-

Posts

237 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kenneth Powell

-

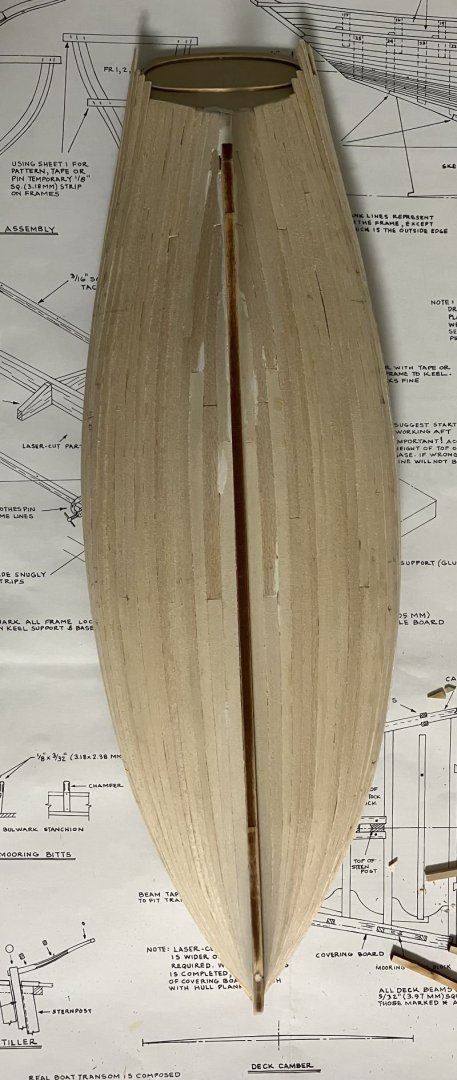

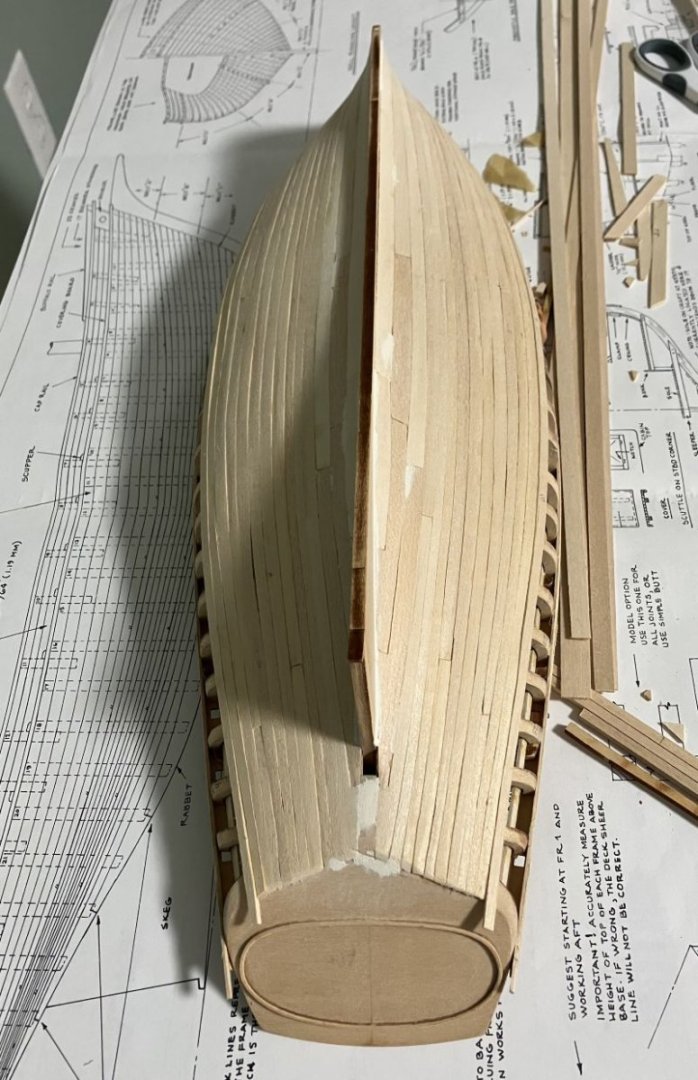

Hello Everyone - Checking in with some progress. Spring has sprung here on the gulf coast. So, I've been busy with yard work and honey does and stuff outside. Chores really take away time from hobbies. Anyway, I've finished belt B and sanded a little with 80 grit. I also added a plank in belt A and the sheer plank. The kit supplied planks are longer than the model, so I've mostly been able to cut one plank for the entire strake. Then I cut its duplicate for the other side - back and forth, back and forth. I kept the cut-offs and in the spirit of conservation of wood I can use 3 of them to make planks for one strake. I should be able to steal a few minutes here and there and set the rest of the planks. But I don't want to rush things either and get in a hurry. There has to be a balance. Then it's the 80 grit treatment followed by 150 grit. Then a few open seams and such will be filled and sanded. Comments welcome Thanks for stopping in - Kenneth

-

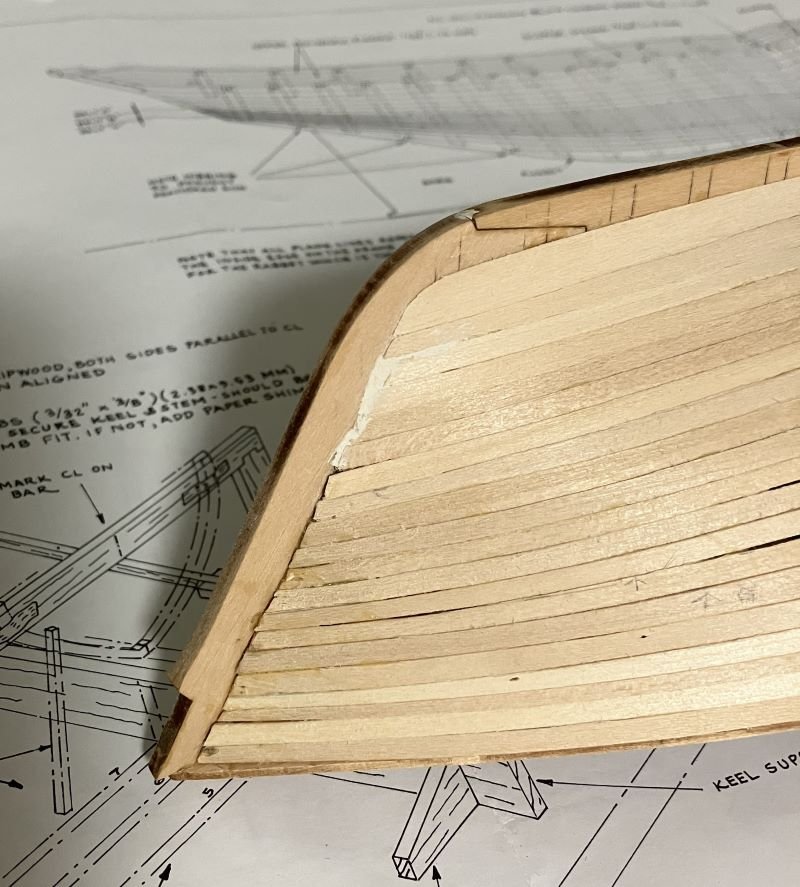

Hello everyone - Planking has started. The Modelshipways method of planking in belts works pretty well. It gives an opportunity to pause and check the progress and the math works out if the plan is followed. I followed it on my Rattlesnake and it worked well. I added belt C and sanded a little, then added a little putty in the seams. Once all the planking is complete, I'll sand and touch up everything. I won't use a lot of putty. The planks are visible on most wooden boats and I like the beauty marks. This is my first shot at nibbing hull planking, so please be gentle. Thanks - Kenneth

