Peter Cane

Members-

Posts

240 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

Mirabell61 reacted to a post in a topic:

Coast Guard Cutter Pequot 1908 by svein erik - FINISHED - 1/48 scale

Mirabell61 reacted to a post in a topic:

Coast Guard Cutter Pequot 1908 by svein erik - FINISHED - 1/48 scale

-

Mirabell61 reacted to a post in a topic:

Bluenose by Peter Cane - 1:24 scale - RADIO - schooner in RC and working sailing model

Mirabell61 reacted to a post in a topic:

Bluenose by Peter Cane - 1:24 scale - RADIO - schooner in RC and working sailing model

-

John Murray reacted to a post in a topic:

Wood Suppliers in Australia

John Murray reacted to a post in a topic:

Wood Suppliers in Australia

-

EricWilliamMarshall reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

EricWilliamMarshall reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

-

EricWilliamMarshall reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

EricWilliamMarshall reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

-

popeye the sailor reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

popeye the sailor reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

-

popeye the sailor reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

popeye the sailor reacted to a post in a topic:

Zeesboot by Mirabell61 - FINISHED - scale 1:24 - wooden fishing vessel c. 1876 - small

-

Mike Zoll reacted to a post in a topic:

Brando by Peter Cane - FINISHED - A Footy class RC Catboat design by Flavio Faloci

Mike Zoll reacted to a post in a topic:

Brando by Peter Cane - FINISHED - A Footy class RC Catboat design by Flavio Faloci

-

Mike Zoll reacted to a post in a topic:

Brando by Peter Cane - FINISHED - A Footy class RC Catboat design by Flavio Faloci

Mike Zoll reacted to a post in a topic:

Brando by Peter Cane - FINISHED - A Footy class RC Catboat design by Flavio Faloci

-

Project done! I have restored it as it was rigged warts an all. A small white boat was missing so a carved up a replacement. Pete

- 10 replies

-

- sailingship

- restoration

-

(and 1 more)

Tagged with:

-

Peter Cane reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Peter Cane reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Roter Löwe 1597 by Ondras71

Peter Cane replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Your ship is in order!!! Peter -

Roter Löwe 1597 by Ondras71

Peter Cane replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

You have even stepped the plank levels for " elevation." I am an ex army gun fitter so I appreciate things " gunnery" Commendable my dear friend. I often wonder what the words of command were from the gunnery officer.. Some thing like " lower plank "" ...or " middle plank " elevation. I am so impressed. You have really thought this out. They will need recoil ropes!!! Superb!!! Pete -

Roter Löwe 1597 by Ondras71

Peter Cane replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Beautiful. Don't forget the firing holes!!!! Pete -

I am glad that two people have already said that they thought they were looking at the real thing. That exact thought went through my mind but I did not want to make a fool of myself by asking. This means you have fooled at least three people including me into having thought it was the real thing. That is surely the whole point. What a modeller!!!! Pete

-

Yes John keep the ol cells working! Thanks all for the likes and nice comments. I did not have any 3/16" birch ply so made the keel from 1/8" ally sheet. It is epoxied into the hull so going nowhere except where the hull goes. The bulb halves are bolted from both sides and epoxied. Then a coat of body filler to smooth everything down. Just a few more rubs now and the hull is ready for painting. My son will two coat it with his spray gun after christmas. I was not sure of the plywood rudder de laminating, maybe parting company with the rudder post because of just relying on epoxy to hold it and also the rudder throw was limited because of the half tube epoxied into the skeg. So I have over engineered it as Aussies do!! and made a solid larger rudder from 1mm brass sheet soldered to the rudder tube. It is NOT going to come off otherwise there will be some hat eating to do. Okay its a bit heavy but I do not think it will have any down sides. I now have 180 degree swing so this boat will definately turn!!!. Pete. Happy christmas my good friends. Hugs all round.

