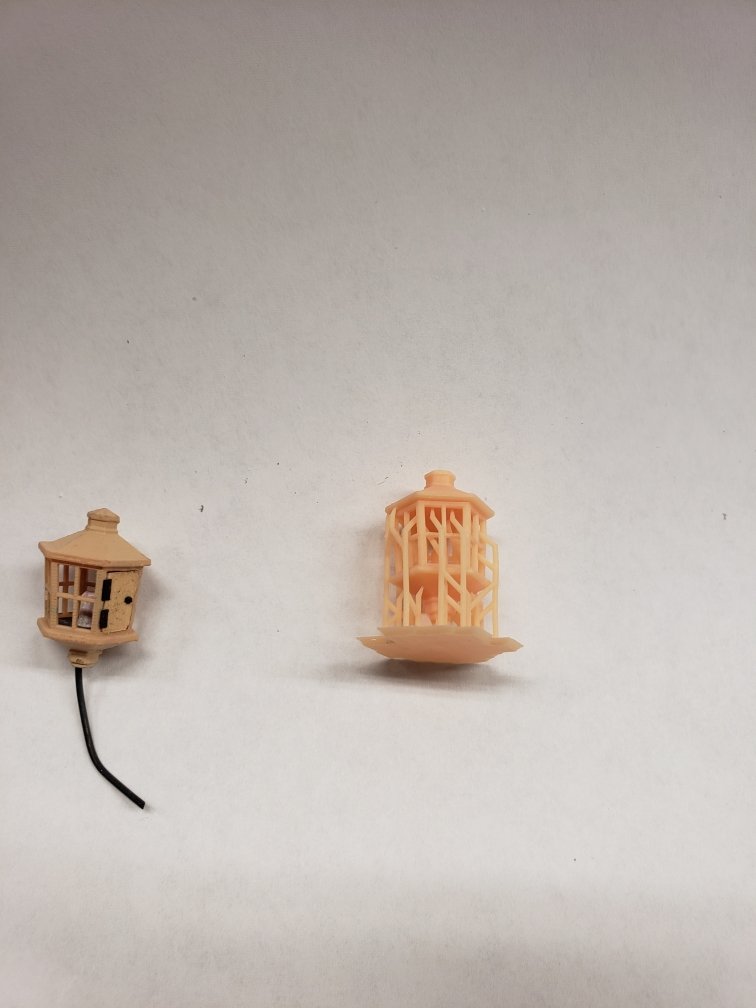

I just 3d printed a latern for my Winchelsea model. It seemed an almost impossible task, but I was able to get a pretty good result. I draft in full scale, then scale down to model size. At that point you are correct, the parts are too thin to print. So i make things thicker to overcome this. When printed and viewed very few can detect the difference. If your a purist well none of this will work. Link to lantern https://modelshipworld.com/topic/22779-hms-winchelsea-1764-by-mldixon/?do=findComment&comment=926251- 17 replies

-

- ancre

- CAD print resolution

-

(and 2 more)

Tagged with:

-

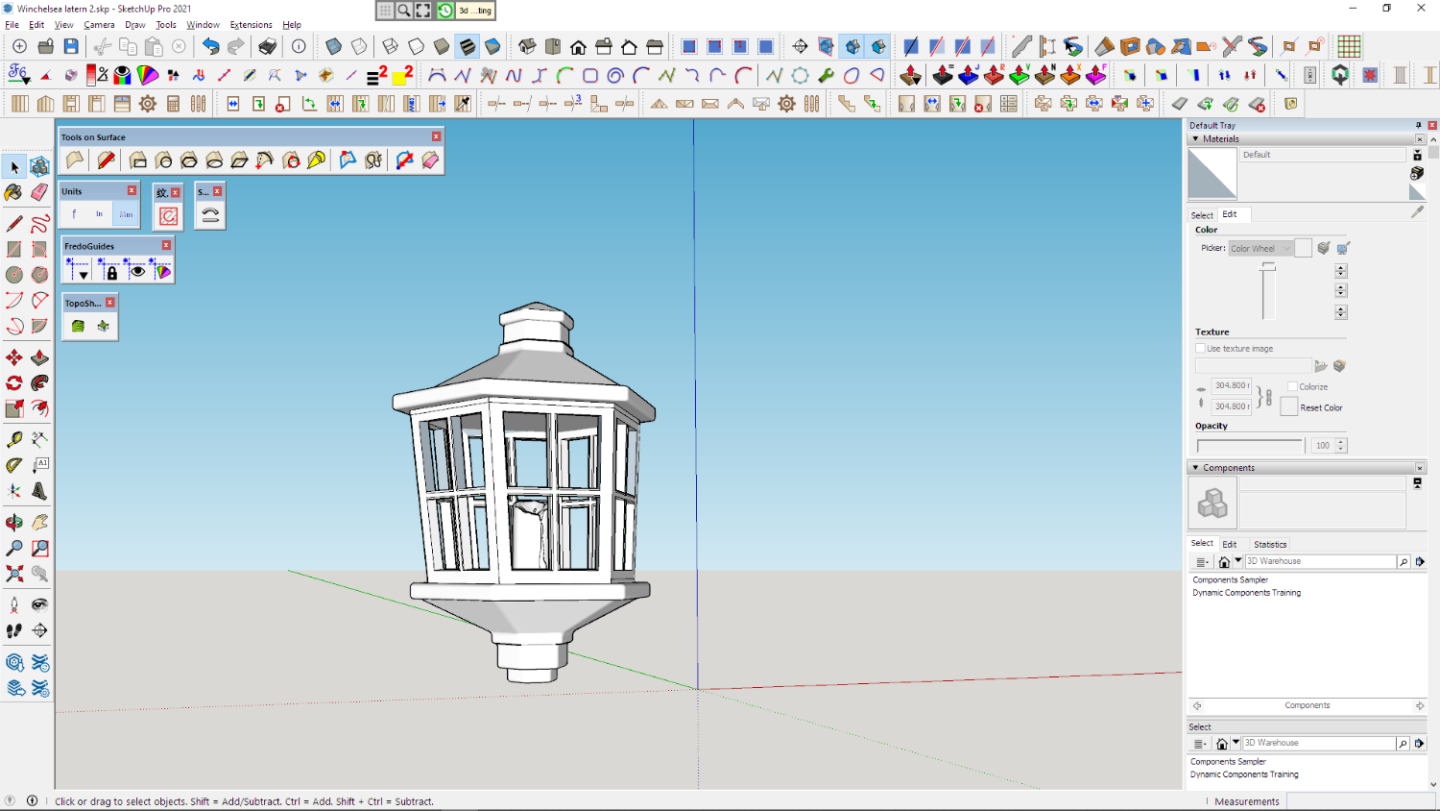

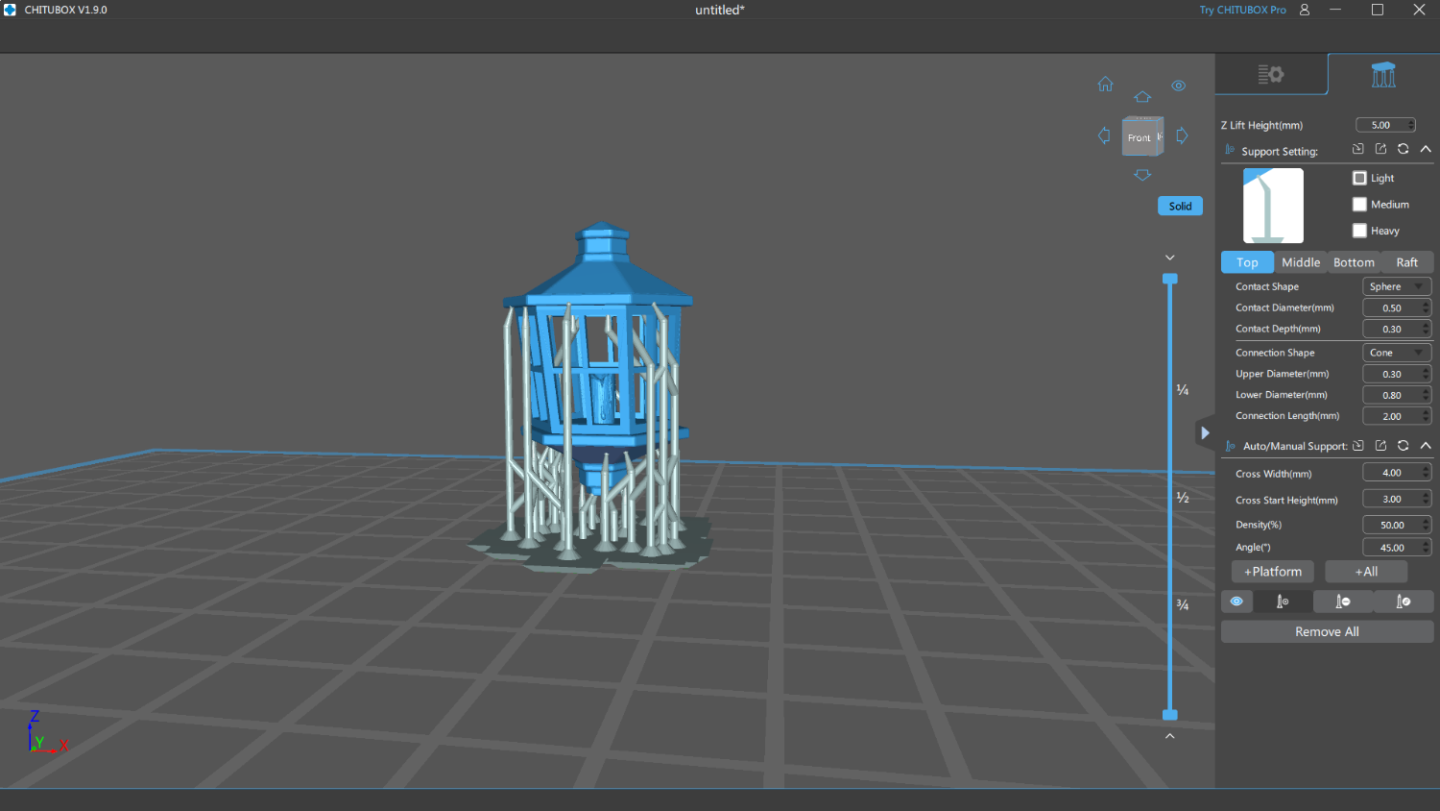

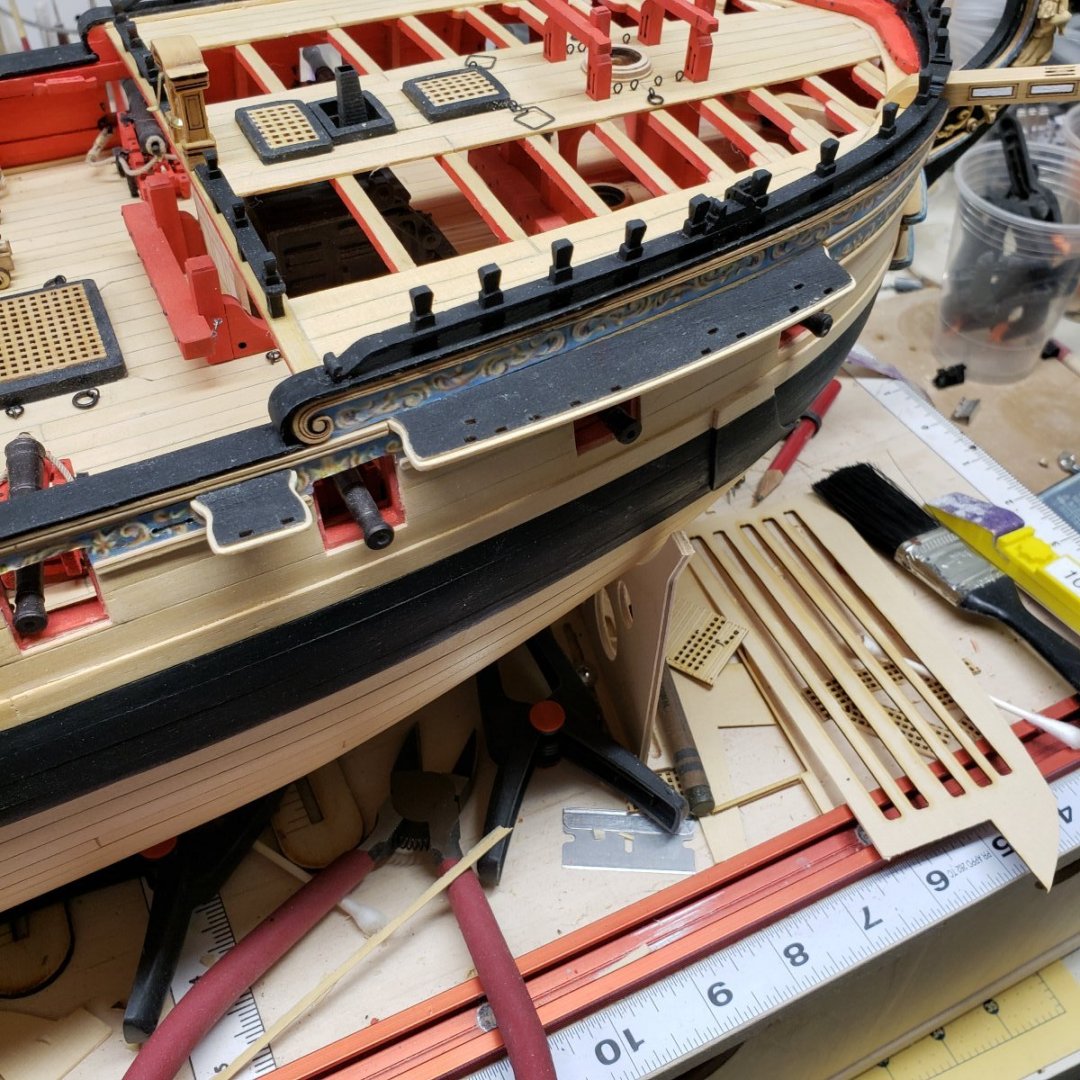

Lantern This was modeled in Sketchup Pro 2021 from the drawings Chuck posted in his thread. It was adjusted for size based on the prints. Then I used a Anycubic Mono resin printer to get the final product. Airbrushed the piece to match the Alaskan Yellow Cedar ( which was by far the hardest part of the job) the interior parts were hand painted with a very fine brush to get the details of the candle and the floor. Mounted on the first side 🔻 Hinged Door shot 🔻 Here is what the sketchup model looked like🔻 and this is what the pre print file looked like 🔻 and what it looked like when it was out of the printer before the removal of the supports I really need to get a crappier camera, or boost my skills by a magnification of 10...but it really looks good when your just standing and looking at it. I'll post some nice white screen backdrop shots when I clean the model up at the conclusion to this build.

-

Well we've been cutting through molding already in other areas. So I kind of like the way you drafted it, by the way those fenders are really intricate I'm not sure how you manage these surgically small cut lines....

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.