-

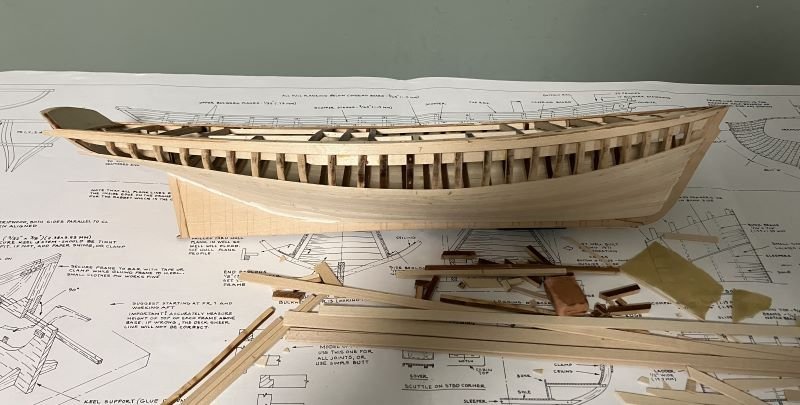

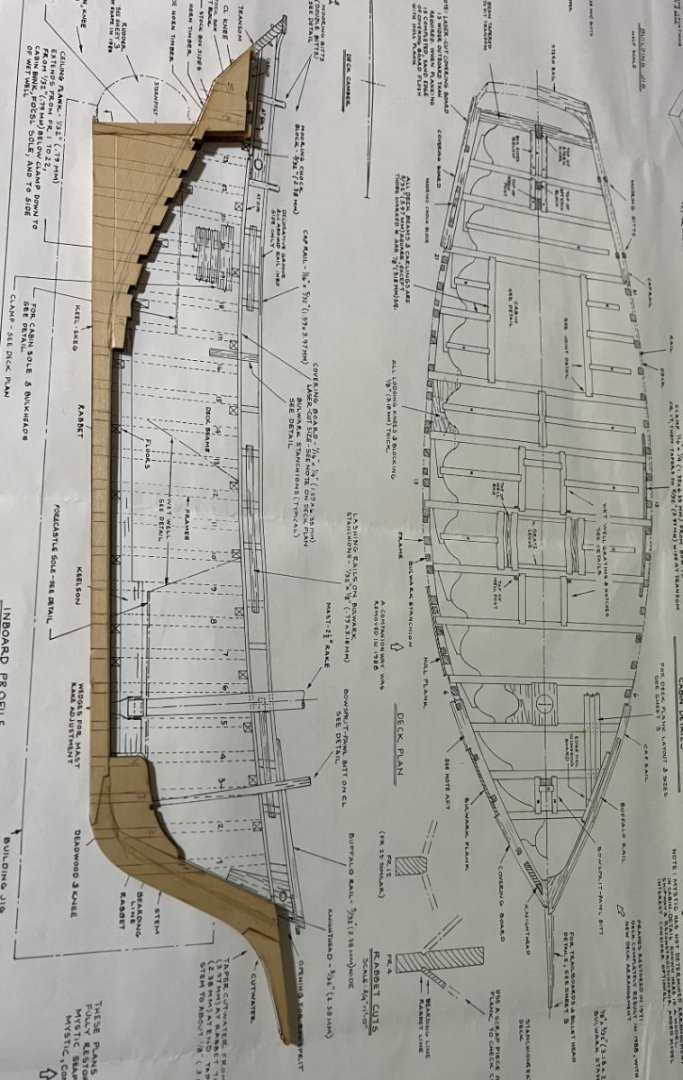

Thanks for the visits and the likes. I've finished the deck framing. I have a lot of sanding to do. I went across all the beams with a 1/16 inch thick piece of deck planking and checked all the beam heights and the sheer. They actually lined up pretty good. The strip at the transom seems a little off, bit it all lines up. It also seems solid and not too fragile. The forward cabin will be a little larger than the original cabin as seen in the photo. After sanding and double-triple checking heights and fairness, I'll install the covering boards. Comments welcome - Kenneth

-

Great build with the working rudder and all. Midwest does make very good kits and I really what you've with it. - Kenneth

- 21 replies

-

- Muscongus Bay Lobster Smack

- Model Shipways

- (and 2 more)

