Tony Hunt

NRG Member-

Posts

544 -

Joined

-

Last visited

About Tony Hunt

Profile Information

-

Location

Sydney, NSW

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Herbs Ships reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

Herbs Ships reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

-

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Mike Y reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

Mike Y reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

-

PaddyO reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

PaddyO reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

-

paul ron reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

paul ron reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

-

wefalck reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

wefalck reacted to a post in a topic:

Copper plate overlapping (< > 1794) - lower overlaps upper or vice versa?

-

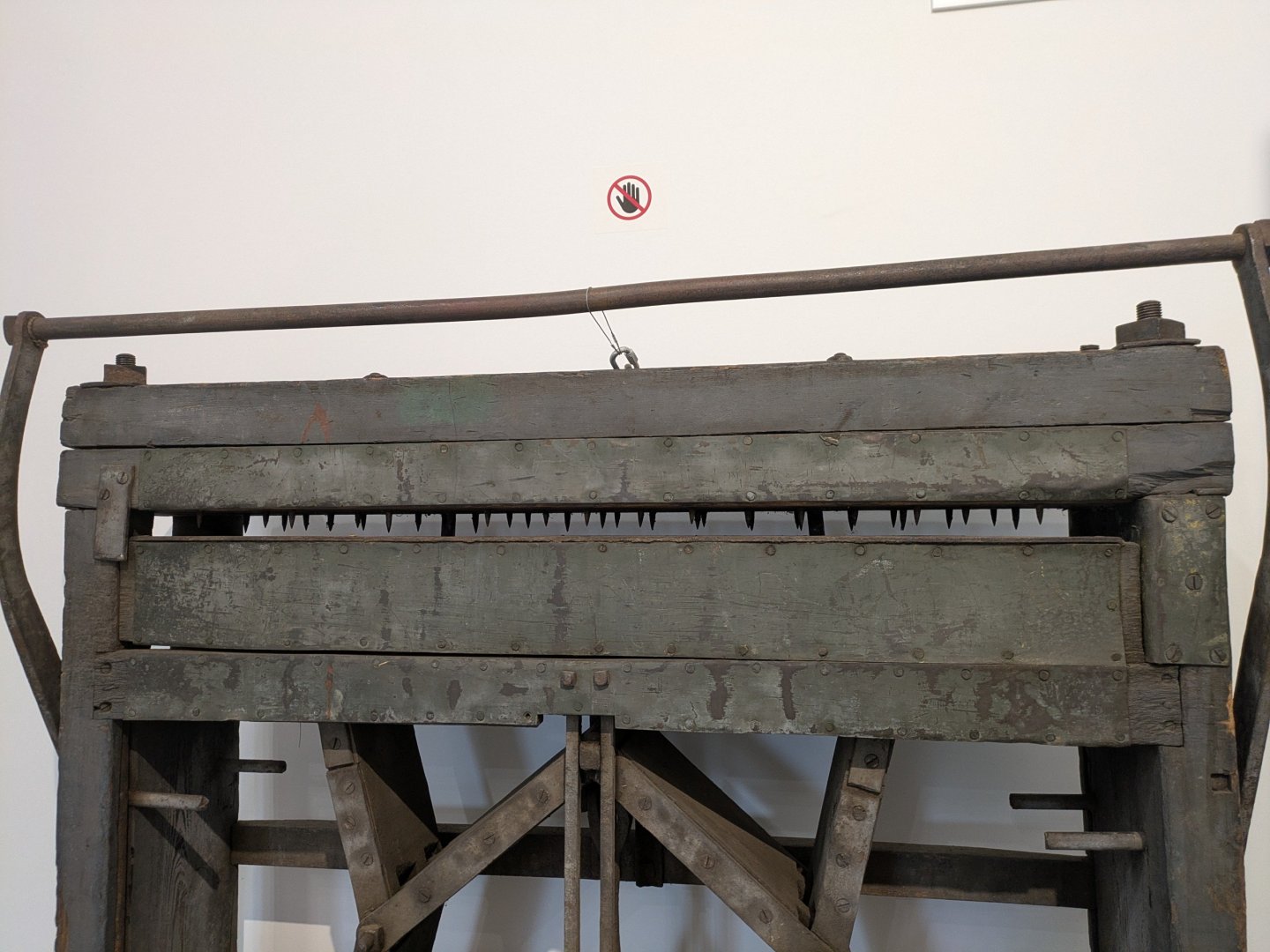

Here are a couple more pictures to add to this story. The example of coppering is the bow of the clipper Snow Squall, now on display at the exclellent Maine Maritime Museum. Nearby was a fascinating exhibit, seen in the second photo, showing a machine used by the shipyard to pre-punch the nail holes in the copper sheets. The sheet is put in, the lever is pressed down, and presto, out comes the sheet with all the holes pre-punched. I'd never seen one of these before!

-

Tony Hunt reacted to a post in a topic:

Trireme Olympias by Richard Braithwaite

Tony Hunt reacted to a post in a topic:

Trireme Olympias by Richard Braithwaite

-

Tony Hunt reacted to a post in a topic:

Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

Tony Hunt reacted to a post in a topic:

Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

-

Tony Hunt reacted to a post in a topic:

Atlantica by Wintergreen – Scale 1:30 - POF - sail training ketch - a smack of English heritage

Tony Hunt reacted to a post in a topic:

Atlantica by Wintergreen – Scale 1:30 - POF - sail training ketch - a smack of English heritage

-

Canute reacted to a post in a topic:

Innocraftsman Mill

Canute reacted to a post in a topic:

Innocraftsman Mill

-

Tony Hunt reacted to a post in a topic:

HMCSS Victoria 1855 by BANYAN - 1:72

Tony Hunt reacted to a post in a topic:

HMCSS Victoria 1855 by BANYAN - 1:72

-

Keith Black reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

Keith Black reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

-

Tony Hunt reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

Tony Hunt reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

-

Tony Hunt reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

Tony Hunt reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

-

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Tony Hunt reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

I bought one of their drill presses a little while ago. I haven't used it much so far, so no in depth experiences to share yet! First impressions - it's true, it's a bit of a toy, but it is well-made and works quite precisely. For small work I think these machines probably work quite well, for the money. But don't expect to be milling steel with it! Wood and plastic, sure, small cuts. Aluminium maybe.

-

MAGIC's Craig reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

MAGIC's Craig reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

-

Rick310 reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

Rick310 reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

-

Keith Black reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

Keith Black reacted to a post in a topic:

Loreley 1884 by Ilhan Gokcay - 1/75 - Scale Steam Yacht

-

I love the gratings at the stern! This is going to be an exquisite model of a very beautiful ship.

-

I remember reading the articles Harold Hahn wrote for Model Shipwright magazine, MANY years ago (!), about building his model of the Oliver Cromwell, and being awed by his superb craftsmanship and his skilful use of differently coloured woods to build a beautiful model without using any paint. You're doing an amazing job of matching his standard!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

The steamed Swiss pear that lots of specialty modelmaking wood suppliers have is very reddish and very fine-grained. Harold Hahn used it for the inner faces of the bulwarks on his model of the Oliver Cromwell for that reason. I think it would be a good mahogany substitute, you should be able to get it in veneer sheets or scale lumber dimensions.

-

Like Clipperfan, I recently visited the Mystic Seaport and got to admire Ed's wonderful model of Young America. It's even more impressive in real life (which is really saying something!) because of the fine scale - the detail and sense of grace that he has achieved at 1:72 scale is amazing.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I think Howard Chappelle redrew this plan and published it in one of his books - probably The American Sailing Navy?

-

Tony Hunt started following Javier Baron

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.