PhillH

Members-

Posts

61 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

North Bucks

-

Interests

Modelling and Motorbikes

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

PhillH reacted to a post in a topic:

HMS Speedy by usedtosail - FINISHED - Vanguard Models - Scale 1:64

PhillH reacted to a post in a topic:

HMS Speedy by usedtosail - FINISHED - Vanguard Models - Scale 1:64

-

Old Collingwood reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

Old Collingwood reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

-

PhillH started following HM Cutter Alert by Goemon - FINISHED - Vanguard Models - 1:64 , Gun Carriage questions , Method for attaching breaching rope to cascable and 7 others

-

PhillH reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

PhillH reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

-

PhillH reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

PhillH reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

-

PhillH reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

PhillH reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

-

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - FINISHED - Vanguardodel Ms - 1:64

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - FINISHED - Vanguardodel Ms - 1:64

-

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - FINISHED - Vanguard Models - 1:64 - Feb 2023 to June 2025

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Kevin - FINISHED - Vanguard Models - 1:64 - Feb 2023 to June 2025

-

PhillH reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

PhillH reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

-

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

PhillH reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

-

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

-

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - FINISHED - Vanguard Models - 1:64 - first build

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

-

Stunning work Mike and and insperation to us all.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Javelin reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

Javelin reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

-

Javelin reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

Javelin reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

-

Looks like the fitting, tweaking and re-fitting paid off. Excellent work again Mike.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

mtaylor reacted to a post in a topic:

HMS Sphinx 1775 by Glenn-UK - FINISHED - Vanguard Models - 1:64 - V2 Kit by Glenn Shelton

mtaylor reacted to a post in a topic:

HMS Sphinx 1775 by Glenn-UK - FINISHED - Vanguard Models - 1:64 - V2 Kit by Glenn Shelton

-

You have built a wonderful model Glenn. Thanks for taking us along on the journey with your detailed log. Phill

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

iosto reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

iosto reacted to a post in a topic:

HM Cutter Alert by PhillH - Vanguard Models - 1:64 scale

-

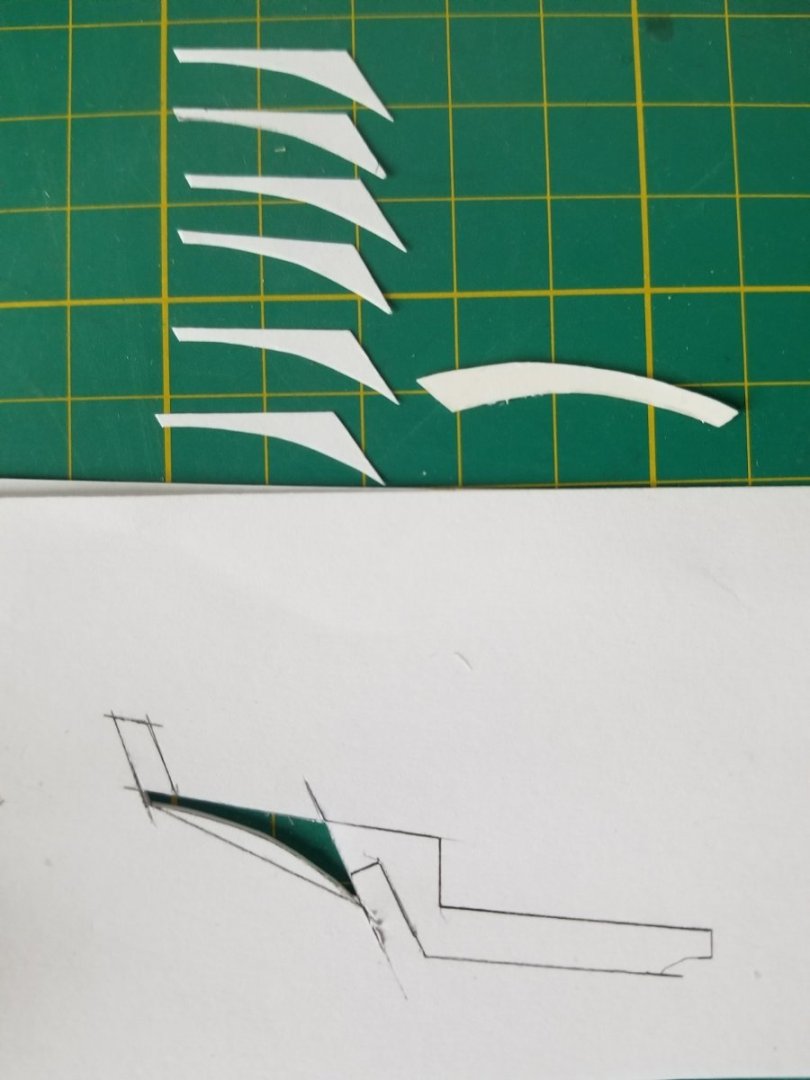

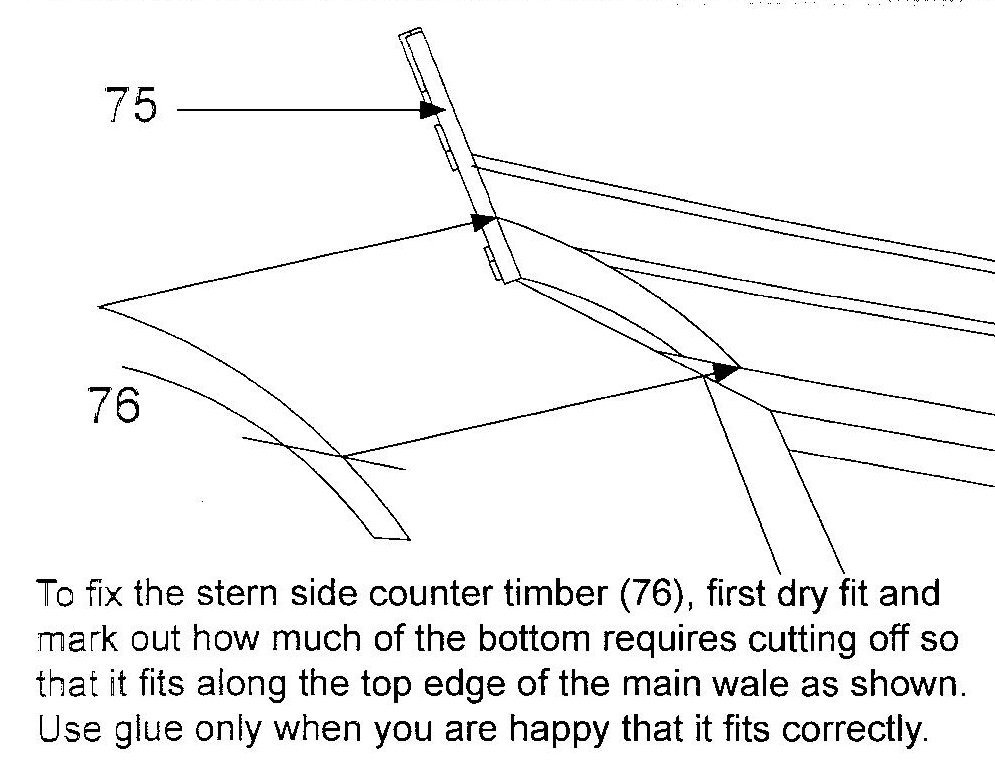

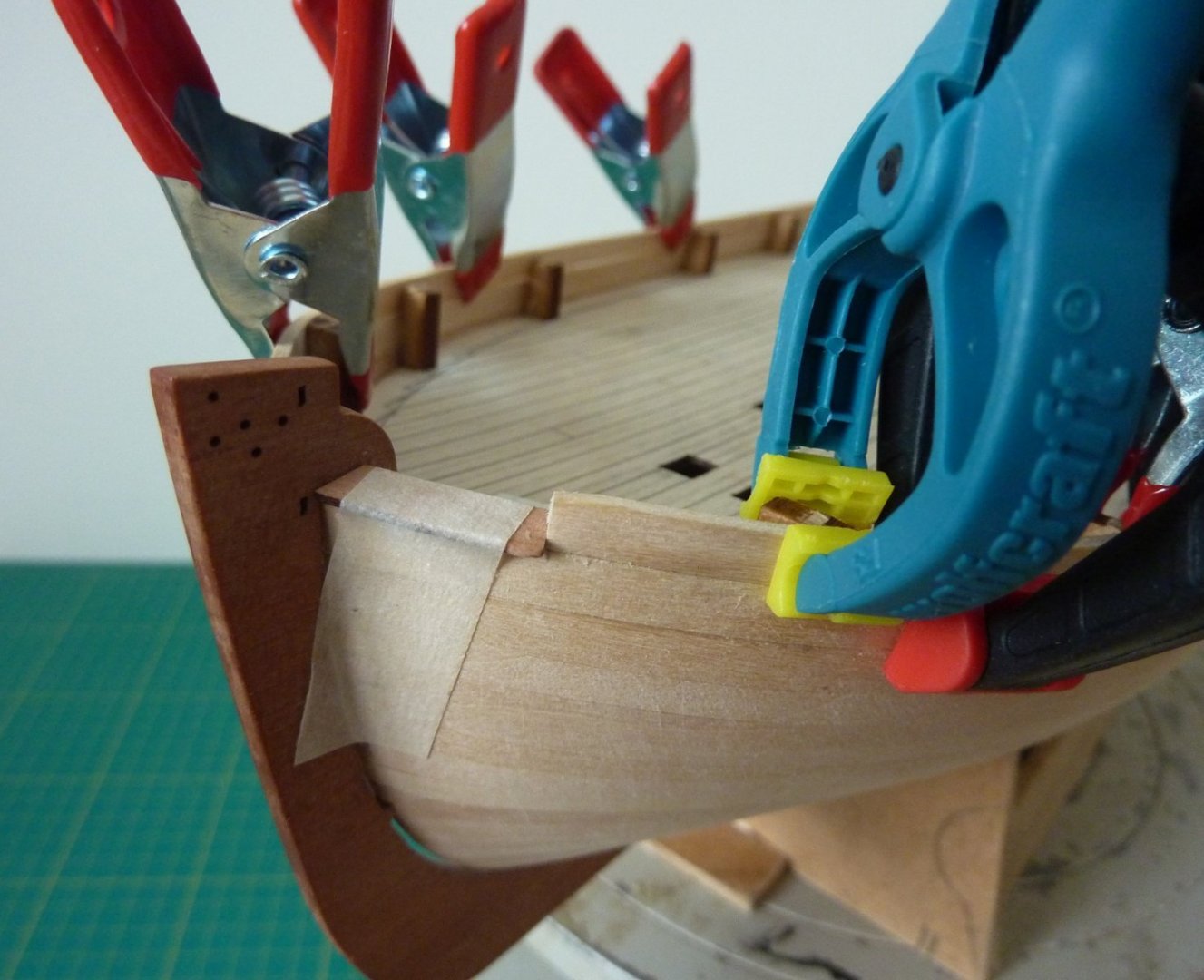

To achieve a curved counter, I needed to put a corresponding curve into the bottom of the transom frames. I used the scrap material pattern left after removing the transom frames, to draw a small sketch of the transom area. I then cut out a cardboard version of part 76 and used this to draw on the stern planking and onto the sketch the required curve which allowed me to determine the shape the transom frames would need to be modified to. I then layered several sheets of paper under the sketch and cut multiple patterns with a scalpel. These patterns where then glued to the transom frames to give a guide for sanding. I used the curve of part 76 to find an item with a similar curvature to use as a sanding guide and in the end the best fit was a jam jar. I wrapped sandpaper around the jam jar and gradually sanded back the frames until I reached the patterns I had glued on. The counter was next soaked in hot water and clamped to the same jam jar and left to dry. I decided not to glue the sternpost permanently in place at this stage but used the packing pieces previously fitted to hold the top in place while the base was held with a clamp. The stern angled planking was then cut and glued in place using PVA. I then removed the temporarily fitted sternpost and sanded the stern planking. I will leave the sternpost off for now as this will allow me to fit the planks overlapping the stern. The planks will then be cut back flush, and the stern piece refitted once all the sanding has been completed. The curved counter was next removed from its jam jar former and glued in place. Finally, the counter was sanded back to align with the hull planking. The next challenge is the second layer of planking. Phill