-

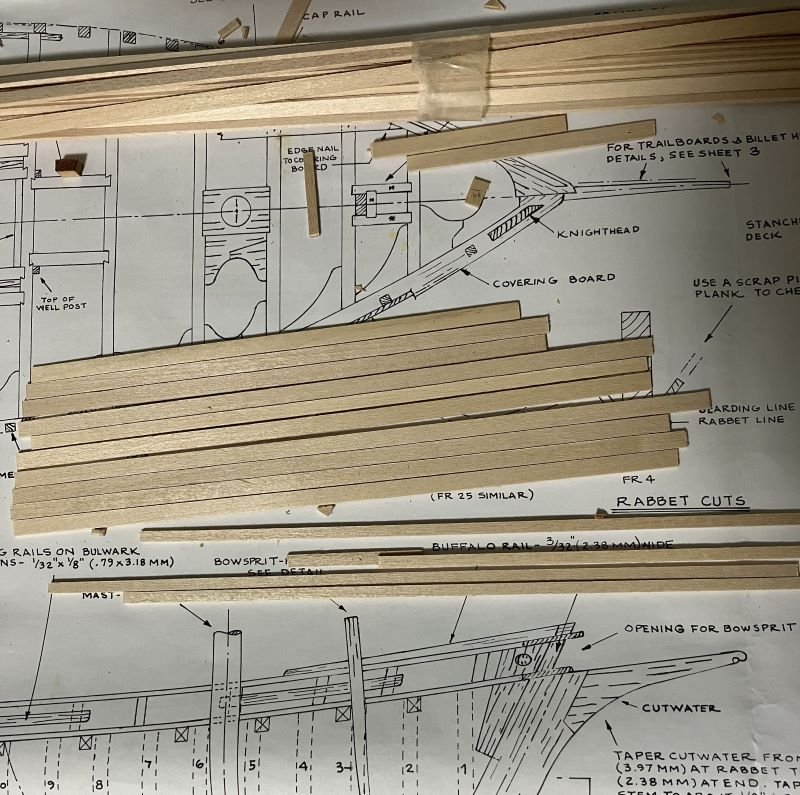

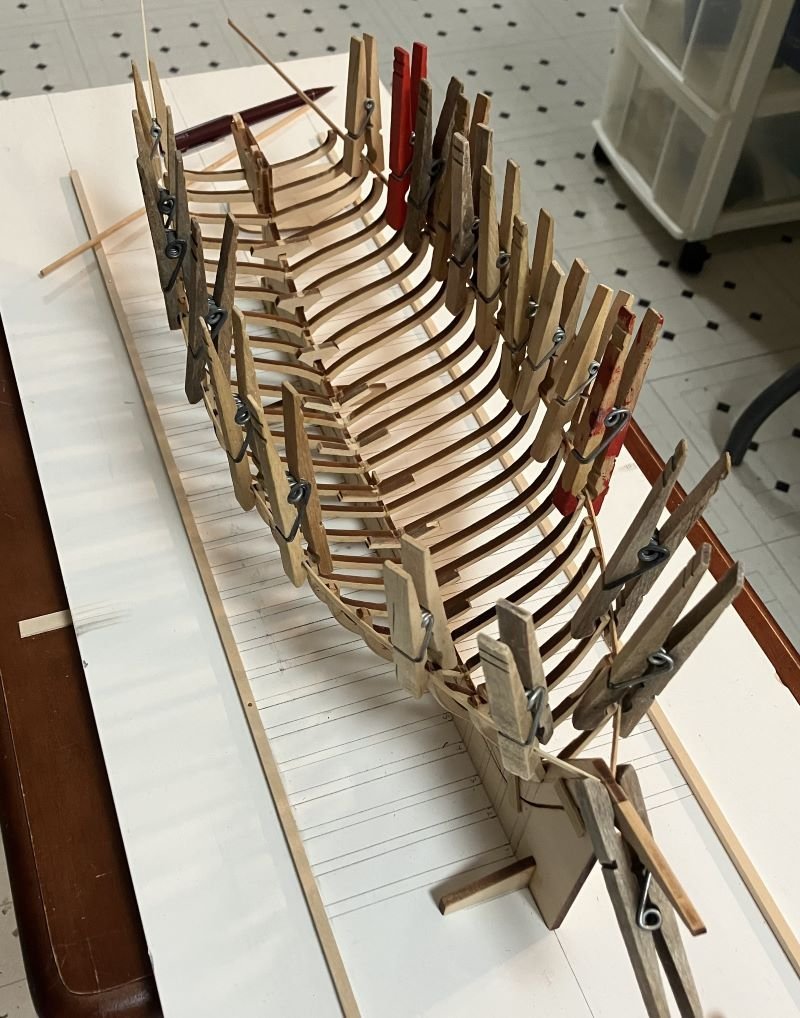

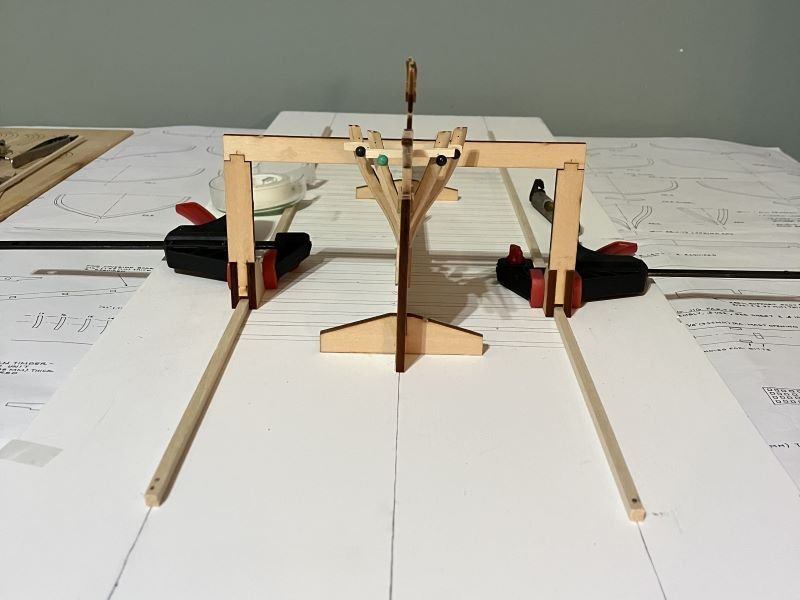

I exchanged clothes pins for push pins on the batten to make room to clamp the clamps. The clamp installed as per instructions with the bow sprit pawl just sitting there. Once the glue of the clamps dried, I went straight to installing the large deck clamps It was hard to edge bend the wide clamps to make the sheer, so some of the large deck beams have shims to bring them to the proper height. This is where I'm going off the grid. I'll frame the original cabin, then frame a larger cabin three beams forward of the original. The space can be seen in the above photos. - Kenneth

