-

Posts

920 -

Joined

-

Last visited

About robert952

- Birthday 09/27/1952

Profile Information

-

Gender

Male

-

Location

Aberdeen, North Carolina, USA

-

Interests

American Civil War era ironclads, small work boats, nautical history. Other: 3D CGI (still images) and too much game playing on the PC.

Recent Profile Visitors

-

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by Stubby - Model Shipways - 1:24 Scale

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by Stubby - Model Shipways - 1:24 Scale

-

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by Stubby - Model Shipways - 1:24 Scale

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by Stubby - Model Shipways - 1:24 Scale

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by DocTom - Model Shipways - 1:12

-

MikJ reacted to a post in a topic:

Lowell Grand Banks Dory by MikJ - Model Shipways - 1:24 - First Build

MikJ reacted to a post in a topic:

Lowell Grand Banks Dory by MikJ - Model Shipways - 1:24 - First Build

-

Make room. I am jumping on board the log. Good luck on your build and do not be afraid to ask questions. And, yes, adding to the build logs, even it there's a bunch out there, on the same ship/boat, you will bring a fresh perspective as you proceed.

- 21 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

robert952 started following Picket Boat #1 by k-slak - Model Shipways - 1:24 , Lowell Grand Banks Dory by MikJ - Model Shipways - 1:24 - First Build , Ramble Intro and 7 others

-

druxey reacted to a post in a topic:

Ramble Intro

druxey reacted to a post in a topic:

Ramble Intro

-

Welcome aboard.

-

There was also a suggestion to add SMALL to the title if it was a model of a small vessel (not a small model). Example Dinghy by Robert952 - Midwest Model - 1:12 - SMALL Not critical, and not my idea. However, I do like looking at the small boats. Besides being great models for beginners, they give an opportunity for a lot of extra details.

-

Mainly the weathering you have done on everything. The buildings are weathered very nicely. I tend to 'overweather' items. You show a light touch to make a nice effect. Seeing the Inman building progress was interesting. Similarly, the landscaping texturing is very nice on the tunnel and rock faces. For a small boat (dinghy) project on my planning board, I want to make it a diorama. Though the scale will effect my approach (it's 1:12 - doll house scale?), the way you layer shows me a techinique to use.

-

My humble opinion (and limited experience): I think cutting the filler planks for larger areas like you did in the top photo of the topic #11 is the better way to go. That is because I get too carried away with applying filler in gaps and end up with a mess. Your results may vary. I just think it's worth the time. The bottom photo in topic #12 where you see the filler 'plank' looks very nice to me and will probably need minimal sanding to smooth it out.

-

Nicely done. Great looking model. Congrats on finishing it.

- 167 replies

-

- Picket Boat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I realized how often I look at your posts on this build as I peruse recent posts. I am jumping on board to watch the rest of the build. As with most projects there's problems we have to solve (like the deteriorated decal) that need unique solutions. Part of the challenge and rewards when assembling model.s The model looks good. I look forward to the rest of the build.

- 73 replies

-

- Steam Cutter

- Harriet Lane

-

(and 2 more)

Tagged with:

-

I go back to the basic concept of what is of interest to me. I temper that with a bit of what will I learn or get better at skill set-wise. I won't be surprised if I pick out a non-ship model plastic model (or even metal) in the future as variety is the spice of life. I know I need to relearn and improve my plastic assembly, detailing and painting skills. So, that may be in my future, too.

-

Getting Started: From Dollhouses to the USS Constitution

robert952 replied to Jasennord's topic in New member Introductions

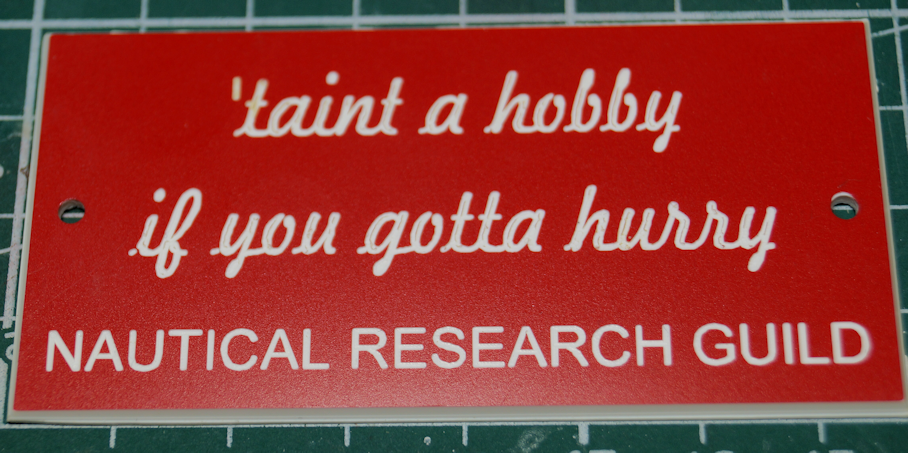

Welcome to the madness of MSW. Your tale is similar to mine. I still have a skelton hull about half-way planked of the Golden Hinde from Mamoli. I enjoyed what I did and what I learned from that work, but realize I had to get some of the basics under my belt. Start a log on your build. You'll find a lot of people who like to learn from others and share their experiences and expertise. (From me, you get more of the former than the latter.) Have fun. And remember:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.