-

Posts

71 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://dragontoothgrognard.blogspot.com/

Profile Information

-

Gender

Male

-

Location

Near Valançay, central France

-

Interests

RPGs, figure painting, terrain and scratchbuilding

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Archi reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

Archi reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

-

Archi reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

Archi reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

-

thibaultron reacted to a post in a topic:

Medieval longship by bolin - FINISHED - 1:30 - based on reconstruction Helga Holm

thibaultron reacted to a post in a topic:

Medieval longship by bolin - FINISHED - 1:30 - based on reconstruction Helga Holm

-

thibaultron reacted to a post in a topic:

Medieval longship by bolin - FINISHED - 1:30 - based on reconstruction Helga Holm

thibaultron reacted to a post in a topic:

Medieval longship by bolin - FINISHED - 1:30 - based on reconstruction Helga Holm

-

mtaylor reacted to a post in a topic:

Gokstad c. 900 AD by bigpetr - 1:48 - CARD - viking ship

mtaylor reacted to a post in a topic:

Gokstad c. 900 AD by bigpetr - 1:48 - CARD - viking ship

-

Old Collingwood reacted to a post in a topic:

10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

Old Collingwood reacted to a post in a topic:

10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

-

mtaylor reacted to a post in a topic:

10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

mtaylor reacted to a post in a topic:

10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

-

Cathead reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

Cathead reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

-

Louie da fly reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

Louie da fly reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

-

mtaylor reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

mtaylor reacted to a post in a topic:

Nef by PhilB - scale c. 1:50 - Early Medieval Ship

-

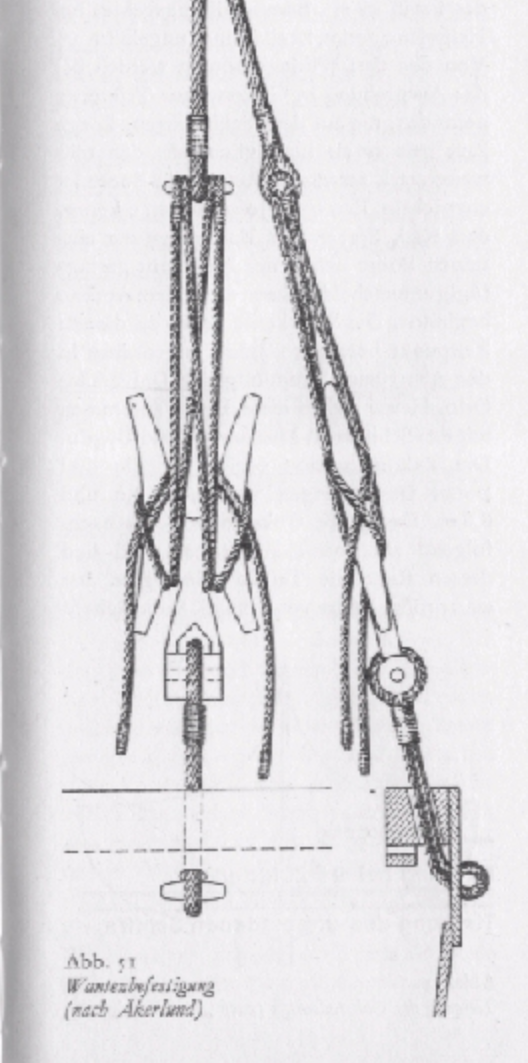

I should hasten to add that the forestay picture is not mine, I grabbed it off google to illustrate the idea of replacing the "butterfly cleats" with heart blocks. I hope that mine looks almost as good when it's done. Edit: on a related note, should I add some shoulder pieces near the top of the mast where the stays are attached? It's the forestay attachment on the borrowed heart block picture that made me think of it.

-

Well, as a test, I tried to make one "butterfly cleat". The key to getting the right shape without splitting the wood was to shape it first with a small Xacto saw. Still, it looks a little on the over-large and clunky side. Probably best to go with heart blocks - easier to shape, and less clunky-looking. So I'm thinking I should try something like this, though slightly smaller:

-

I suppose I could call it a "butterfly cleat" or a "dragonfly cleat" or something like that. I think I'll need another one on the forestay, at the very least. Or I could chicken out and use heartblocks. My first attempts at carving this double cleat all resulted in the basswood splitting down the middle. I may need to run a pin through the center to strengthen each piece before cutting the deep "V" in between the two cleats.

-

Looking great! I'm jealous of this wonderfully planked and framed hull. Will the frame still be visible once the ship gets a deck?

-

Actually, the windlass can still be used for anchor duty, as long as the rope is belayed around an appropriately placed beam. Surely there something there which can serve.

-

It's hard to tell if that is in fact a depiction of a stern rudder, or simply a failed attempt at perspective, as you often see in this period.

- 179 replies

-

- longship

- Helga Holm

-

(and 1 more)

Tagged with:

-

I'm attempting to carve some cleats to set on each side of the mast - it's hard going! But I'll get there. Two questions: 1) I've seen some models with a beam just aft of the mast, and forward of the windlass. Is this beam used primarily for attaching rigging, or as a belaying point for hoisting the mainsail yard? 2) What do you call this double cleat thingy, that looks like a very important part of the longship rigging plan I'm thinking of trying to emulate?

-

A longship with a stern rudder? That does look unusual. Keep us posted.

- 179 replies

-

- longship

- Helga Holm

-

(and 1 more)

Tagged with:

-

What size cords for the rigging of a 1/50 medieval nef?

PhilB replied to PhilB's topic in Masting, rigging and sails

My order came in. I ordered: 1mm and 0.75mm in black for standing rigging, and 0.25 and 0.5 in beige for running rigging. At first glance, the 0.25mm is far too light. And even the 1mm is too light for some applications. This, from a complete novice shipbuilder. So I'm going to order some more: black goes up to 1,3mm, beige goes up to 2mm. I think I need black at 2mm, so I'll see if I can locate some. -

The side rudder is finished, and the glue is drying. I also finished two ladders, but one of them is too uneven and has to be discarded - gotta make another, for the sterncastle. I also gave the hull some painting love: dark caulking, and hundreds of dots for the trenails. A little drybrushing over the top, and it looks much better than before. Also, I received the Amati rope I ordered, looks great, but I can see I'll need some larger sizes. I ordered 0.25mm, 0.5mm and 1mm, but I think some 1.3mm or ever 2mm are in order.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.