-

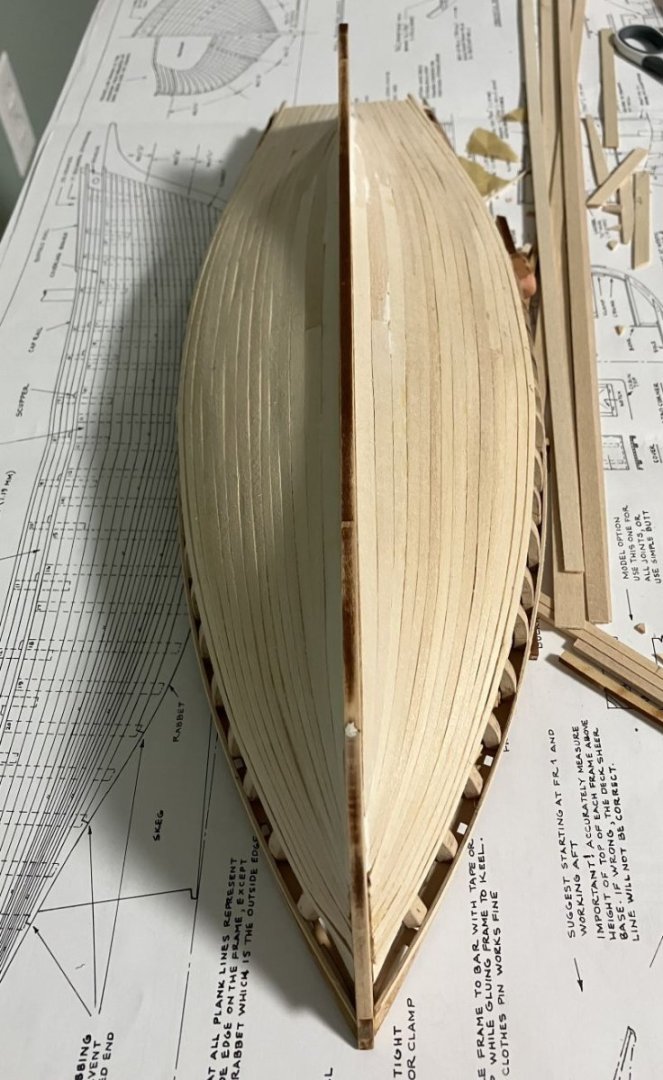

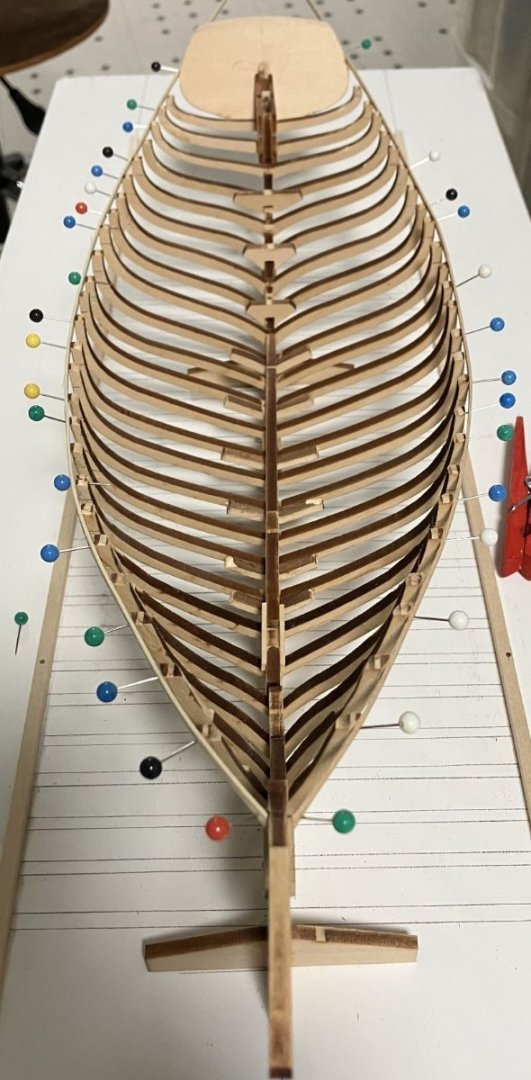

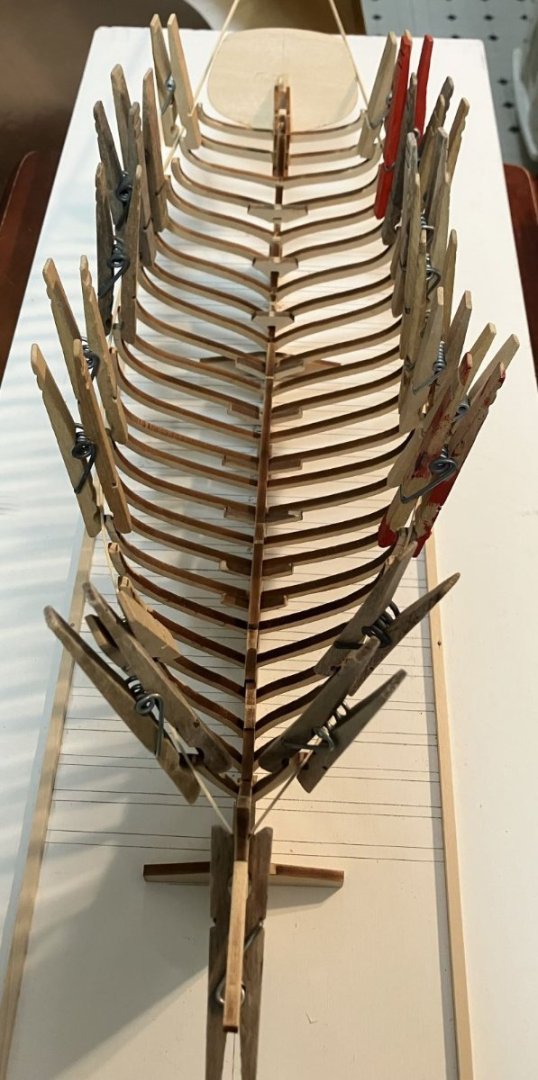

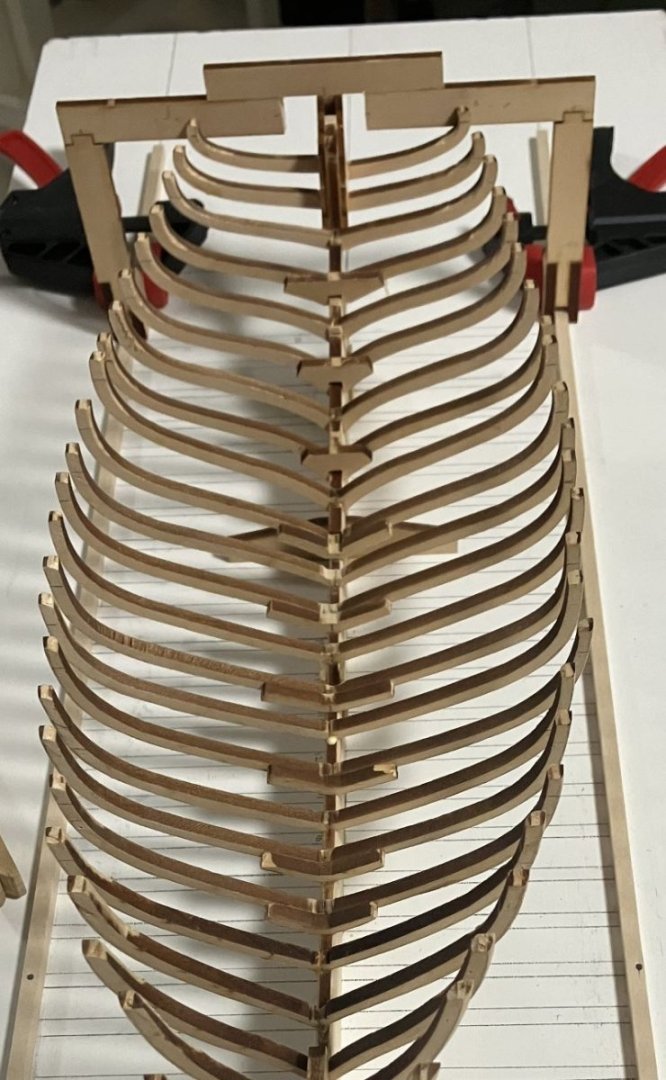

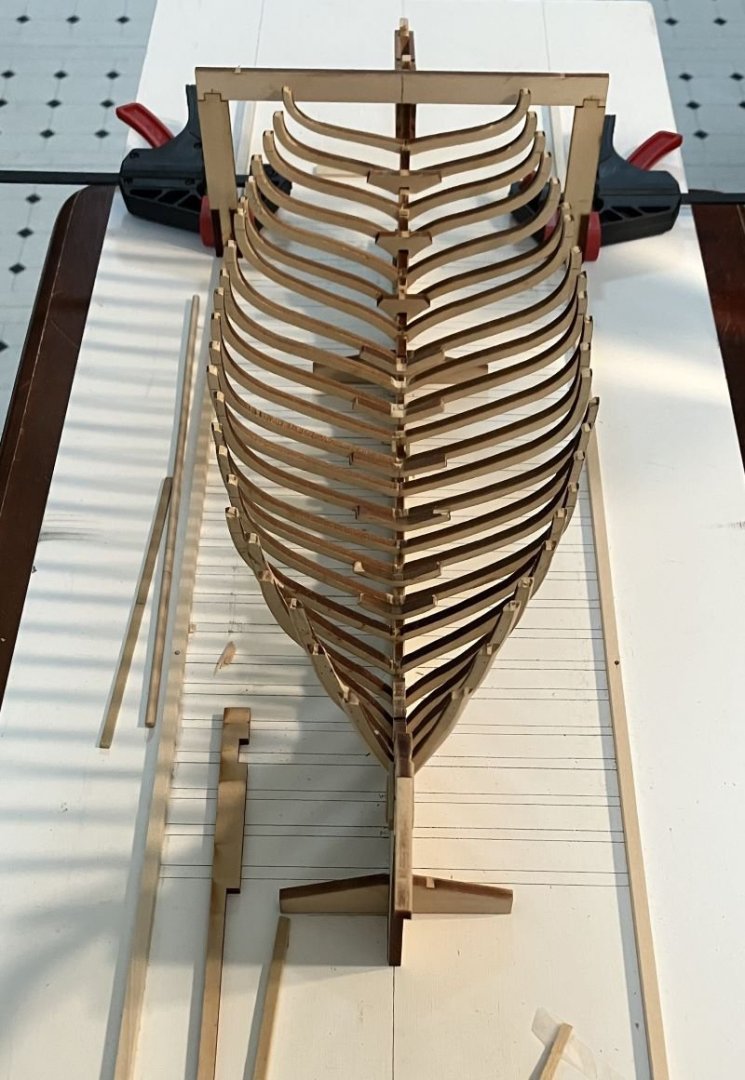

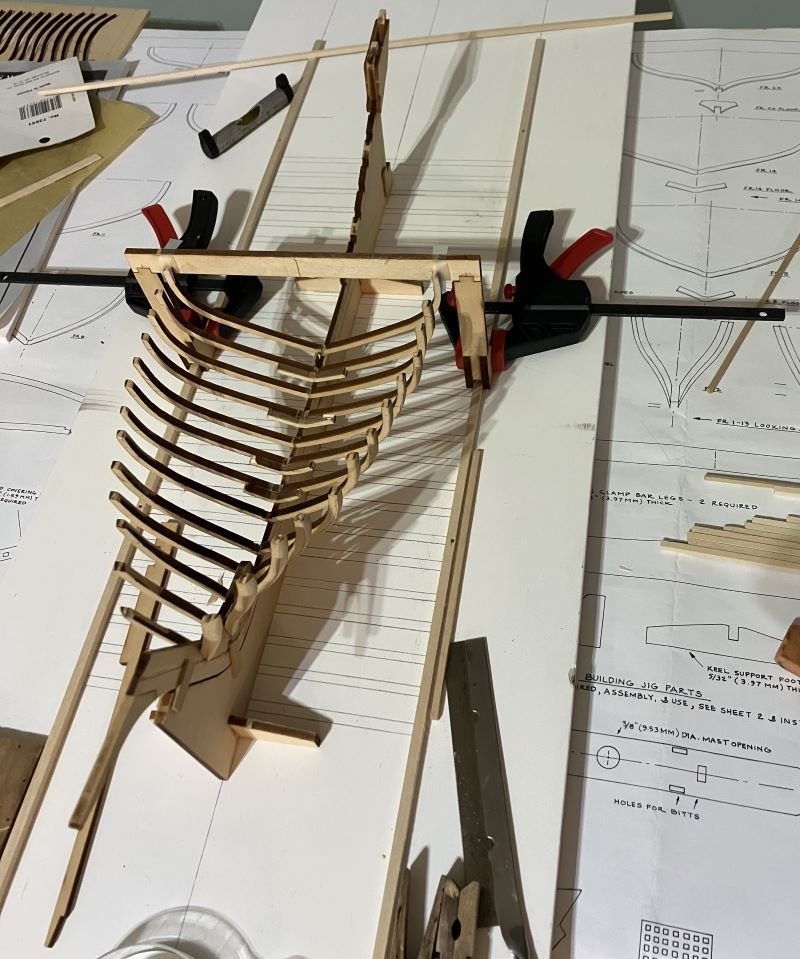

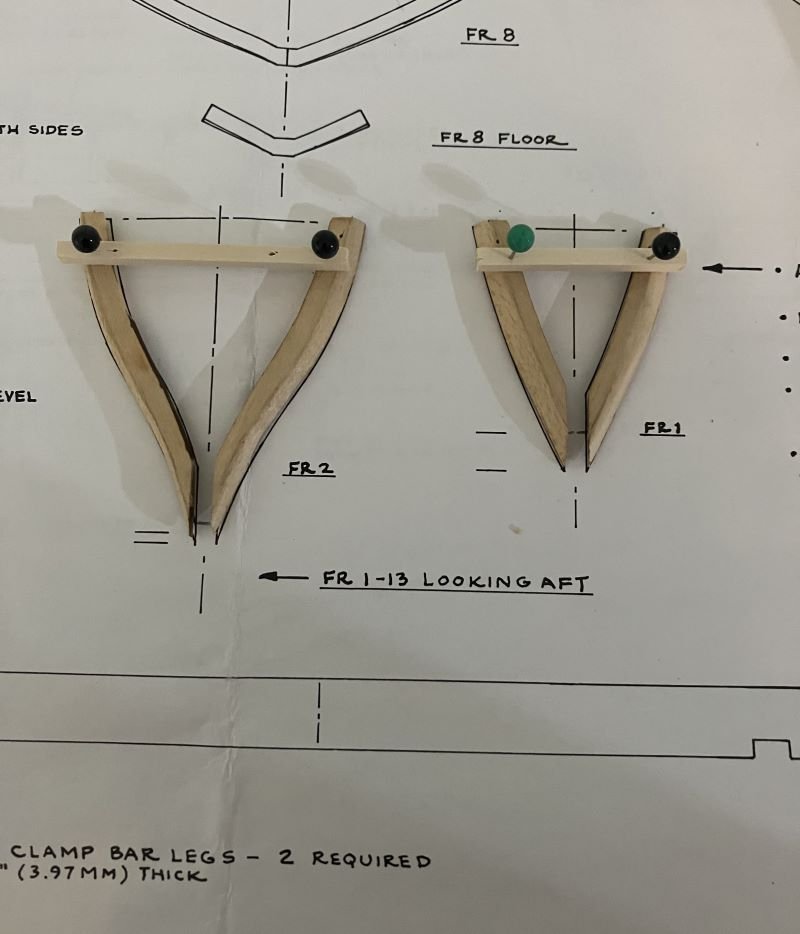

Hello, Everyone - The frames with no floors have a very small surface area for glue, so I cut a small piece of 1/32 strip and glued it to the front and out of the way before lifting them from the plans. They did help hold things together. I made my notch by cutting a piece from the laser cut sheet of the building fixture and gluing it on top. The thickness is the same and it's square. Then I carefully cut and removed the small section to allow the horn timber assembly to pass. There's no room for temporary strips on the last two frames, so I marked the height on the building fixture and clamped them in place. The temporary batten did tighten things up. She looks pretty fair and the clamps will finish holding things together. I will also dry fit the covering boards as I go to make sure things really fit accurately. Next on the list is to install the keelson and transom. Comments welcome - Kenneth

-

Update - I made it to frame 23 She looks a little snaggle toothed but the frames should pull in and level out with the clamps and battens. The keel assembly is too tall for the last two frames, so I'll have to cut a notch in the building fixture for them. It's important to check the height of each frame to keep the proper sheer. I've found that the height of each frame that sits on the keel is almost dead-on once it's made and glued. This is a really good kit. - Kenneth