-

Thanks RDDP and Diver for the kind words and to everyone for the "Likes". @Diver I agree, without patience you will never achieve your desired result. I would prefer to spend a day getting a plank correct than to look back with regret because I rushed things, which is why this build is taking so long. @RDDP I was an industrial controls system specialist but some of my customers made me feel like I was pulling teeth.😉 Phill

-

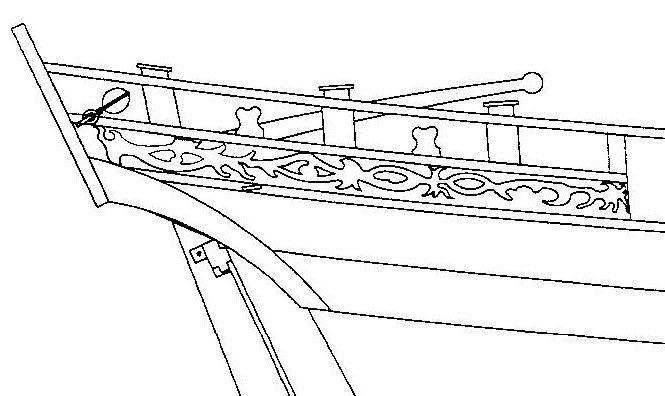

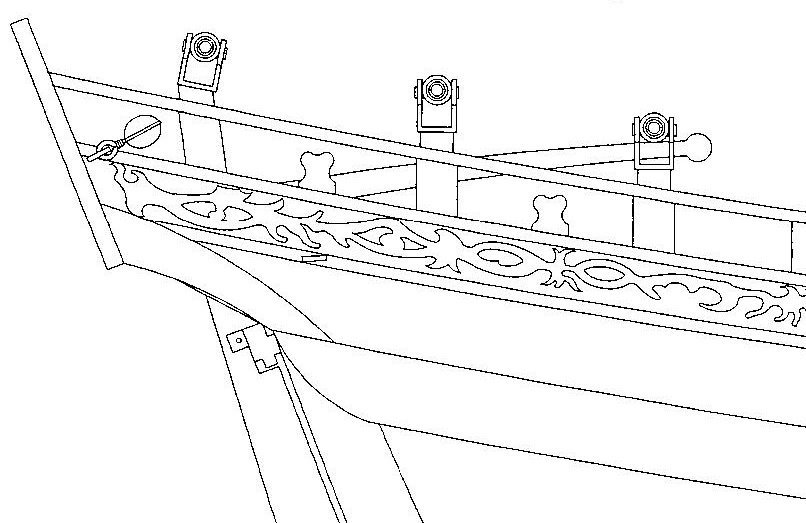

Next on the agenda was the counter which is an area that I had been trying to decide on for some time. The manual shows that part 76 should be cut to fit along the top edge of the main wale with a straight counter. However, this picture shows it cut to fit along the top edge of the main wale with a more curved counter. And finally in this picture it is fitted abaft of the main wale with a curved counter as per the ATOS book I was unsure whether to go with a flat or curved counter but have finally decided on a curved counter which looks the most appealing to my eye. Phill

-

Good to hear that the fix for your eyes has worked. 👍

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks, there has been very little time spent at the shipyard Theodosius. I have been spending a lot of time caring for my father who is suffering from Alzheimer's and I have been making the most of the time we have together. That said I have managed some work on the counter so I must get round to updating my log with progress so far. Phill

-

Bellissimo lavoro Iosto. Its good to see you back. Phill

- 60 replies

-

- enterprize

- caf

-

(and 1 more)

Tagged with:

-

Good to see this build back on the slipway Kevin. It looks like it is coming along well. I will be following along. Phill

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.