-

Theres a method here. Now if wifey makes the sails she then becomes a part of the model build right? So when it comes to the next one..... There will be no complaints!!!! Merry Christmas. Pete

-

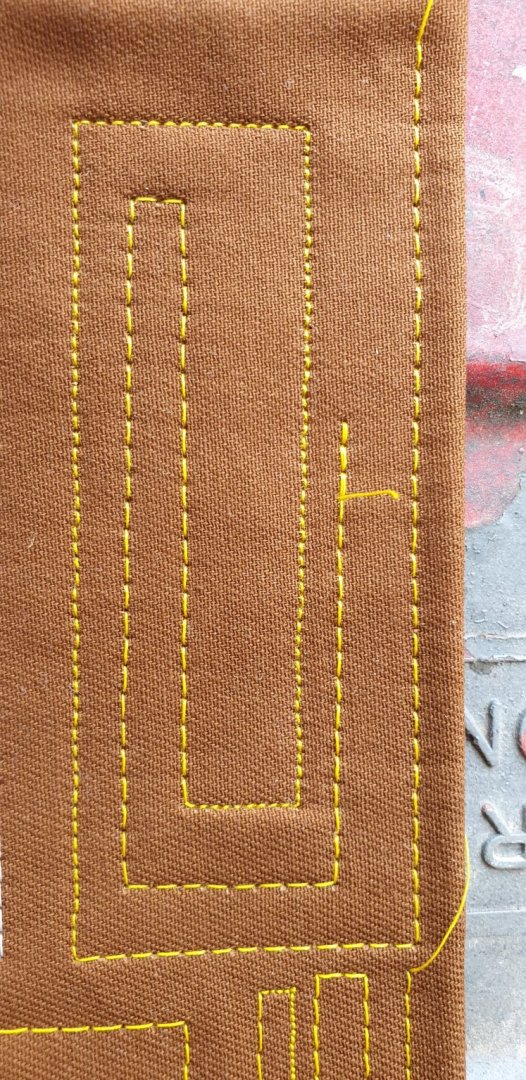

Beautiful rudder and nice knot. My mind goes crazy figuring out how to tie knots. The mere thought of it ties my brain in knots? Re sewing up some sails. Operating a sewing machine is not difficult. All you need is an old straight stitcher. They can be bought really cheaply now. You can get a brand new Singer Starter model now for £50. It is great fun and exciting. If that is an absolute no with you , send the sail plan and I will sew one up for you!. Will not cost you a bean. Pete. I was GIVEN this little beauty three days ago. It is 130 years old and sews a perfectly straight stitch. It was the best machine Singer ever made. It is a hand cranker so I have ultimate control on each stitch. Hope you likey!. How cheap is that?

-

Thank you for your encouraging words. I am not defeated.( Yet) !!! I think in my field of modelling that there is boat building and sail making. Sail making is a whole new and for me, an undiscovered ball game. I am reading up a whole nine yards of material that sends me in circles. I could get Nylet or someone to make me a perfect set of sails but if I did so I learn nothing and satisfaction levels will be Zero. So the bins will continue to fill up. I will have to take this in stages. Stage one is to make simple unpanelled sails from cotton poplin. I have seen Gary Webbs sratch built boats with simple cotton sails sail beautifully. A friend of his built him a set of professional panelled mylar sails and Gary said that yes,....it sails better..." but only a little bit!" Starlet will not be raced so no pressure here and now. I have been invited to join a group that race Marbleheads. It will be interesting to have a fun race with Starlet verses a full on carbon hulled racing Marblehead. The outcome of course will be obvious....but by how many boat lengths? Ha ha. I can see that I may get interested but of course then the sails must be Mylar and panelled. I know the procedures in making the sail block but placing the ideal camber is the art of it. The serious ones of course will not let on else they stand to loose! Win or loose, I am not interested but what intrigues me is HOW they do it!!! I have the plans for a marblehead, made the baseboard and bought balsa wood to plank the hull. It will be 50" long and barely a 7" beam. I will be experimenting with sailmaking for a long time. But thats okay...it keeps the old brain working. Pete

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.