-

Thanks, Adam and all the likes. To add a few building comments: The instructions call to carve the bevels in the frames but I find that 80grit sandpaper with a good sanding block works better. Also, I'm dry fitting the keelson as I go to make sure the frames are cut accurately and to help place them properly on the keel. Don't want any surprises later on. Photos to follow - Kenneth

-

Sail patterns held in place by tape: You can see where I trimmed and added material to make everything fit. The material was given to me by a friend. It was left over from his own sail making. Comments welcome - Kenneth

- 27 replies

-

Thanks everyone for the visits and likes. Yves - I don't have any photos or plans. On page two of the instruction manual under history, it says that she was rescued by F. Slade Dale who purchased her for a yacht. Several, several wooden work boats have been built here in Biloxi with many of those have converted to pleasure craft and that's kind of the guide I'll use. I'll frame the new cabin one deck beam forward of the original cabin to the king plank and keep the width and height of the original. This will take the space of the fish well. Comments welcome - Kenneth

-

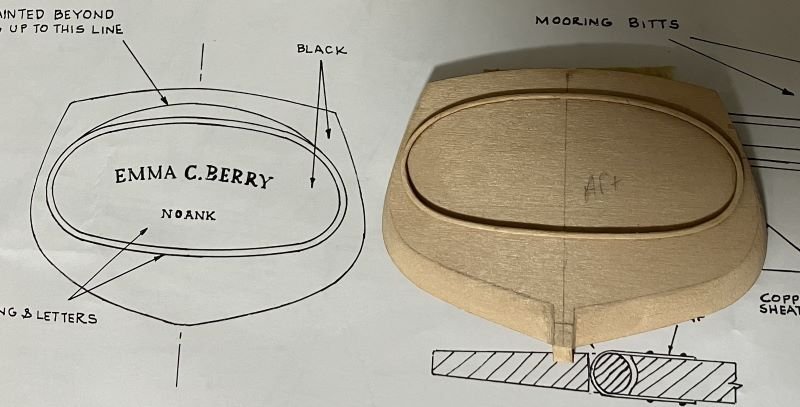

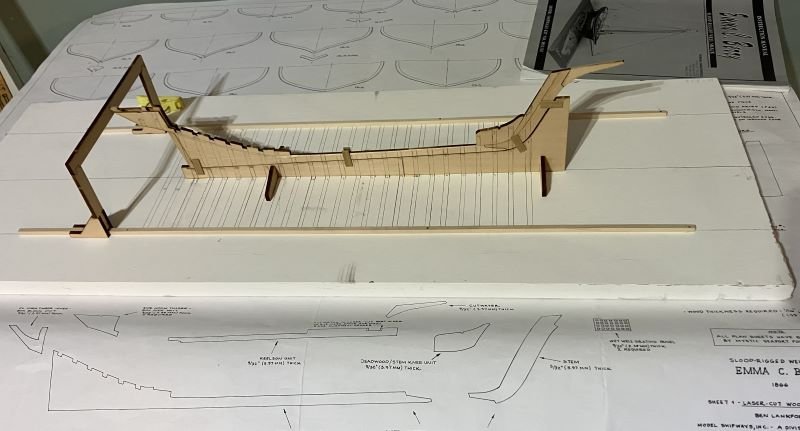

I received this kit as a Christmas gift from my brother in 2007. That is not a typo; 2007. I wanted to finish the Rattlesnake, then I started my Coastal Pirate and all kinds of life stuff has gone by. I'm finally to the point where I'm comfortable doing this build. Thank goodness it's been patient. The instruction book mentions that a few years of her long life was spent as a yacht - that's what I'm going for. The fish well will be converted to cabin space for this build. This is my first plank-on-frame model and I really like the building jig included in the kit. I built a local skiff years ago with no jig or anything and it's shaped something like a banana. Basic start of the keel assembly: The pencil marks will be erased/sanded. The building jig: As per the instructions, the frame locations were lifted from the plans and transferred through the keel to the jig and board. It took a little while to put everything together, but time well spent up front will result in a more precise build with fewer problems. The board is a piece of straight, square, pre-primed and sealed 1 X 12. I drew the center line and marked the location for the keel support and each frame along the line. Before I glued the keel support, I used a T square and marked each frame. I built the frame clamp bar fixture and marked the lines for the strip runners on the board. I made sure it moved smoothly but stayed firm along the whole route, then nailed it down. All of this is outlined in the instruction manual - which has to be read and reread over and over. Now that everything is set in place, it all lines up just right; it's level, plumb and square. Next, I will cut the bevels in the frames. Comments Welcome, especially from other Berrys - Kenneth

-

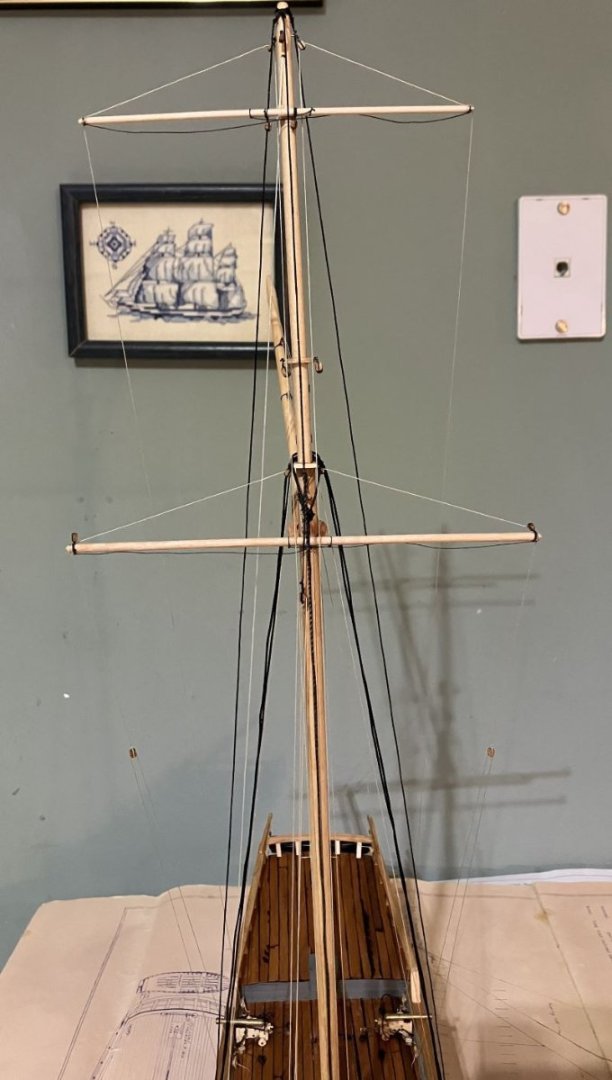

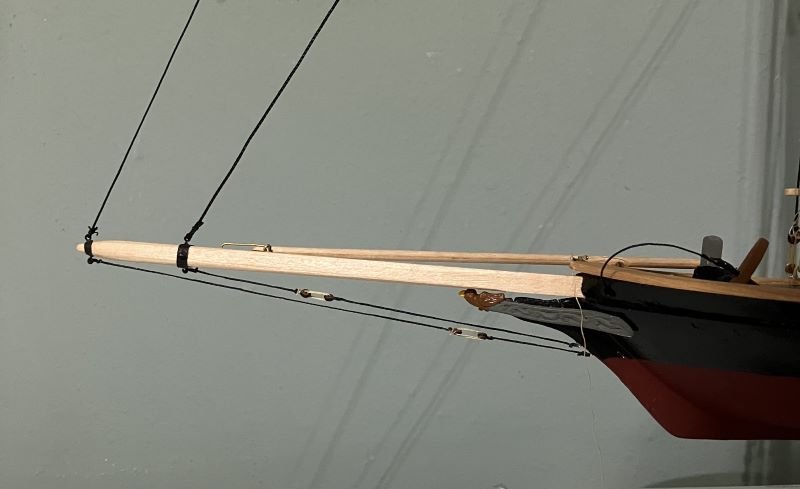

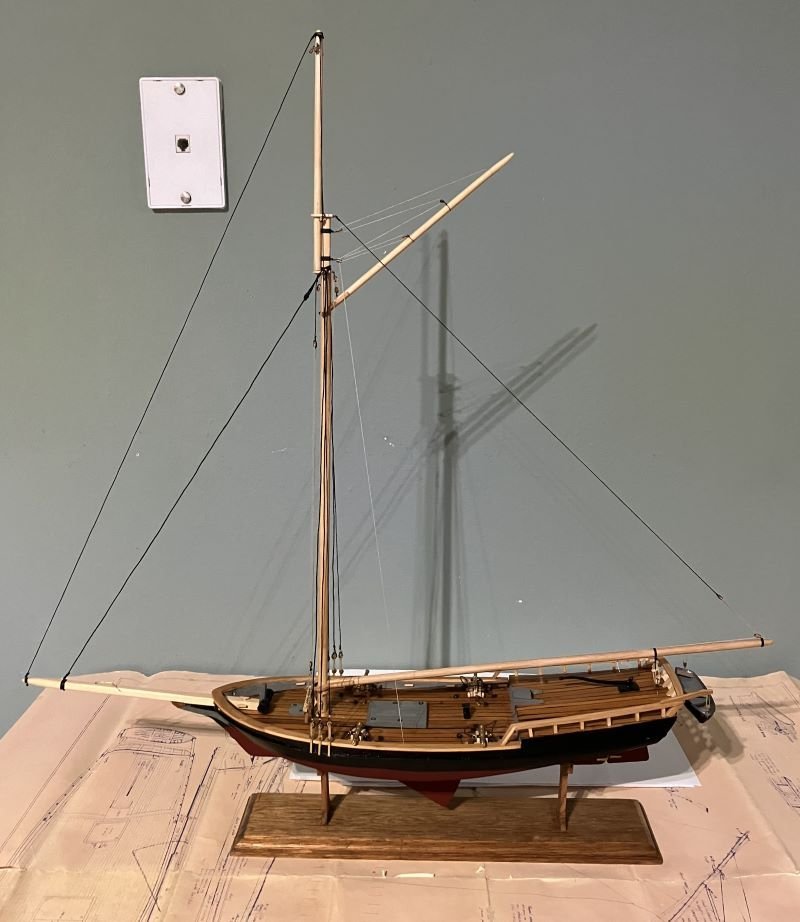

Hello Everyone - I did a few chances to slip away and do some work on the model. Straightforward rigging: And I also finished and added the anchor. Sails are next. This will involve the admiral and her sewing machine. Let me go practice my sweet talk. Comments welcome - Kenneth

- 27 replies

-

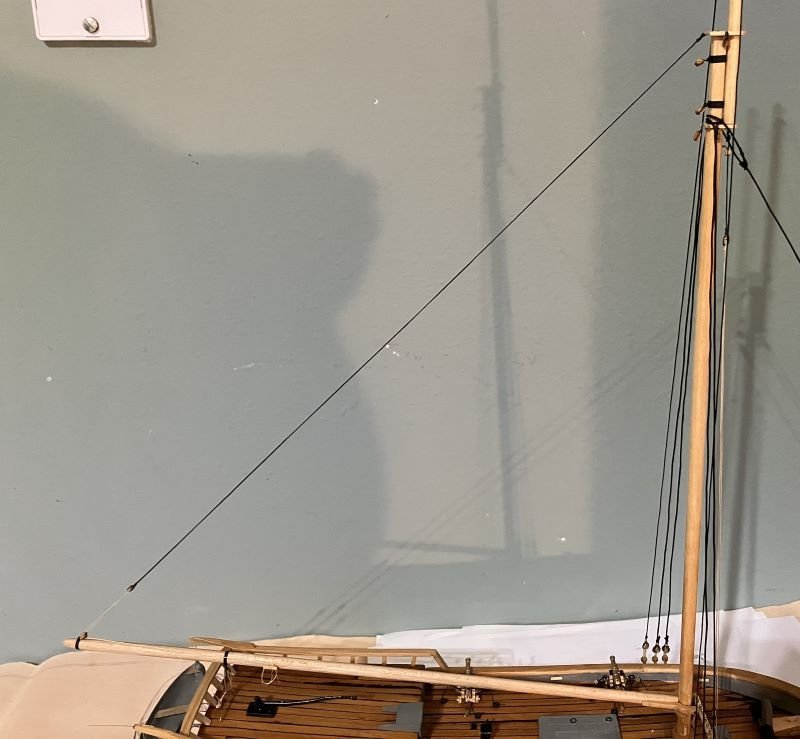

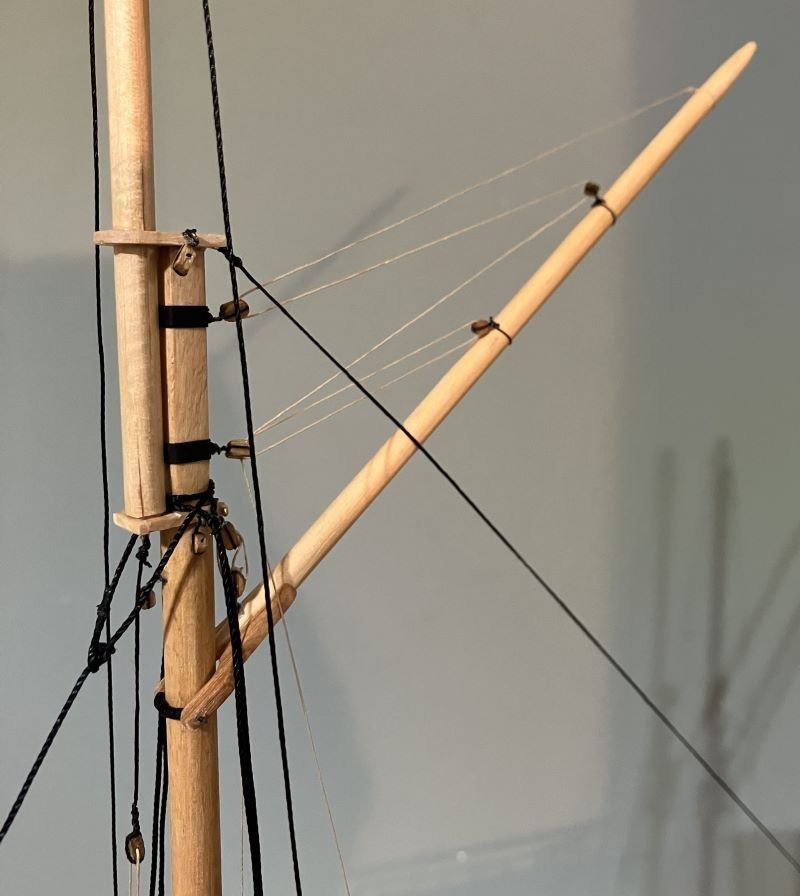

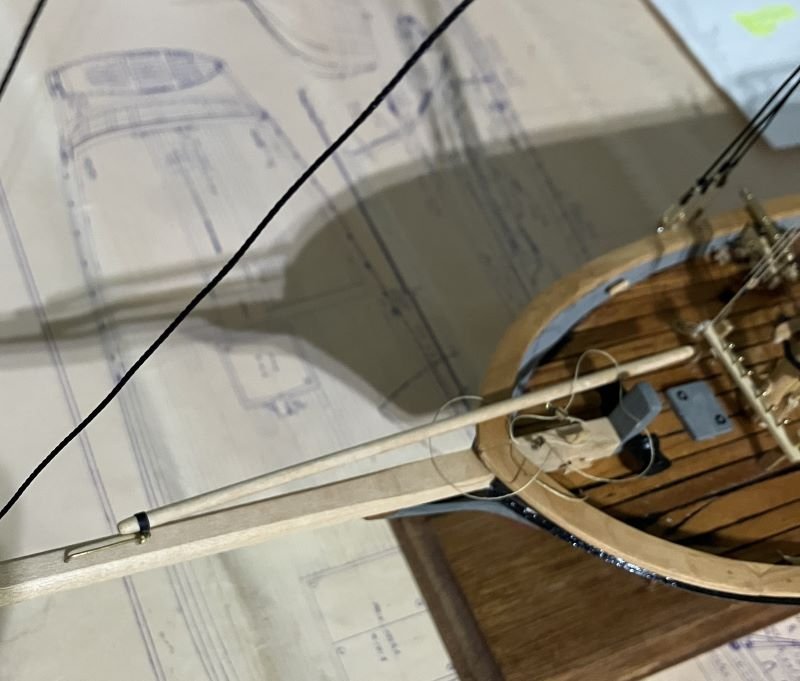

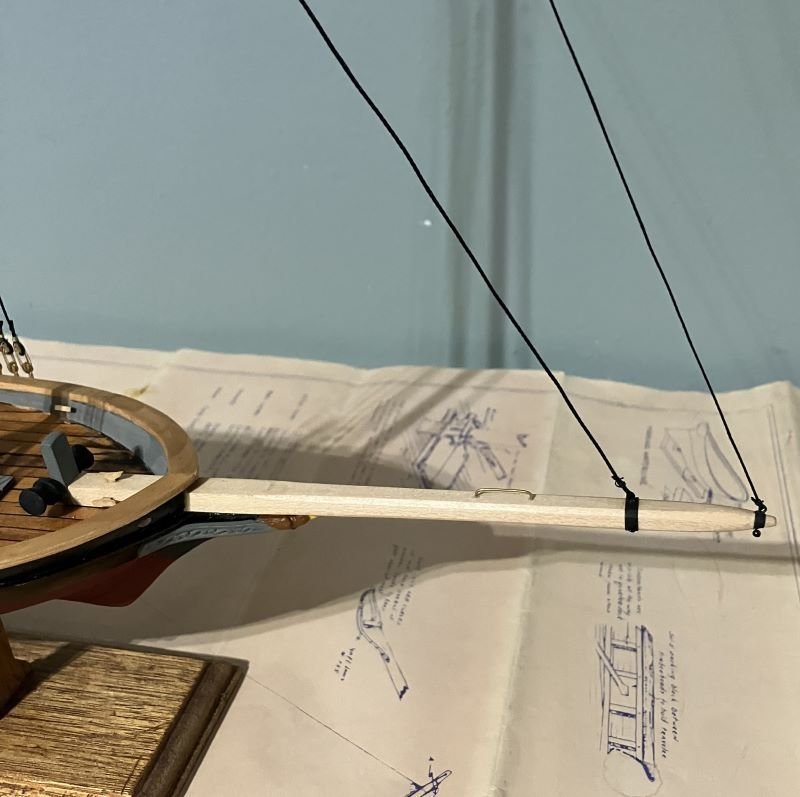

Hello - I installed the boom with the topping lift. The gaff and staysail boom built and installed Loosely installed waiting for sails The spars are next, but I don't know how much I'll be able to do this close to Christmas with all the holiday honey-dos the admiral has for me. We'll see. If I don't post; Happy Holidays and Peace to all and in your own way. - Kenneth

- 27 replies

-

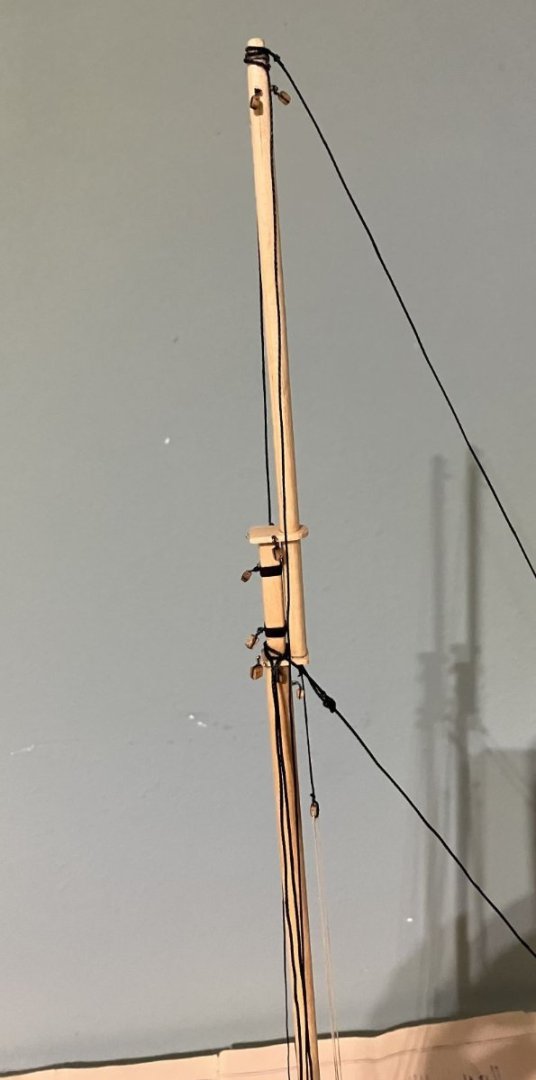

This weekend was wet, nasty and rainy. So, I stayed inside and installed standing rigging: I also secured the cargo hook. I'm going to do some touch-up today if I can. Comments welcome = Kenneth

- 27 replies

-

- 27 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.